Electrode cap changing tool for projection welding robot workstation welding

An electrode cap and automatic technology, applied in welding equipment, manufacturing tools, resistance welding equipment, etc., can solve problems such as tool deformation, welding spot misalignment, tool weight, etc., achieve moderate stability, increase life, and not easy to misalign Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

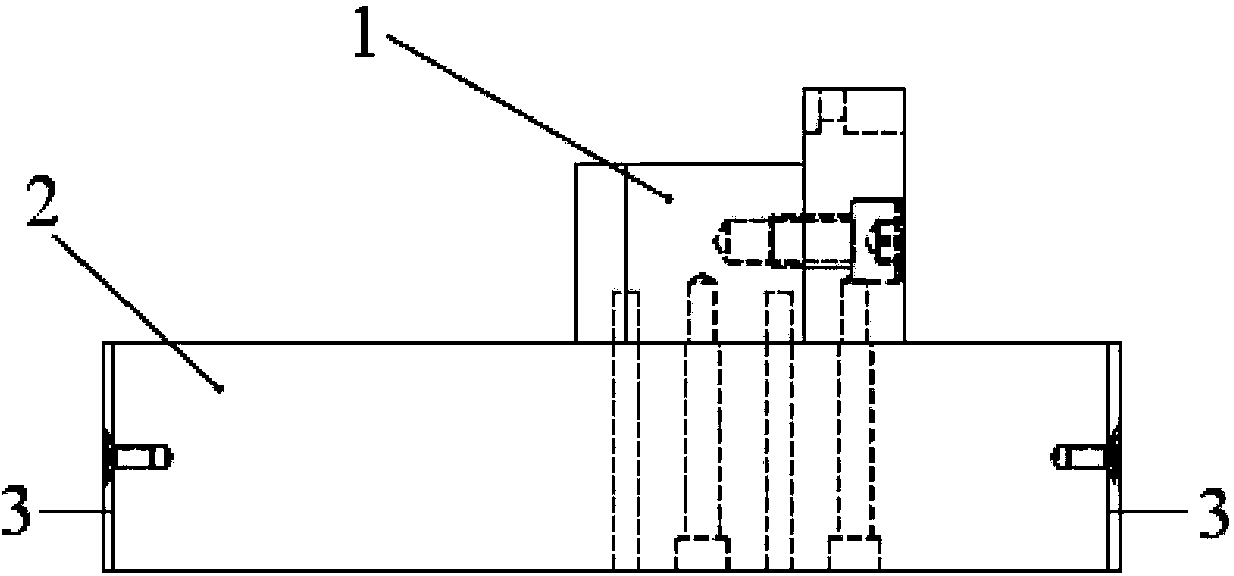

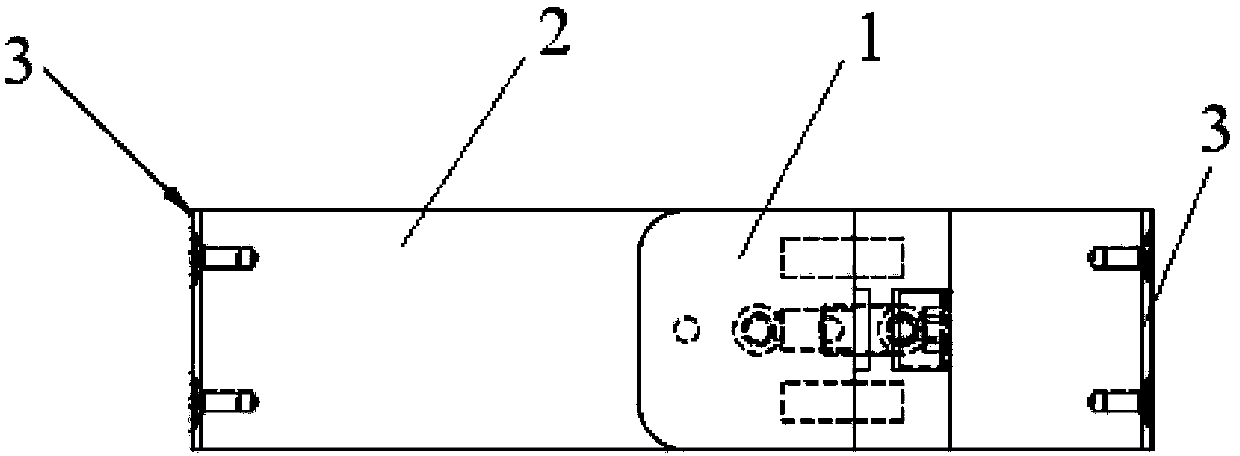

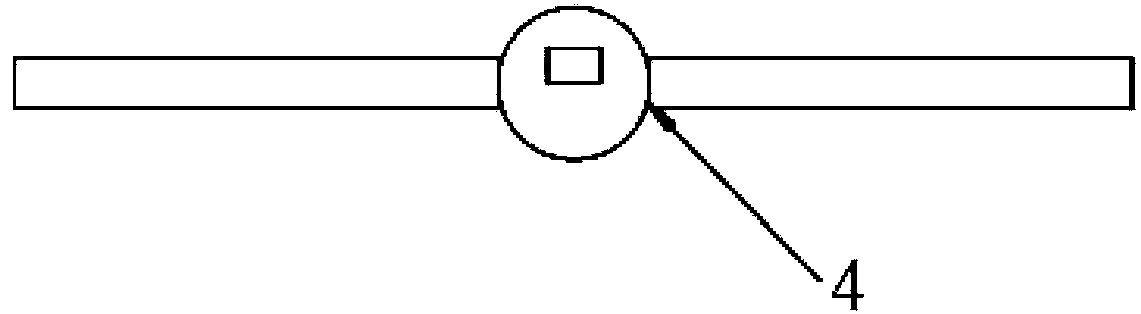

[0025] A tool for replacing electrode caps for projection welding automatic robot station welding, including an electrode cap preliminary positioning base and an electrode cap fixing knocking rod, wherein the structure of the electrode cap preliminary positioning base is as follows: Figure 1-2 As shown, it consists of an iron bracket 1, a nylon base 2 and an induction iron sheet 3. The iron bracket 1 is connected to the upper part of the nylon base 2 by bolts, and the electrode cap to be processed is placed on the nylon base 2. The electrode cap passes through the iron bracket 1. fixed. The nylon block is light and durable as the base, and the fixing of the iron support 1 and the nylon block is reasonable and firm. The induction iron sheet 3 is connected to the end of the nylon base 2 via bolts. The electrode cap fixes the structure of the knock rod 4 as image 3 As shown, it is composed of a striking body and rods at both ends. There is a rectangular through hole in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com