Patents

Literature

73results about How to "Not easy to deviate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

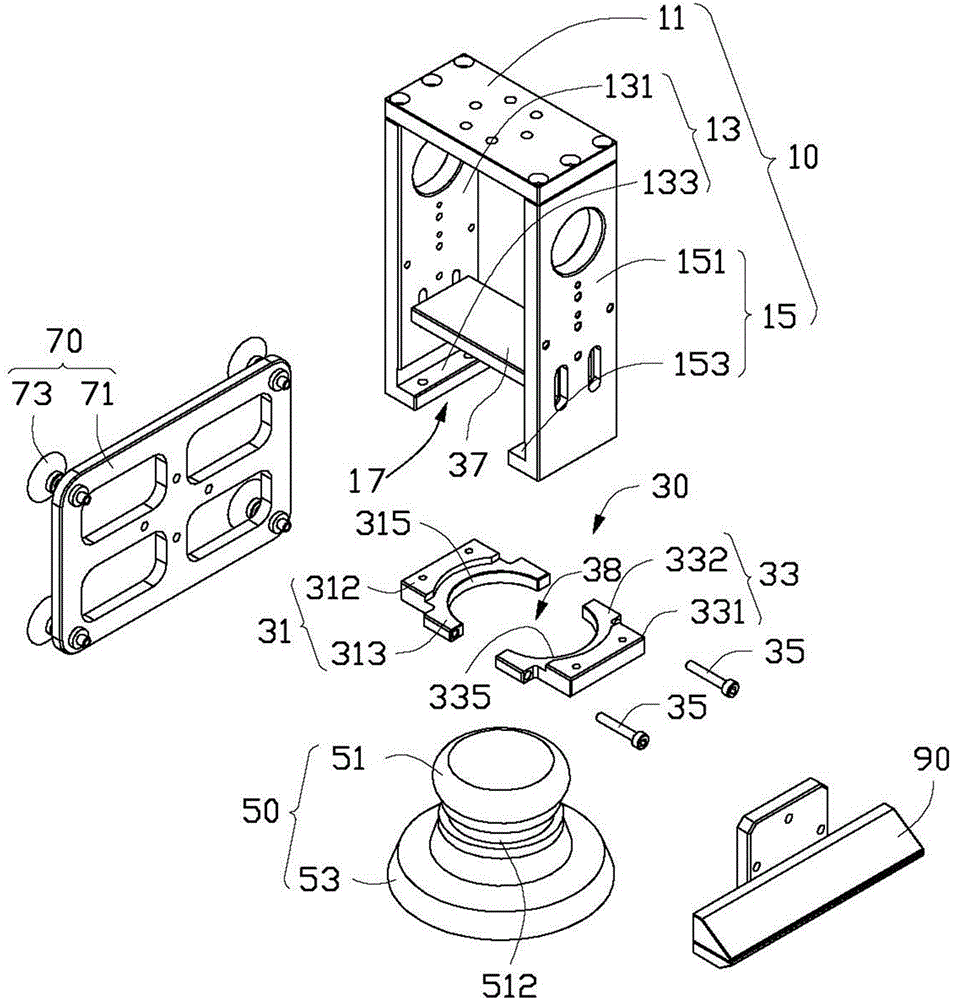

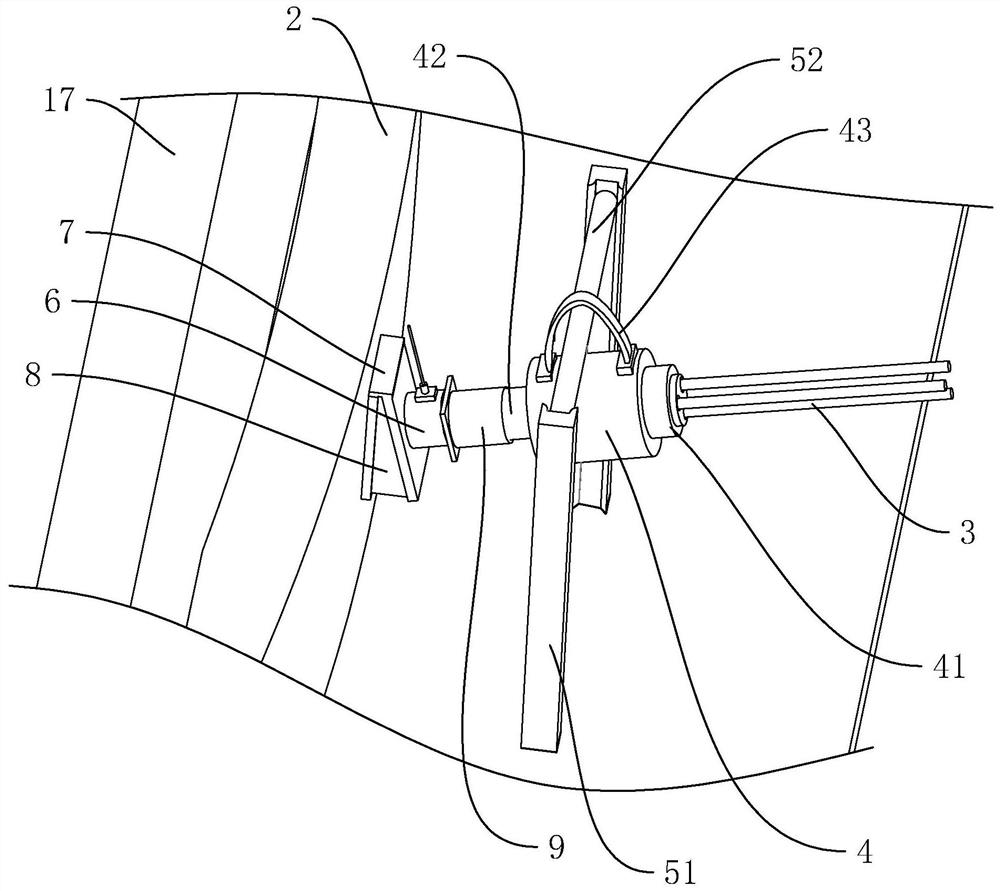

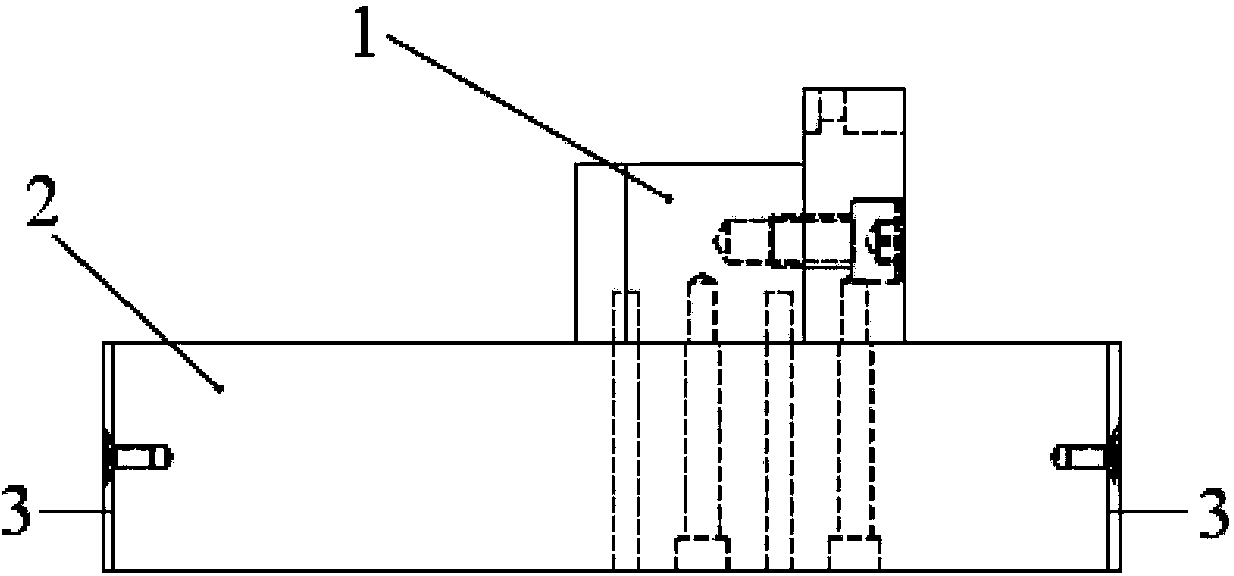

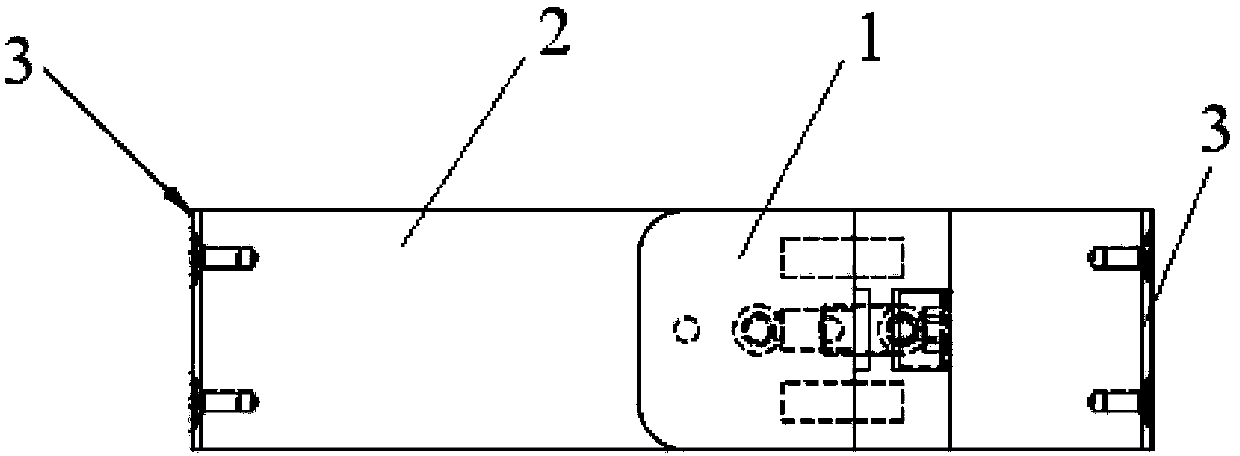

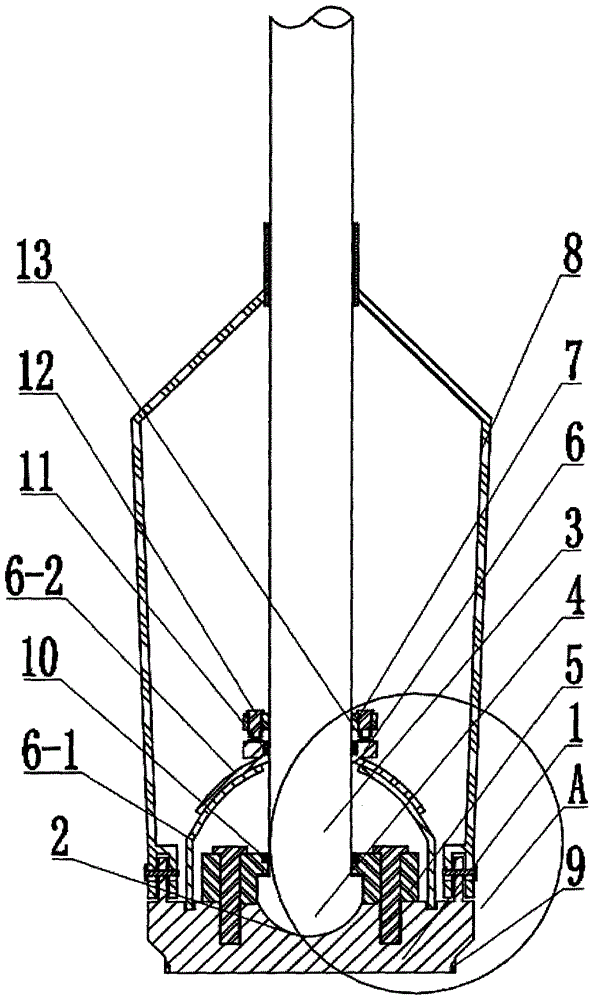

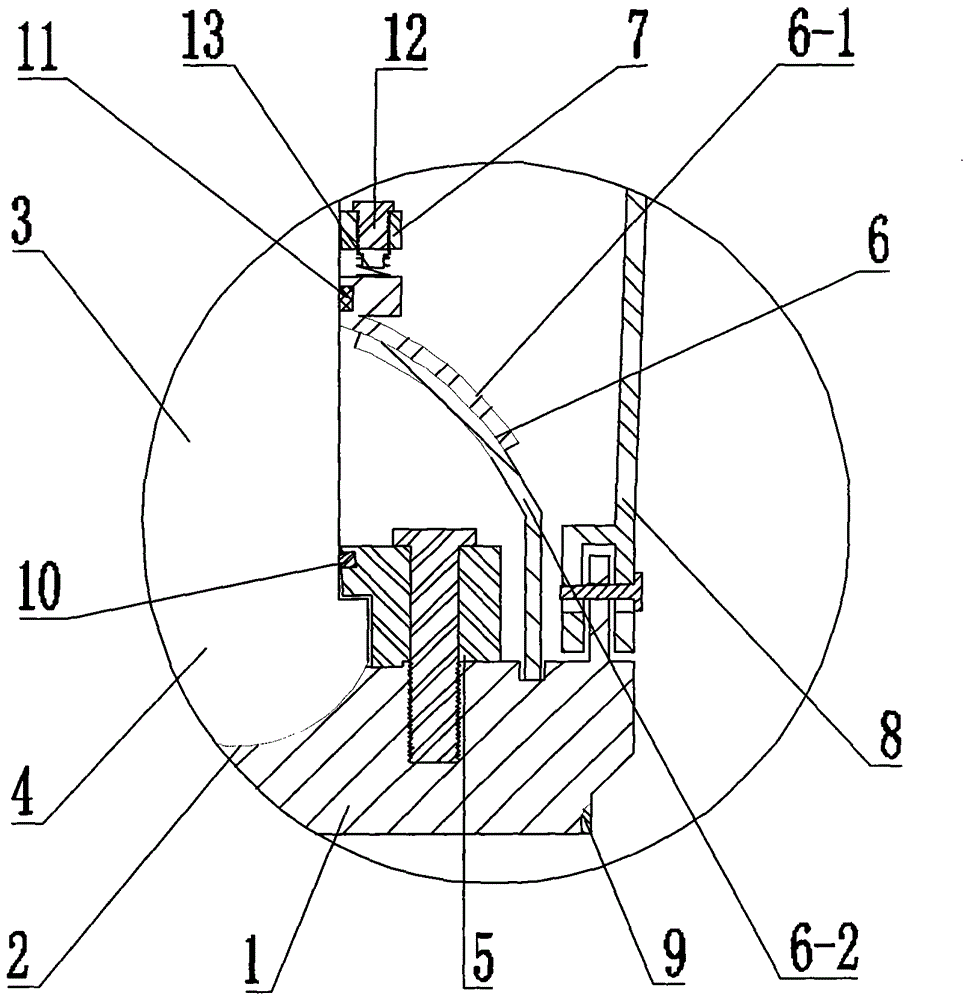

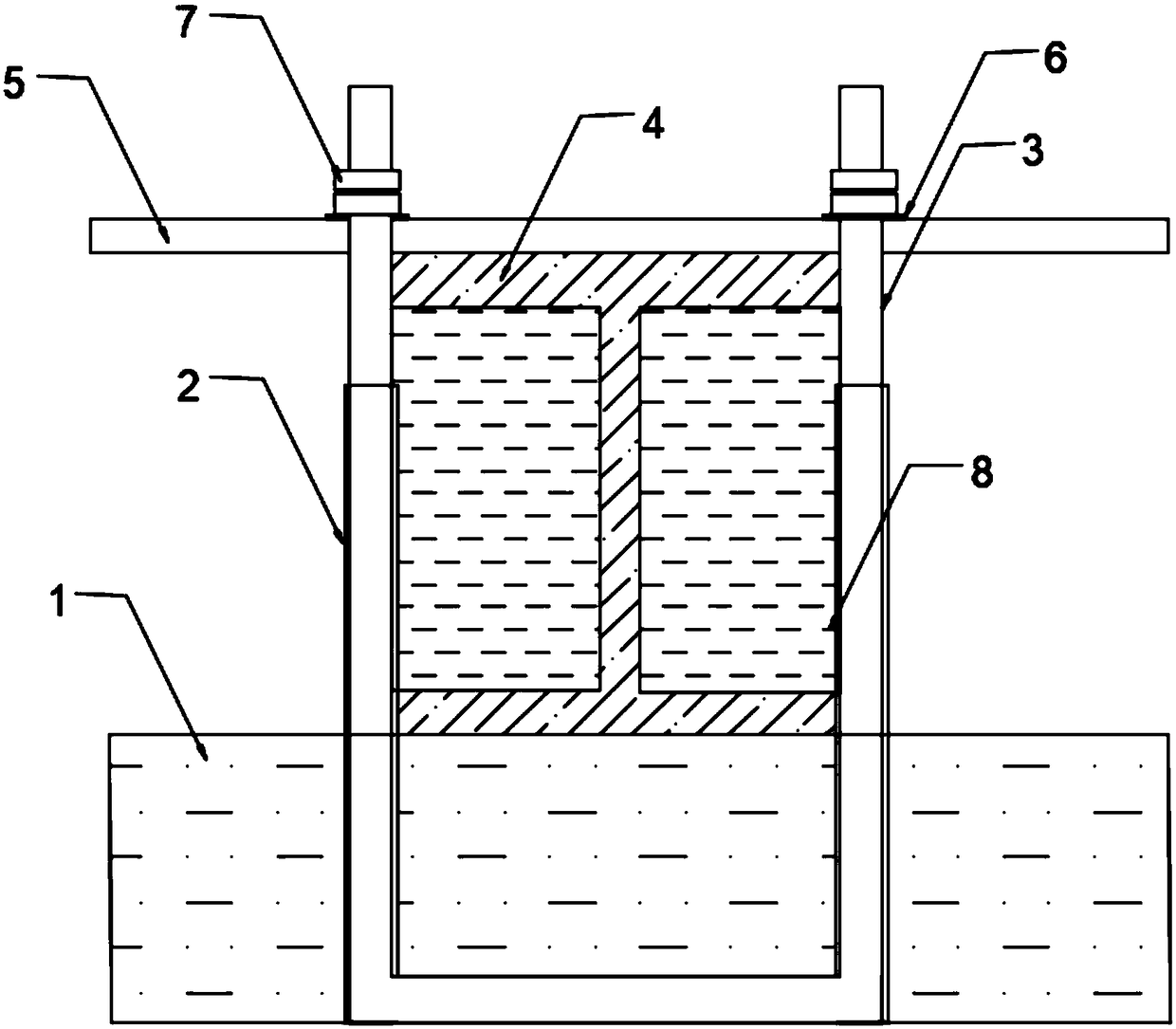

Sewage treatment mixing device and assembling and disassembling methods thereof

ActiveCN103112936AQuick changeExtend working lifeRotary stirring mixersMixer accessoriesStructural engineeringSewage treatment

The invention belongs to the field of sewage treatment equipment, and relates to a sewage treatment mixing device and assembling and disassembling methods thereof, which aims at solving the problems of the prior art that the structure is complicated, the angle and the agitating diameter of an agitating blade are difficultly adjusted and the blade is not easily disassembled and replaced quickly. According to the technical scheme adopted, an upper shell and a lower shell are rotatably connected in a buckling manner, the blade is connected with an impeller sleeve by a positioning rod, to be capable of relatively rotating so as to adjust the inclination angle of the agitating blade, and the agitating diameter of the extended blade can be adjusted through small holes in the blade sleeve and spring ejector pins in a trapezoidal slot of the positioning rod. According to the sewage treatment mixing device and assembling and disassembling methods thereof, the structure is simple, the angle and agitating diameter of the agitating blade are conveniently adjusted and the blade can be disassembled and replaced quickly.

