Prepreg cutting and drilling integrated device and machining process

A prepreg and cutting technology, which is applied in the processing of insulating substrates/layers, metal processing, electrical components, etc., can solve the problems of complex and tedious process flow, high scrap rate of prepreg, and high labor cost, and achieves simplified processing and production. Low cost and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

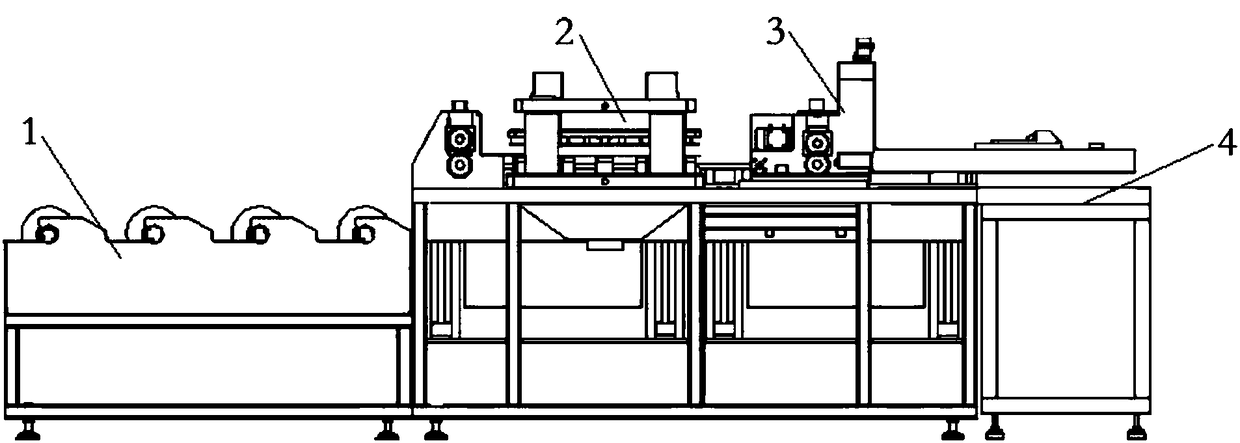

[0031] This implementation provides an integrated prepreg cutting and punching device, which is used for cutting and punching the prepreg coil, so that the processed prepreg is suitable for the subsequent pressing process.

