Limiting assembling structure for heat pipe and heat conduction seat

A limit and heat pipe technology, applied in heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as falling off, increasing material and manufacturing costs, and inability to concentrate heat pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

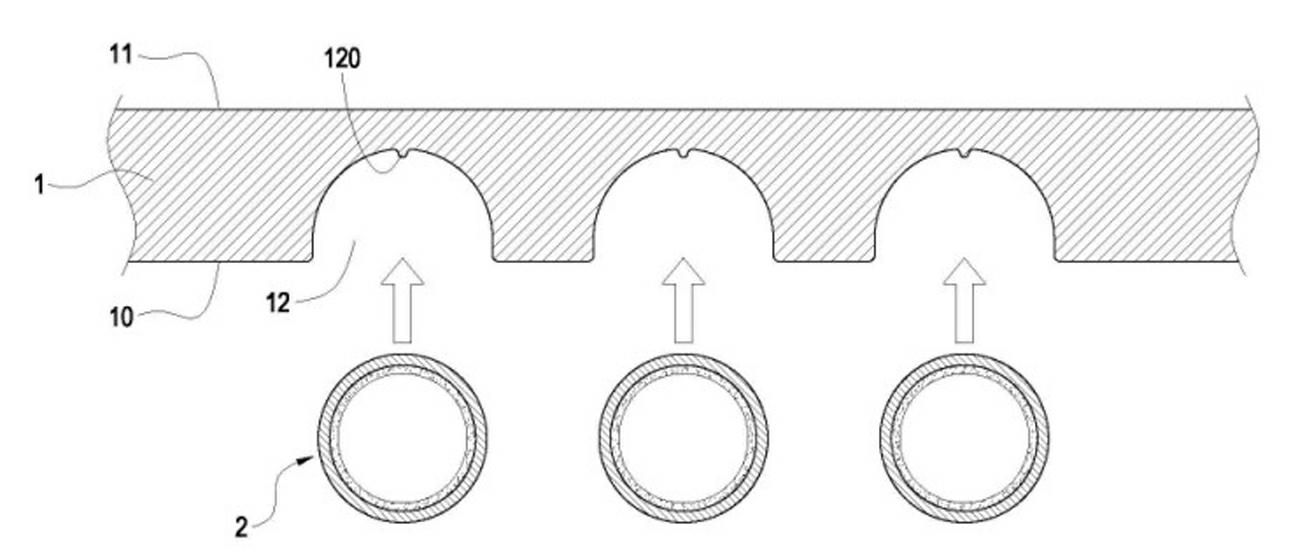

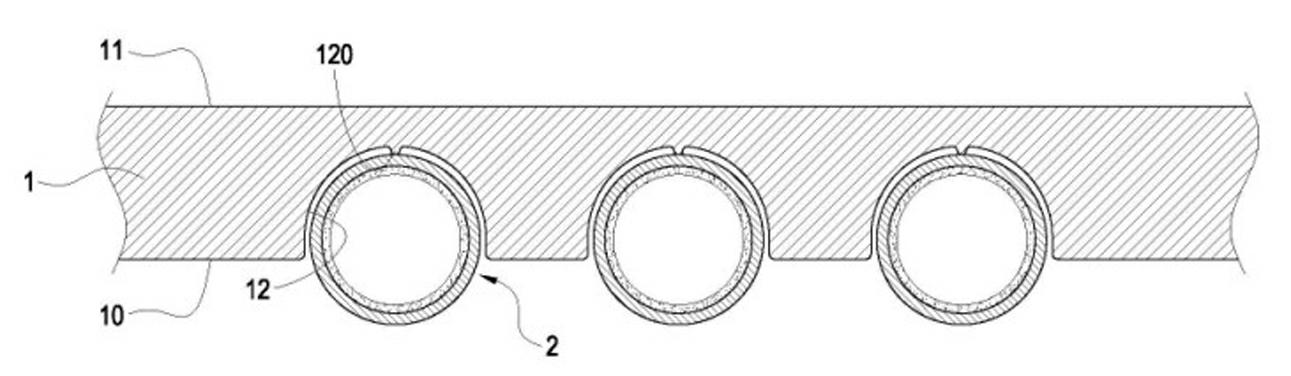

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

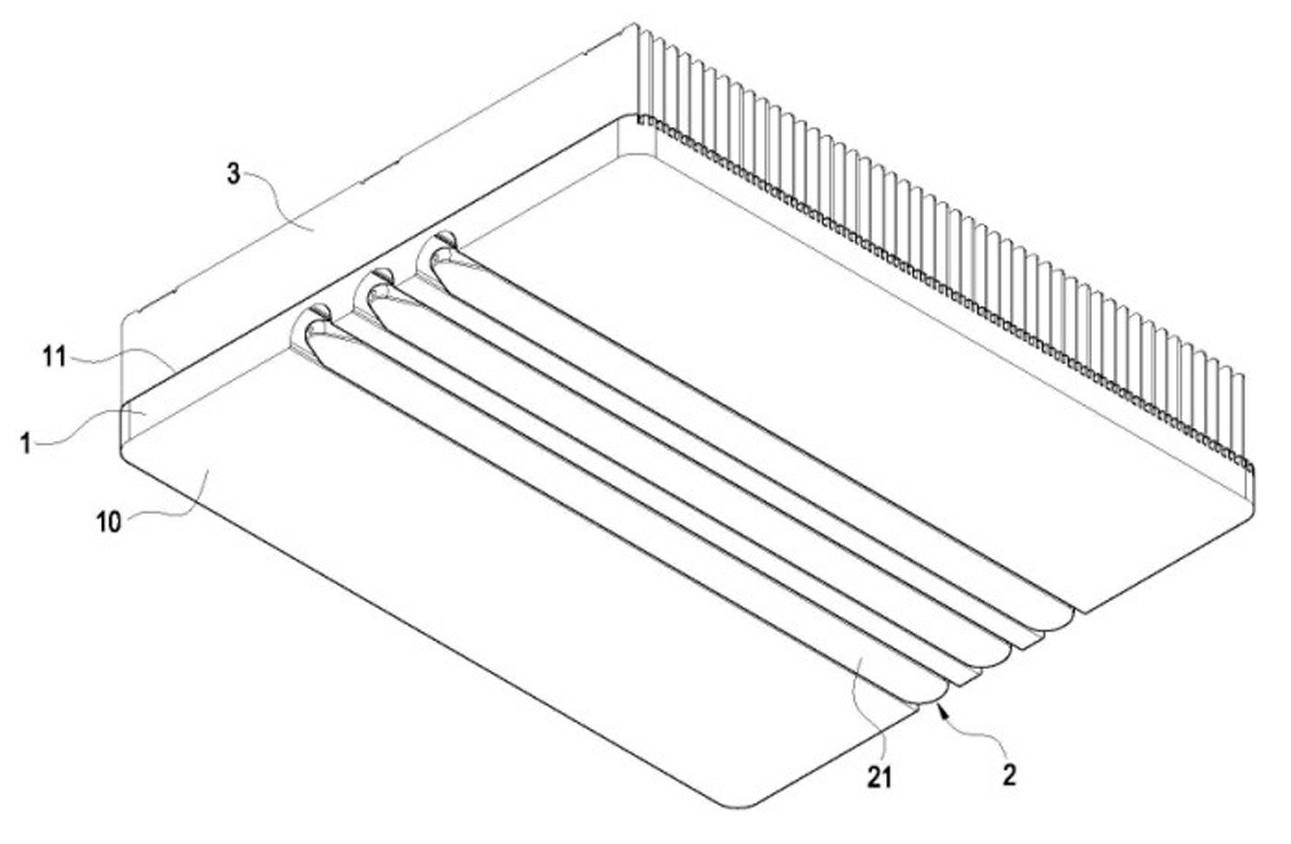

[0034] see figure 1 , is a three-dimensional combination diagram of the present invention. The present invention provides a limited assembly structure of a heat pipe and a heat conduction seat, which includes a heat conduction seat 1 and at least one heat pipe (Heat pipe) 2 pressed against the heat conduction seat 1 so that it can be combined with the heat conduction seat through the heat pipe 2 1, to increase the heat transfer effect of the heat conduction seat 1; where:

[0035] The heat conduction seat 1 can be made of copper or aluminum and other materials with good thermal conductivity, which can be used as a base for attaching a heat source such as a heat sink, and has at least one bottom surface 10 for attaching a heat source, and A top surface 11 opposite to the other side of the bottom surface 10; and in the embodiment of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com