Owner:XIAN TECHNOLOGICAL UNIV

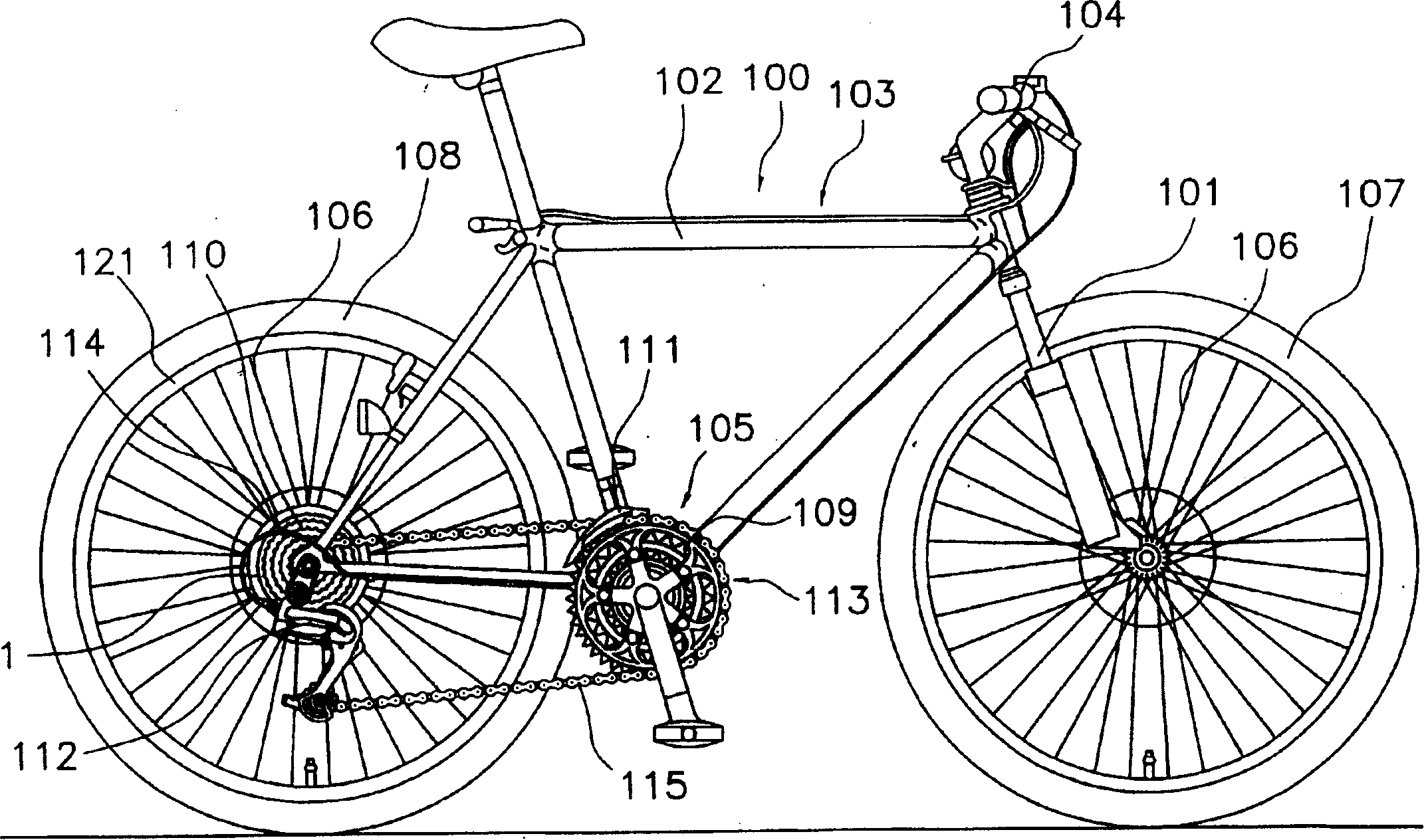

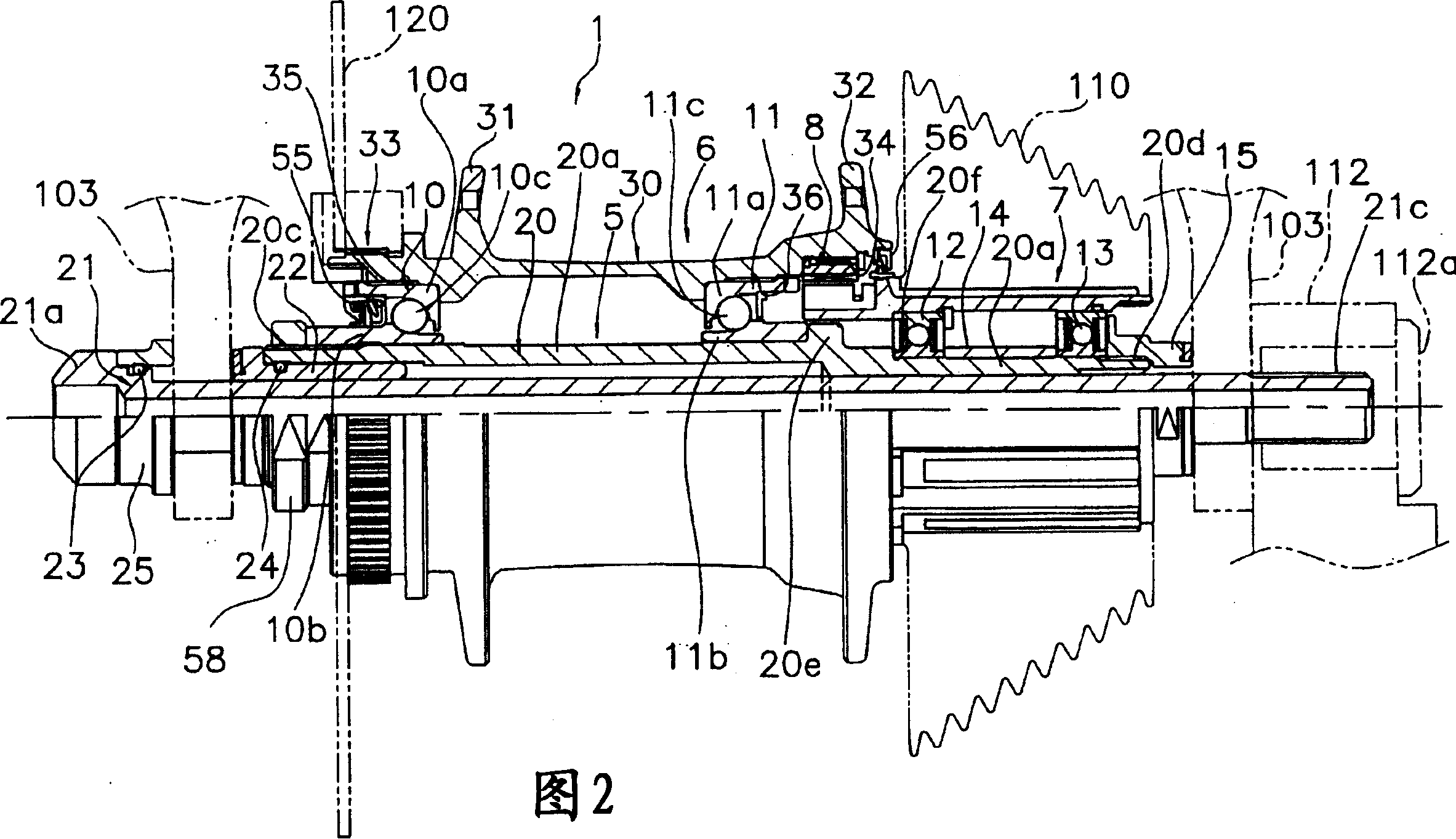

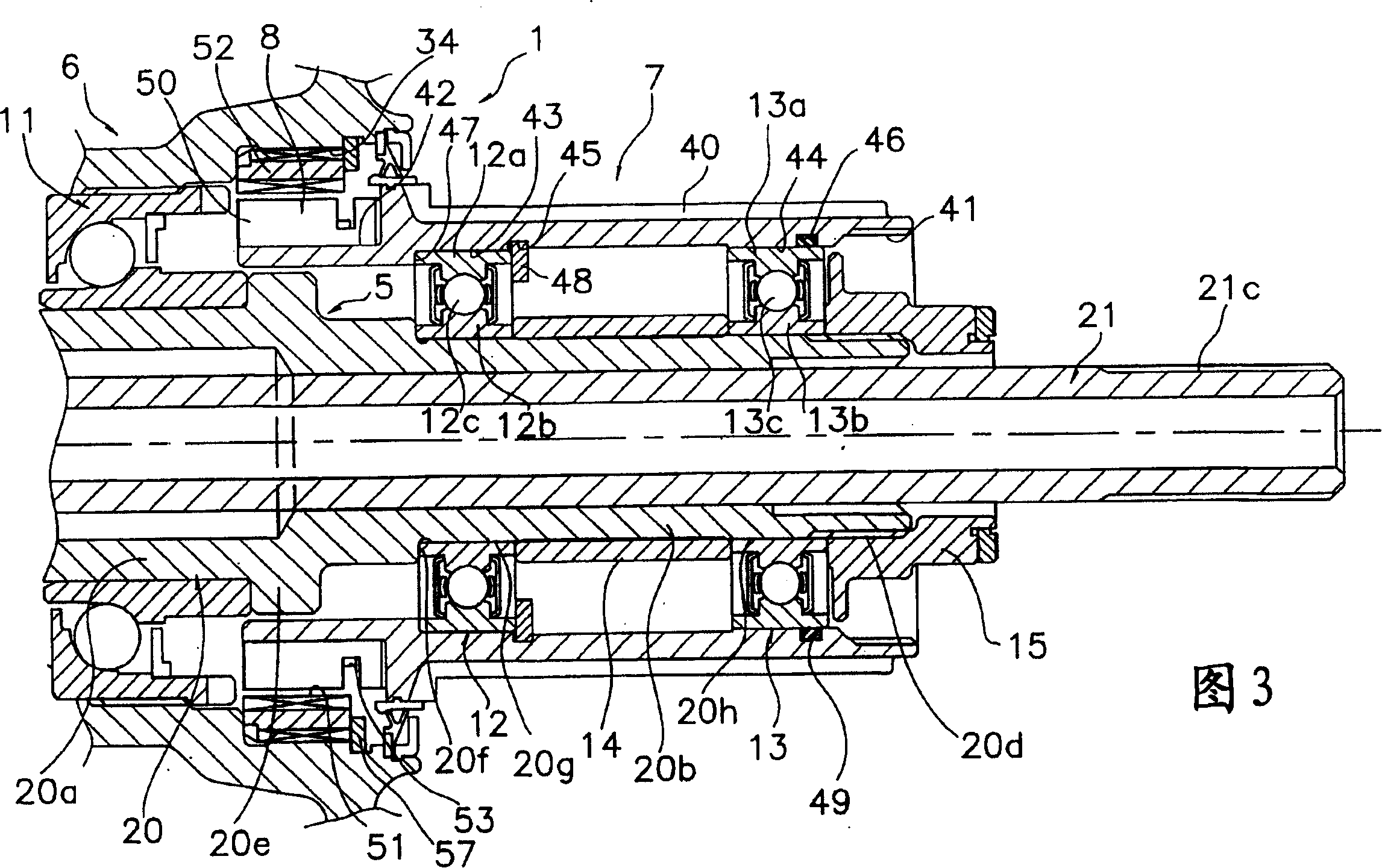

Bicycle hub

InactiveCN1636767ANot easy to moveNot easy to deviateHubsFreewheel clutchesInterference fitRolling-element bearing

The bicycle hub of the present invention can suppress variation in the rotational moment of the drive body. The rear hub (1) has a hub shaft (5), a hub body (6), first and second rolling bearings (10, 11), a driving body (7), a one-way overrunning clutch (8), a third rolling bearing (12) , the fourth rolling bearing (13), the bushing (14) and the pushing member (15). The hub shaft is mounted on the frame. The hub body is arranged on the outer peripheral side of the hub shaft. The first and second rolling bearings are axially separated and arranged between the hub body and the hub shaft. The driving body and the hub body are arranged concentrically, and the sprocket group can be installed. The one-way overrunning clutch only transmits the rotation of the driving body in one direction to the hub body. The third rolling bearing is arranged in the gap between the driving body and the hub shaft, and is in clearance fit with the inner peripheral part of the driving body, and its inner ring is in static fit with the outer peripheral surface of the hub shaft. The fourth rolling bearing is disposed axially outward of the third bearing. The bushing is arranged between the third bearing and the fourth bearing. The pressing member is screwed into the hub shaft, and presses the inner ring of the fourth rolling bearing.

Owner:SHIMANO INC

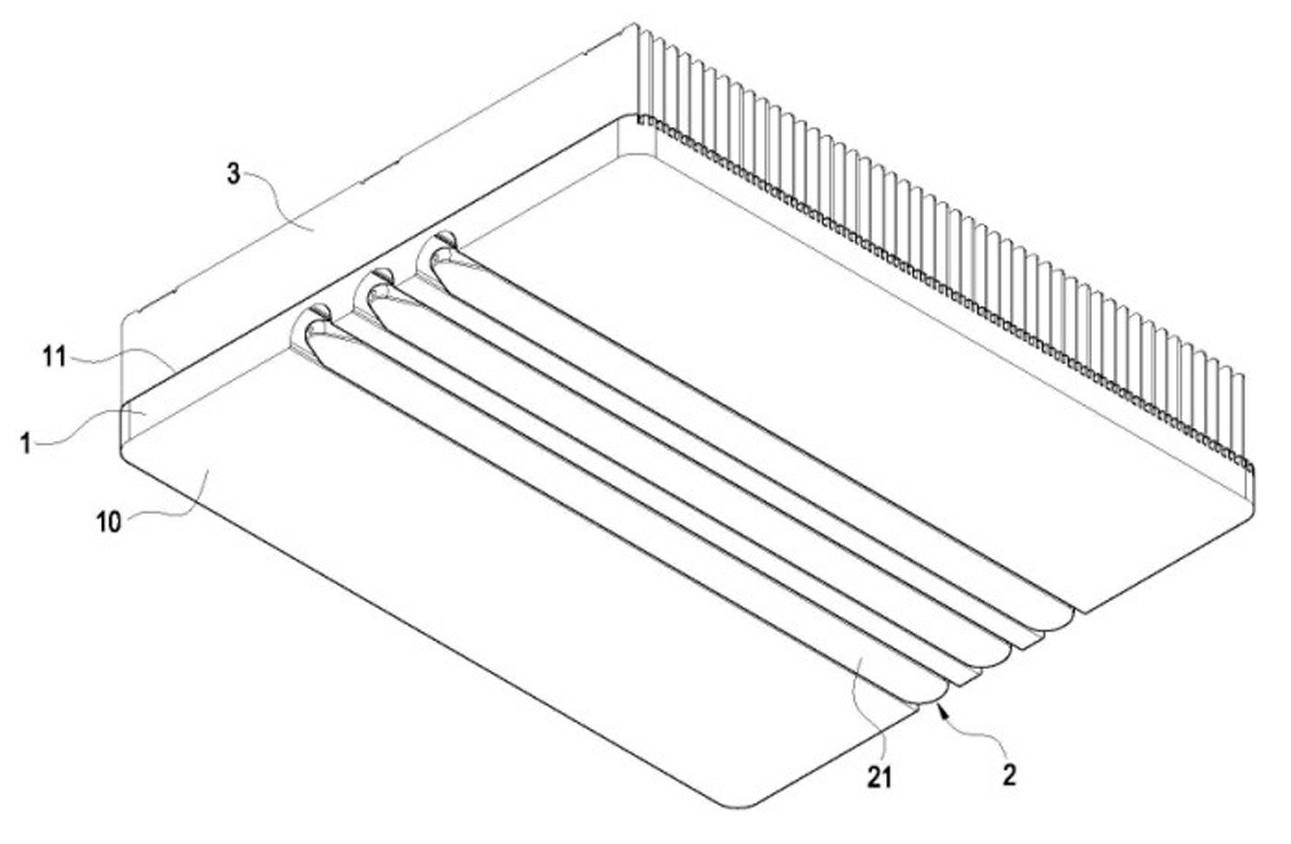

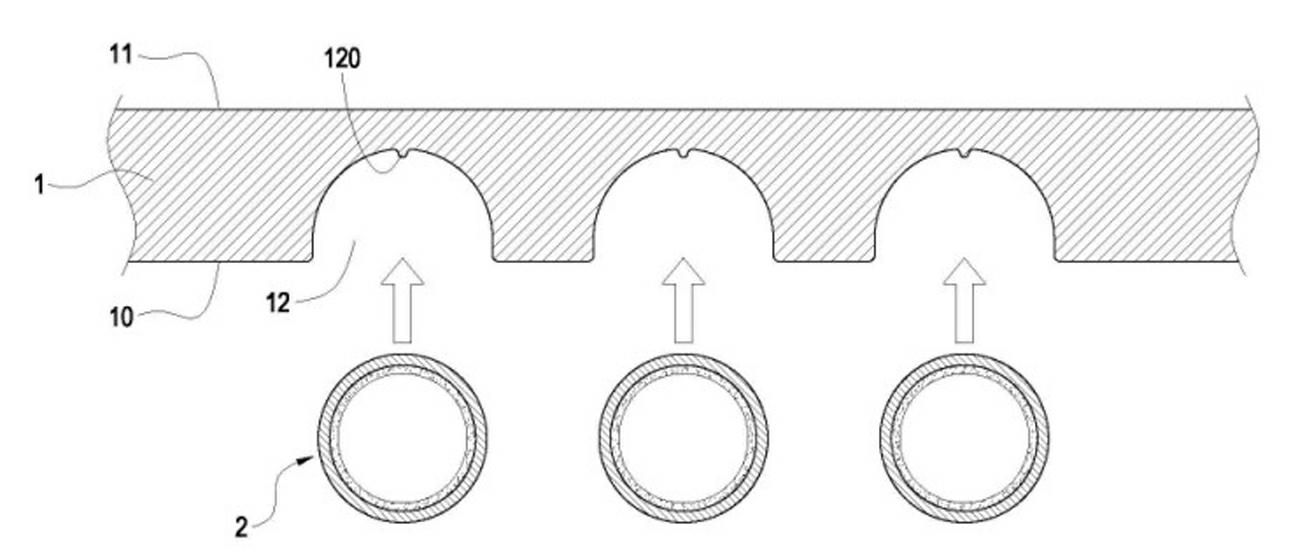

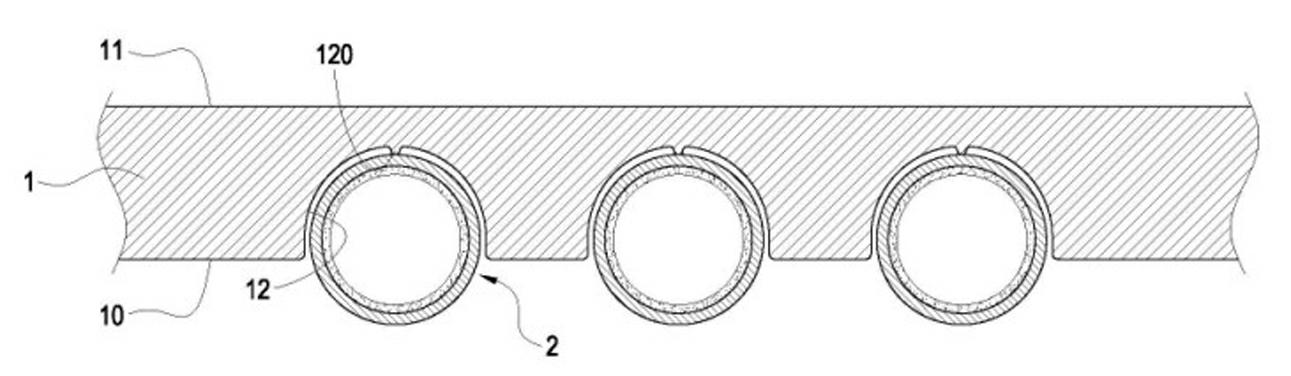

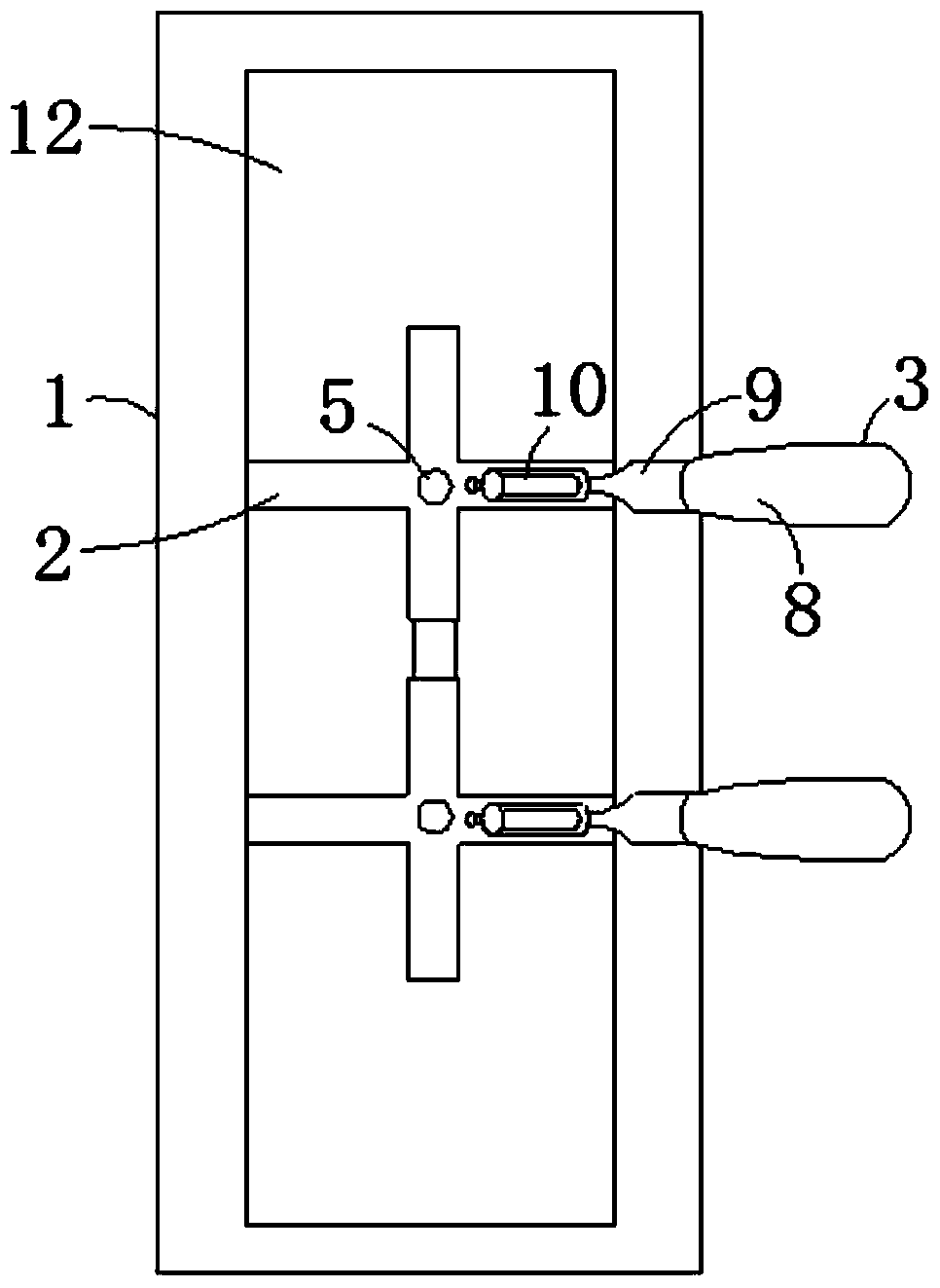

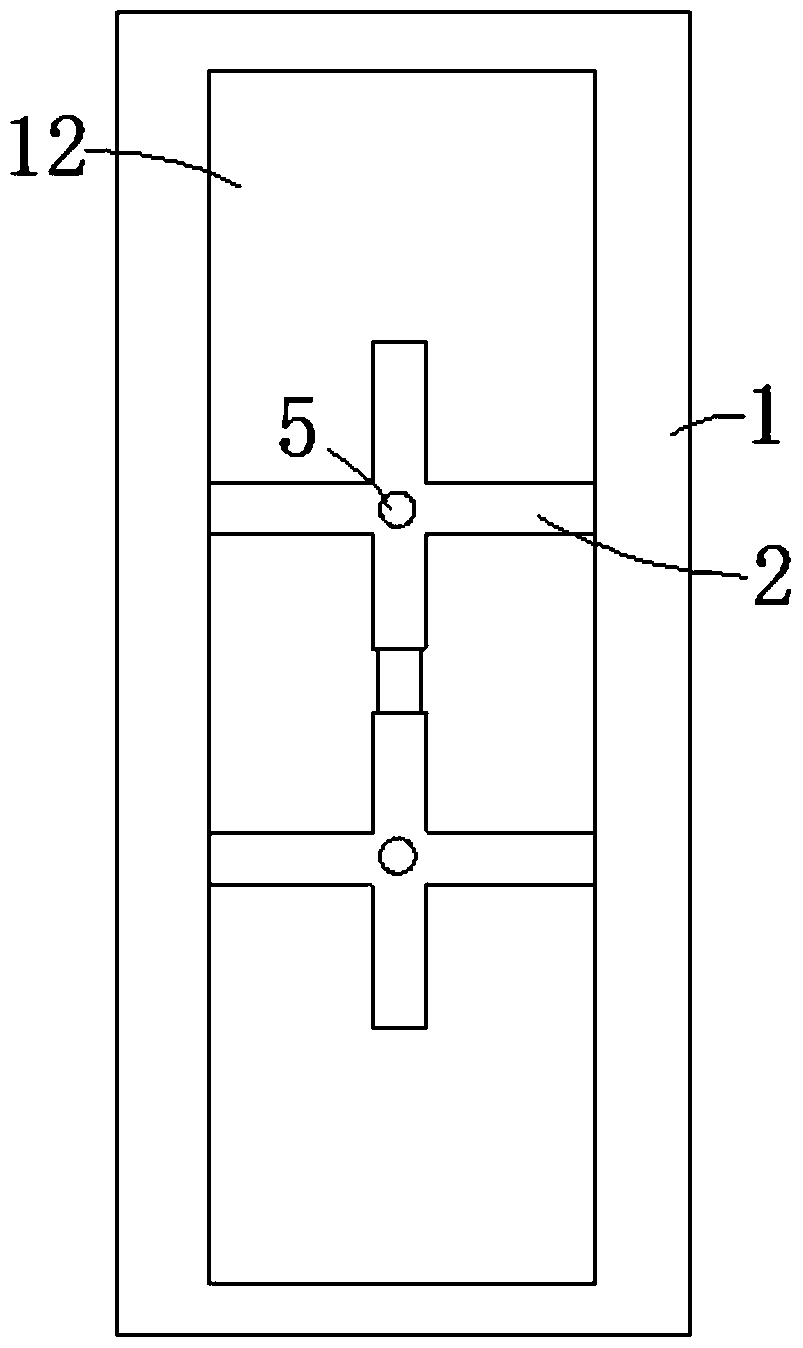

Limiting assembling structure for heat pipe and heat conduction seat

InactiveCN102121801ANot easy to deviateSemiconductor/solid-state device detailsIndirect heat exchangersEngineeringHeat pipe

Owner:DONG GUAN HAN XU HARDWARE & PLASTIC TECH CO LTD

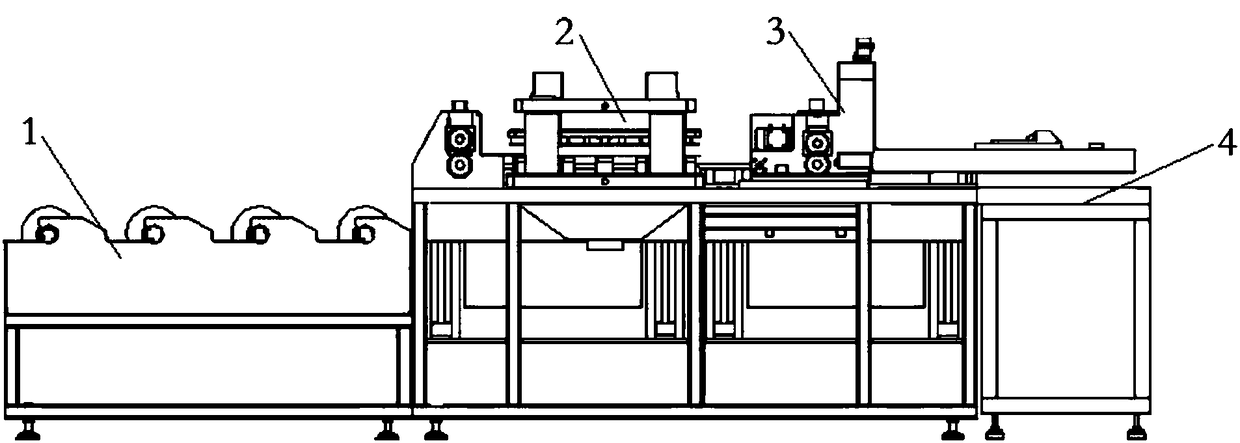

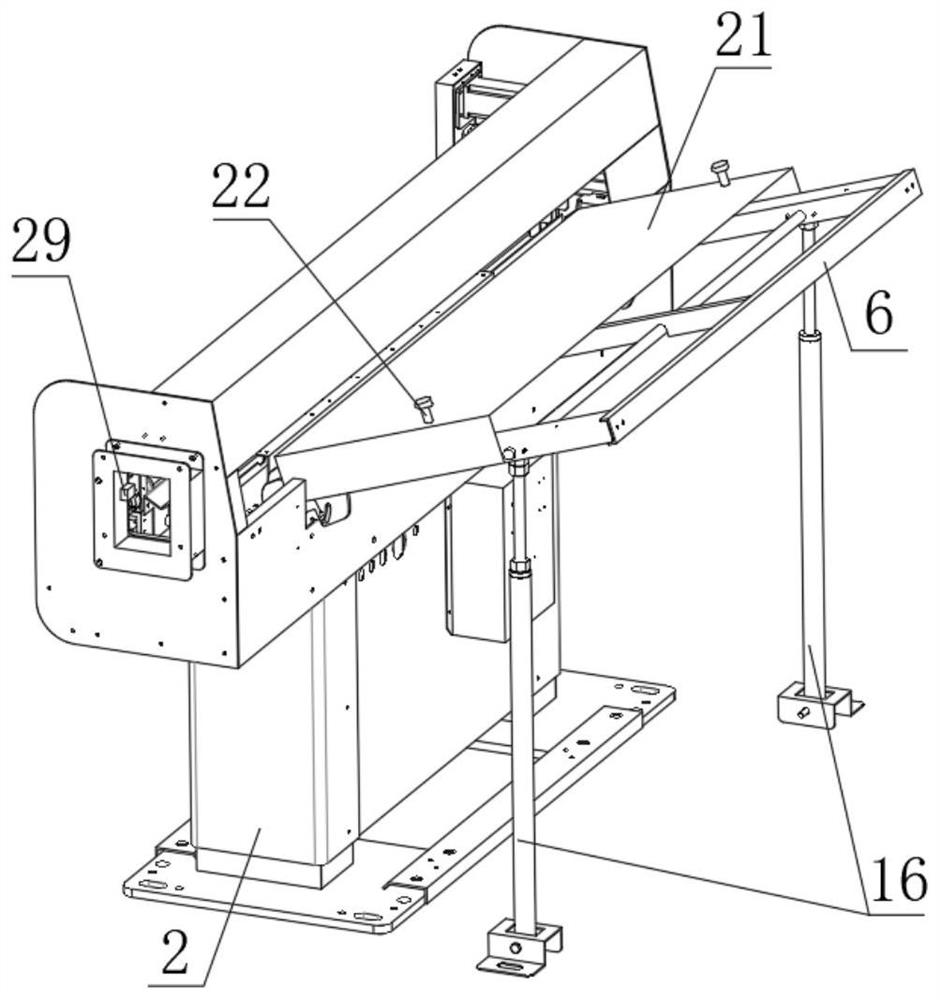

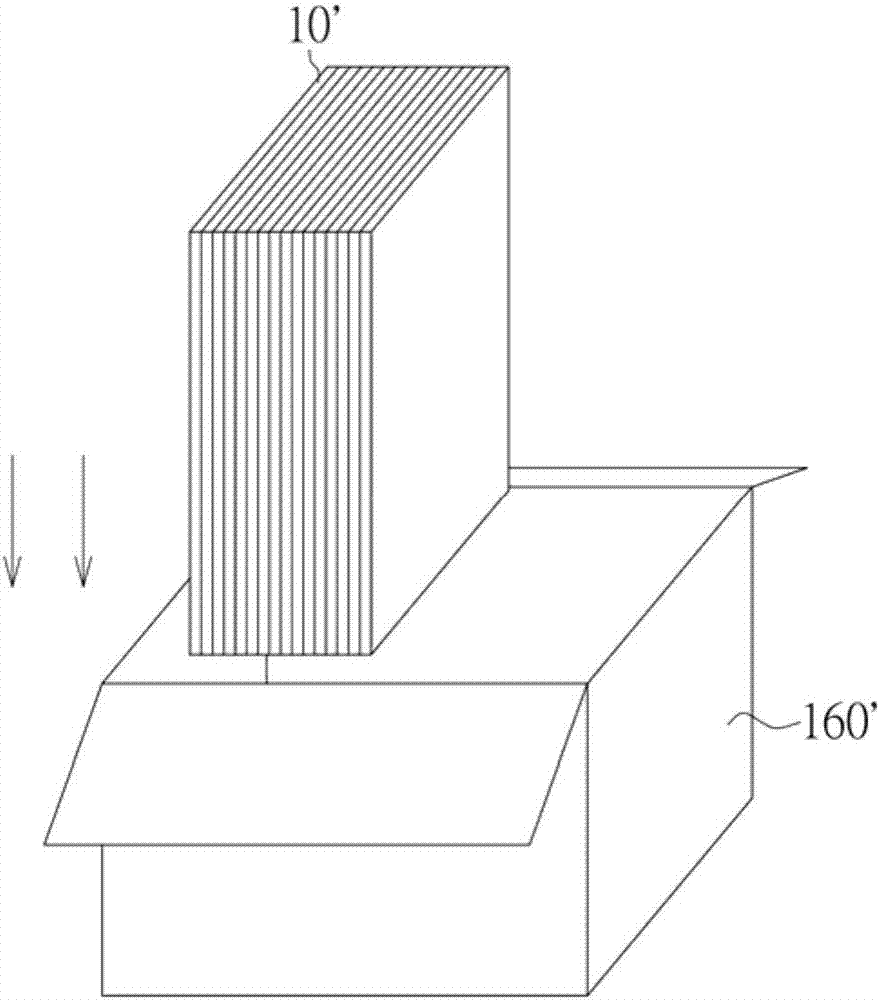

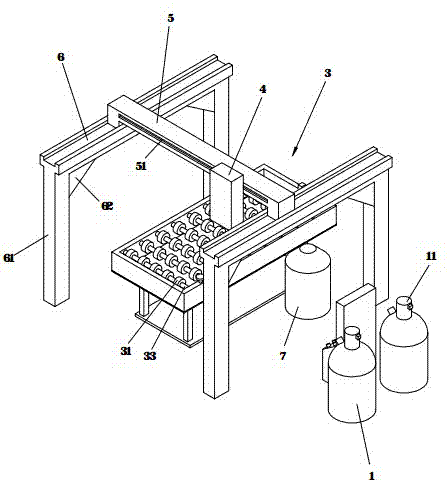

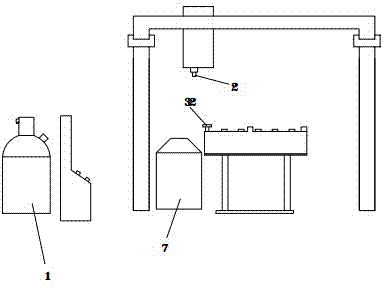

Prepreg cutting and drilling integrated device and machining process

InactiveCN108274529AImprove punching accuracyNot easy to deviateInsulating layers/substrates workingMetal working apparatusPunchingLocking mechanism

The invention discloses a prepreg cutting and drilling integrated device. The prepreg cutting and drilling integrated device comprises a prepreg coiling and locking mechanism, a punching mechanism, acutting mechanism and a collection mechanism. The punching mechanism and the cutting mechanism are progressive die mechanisms. The cutting mechanism and the collection mechanism are connected througha conveying mechanism. According to the prepreg cutting and drilling integrated device, the punching mechanism is additionally arranged in front of a cutting position and can complete the punching procedure before cutting. The prepreg cutting and drilling integrated device is high in punching precision, not prone to deviation and low in product rejection rate. The punching procedure is conducted before the cutting procedure. Time consumed for manually collecting and stacking plates is saved. The number of equipment purchasing types is reduced. The connection time between a slicing machine anda punching machine and the preparation time are saved. The production efficiency is improved. The production cost is lowered. The requirements for automatic production are met. The invention further discloses a machining process. The machining process is high in machining precision, efficiency and automation degree and low in production cost.