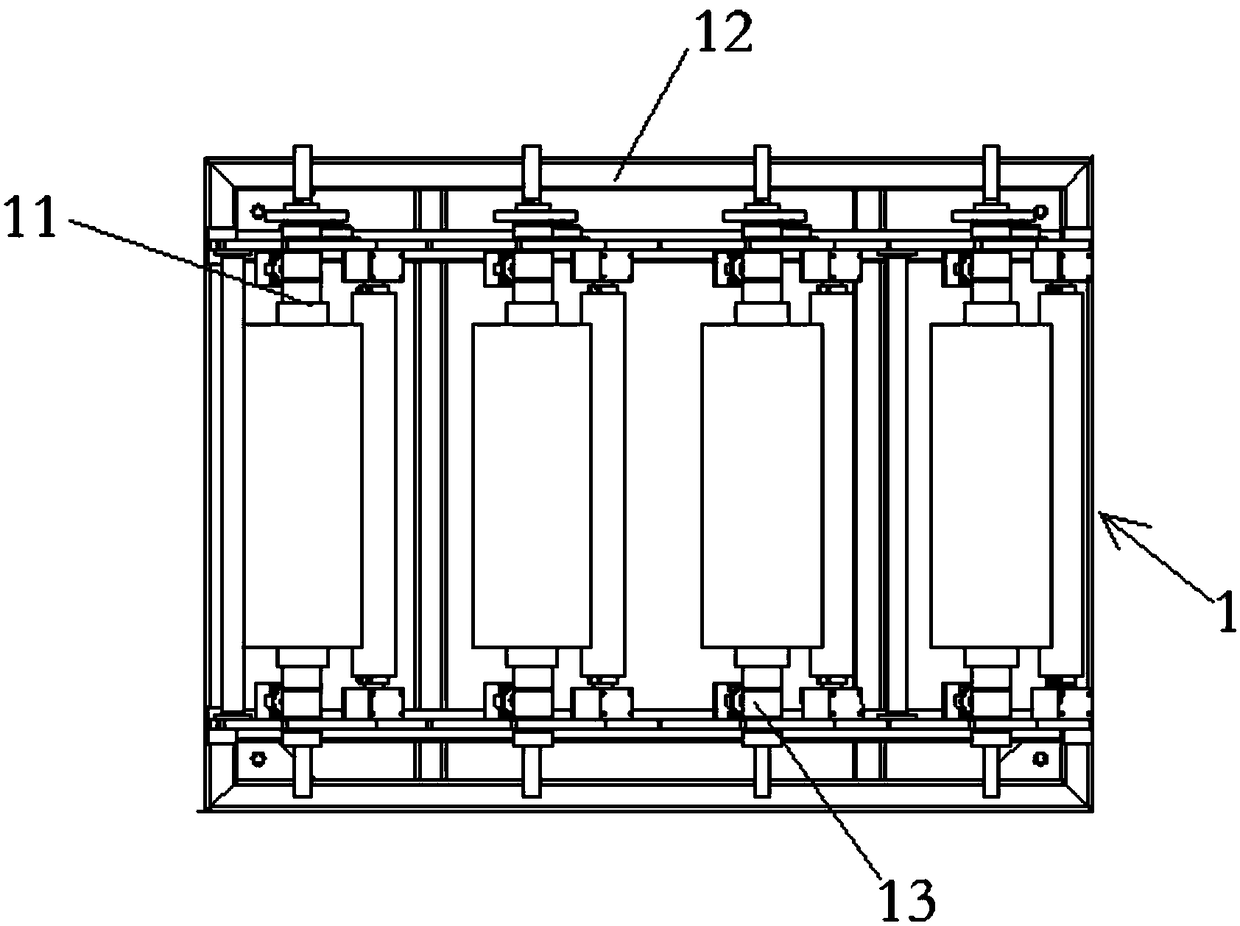

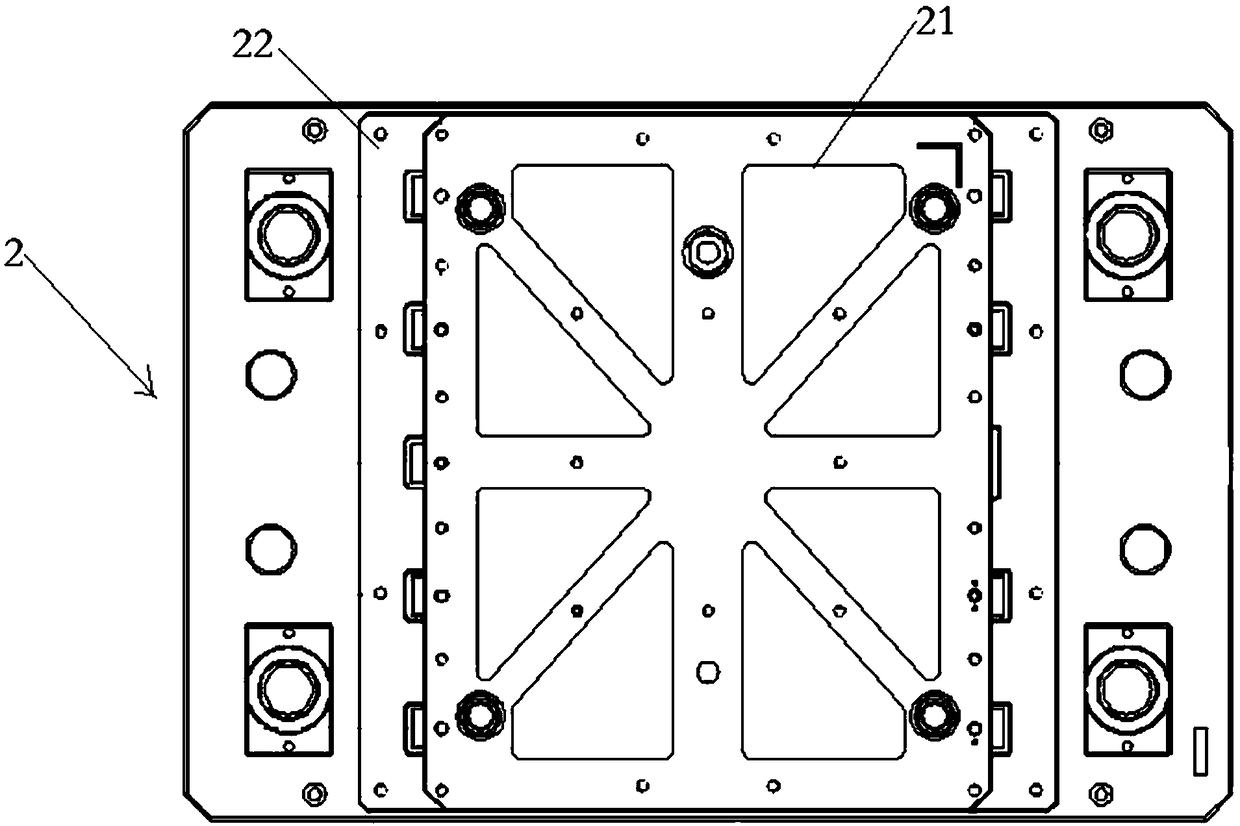

[0032] The integrated device for cutting and punching the prepreg is as follows: figure 1 As shown, it includes a prepreg winding locking mechanism 1, a punching mechanism 2, a cutting mechanism 3 and a receiving mechanism 4 arranged in sequence, wherein the prepreg winding locking mechanism 1 is used to install a prepreg (PP) coil , the prepreg winding locking mechanism 1, such as figure 2 As shown, it includes at least one feeding shaft 11, the two ends of the feeding shaft 11 are connected to a support frame 12, and the feeding shaft 11 can rotate relative to the support frame 12, and the prepreg coil is installed on the feeding shaft 11 Above, the feed shaft 11 is equipped with a hand wheel for controlling the rotation of the feed shaft 11 and then m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com