Concrete sleeper drilling support

A technology for concrete and sleepers, which is applied in tracks, track laying, track maintenance, etc., can solve problems such as hidden dangers of train operation, large deviation of drilling direction, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

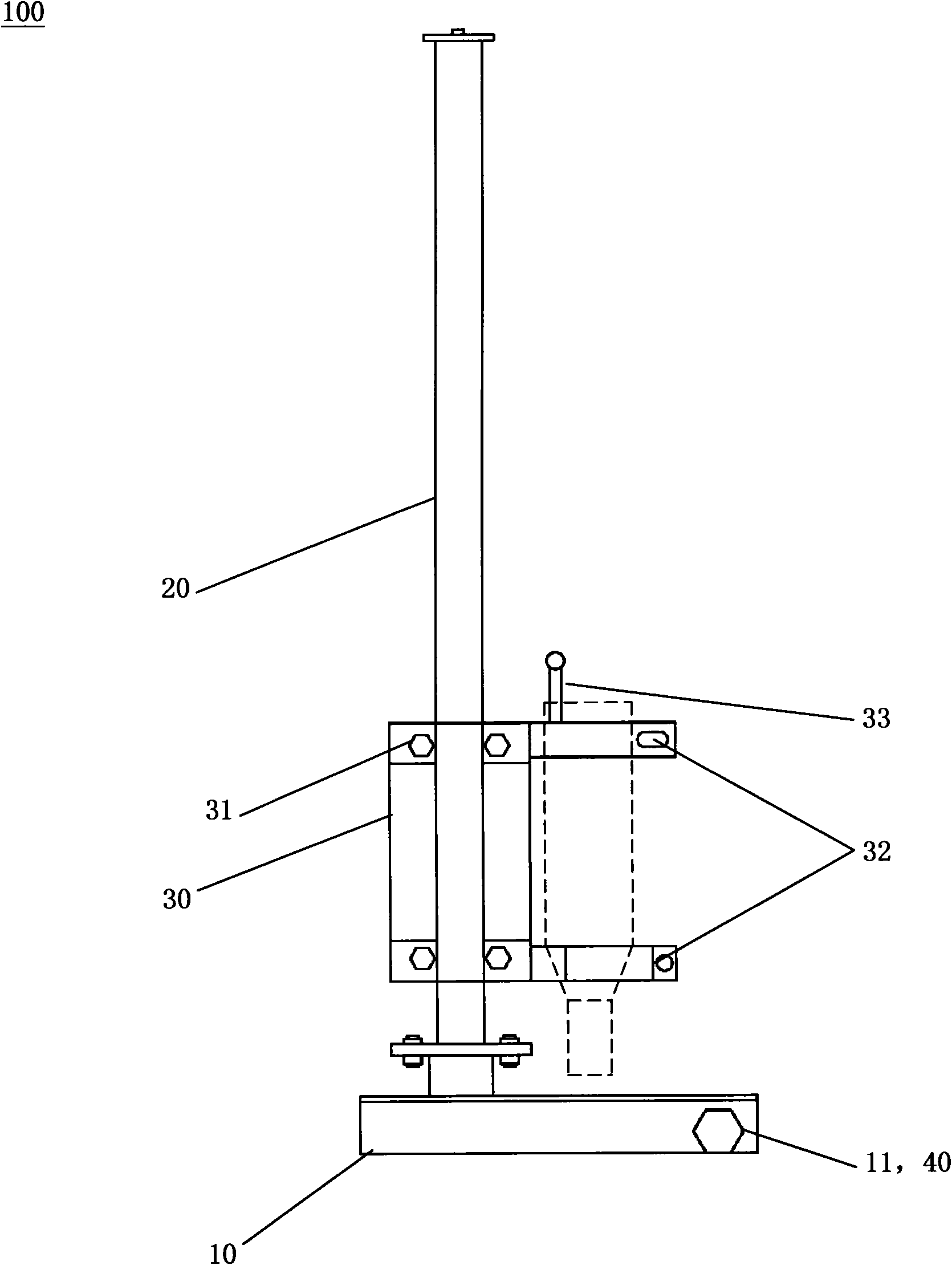

[0021] please see figure 1 As shown, the side of the concrete sleeper drilling support in the present invention is shown in the figure, the concrete sleeper drilling support 100 is composed of a base 10, a sliding rod 20, a fixing frame 30 and an adjusting screw 40, and the shape of the bottom of the base 10 is It is designed in conjunction with the shape of the sleeper (not shown). The lower part of the base 10 is provided with a fixing device. The fixing device is provided with screw holes 11 on both sides of the base 10 , and an adjusting screw 40 is arranged in the screw hole 11 . By tightening the adjusting screw 40, the base 10 can be well combined with the sleeper. The upper part of the base 10 is provided with a sliding rod 20 perpendicular to the base 10, and the sliding rod 20 is provided with a fixed frame 30 that can slide up and down along the sliding rod 20, and the sliding mode between the fixed frame 30 and the sliding rod 20 is a pulley Sliding, the pulley 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com