Owner:江西景旺精密电路有限公司

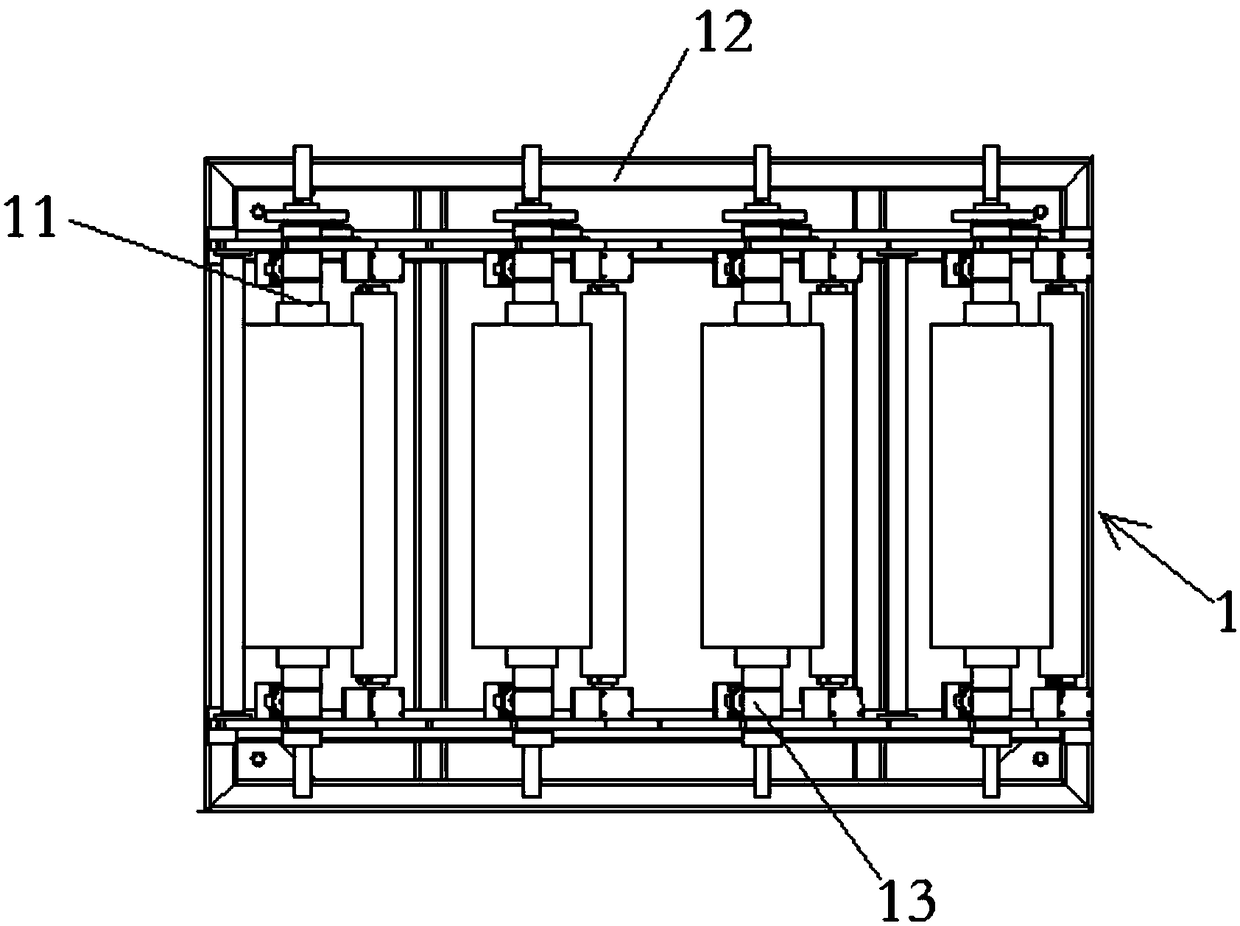

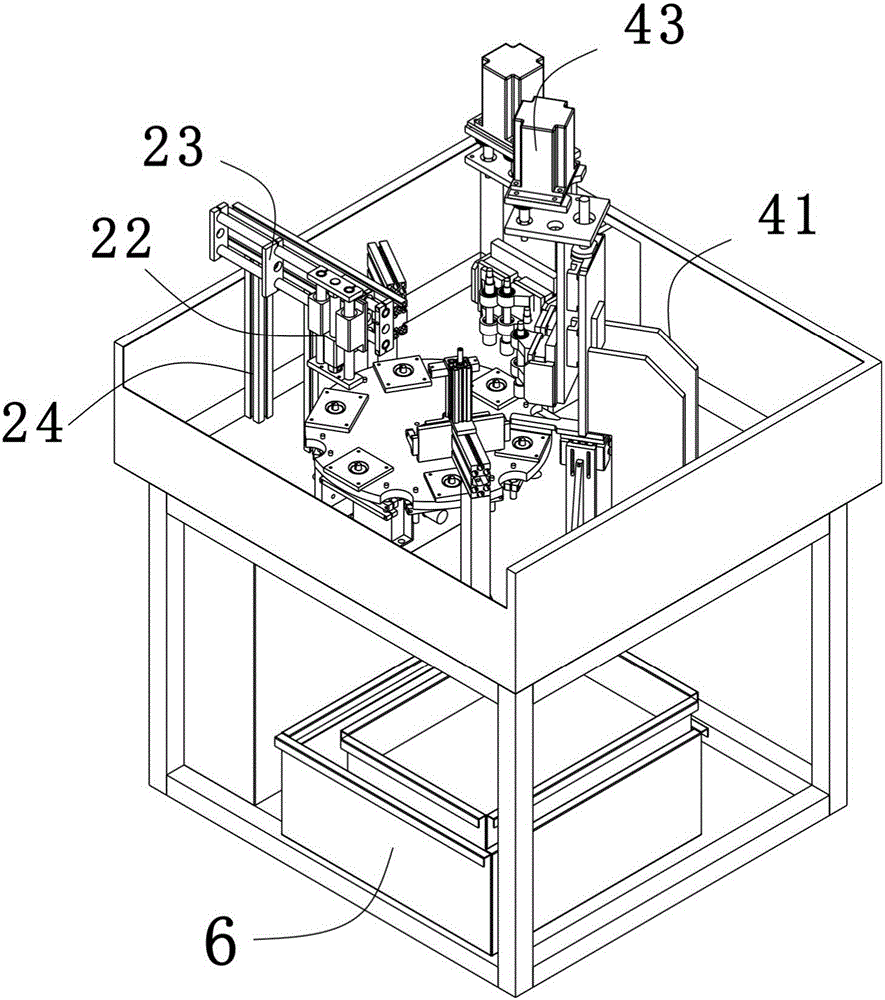

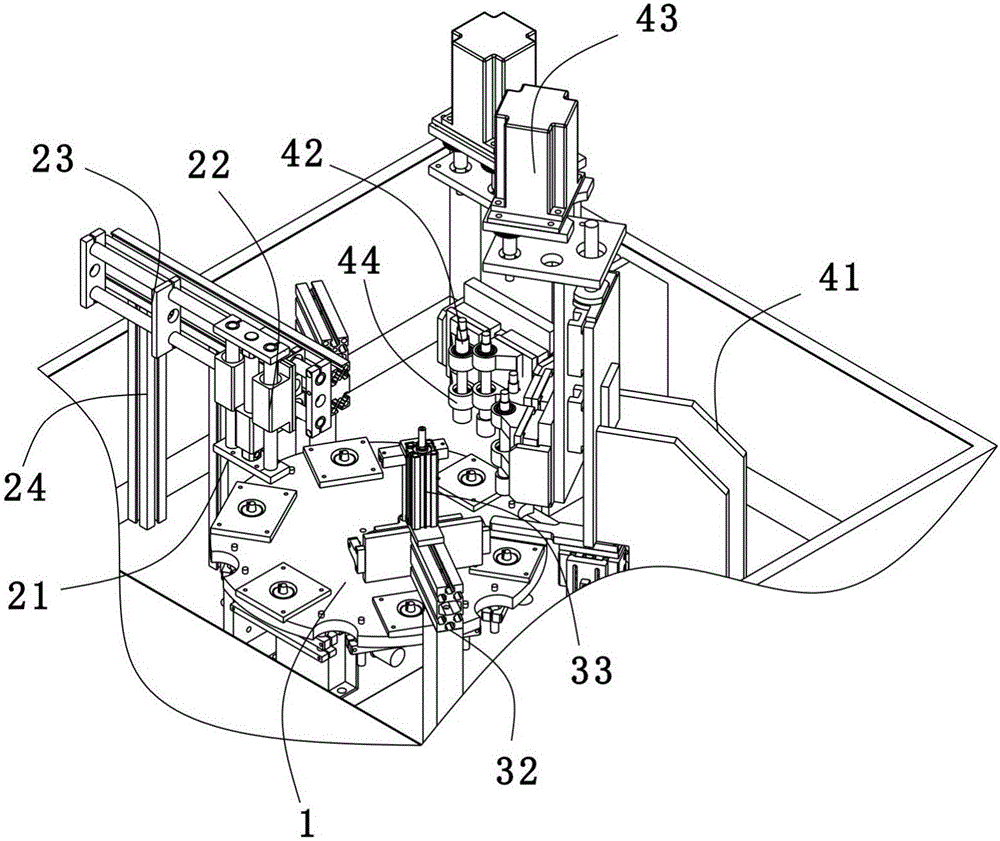

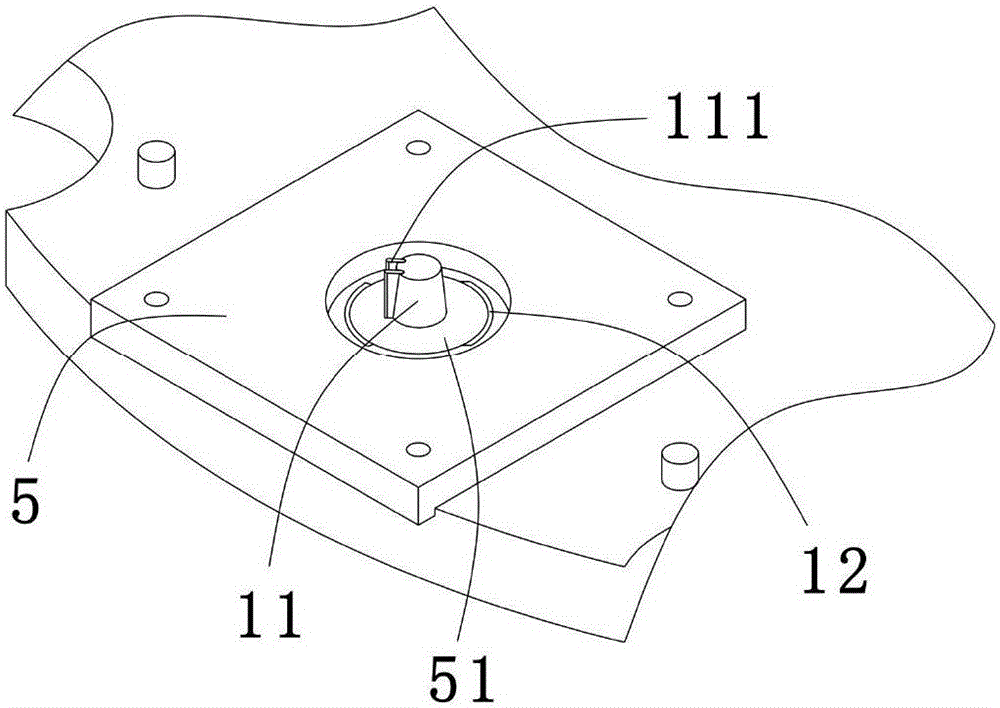

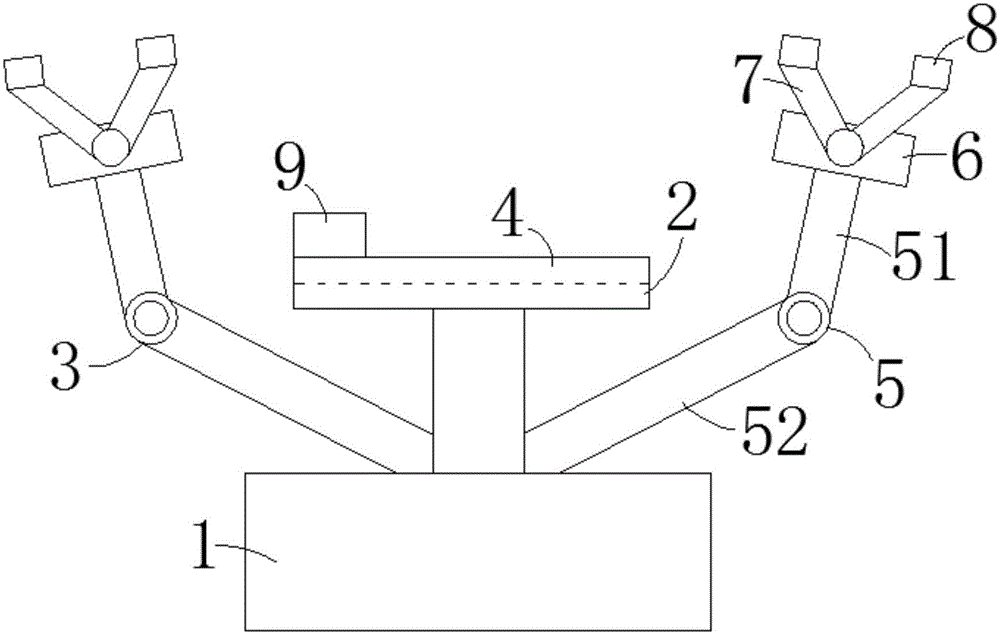

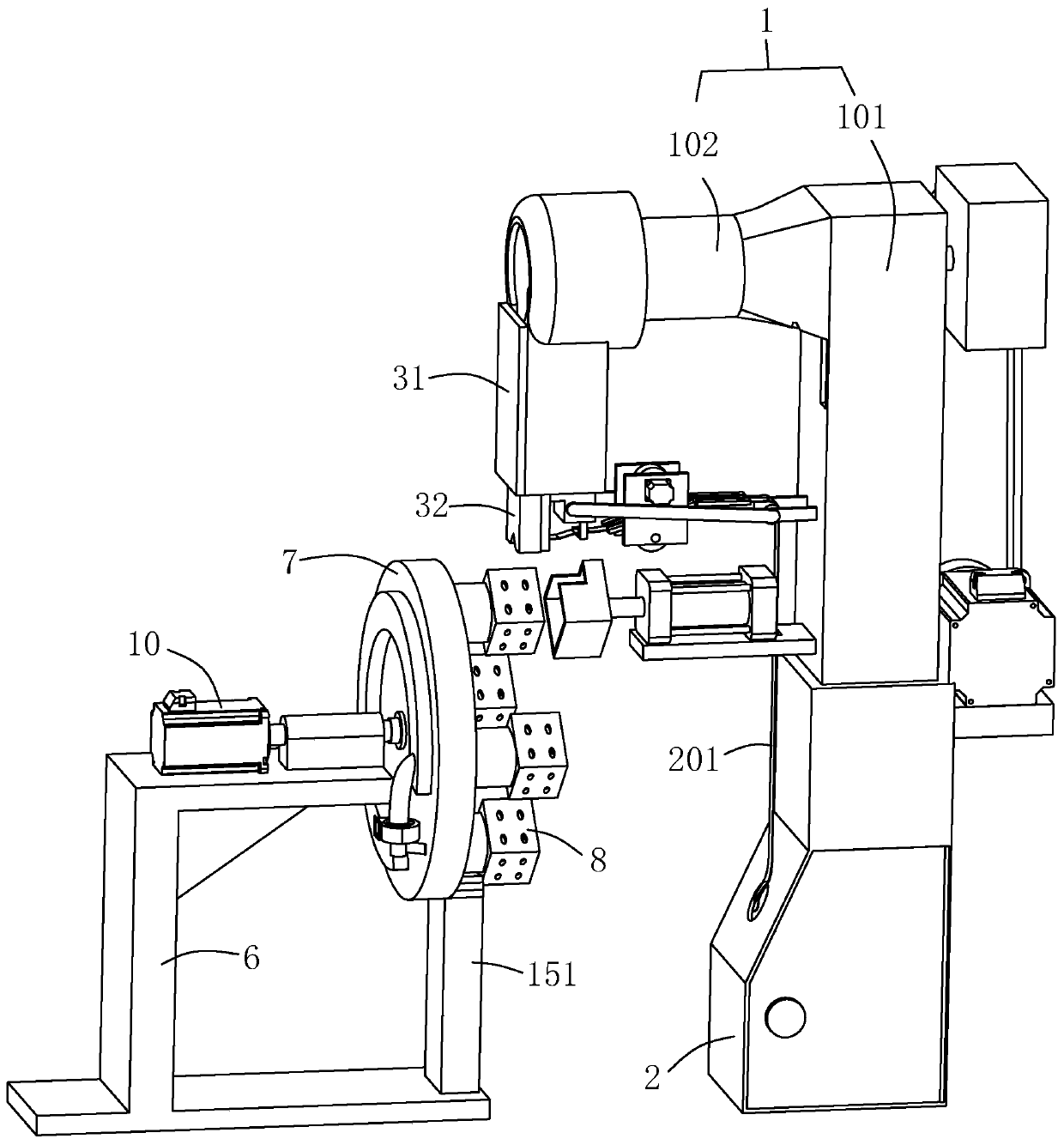

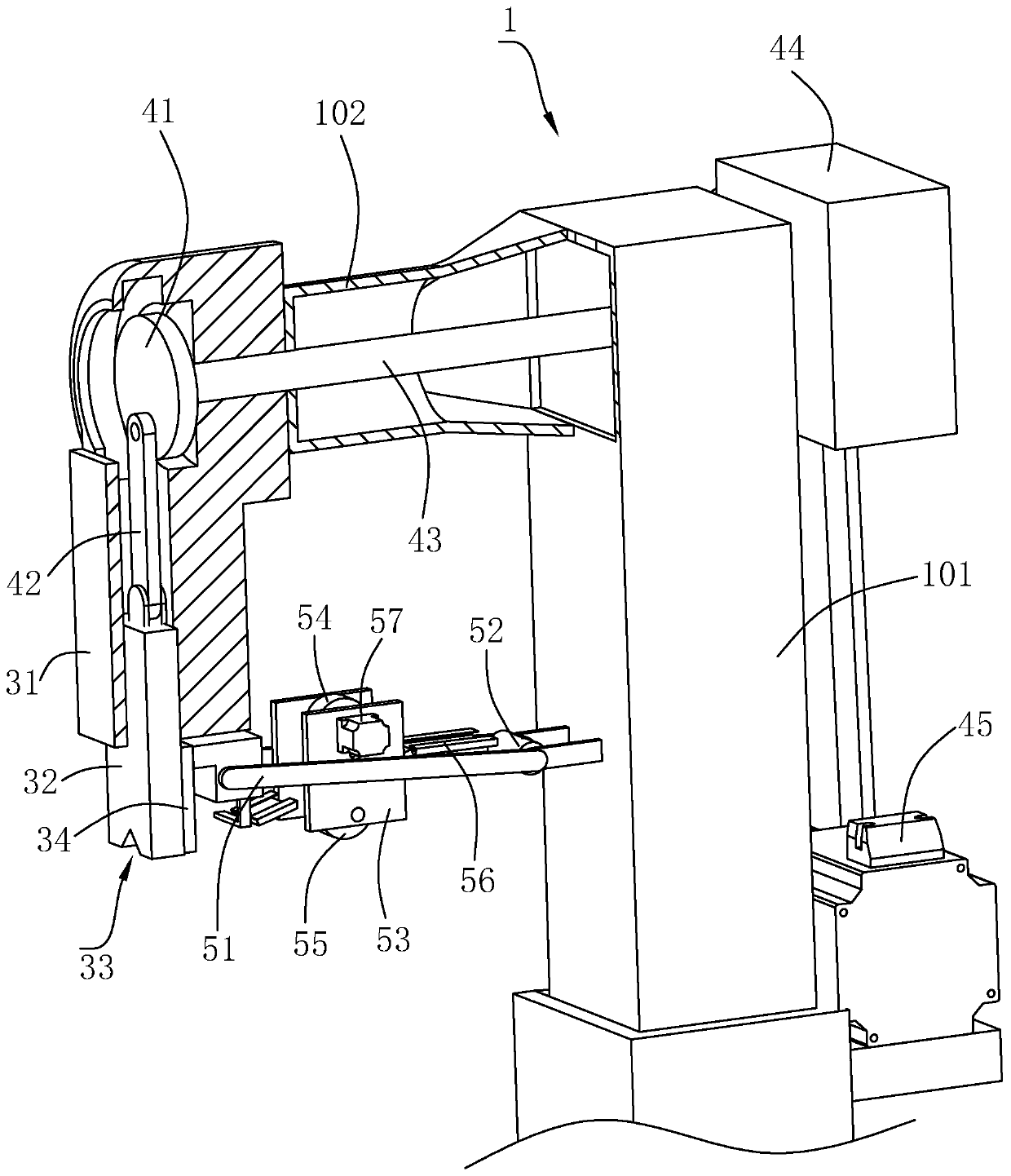

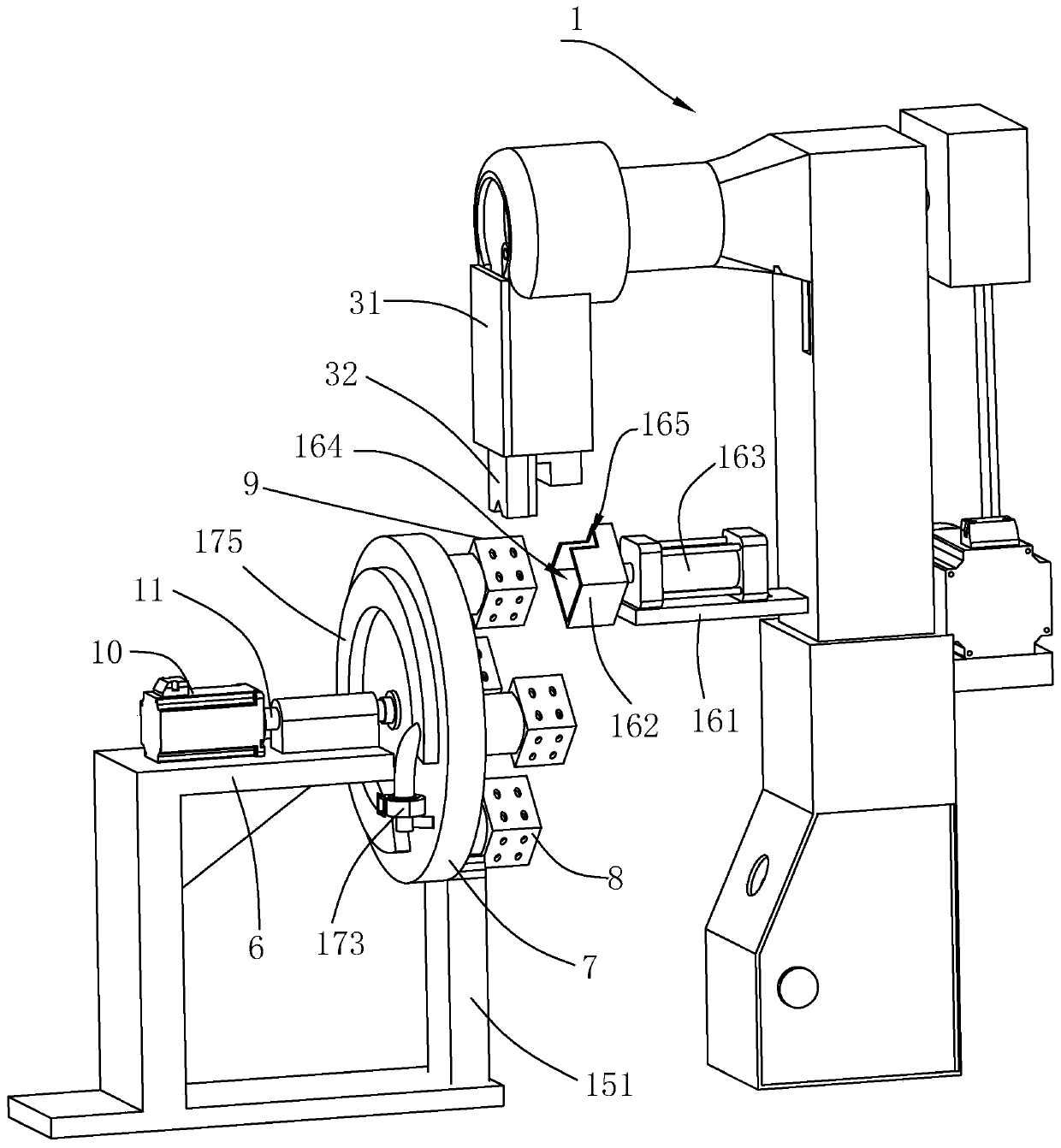

Automatic flywheel screw hole machining equipment

InactiveCN106181384AStrong dimensional consistencyStrong location consistencyWork clamping meansOther manufacturing equipments/toolsFlywheelDrill

The invention discloses automatic flywheel screw hole machining equipment which comprises a bracket, a turntable, a pressing station cooperated to locate a workpiece, a drilling station, a tapping station and a control unit, wherein the turntable is connected with a first driving piece for driving the turntable to rotate; a plurality of locating parts are uniformly arranged on the turntable in a spacing manner; the pressing station comprises a pressing plate, a second driving piece for driving the pressing plate to move up and down, and a third driving piece for driving the pressing plate to move back and forth; and the drilling station comprises a double-head drill, a drilling bracket which is used for supporting the position of the double-head drill above the locating parts and a fourth driving piece for driving the double-head drill to move up and down. Due to the control of the control unit over all the stations and the turntable, the automatic flywheel screw hole machining equipment realizes automatic machining of the workpiece, and is high in working efficiency; and the workpiece is high in consistency and qualification rate.

Owner:ZHENGJIANG FENGLONG ELECTRIC CO LTD

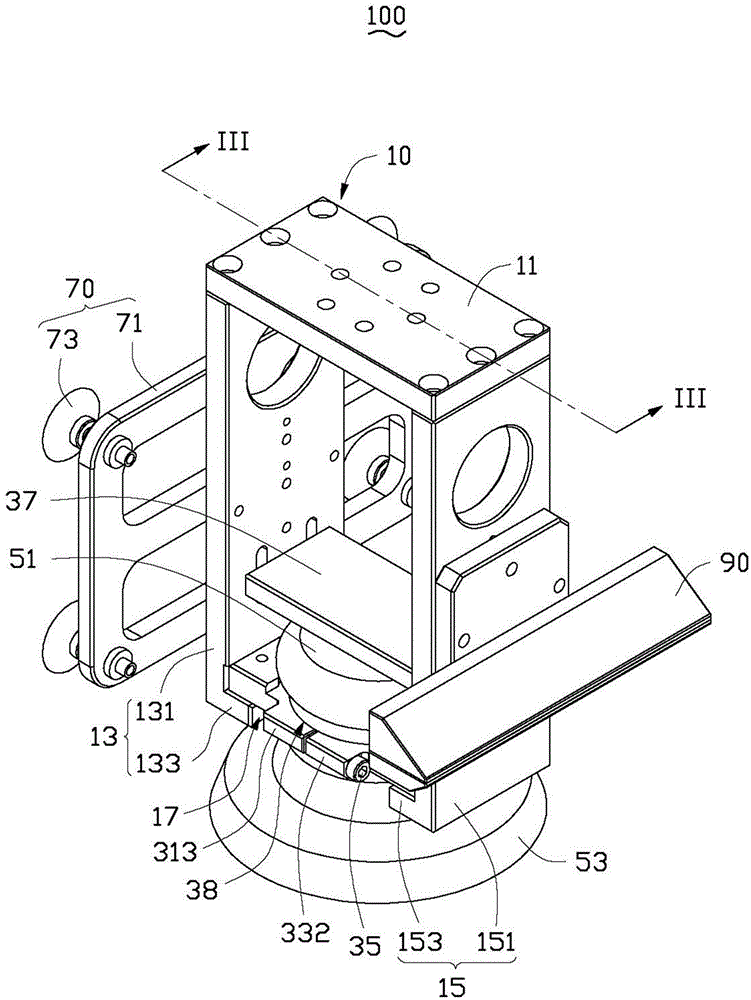

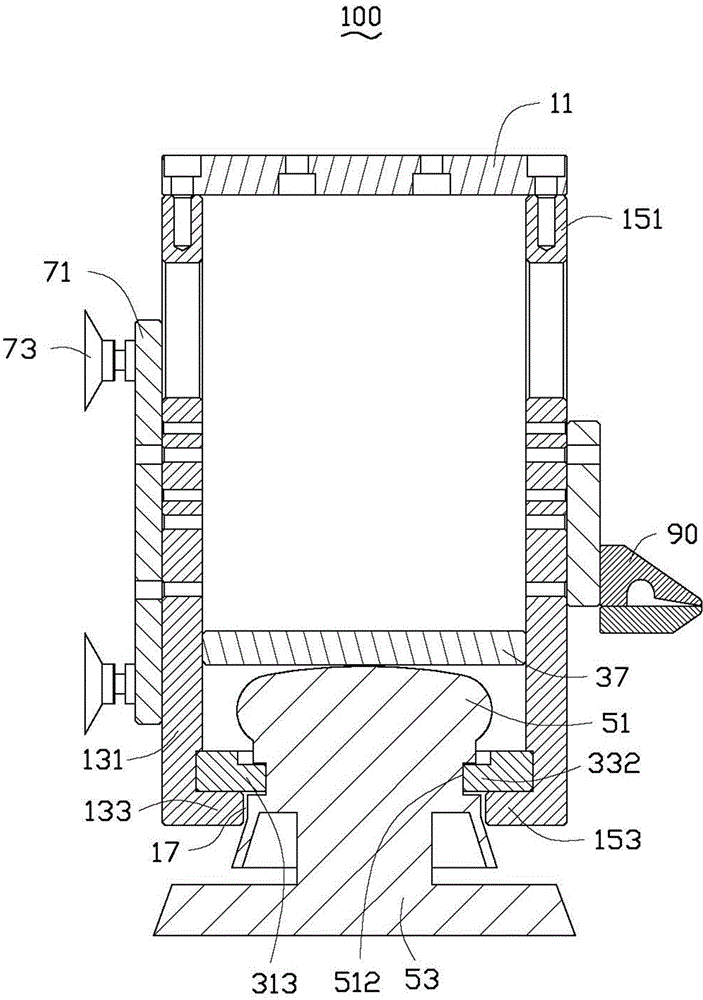

Polishing mechanism

InactiveCN104551905ANot easy to deviateAvoid wear and tearEdge grinding machinesGripping headsEngineeringMechanical engineering

A polishing apparatus connected to a robot arm and used to polish a workpiece includes a bracket, a polishing assembly, and a positioning assembly. The polishing assembly is mounted on the bracket and includes a driver and a polishing plate connected to the driver. The driver is capable of driving the polishing plate to rotate, and defines an annular positioning groove around the spin axis. The positioning assembly includes a first positioning plate and a second positioning plate mounted on the bracket and opposite to the first positioning plate. The first positioning plate and the second positioning plate are clamped into two sides of the positioning groove, whereby the driver is clamped between the first positioning plate and the second positioning plate.

Owner:FU DING ELECTRONICSAL TECH JIASHAN +2

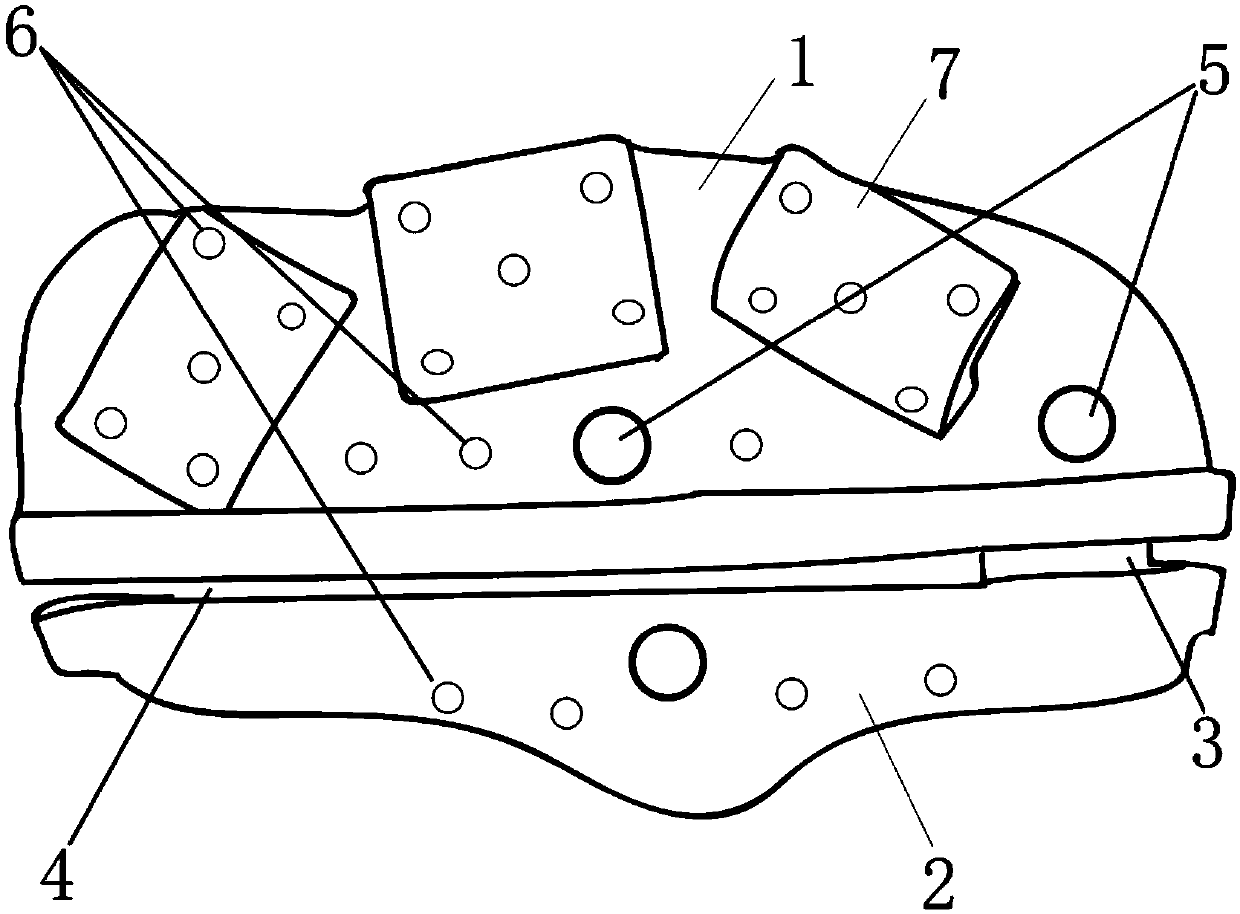

Bone support type bone cutting and navigation registration guide plate for temporal-mandibular joint arthroplasty

PendingCN109567913AAccurate and stable positioningNot easy to deviateSurgeryJoint arthroplastyJaw bone

The invention relates to a bone support type bone cutting and navigation registration guide plate for temporal-mandibular joint arthroplasty. The guide plate comprises an upper fixing part, a lower fixing part and a connecting part, wherein the inner surface structures of the upper fixing part and the lower fixing part are matched with the shape of the outer contour of the jaw of a patient; the upper fixing part and the lower fixing part are connected through the connecting part; a bone cutting groove is formed between the upper fixing part and the lower fixing part; fixing holes and registration points are respectively arranged in the upper fixing part and the lower fixing part; the registration points are of a concave point structure. The bone cutting position can be accurately and stably positioned by the invention; the fast registration of the navigation in the operation can be realized; the efficient implementation of the operation is facilitated; the operation time is shortened,and the bleeding and side effects are reduced.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL AFFILIATED TO SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

Automatic bar stock processing machine tool

PendingCN111822730AIncrease profitImprove feeding effectTurning machinesMetal working apparatusControl engineeringBar stock

The invention discloses an automatic bar stock processing machine tool. The automatic bar stock processing machine tool comprises a processing machine frame, and a loading machine frame is arranged onone side of the processing machine frame; a feeding plate is arranged on the loading machine frame, and a pushing device is arranged above the feeding plate; the feeding plate is arranged in a V shape, and a first telescopic rod is connected to a supporting block of the bottom surface of the feeding plate; a main shaft is rotatably arranged on the processing machine frame, and an encoder is connected to the main shaft; a transverse sliding seat is arranged on the processing machine frame, and a transverse pushing device is connected between the transverse sliding seat and the processing machine frame; a longitudinal sliding seat is arranged above the transverse sliding seat, and a longitudinal pushing device is connected between the longitudinal sliding seat and the transverse sliding seat; and a plurality of turning tools are arranged on the top surface of the longitudinal sliding seat. The automatic bar stock processing machine tool can improve the feeding effect, and further has the advantages that the processing operation is relatively convenient, the labor strength is small, the bar stock utilization rate is high, the using is relatively convenient, the application range is wide, the control precision is high, the processing precision is high and the discharging is relatively convenient.

Owner:兰溪瑞鼎机床股份有限公司

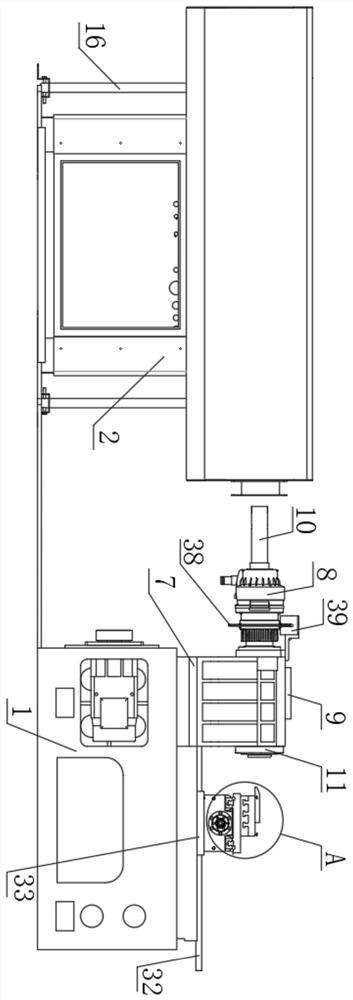

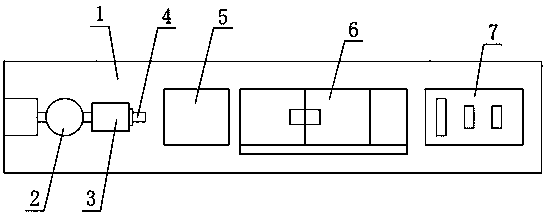

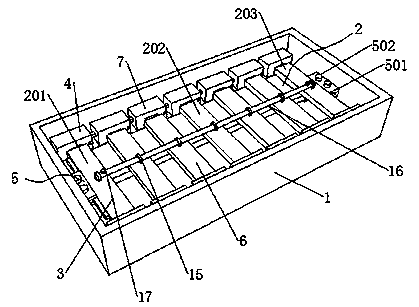

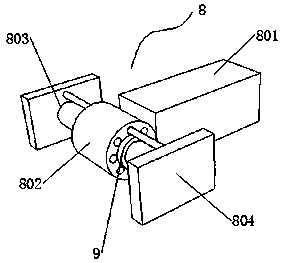

Interval flower color dovetail groove pipe head sucking pipe machining production line

ActiveCN110341159AConvenient distanceImprove cooling and shaping effectMetal working apparatusProduction lineEngineering

The invention discloses an internal flower color dovetail groove pipe head sucking pipe machining production line which comprises a rack (1), and a feeding device (2), a heating device (3), an extrusion molding die (4), a vacuum foam removing device (5), a cooling plastic device (6) and a cutting discharging device (7) which are sequentially arranged on the rack (1). The cooling plastic device (6)comprises a cooling box (8) fixedly connected with the rack. The two ends of the cooling box (8) are provided with a sealing feeding opening (9) and a sealing discharging opening (10) correspondingly, wherein the sealing feeding opening (9) and the sealing discharging opening (10) are the same in height. A partition plate (11) is arranged in the cooling box (8) and provided with a sealing transition opening (12). The height of the sealing transition opening (12) is the same as that of the sealing feeding opening (9). The production line is convenient to operate, and has the advantages of being low in cost, uniform in coloring, high in working efficiency and good in product quality.

Owner:义乌市城西机械有限公司

Automobile parts detecting fixture

The invention relates to an automobile parts detecting fixture comprising a base, a detection bed and two fixing arms. The detection bed is fixed at the upper end of the base. The two fixing arms are fixed at the upper end of the base and provided on two sides of the detection bed respectively. A first magnetic attractor is disposed in the detection bed. Compared with the prior art, the automobile parts detecting fixture allows convenient clamping and fixing and is high in detection efficiency and detection precision.

Owner:CHONGQING CITY DAZU DISTRICT CHENJIA MACHINERY FACTORY

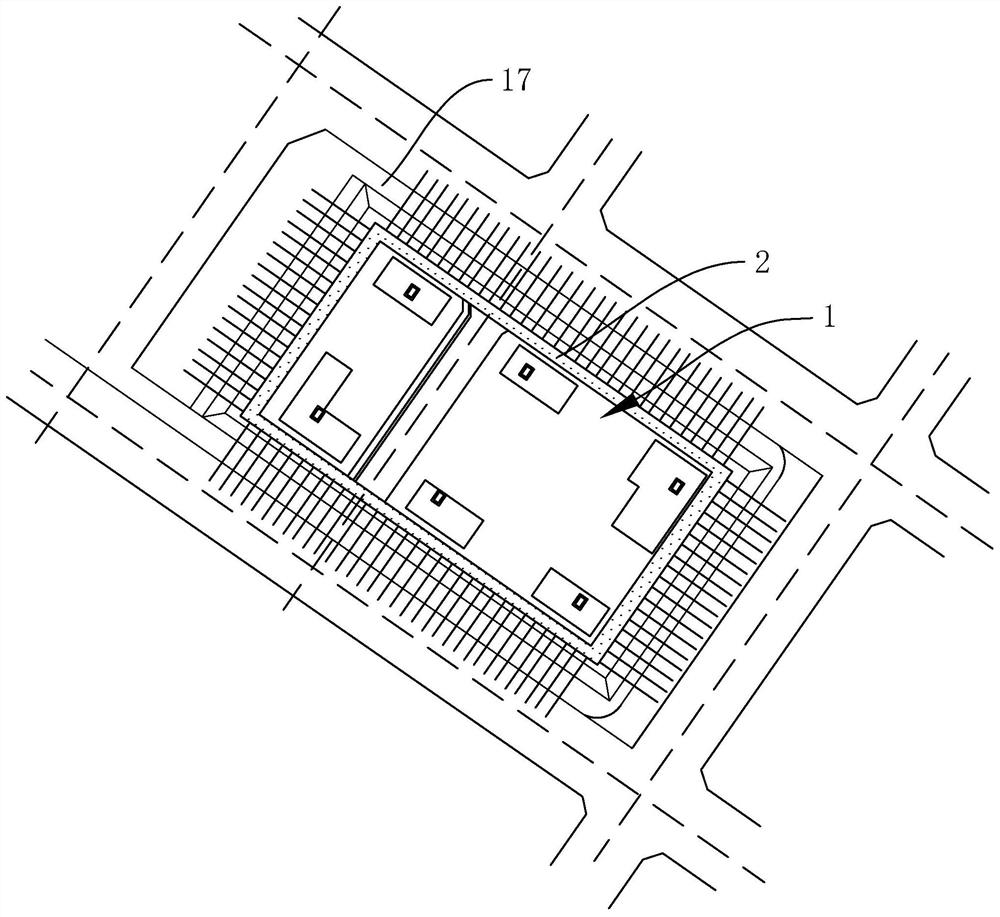

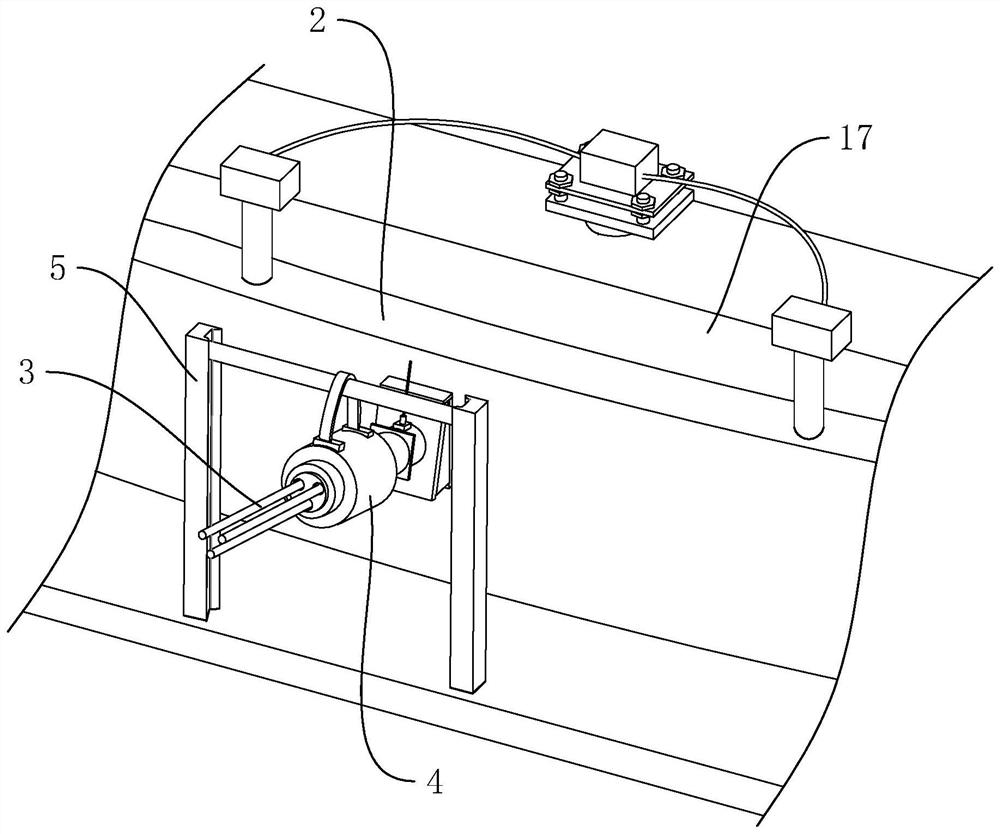

Automatic foundation pit support monitoring system

InactiveCN113482068AEasy to formulateReduce construction safety hazardsFoundation testingExcavationsArchitectural engineeringStructural engineering

The invention discloses an automatic foundation pit support monitoring system. The automatic foundation pit support monitoring system comprises an enclosure body, an anchor cable axial force monitoring device is arranged on the enclosure body and comprises an anchor cable arranged on the enclosure body in a penetrating mode and a tensioning mechanism used for providing tension for the anchor cable, one end of the anchor cable is poured into a slope body, a hole allowing the anchor cable to penetrate is formed in the enclosure body, and the tensioning mechanism is arranged at the end, away from the slope body, of the anchor cable and clamps the anchor cable. The anchor cable axial force monitoring device further comprises an anchor cable meter, the anchor cable meter and the anchor cable are concentrically arranged, an angle adjusting assembly is arranged on the enclosure body, a sleeve is arranged between the anchor cable meter and the tensioning mechanism, and the sleeve abuts against the anchor cable meter and the tensioning mechanism. Tensioning force is provided for the anchor cable through the tensioning mechanism, stress dissipation of the anchor cable meter is monitored, so that dissipation of prestress of the anchor cable is indirectly obtained, the prestress variable quantity of the slope body around the foundation pit is judged, workers can take and formulate necessary engineering measures in time, potential safety hazards of construction are reduced, and the construction safety is improved.

Owner:CRPCEC SHENZHEN ENG +1

Electrode cap changing tool for projection welding robot workstation welding

The invention relates to an electrode cap changing tool for projection welding robot workstation welding. The electrode cap changing tool comprises an initial electrode cap positioning base and an electrode cap fixing stamping rod. The initial electrode cap positioning base comprises an iron support, a nylon base and sensitive steel sheets, the iron support is connected to the upper portion of the nylon base through bolts, the sensitive steel sheets are mounted at the end of the nylon base, and the electrode cap fixing stamping rod comprises a stamping member and rods at two ends of the stamping member. Compared with the prior, the electrode cap changing tool has the advantages of lightweight, durability, safety, reliability and the like.

Owner:SHANGHAI ANDELAI AUTO PARTS

Method for laying reinforced meshes of cast-in-situ concrete floors

InactiveCN105220884AImprove crack resistanceImprove integrityFloorsBuilding material handlingFloor slabSurface layer

The invention relates to a method for laying reinforced meshes of cast-in-situ concrete floors. The method is characterized by comprising steps of 1), designing and welding the reinforced meshes; 2), laying the reinforced meshes of bottom layers of the floors; 3), laying the reinforced meshes of surface layers of the floors; 4), arranging plastic cards or mortar spacers on the reinforced meshes of the bottom layers and arranging horse-shaped stools on the reinforced meshes of the surface layers at intervals of 600-900 mm. The plastic cards or mortar spacers are equivalent to the thicknesses of the protective layers. The method has the advantages that reinforcing steel bars of the concrete floors can be constructed by the aid of the method, accordingly, straight stressed reinforcing steel bars in longitudinal and transverse directions can be guaranteed, grids of the reinforcing steel bars have uniform sizes, and the meshes, which are formed by means of welding, of the reinforcing steel bars are good in integrity, high in stiffness and difficult to deform and are difficult to locally bend, deform and deviate even under the effect of external force in concrete pouring construction procedures; the concrete protective layers, which are formed by means of pouring, of the reinforcing steel bars of the floors have uniform thicknesses, and accordingly the crack resistance of the floors can be improved; a large quantity of labor can be saved, the production efficiency can be improved, and good economical effects can be realized.

Owner:广西矿建集团有限公司

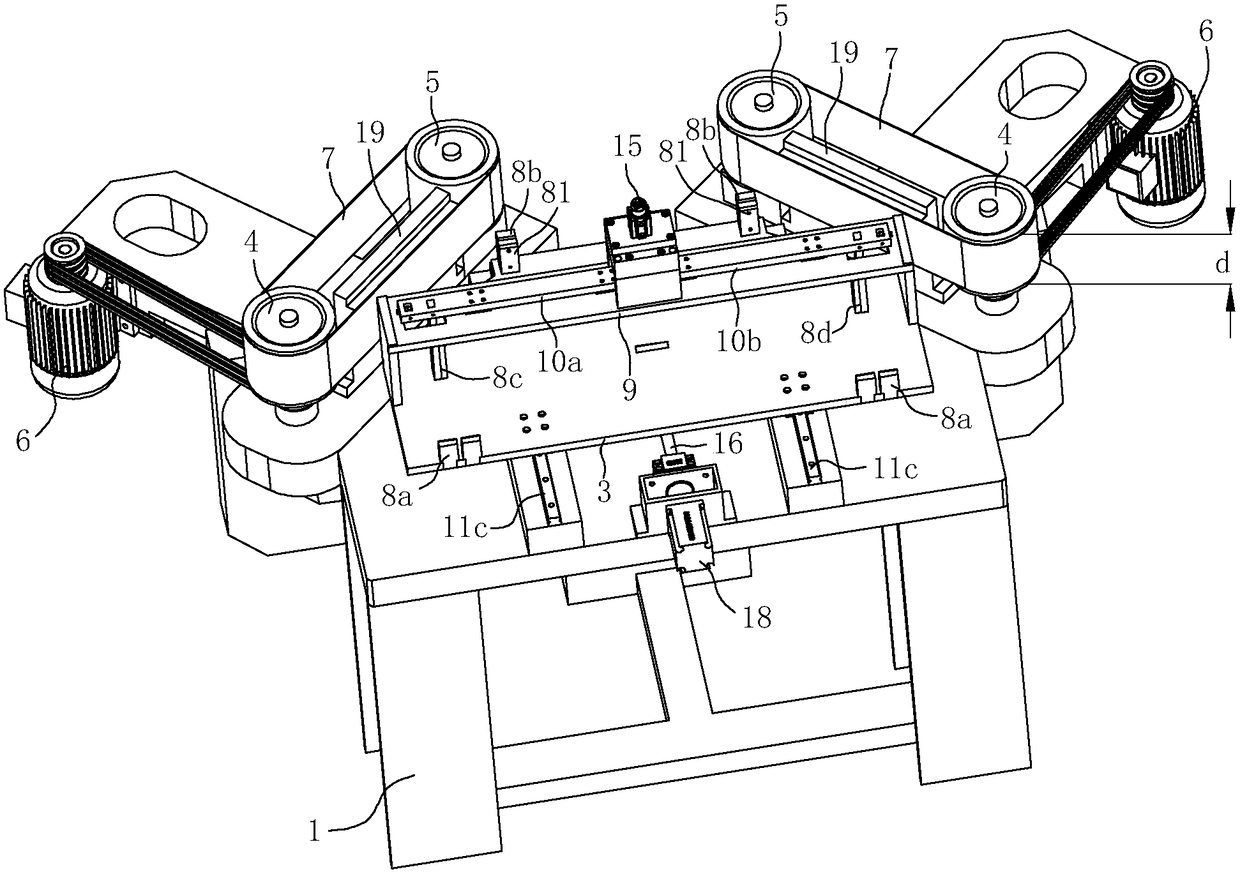

Angle pasting machine for carton

ActiveCN111497332AHigh degree of automationImprove work efficiencyBox making operationsPaper-makingCartonElectric machinery

The invention discloses an angle pasting machine for a carton. According to the technical scheme, the angle pasting machine for the carton is characterized in that the angle pasting machine for cartoncomprises a rack, a belt conveying device and a pressing and pasting device, the belt conveying device and the pressing pasting device are arranged on the rack, a supporting base is arranged on one side of the rack, a rotary table is rotationally arranged on the supporting base, a square tables are rotationally connected to the side, facing the rack, of the rotary table and evenly arranged in thecircumferential direction of the rotary table, the carton wraps the square tables, adsorption devices are arranged on the square tables, a first stepping motor used for driving the rotary table to rotate intermittently is arranged on the supporting base; each square table comprises four folding angles, one of the folding angles faces the pressing and pasting device upwards, a conversion device used for driving the four square tables to sequentially convert the folding angles is arranged on the rotary table, and a fixing device used for fixing the square tables is further arranged on the rotary table, the rotary table is also provided with a fixing device for fixing the square tables; and the rack is further provided with an abutting device used for abutting against and fixing the carton.According to the angle pasting machine for carton, the automation degree of the angle pasting machine is improved, and the working efficiency is improved.

Owner:东莞市航丰包装科技有限公司

Corner grinding machine tool

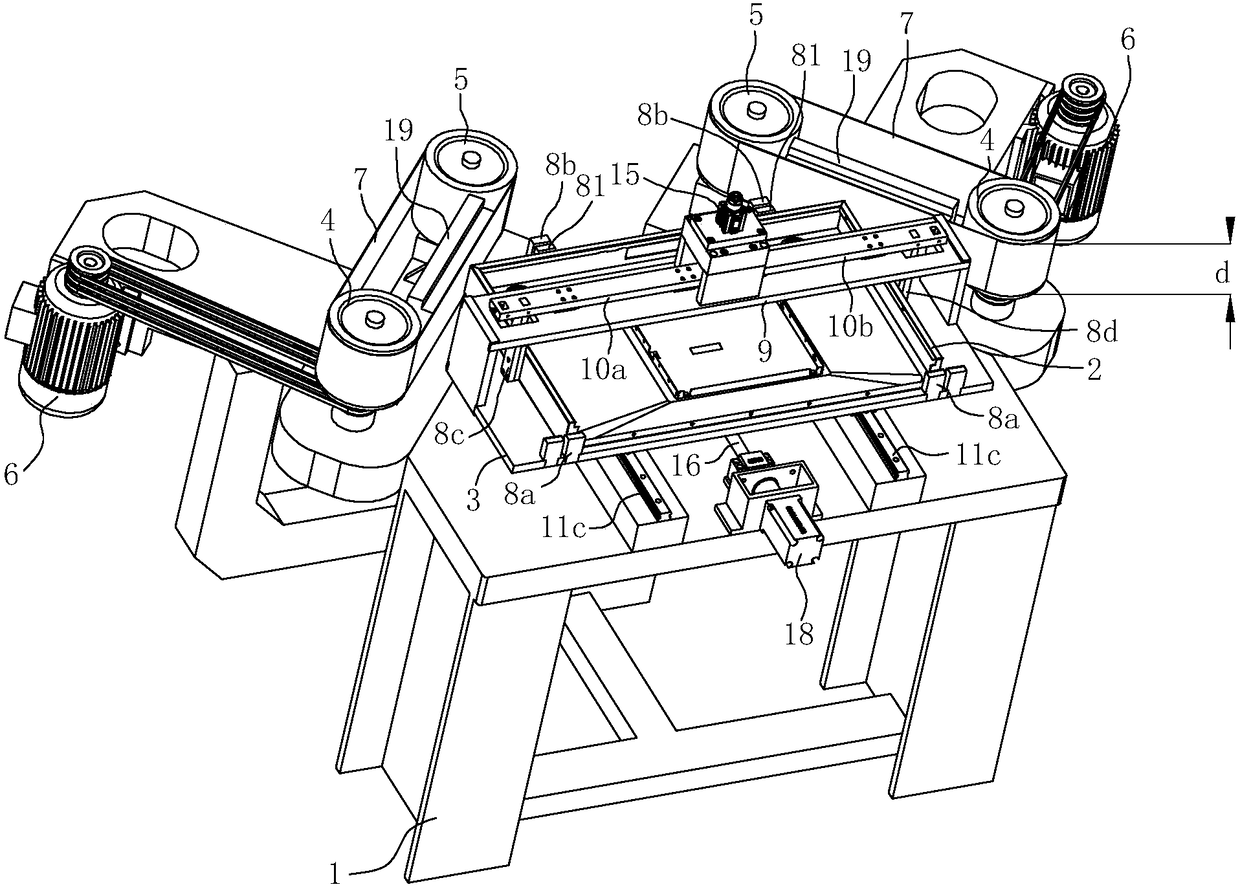

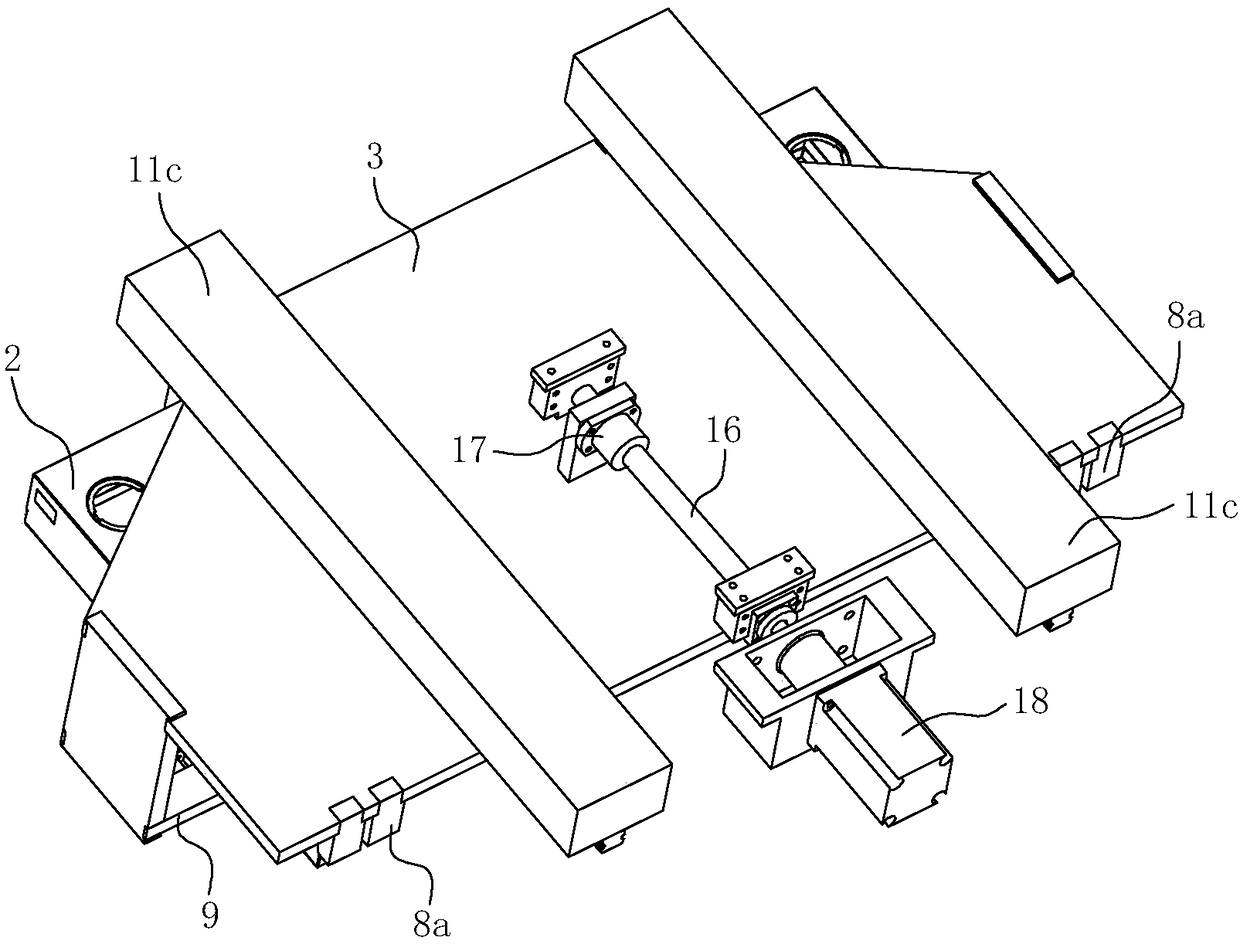

InactiveCN109382732AImprove grinding efficiencyRealize automatic grinding processBelt grinding machinesGrinding feedersMachine toolEngineering

The invention relates to a corner grinding machine tool. The tool is characterized by comprising a rack, a platform used for placing a to-be-ground workpiece, a platform driving mechanism and two grinding mechanisms, wherein the platform is arranged above the table top of the rack, and the positioning structure used for positioning the to-be-ground workpiece on the platform is arranged on the platform; the platform driving mechanism is used for driving the platform to horizontally slide back and forth; the two grinding mechanisms are arranged on the left side and the right side of the rear part of the rack and correspond to two grinding corners of the to-be-ground workpiece respectively; each grinding mechanism comprises a driving belt wheel and a driven belt wheel, an abrasive belt is obliquely arranged between each driving belt wheel and the corresponding driven belt wheel, and the width of each abrasive belt is larger than the height of the grinding corners of the to-be-ground workpiece. The corner grinding machine tool can be used for grinding the two side corners of the to-be-ground workpiece at the same time, and the tool can precisely grind the workpiece with the corners meeting design requirements. The corner grinding machine tool can be used for automatically grinding the two side corners of the to-be-ground workpiece at the same time, and can precisely grind the workpiece with the corners meeting the design requirements.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

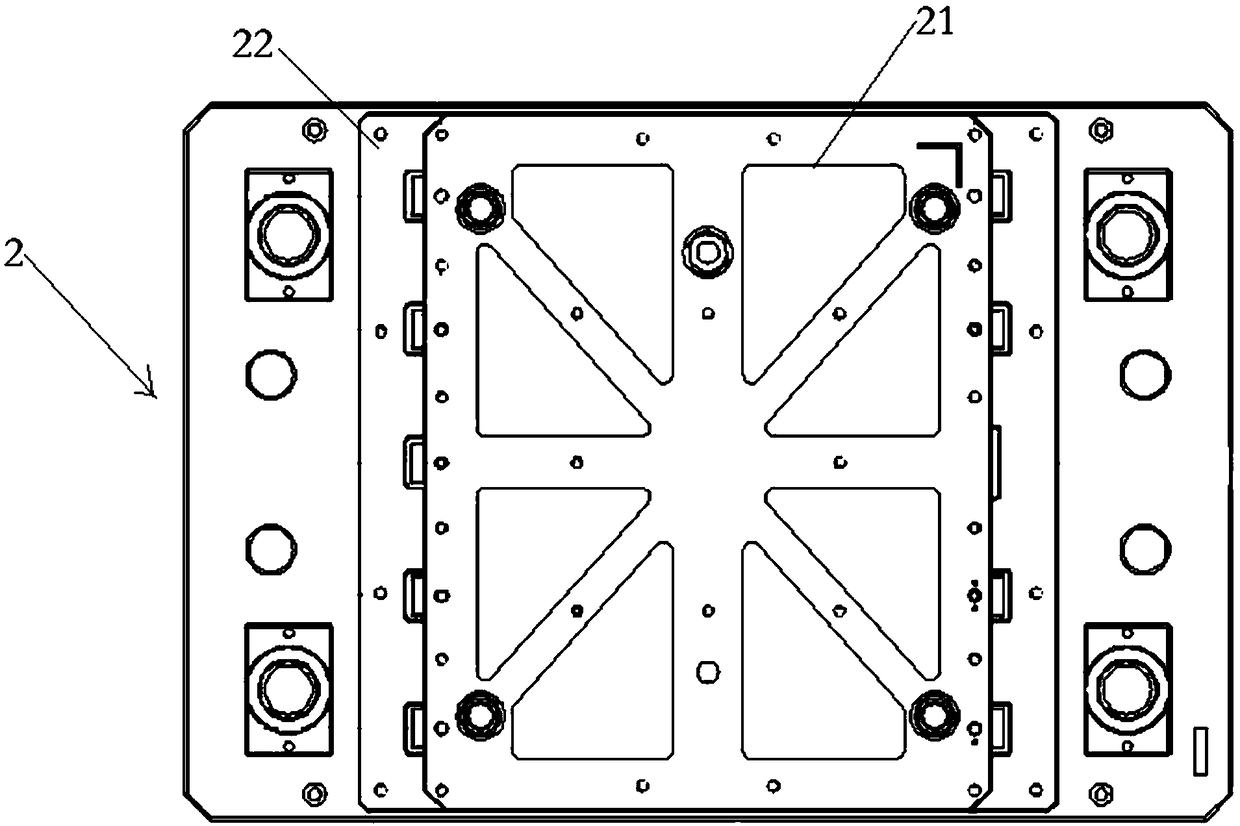

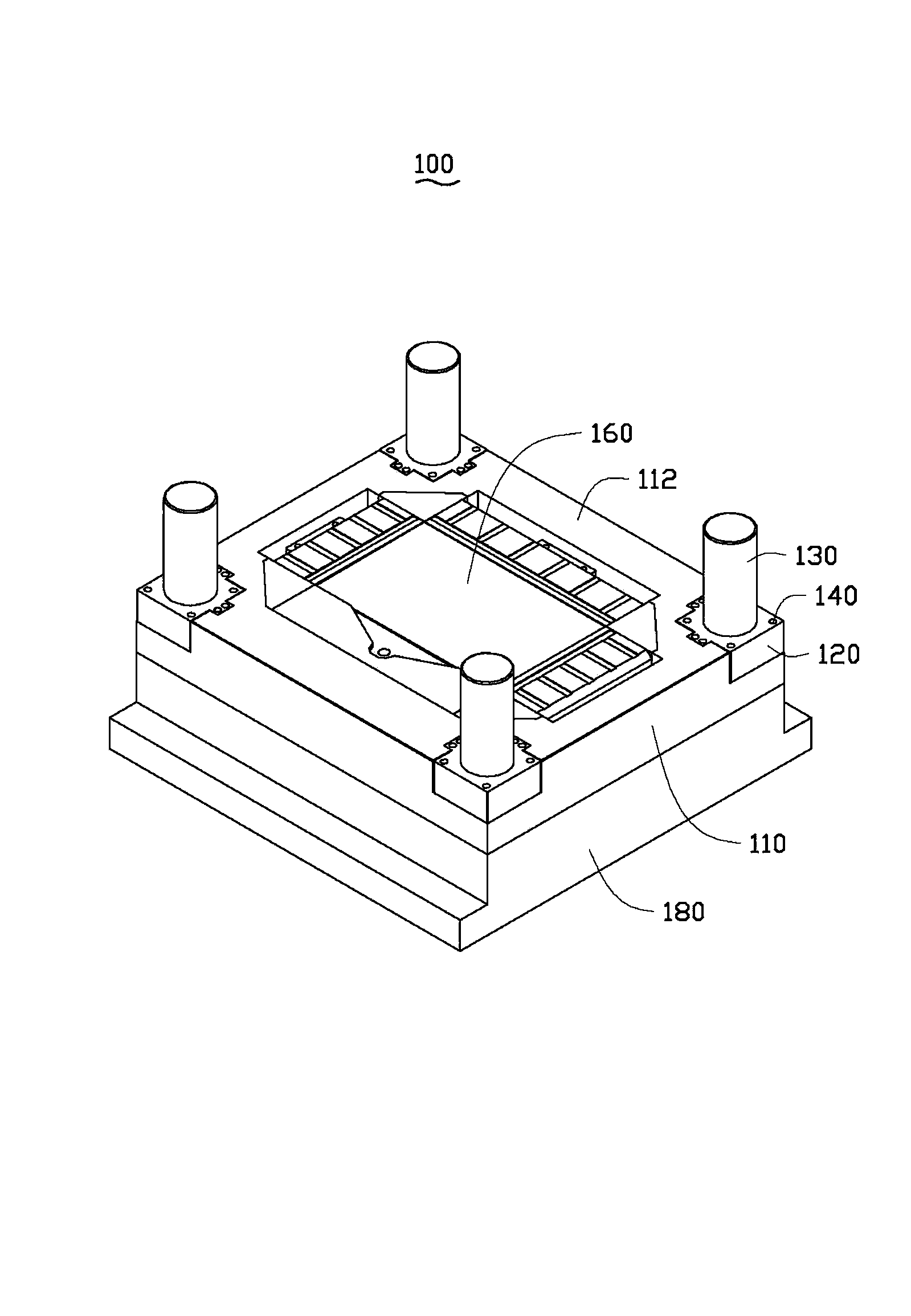

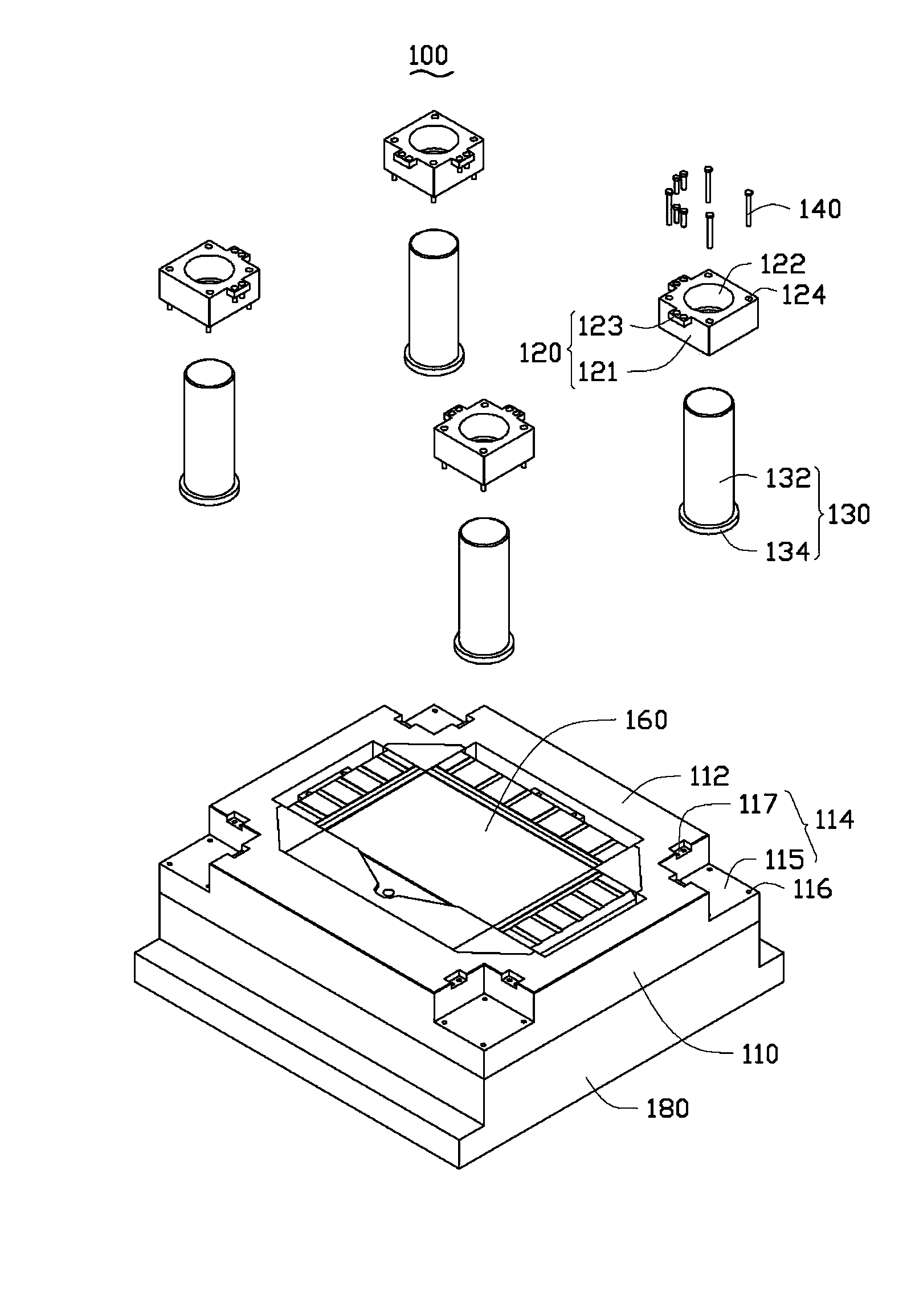

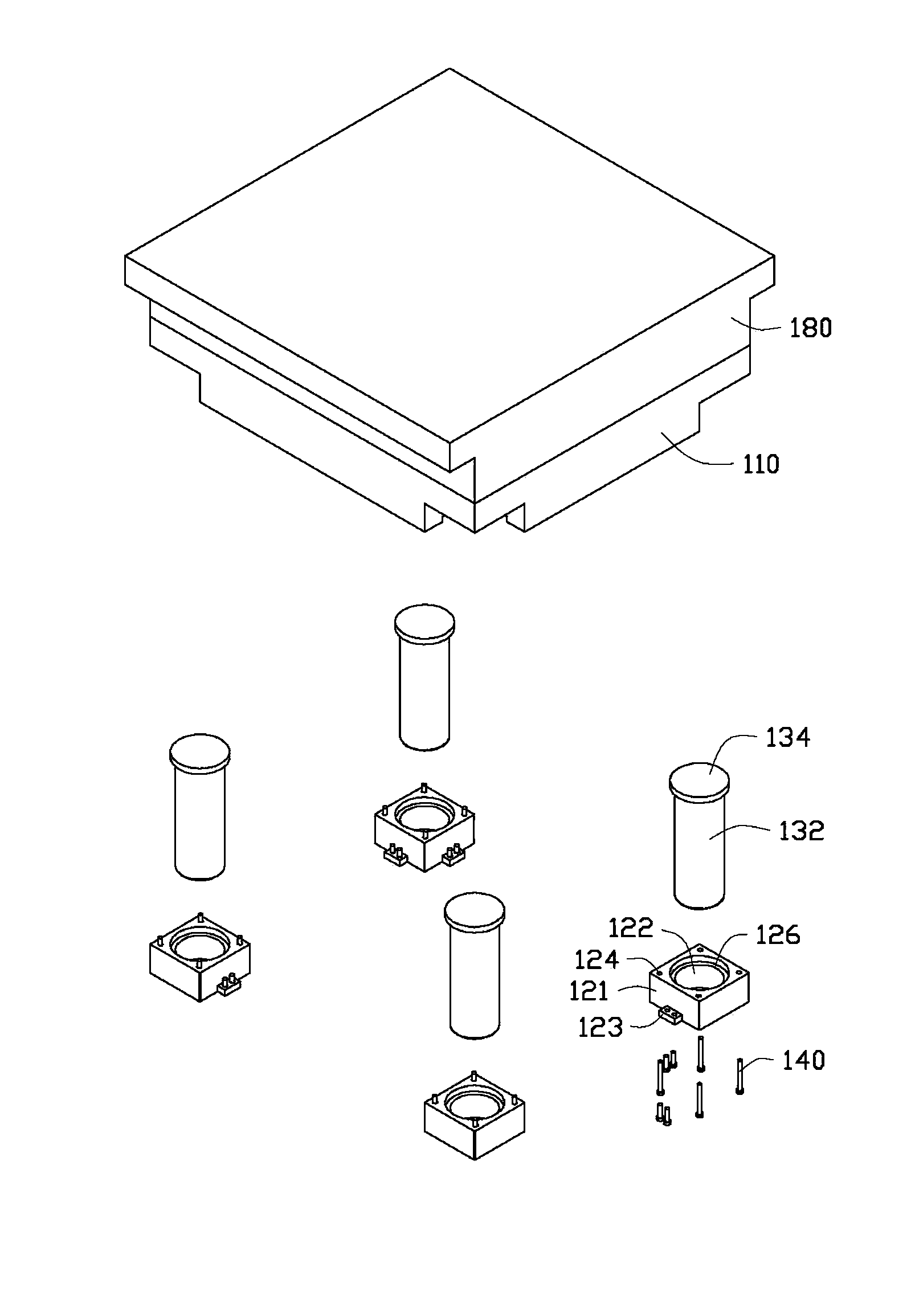

Mold

The invention relates to a mold comprising a mold seat, a plurality of guide column fixing blocks, a plurality of guide columns, and a plurality of screws. The mold seat comprises a sub-mold surface. A plurality of recesses are arranged on the edge of the sub-mold surface. A plurality of screw matching holes are arranged at each recess. Each guide column fixing block is used to be engaged into one recess. A through guide hole and a plurality of screw through holes are arranged in each guide column fixing block. Each guide column comprises a guide rod part and a rim positioned on the bottom of the guide rod and protruding outwards. The outer diameter of the rim is larger than the diameter of the guide hole. The rim of each guide column is set on the recess, and the guide rod part penetrates a guide hole. Each screw penetrates a screw through hole, and is fixed into a screw matching hole, such that the guide column fixing block is fixed into a corresponding recess. The mold as a sub-mold can be used in cooperation with another sub-mold provided with a guide sleeve.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

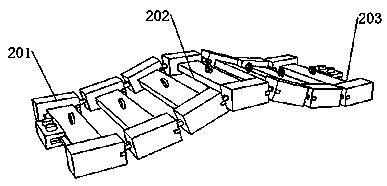

Hull bottom arthropod type suction grille

The invention discloses a hull bottom arthropod type suction grille, and belongs to the technical field of ship equipment. The hull bottom arthropod type suction grille comprises a water inlet fixingframe, and a grille board group is arranged in the water inlet fixing frame and comprises a grille head part, a grille trunk part and a grille tail part. The grille trunk part comprises a plurality ofarthropod grille boards distributed in parallel, each arthropod grille board comprises a second grille board and a pair of second connecting heads, and a connecting mechanism is connected between each pair of adjacent arthropod grille boards. The connecting mechanisms comprise fixed parts and driving connecting parts, the driving connecting parts comprise connecting rods and rotary connecting rings, the connecting rods are fixedly connected with the left ends of the second connecting heads through the rotary connecting rings, and the fixed parts comprise positioning double rods and operativepull boards. The hull bottom arthropod type suction grille can be subjected to matched adjustment according to ship seawater suction inlets under different situations by imitating the body construction of arthropods, and universality of the hull bottom suction grille is obviously improved from two aspects of size adjustment and line type adjustment.

Owner:天长市蓝天船舶设备制造有限公司

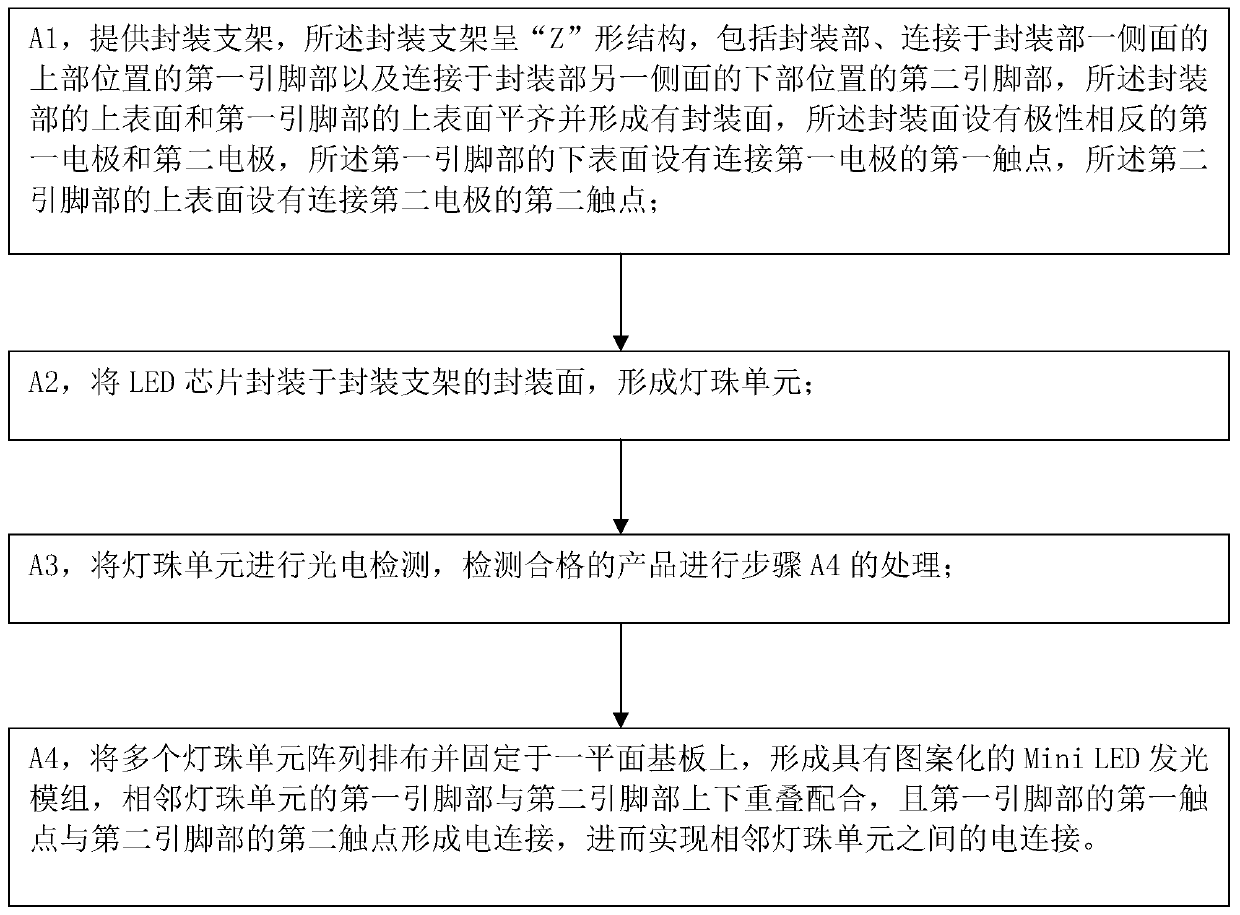

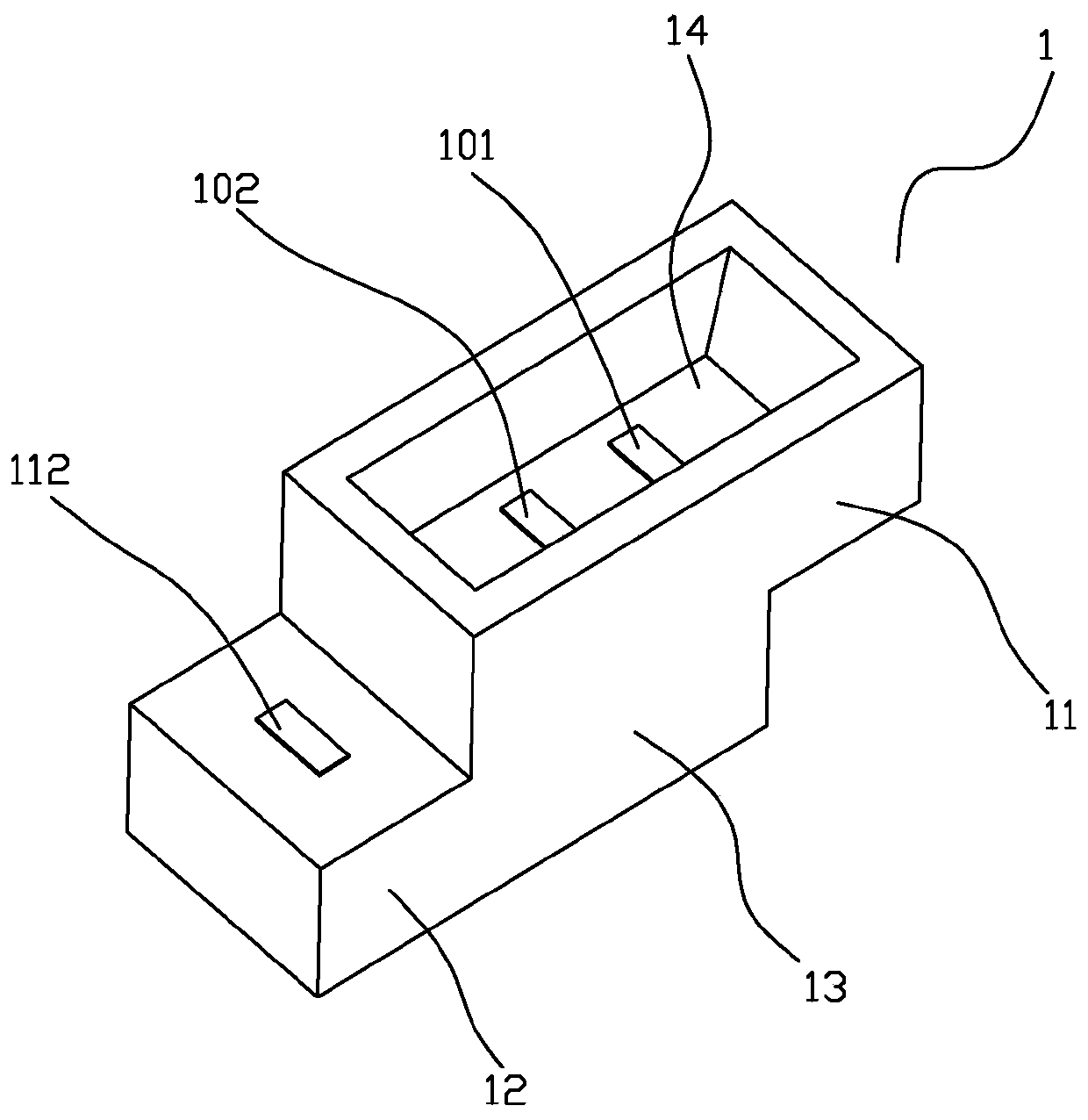

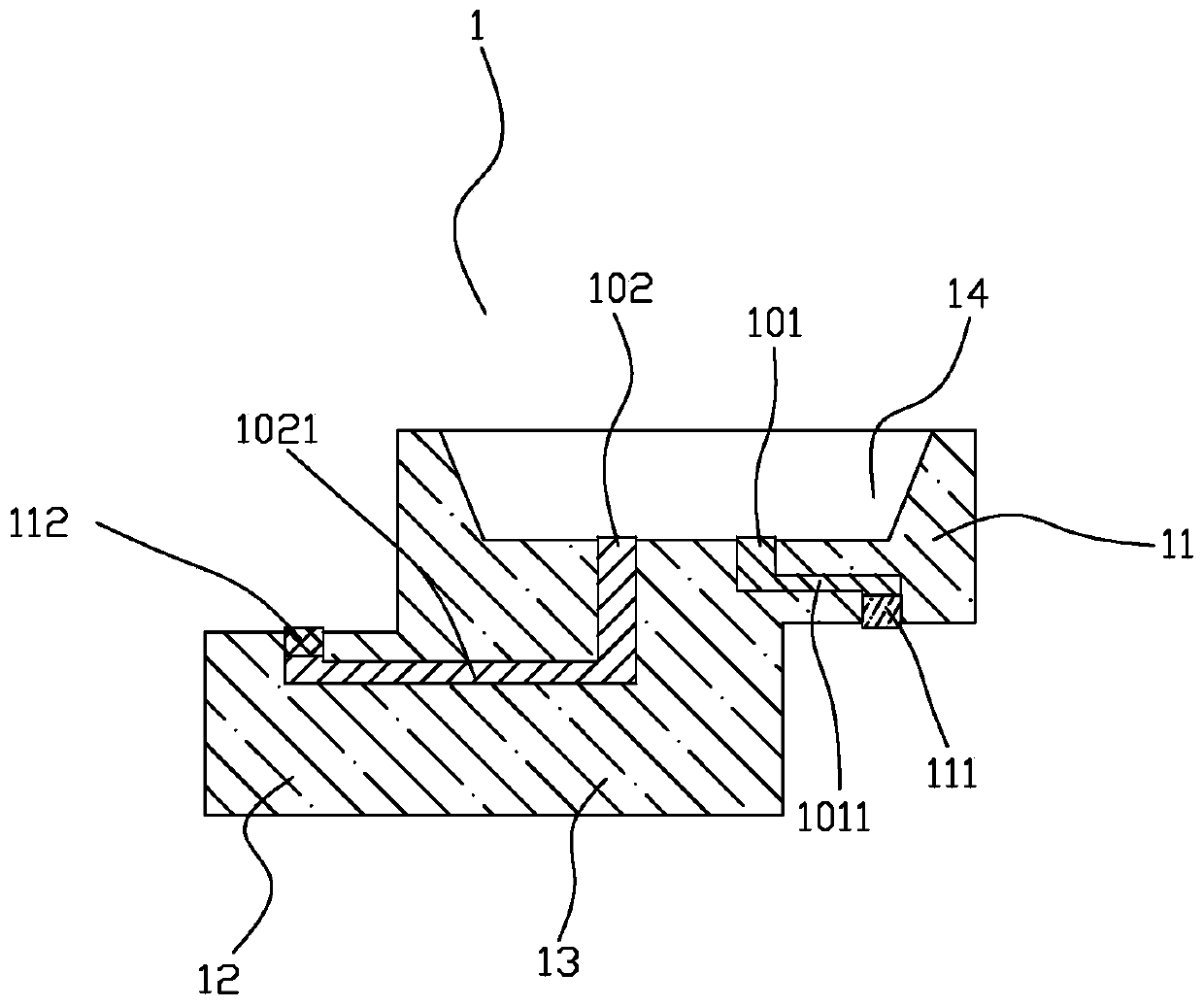

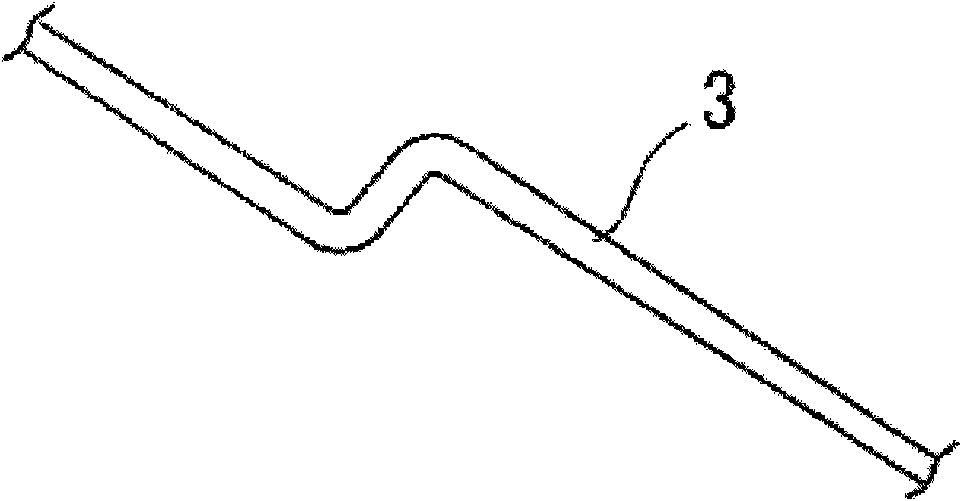

Mini LED packaging method and Mini LED

ActiveCN110429080AEasy to assembleRemove restrictionsSolid-state devicesSemiconductor devicesElectricityElectrical connection

The invention provides a Mini LED packaging method and a Mini LED prepared through the method. A package support is set in a "Z"-shape structure; after package molding, photoelectric detection is performed; then, array arrangement is carried out to form a required patterned Mini LED light-emitting module, and yield is good; the "Z"-shaped structure is easy to assemble, that is, a second pin portion and a first pin portion of adjacent lamp bead units are overlapped and cooperated and are in electrical connection; the connection structure is compact, density is good, arrangement size is accurateand no deviation is caused; and chip package can be carried out without arranging an electrode on a substrate, so that the limitation of the substrate electrode is eliminated, and free arrangement isachieved.

Owner:厦门多彩光电子科技有限公司

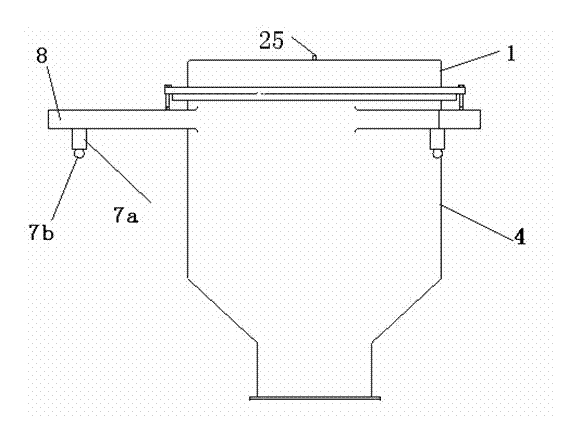

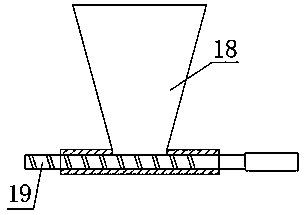

Self-adjusting lower valve head of crushed coal pressurized gasifier ash lock

The invention relates to the technical field of ash discharging devices for the coal chemical industry field, in particular to a smashed coal pressure gasification furnace ash lock self-adjusting lower valve head, which is characterized by comprising a valve head, wherein a concave arc is arranged in the middle of the valve head; a valve rod is embedded in the concave arc and is matched with the concave arc through an arc end at the lower end; a flange is arranged corresponding to the periphery of the arc end in a surrounding way; a pressing cap is arranged on the periphery and the upper part of the flange; a pressing disc is arranged above the pressing cap; an ash retention cover is arranged on the peripheries of the pressing cap and the pressing disc. The structural design is reasonable, the direct position relationship of each part can be slightly adjusted, the tightness and the stability of the structure are ensured, and the service life of the product is greatly improved.

Owner:HEBEI XIAOHUA MACHINERY ACCESSORIES CO LTD

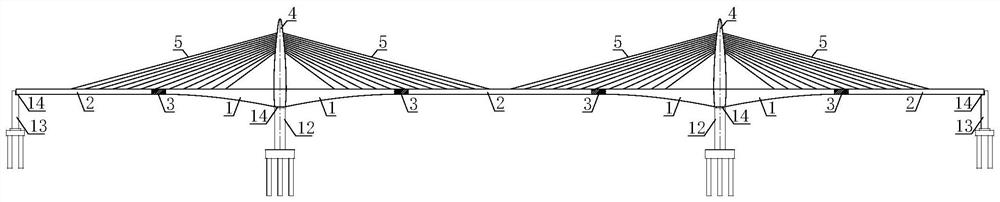

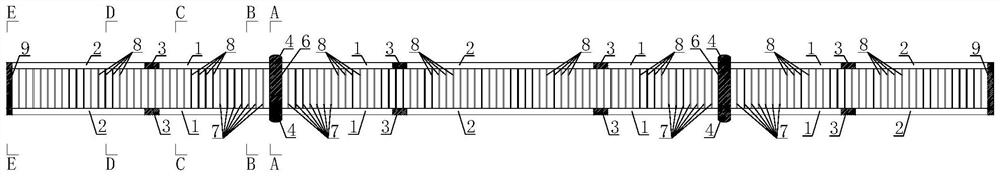

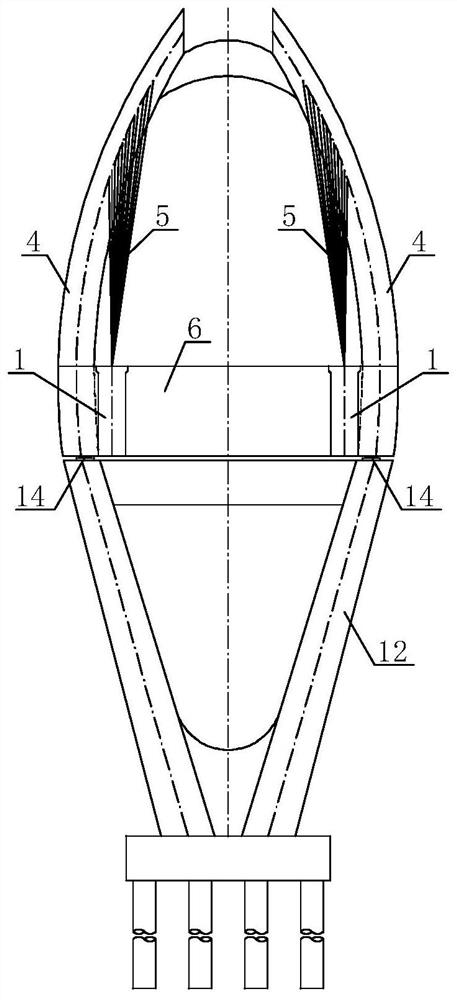

Wide-width large-span hybrid beam extradosed cable-stayed bridge system and construction method thereof

PendingCN112982139AImprove carrying capacityLose weightCable-stayed bridgeBridge structural detailsArchitectural engineeringBridge deck

The invention discloses a wide-width large-span hybrid beam extradosed cable-stayed bridge system and a construction method thereof. The wide-width large-span hybrid beam extradosed cable-stayed bridge system comprises hybrid beams which are composed of concrete box girders and corrugated web steel box-concrete composite beams and arranged on two sides in a transverse bridge direction, wherein the concrete box girders are positioned on two sides of a middle fulcrum and are integrally poured with a bridge tower; the composite beams are located in side span and middle span; the concrete box girders and the composite beams are connected through a steel-concrete combined section; the steel-concrete combined section is formed by pouring combined section concrete in a corrugated web steel box; the hybrid beams are transversely composed of middle fulcrum concrete cross beams, truss type steel cross beams, I-shaped steel cross beams and end cross beams which are connected; a bridge deck is arranged on the hybrid beams; and the hybrid beams are supported by main piers and transition piers. The hybrid beam extradosed cable-stayed bridge system is reasonable in structural design, convenient to construct, good in using effect and capable of being used for wide and large-span bridges. Meanwhile, the invention further discloses a matched construction method. The matched construction method comprises the steps of bridge tower construction, concrete box girder construction, composite beam construction, steel-concrete combined section construction and the like. The construction method is complete, and construction progress is fast.

Owner:甘肃省交通规划勘察设计院股份有限公司

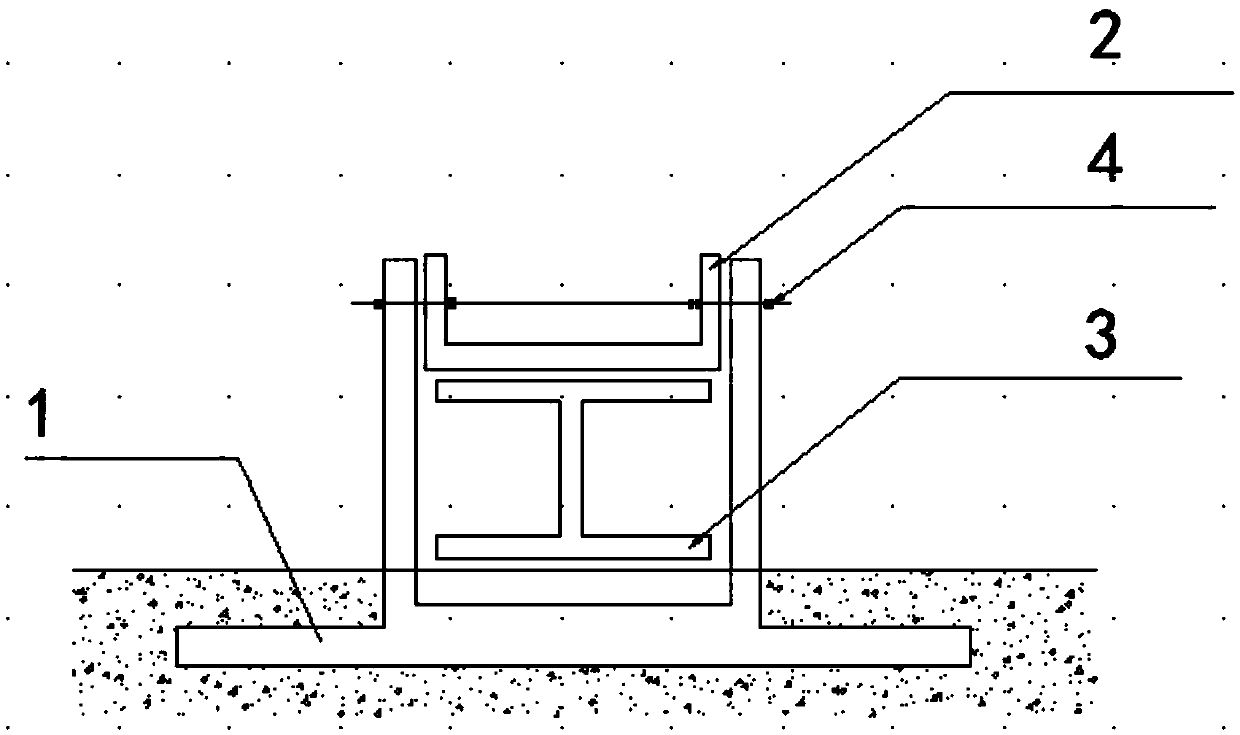

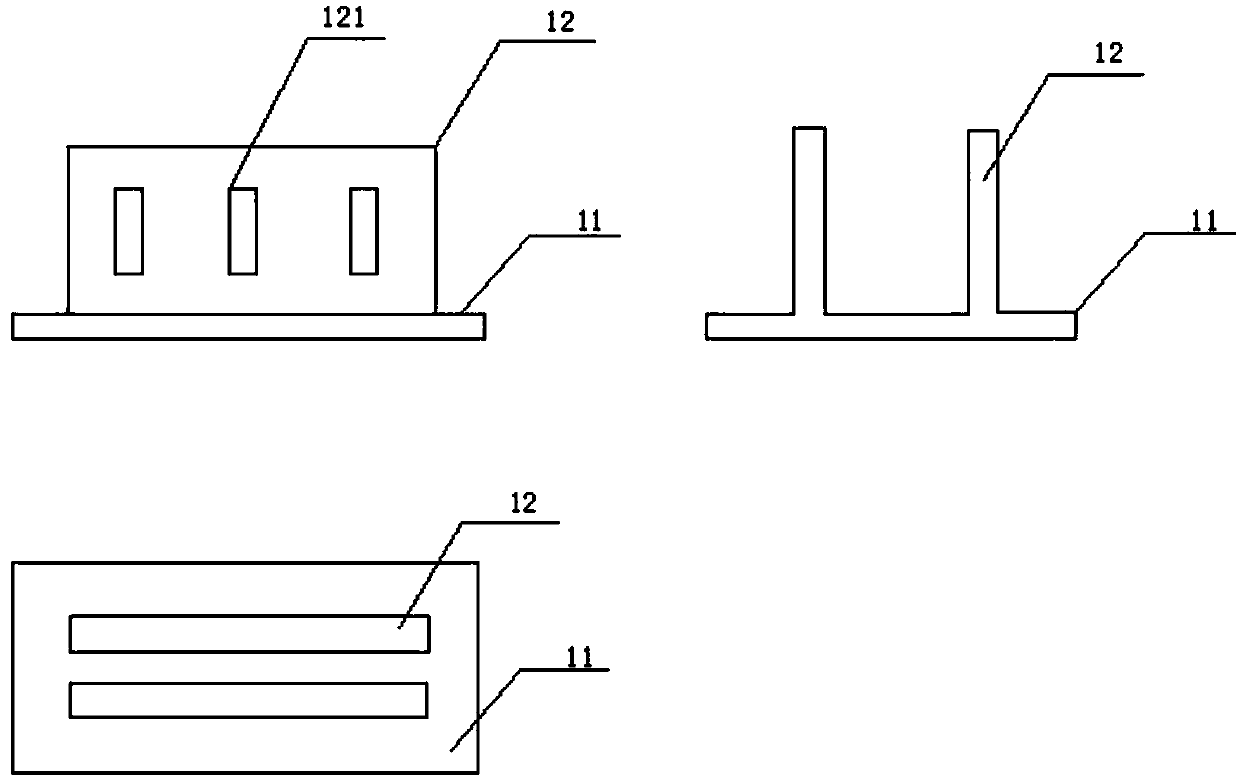

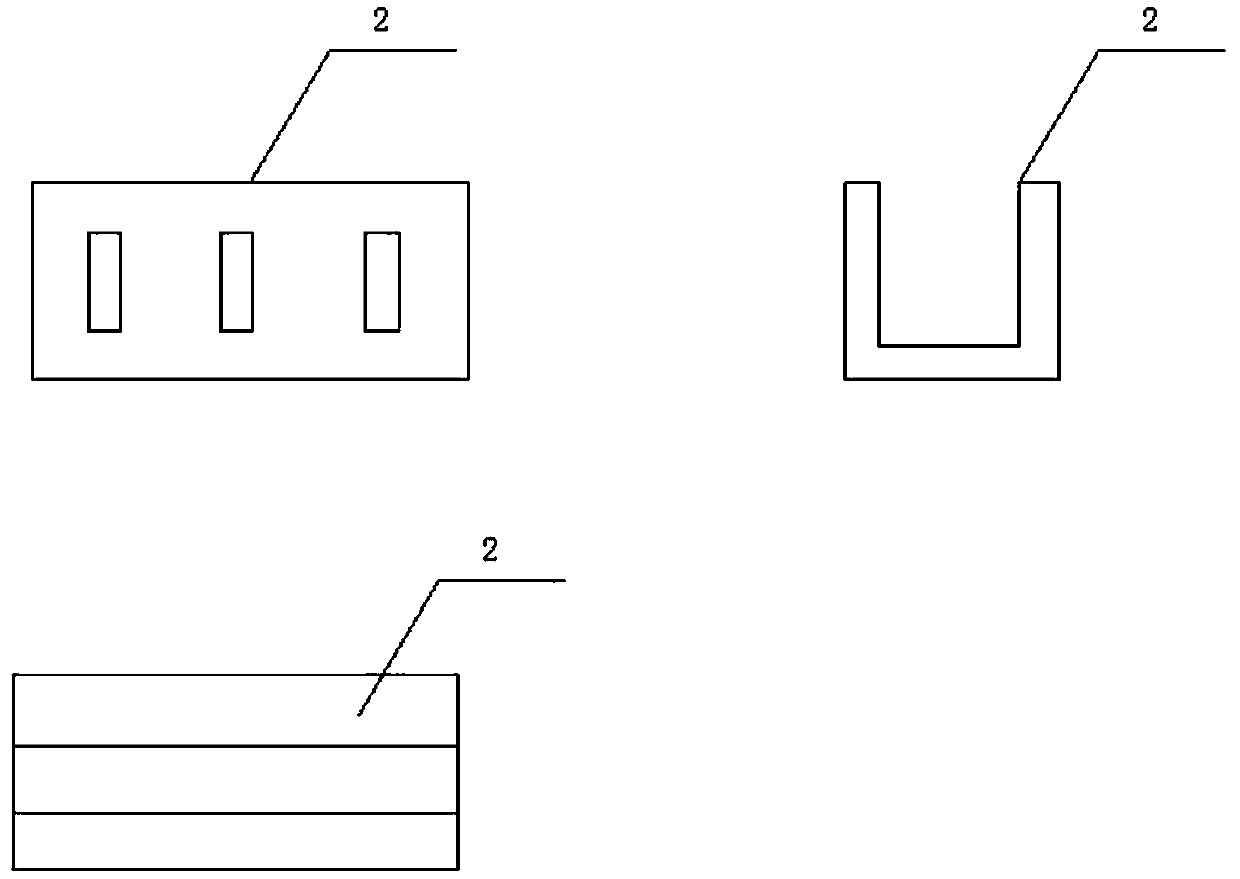

Large-span cantilever structure formwork supporting I-shaped steel pre-embedded part and construction method thereof

The invention discloses a large-span cantilever structure formwork supporting I-shaped steel pre-embedded part and a construction method thereof. The large-span cantilever structure formwork supporting I-shaped steel pre-embedded part comprises a steel pre-embedded part body, a U-shaped fixing piece, I-shaped steel and bolts. The steel pre-embedded part body comprises a bottom plate and two side plates, the two side plates are perpendicularly fixed to the bottom plate, the two side plates are parallel to each other, fixing grooves are formed in the side plates, and fixing grooves are formed inthe side face of the U-shaped fixing piece; and the I-shaped steel is arranged on the bottom plate of the steel pre-embedded part body, and located between the two side plates, the U-shaped fixing piece is located above the I-shaped steel, and the U-shaped fixing piece is fixed to the steel pre-embedded part body through the bolts at the positions where the fixing grooves are formed.

Owner:CHINA MCC17 GRP

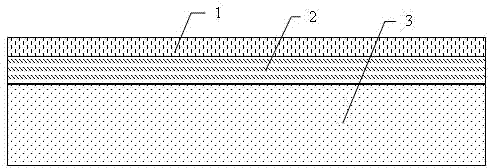

Manufacturing method for diffusion plate used for high-reliability liquid crystal display

ActiveCN103777403AWide range of choicesEasy to operateDiffusing elementsNon-linear opticsDiffusionFlat glass

A manufacturing method for a diffusion plate used for a high-reliability liquid crystal display is characterized in that firstly, plate glass is adopted as a substrate; secondly, the substrate is coated with glue evenly or according to a certain pattern design (I-type patterns, or double-Y-type patterns or fishbone-type patterns or others); thirdly, a diffusion film is attached to the glue, and pressure is exerted to enable the space between the diffusion film and the substrate to be covered with the glue; fourthly, the glue is solidified on the substrate, so that a glue layer is formed on the substrate and is reliable in gluing; finally, after the glue is solidified, the diffusion film is uncovered, the light evening function of the diffusion film is copied to the glue layer, and therefore the glass substrate is changed to be the diffusion plate with the light evening capacity. The manufactured diffusion plate has the advantages of being wide in temperature range, high in anti-impact and anti-vibration capacity, moisture-proof and heatproof capacity and reliability and the like.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

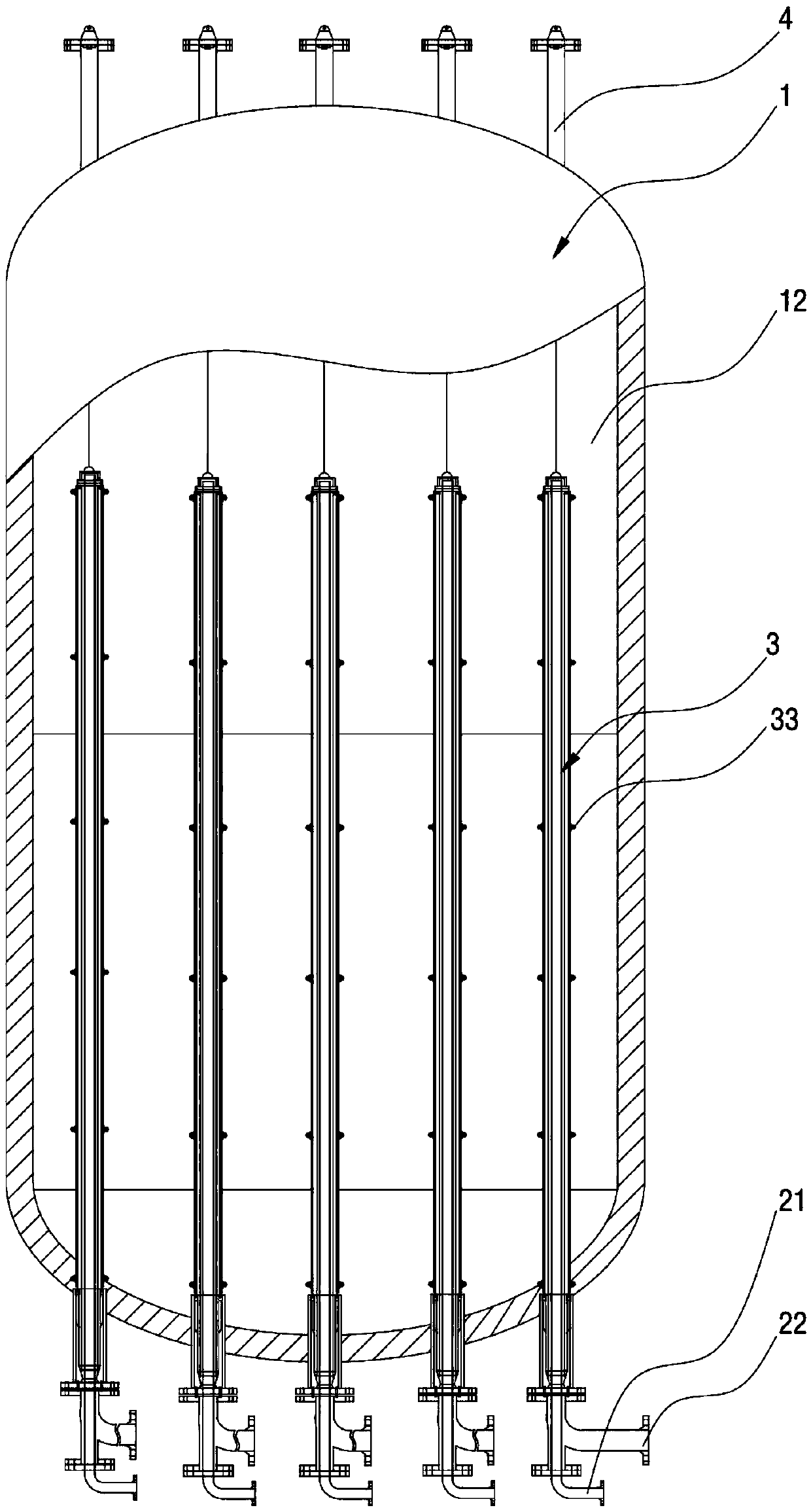

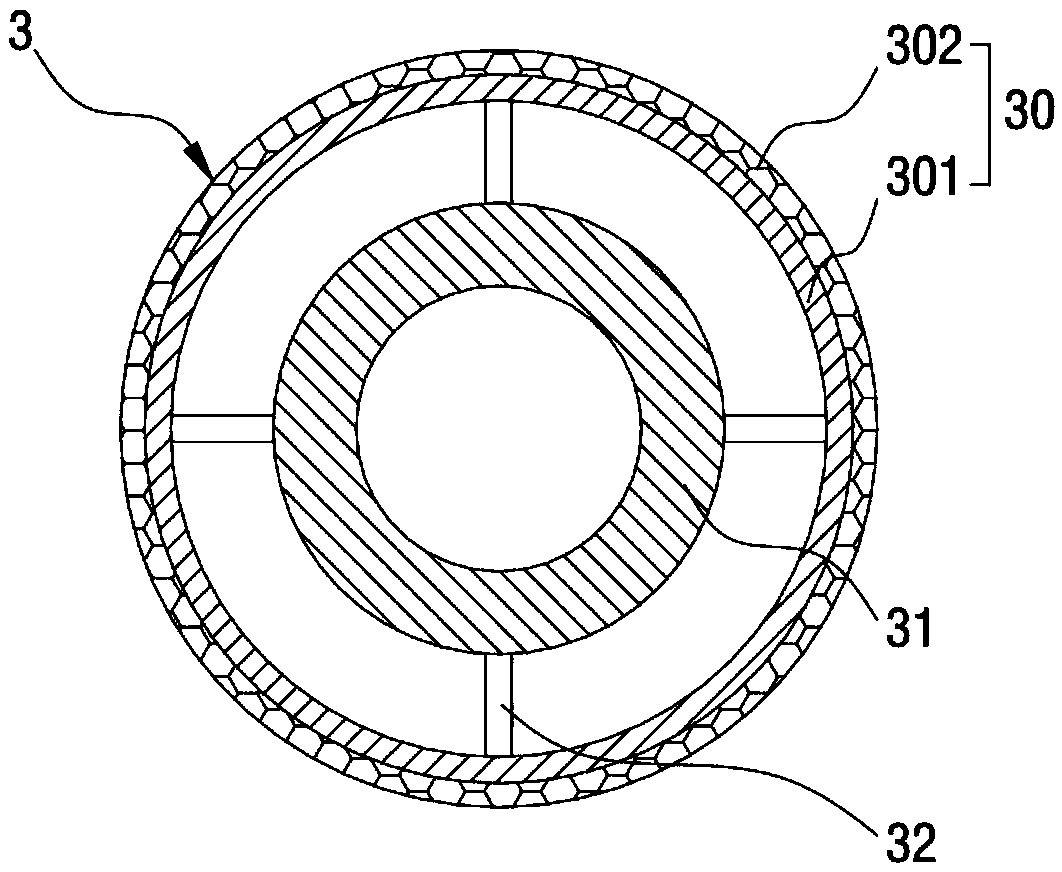

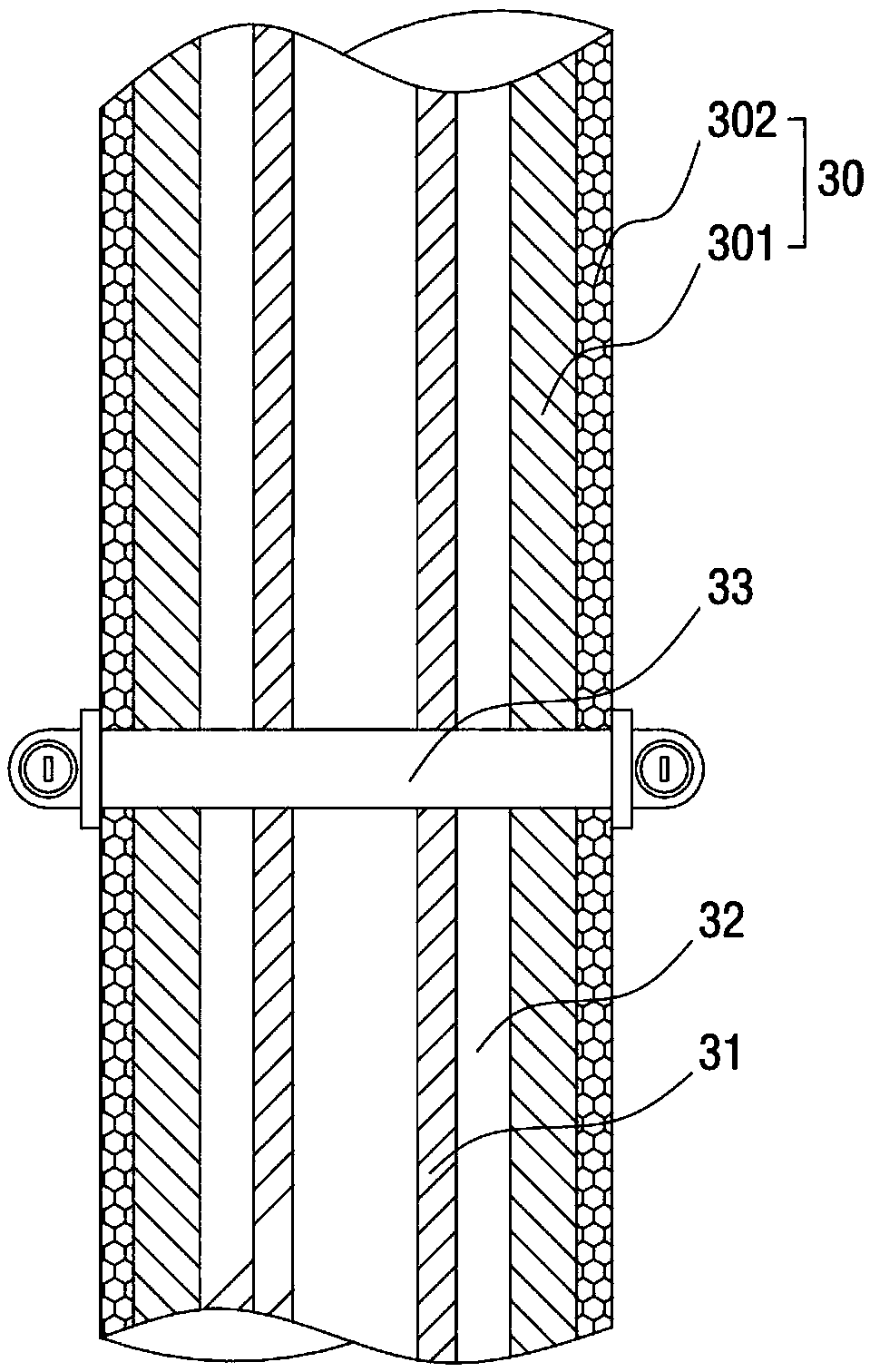

Reaction kettle and three-phase flow catalytic reaction method applying same

ActiveCN105498646AIncrease contact areaImprove reaction efficiencyChemical/physical/physico-chemical nozzle-type rreactorsReagentReaction chamber

The invention relates to a reaction kettle and a three-phase flow catalytic reaction method applying the same. The invention aims to provide the reaction kettle high in production efficiency and meanwhile provide the three-phase flow catalytic reaction method applying the reaction kettle. The invention relates to the field of chemical industrial reaction equipment. In order to achieve the purpose, the reaction kettle comprises a kettle body, wherein a reaction chamber is formed in the kettle body; a flow guiding structure is arranged in the reaction chamber and comprises a permeating part; a feeding hole and a discharging hole are communicated with the flow guiding structure or the flow guiding structure comprises a first flow guiding structure and a second flow guiding structure; the feeding hole is communicated with the first flow guiding structure; the discharging hole is communicated with the second flow guiding structure; reactants are introduced through the feeding hole and then react after entering into the reaction chamber through the permeating part; acquired products are discharged from the discharging hole communicated with the flow guiding structure through the permeating part. Meanwhile, the invention also provides the three-phase flow catalytic reaction method applying the reaction kettle.

Owner:CHENGDU INTERMENT TECH

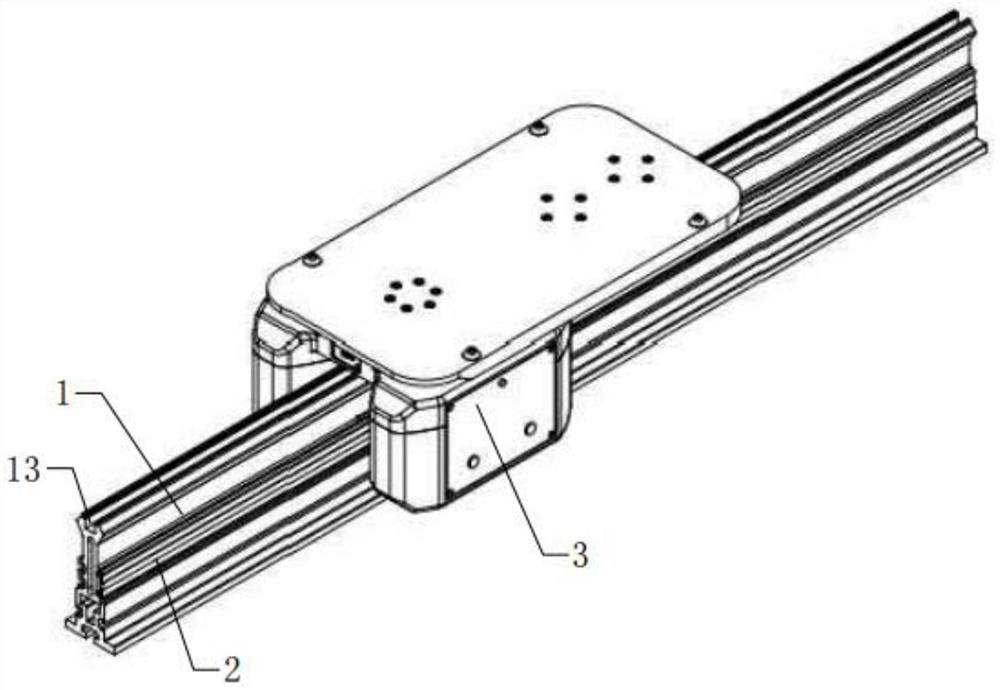

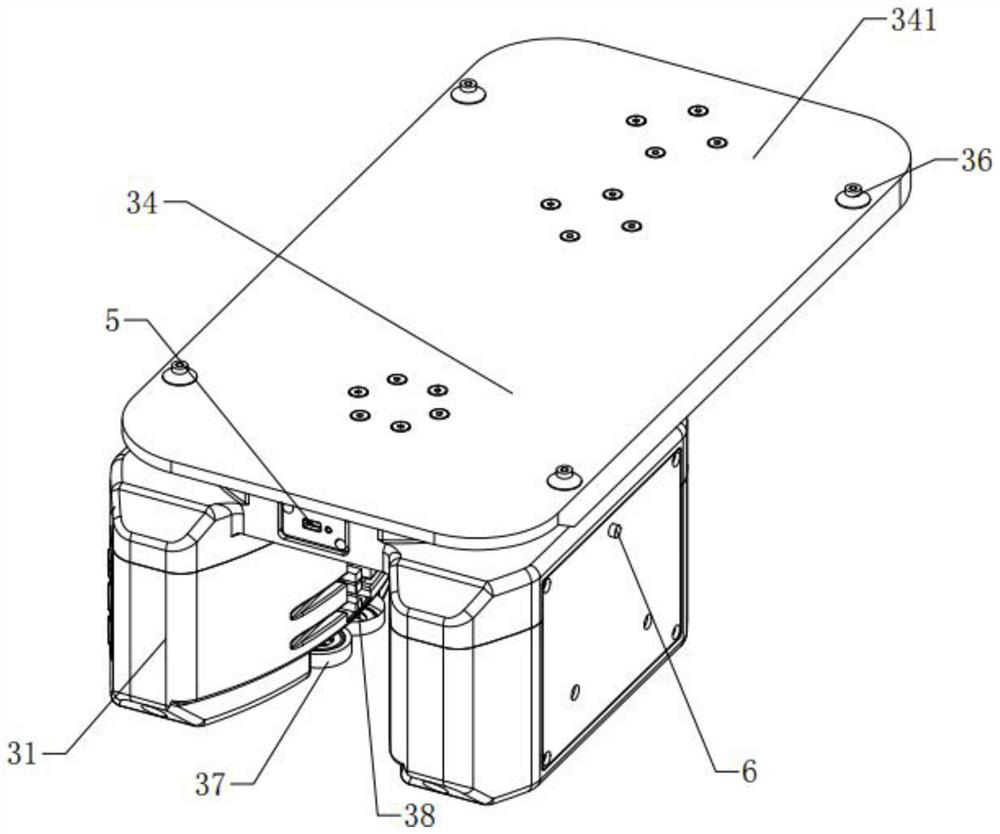

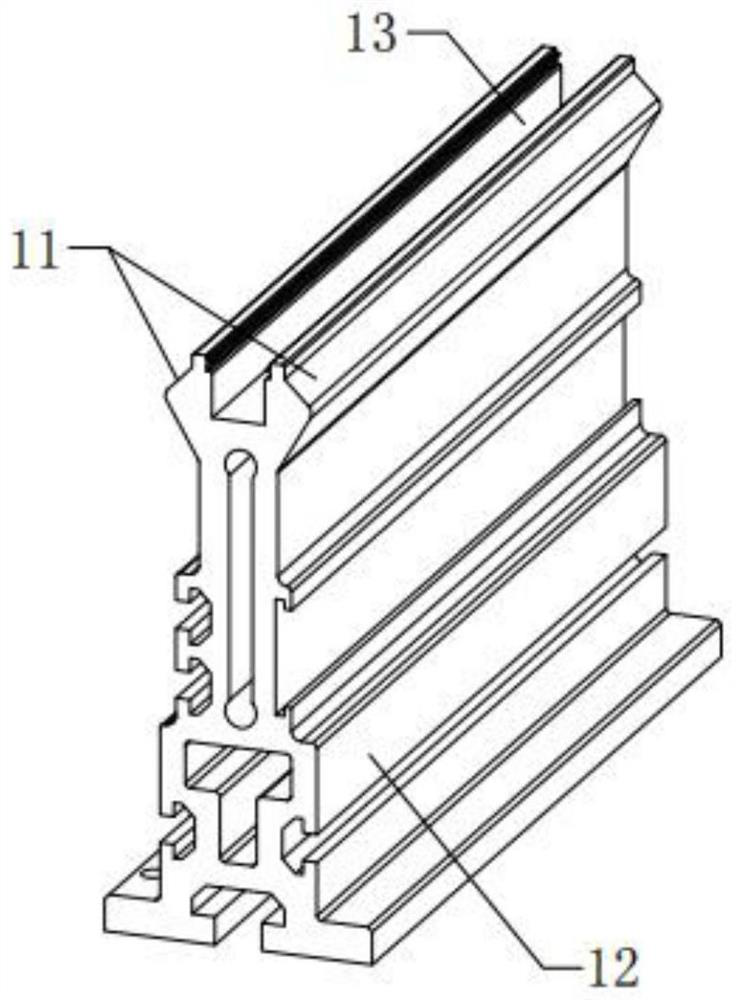

Special rail trolley for friction rolling on rail

InactiveCN113071872AQuiet and smooth operationNot easy to deviateControl devices for conveyorsMechanical conveyorsClassical mechanicsElectric machinery

The invention discloses a special rail trolley for friction rolling on a rail. Two opposite inclined surfaces are arranged at the top of the rail; the upper ends of the two inclined surfaces are close to each other; the lower ends of the two inclined surfaces are far away from each other; a copper strip is arranged on the rail in the length direction; the rail trolley comprises a trolley body; a motor and an even number of inclined surface rollers are arranged in the trolley body; the inclined surface rollers are uniformly distributed on the two sides of the rail and are respectively propped against the two inclined surfaces; the motor drives the inclined surface rollers to roll along the inclined surfaces; an electric brush in contact with the copper strip is arranged on the trolley body; the electric brush is used for supplying power to the motor; a tail plate is arranged on the top surface of the trolley body; the tail plate comprises an extension portion which extends in the same direction or the opposite direction of the running direction of the trolley body; and an even number of supporting rollers are arranged below the extension portion. The rail trolley is driven to move through the friction force between the inclined surface rollers and the inclined surfaces, so that the rail trolley runs more quietly and stably, and the processing requirement is low.

Owner:安徽艾灵科工业科技有限公司

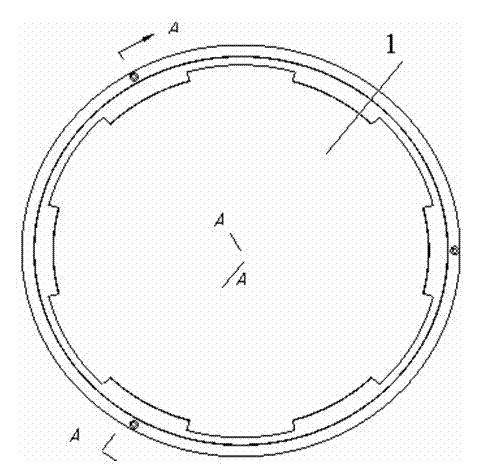

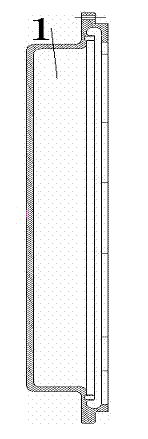

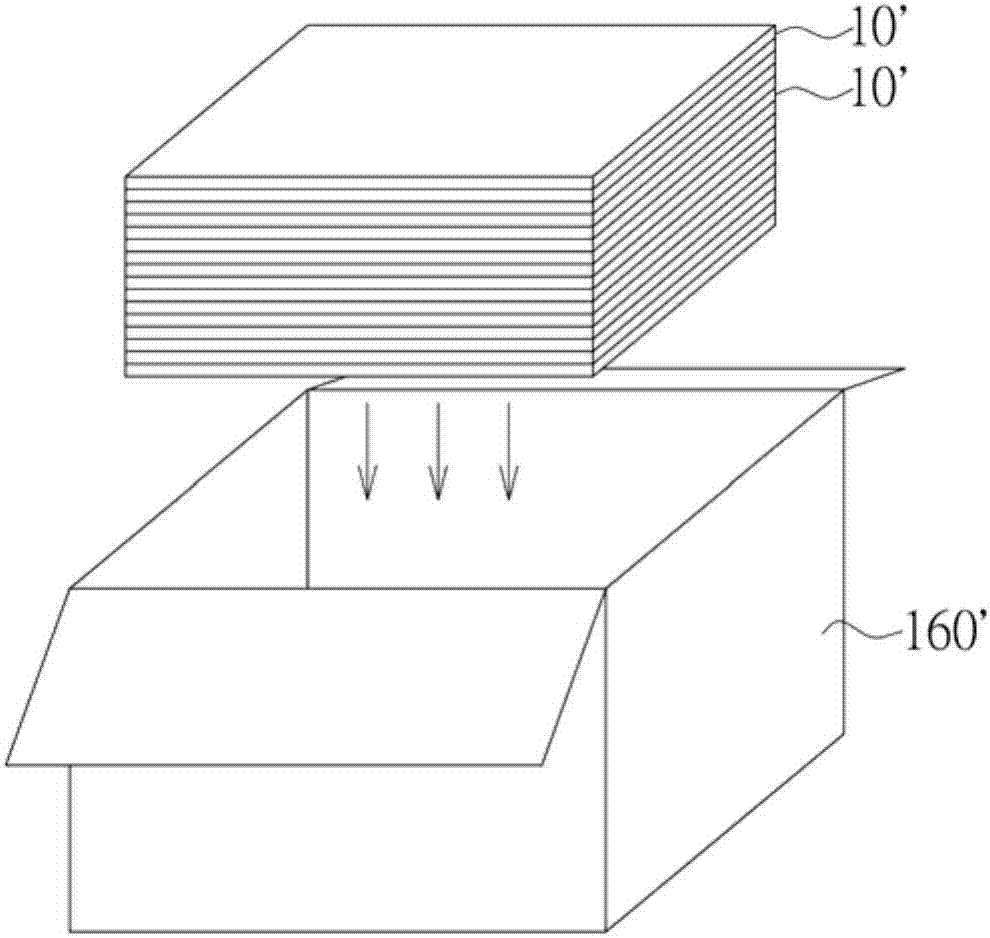

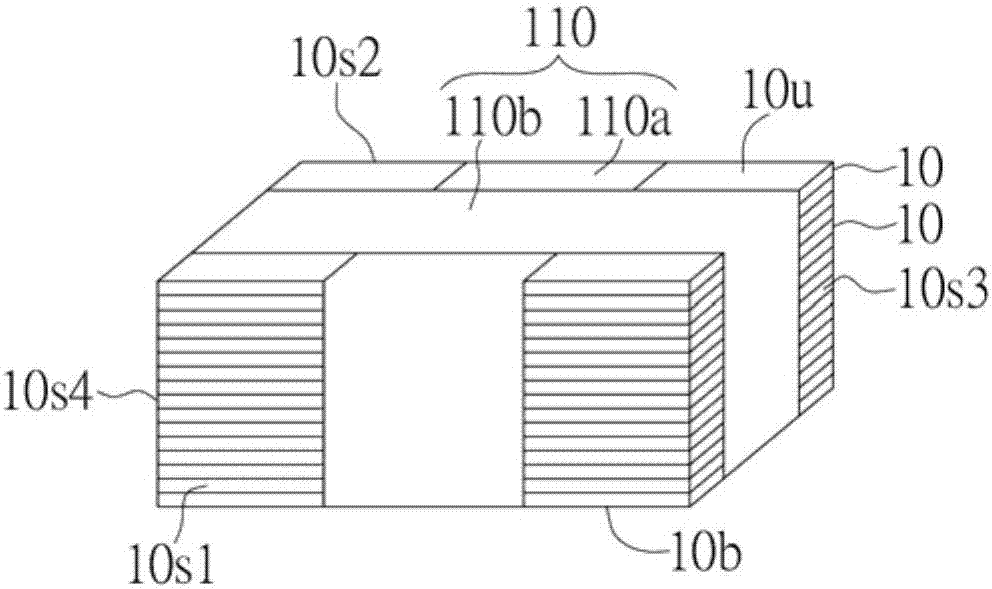

Method for packaging optical film, carrying device, and package for applying the same

InactiveCN106892211APlace stableStable positionRigid containersContainers with multiple articlesEngineeringOptical film

The invention provides a method for packaging an optical film, a carrying device, and a package for applying the same. The method of packaging the optical film comprises the following steps. First, the surroundings surround the plurality of optical films. Then, the plurality of optical films are placed on the carrier case. Then, the space between the carrier and the plurality of optical films is placed to fix the relative positions of the plurality of optical films and the carrier. Then, the cover is provided over the plurality of optical films. The enclosure, the carrier, the plurality of optical films and the cover are then placed in the package box. The position of the optical film using the packaging method of the present invention is stable, stable and easy to be displaced in the carrier case, so that the packaging structure can be placed in the package box in any direction.

Owner:SUMIKA TECH

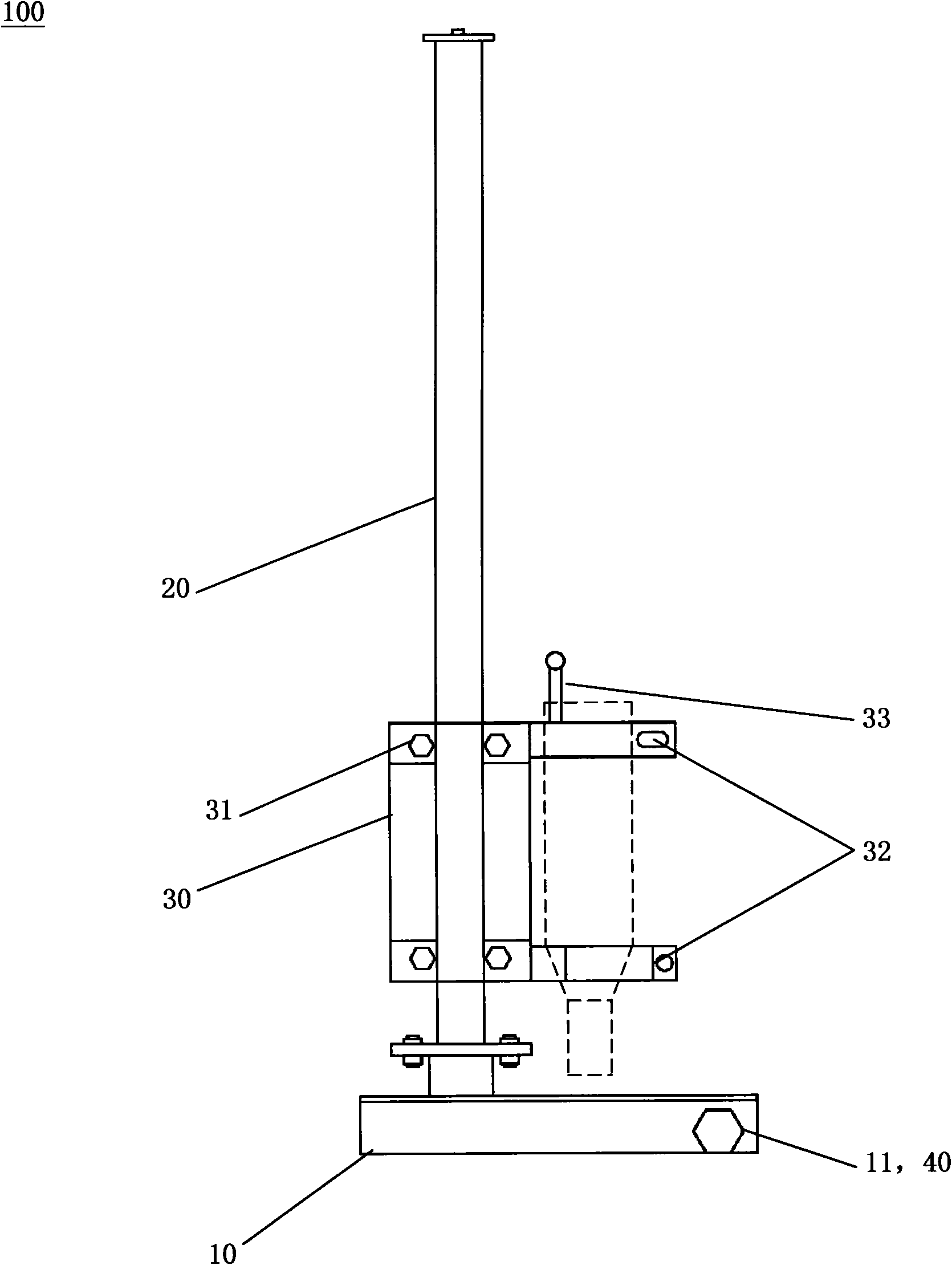

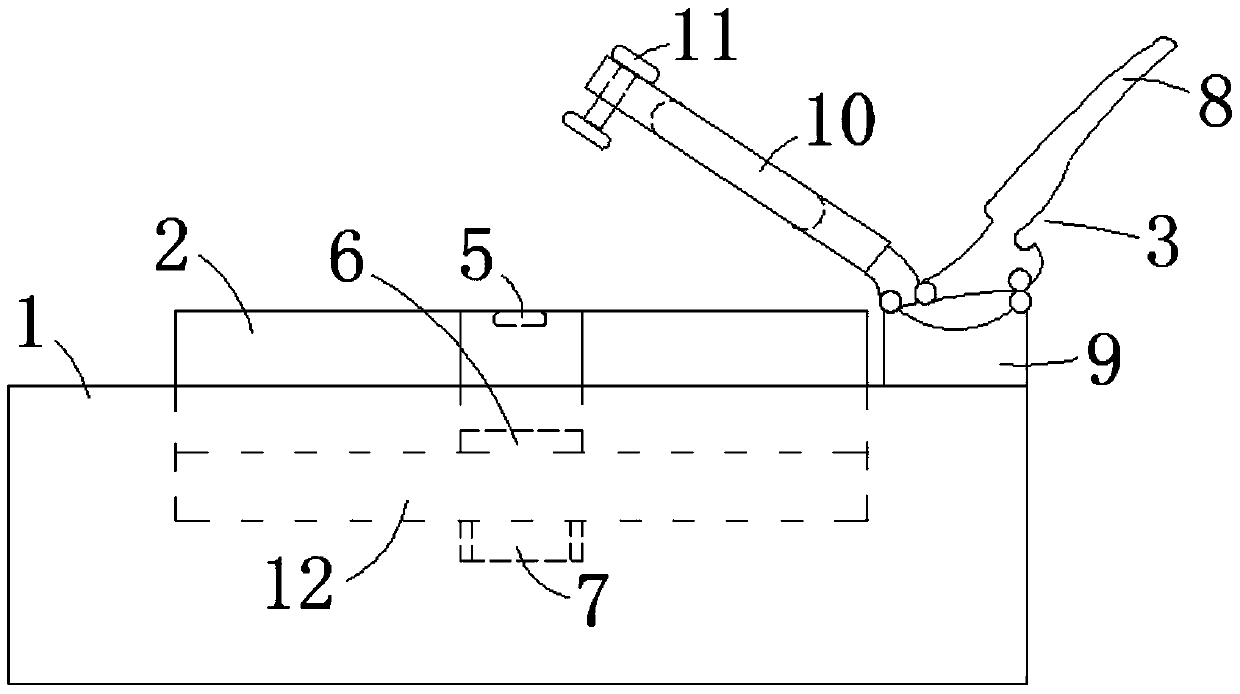

Concrete sleeper drilling support

InactiveCN101629404AExquisite structureEasy to drillRailway track constructionStructural engineeringDrilling machines

The invention provides a concrete sleeper drilling support, which at least comprises a base, wherein the lower part of the base is provided with a fixing device for fixing a sleeper; the upper part of the base is provided with a sliding rod vertical to the base; and the sliding rod is provided with a fixing support for mounting a drilling machine capable of sliding along the sliding rod. The concrete sleeper drilling support provided by the invention has exquisite structure; the milling machine arranged on the drilling support can conveniently drill the sleeper; manpower is saved and deviation is difficult to occur in the drilling process; and the concrete sleeper drilling support also has the advantage of short time for leaving tracks.

Owner:SHANGHAI FAHE BRIDGE & TUNNEL MAINTENANCE ENG TECH

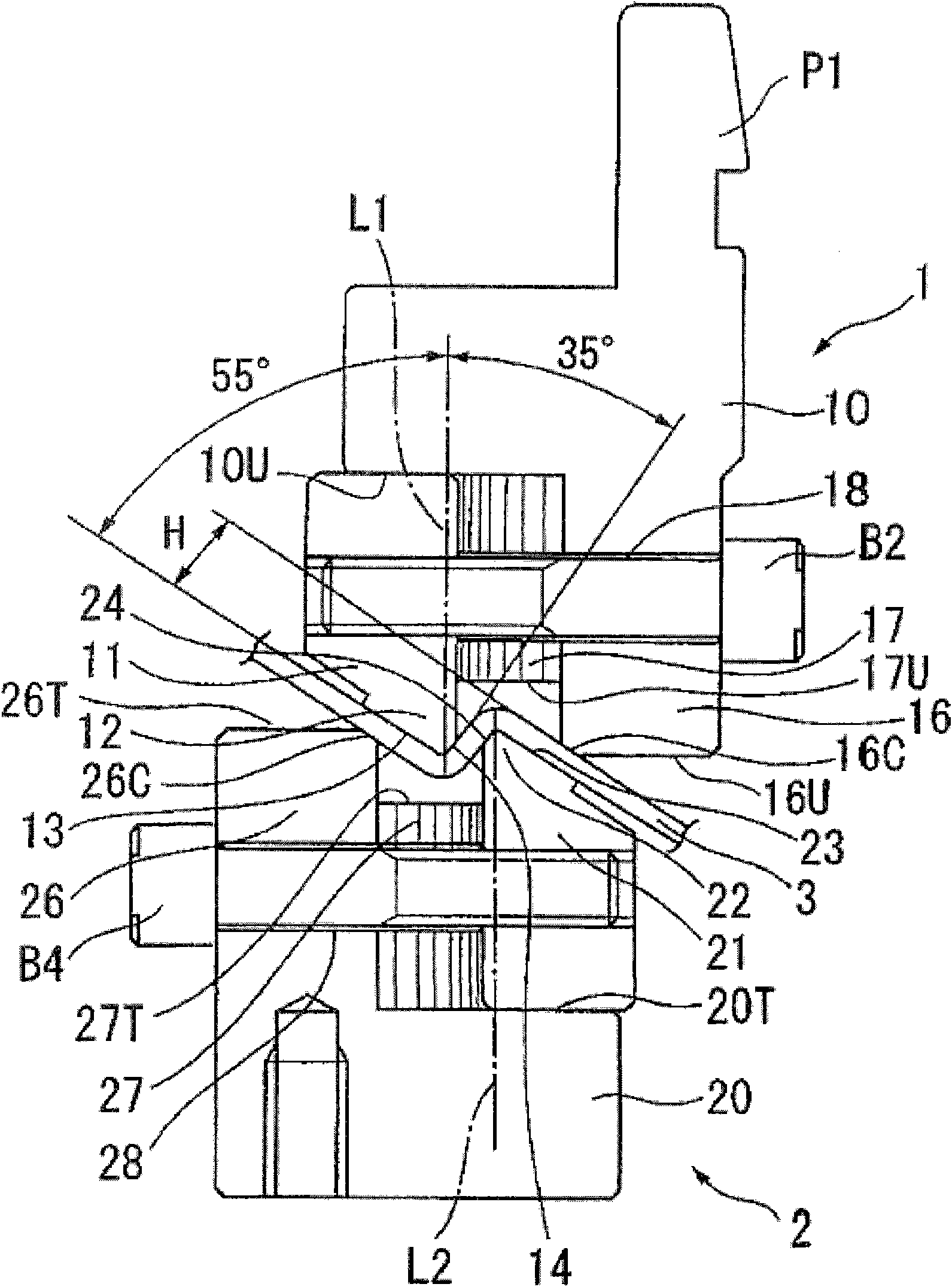

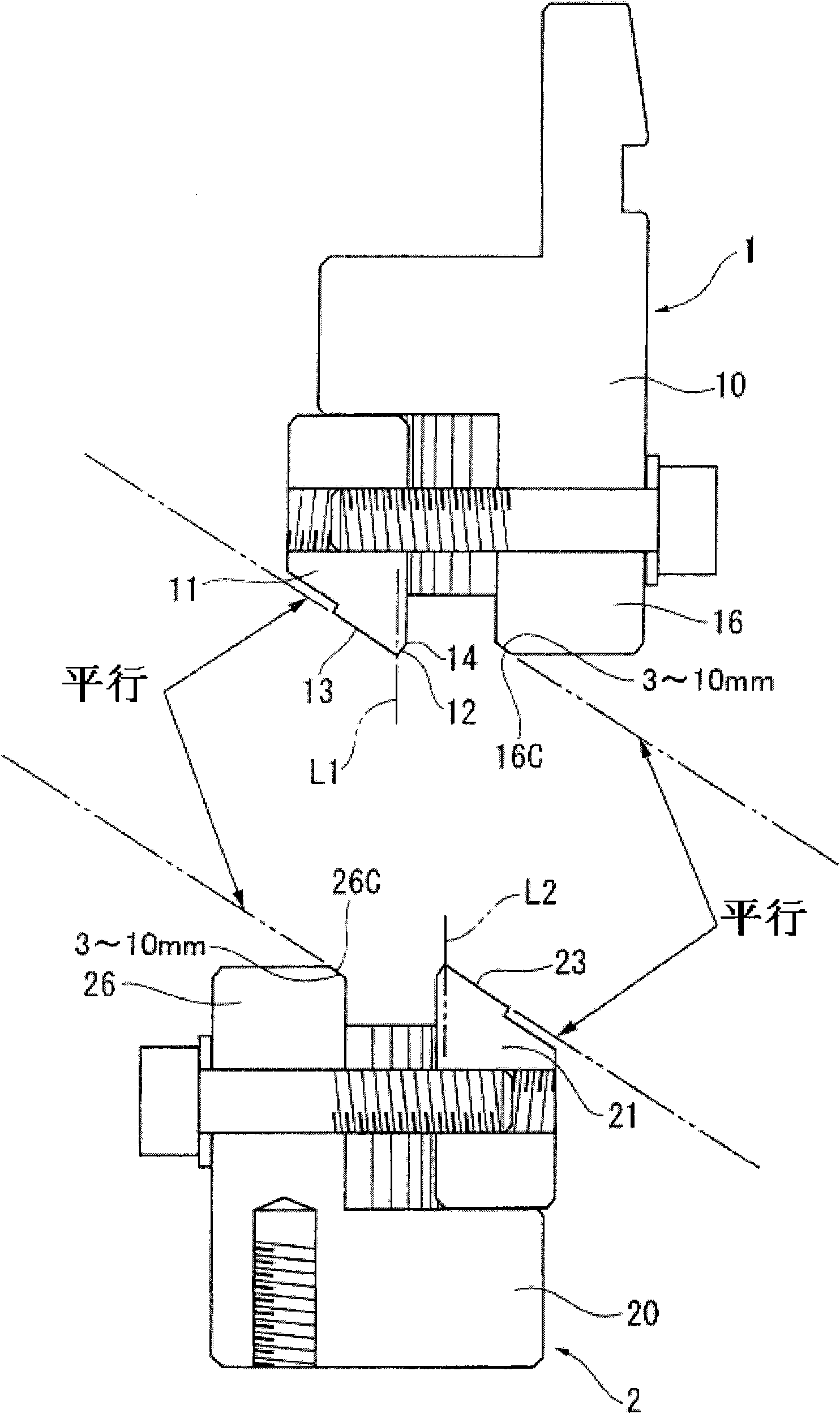

Tool for bending process of bending press

The invention aims to provide a tool for bending process of a bending press to enlarge the length of a to-be-bent object without causing scratches. Technically, an angle formed between knifepoint split lines L 1 and L2 of blades in V-shaped bend moulds and an outside rhombus side of a cross section of the V-shaped bend mould is set to be larger than an angle between the knifepoint split lines L1 and L2 and an inside diamond of the cross section, and an angle between an internal edge of a processing block of the V-shaped bend mould on one side and the outside rhombus side of the cross section of the V-shaped bend mould on the other side is parallel to a chamfering part, the chamfering parts 16 C and 26C forming the internal edges of the rhombus side are shorter, the V-shaped bend mould is positioned in a center position among the knifepoint split line L1 of the V-shaped bend mould on one side, the knifepoint split line L2 of the V-shaped bend mould on the other side and the internal edges of the processing block, i.e. a position closer than the knifepoint split line L2 of the V-shaped bend mould on the other side.

Owner:牧野 攻

Non-bonded detachable embedded part of unloading platform of high-rise building and construction process thereof

PendingCN109162464APrecise positioningNot easy to deviateBuilding material handlingSheet steelReinforced concrete

The invention relates to the technical field of the building design, in particular to a non-bonded detachable embedded part of an unloading platform of a high-rise building and a construction processthereof. The unloading platform includes a reinforced concrete layer; two PVC casing pipes distributed symmetrically are installed and embedded into the reinforced concrete layer; and U-shaped pre-embedded anchor rings are nested and installed in the PVC casing pipes. An overhanging I-shaped steel is installed between the two PVC casing pipes, wherein the bottom surface of the overhanging I-shapedsteel and the top surface of the reinforced concrete layer are arranged at the same level; a steel plate is arranged on the top of the overhanging I-shaped steel and penetrates the tops of the U-shaped pre-embedded anchor rings; gaskets are arranged at tops of connection parts between the U-shaped pre-embedded anchor rings and the steel plate; and nuts are arranged on the gaskets. The steel plateis connected with the overhanging I-shaped steel closely by the gaskets and the nuts; and a wooden wedge layer is arranged between the overhanging I-shaped steel and the PVC casing pipes. The non-bonded detachable embedded part having a simple structure is operated and constructed conveniently; and the non-bonded pre burying of PVC casing pipes is employed and the U-shaped anchor rings are recycled by multiple times, so that the resources are saved.

Owner:JIANGSU XINGSHA CONSTR ENG GRP

A trowel welding fixture

ActiveCN104439728BEffectively fixedSimple structureWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention relates to a plastering trowel welding jig which comprises a base, two covering blocks and two fixed parts, the upper end face of the base is provided with cavity matched with a plastering trowel in shape, the two covering blocks are detachably arranged in the cavity side by side, and the two fixed parts are arranged at the upper end of the base side by side and located on one side of the cavity. Compared with the prior art, the plastering trowel welding jig is simple in structure, convenient to use and capable of effectively fixing the plastering trowel needing to be welded and promotes welding precision.

Owner:重庆市润果五金有限公司

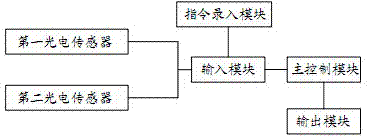

Precision manufacturing control system of distribution box sealing system

ActiveCN102989640BReal-time monitoring of walkingReal-time control walkingLiquid surface applicatorsCoatingsControl signalControl system

The invention discloses a precision manufacturing control system of a distribution box sealing system. The precision manufacturing control system comprises a spraying nozzle of a storage tank, a work bench and a detection apparatus, wherein the spraying nozzle is disposed above the work bench; the detection apparatus comprises two first photoelectric sensors and two second photoelectric sensors; a connecting line of the two first photoelectric sensors is in parallel with a crossbeam; a connecting line of the two second photoelectric sensors is in parallel with a guide rail; the first photoelectric sensors and the second photoelectric sensors are connected with an input module; the input module is connected with a main control module; the main control module outputs control signals to an output module. The spraying nozzle can realize arbitrary track spraying on the surface of the work bench, so that the precision additional equipment has wide applications. Besides, the spraying nozzle can be controlled to move corresponding tracks in time, so that the material sprayed on the work bench is relatively uniform and is not easy to deviate; and processing efficiency and precision are improved.

Owner:ZHEJIANG TIANQI ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com