Patents

Literature

58results about How to "Quiet and smooth operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

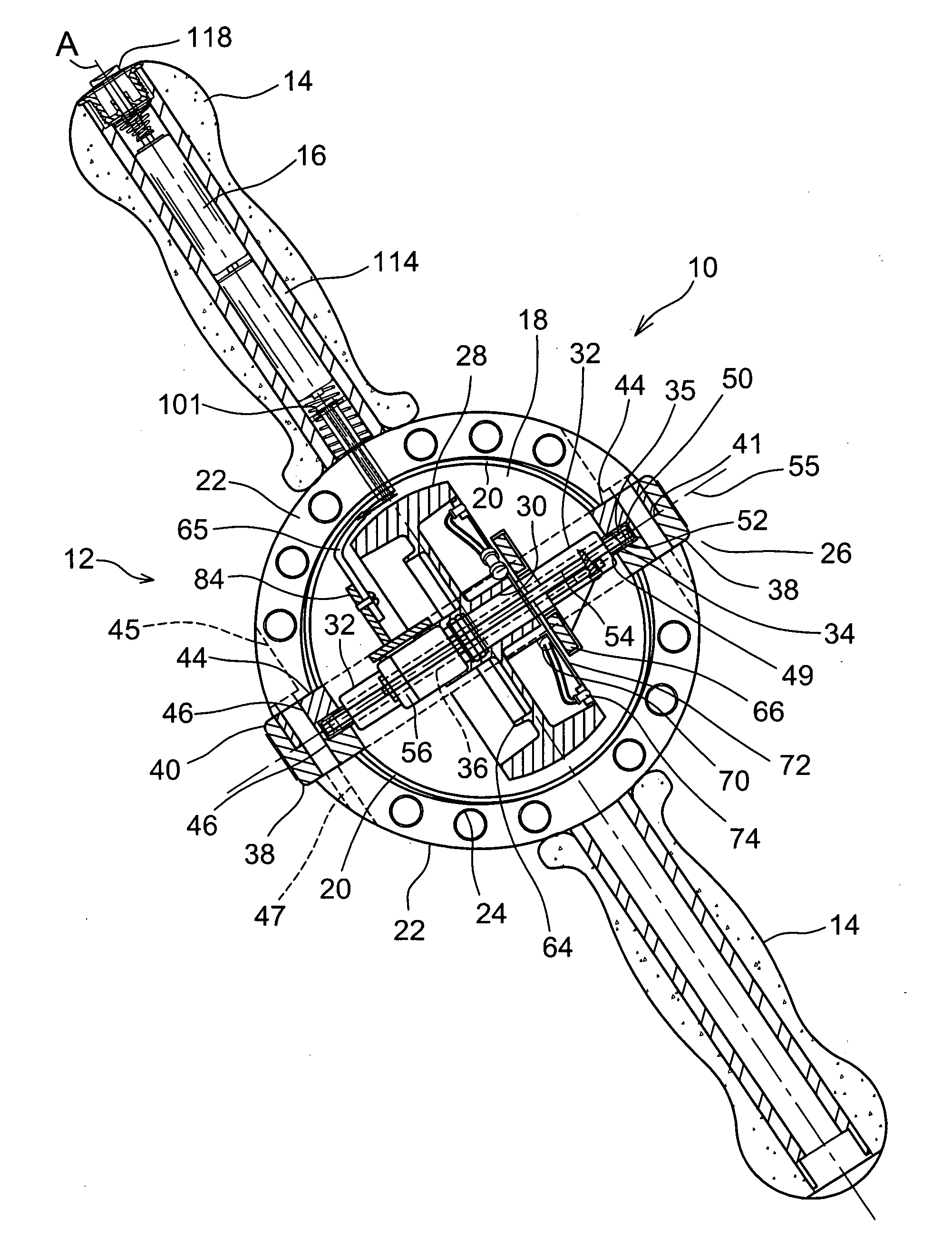

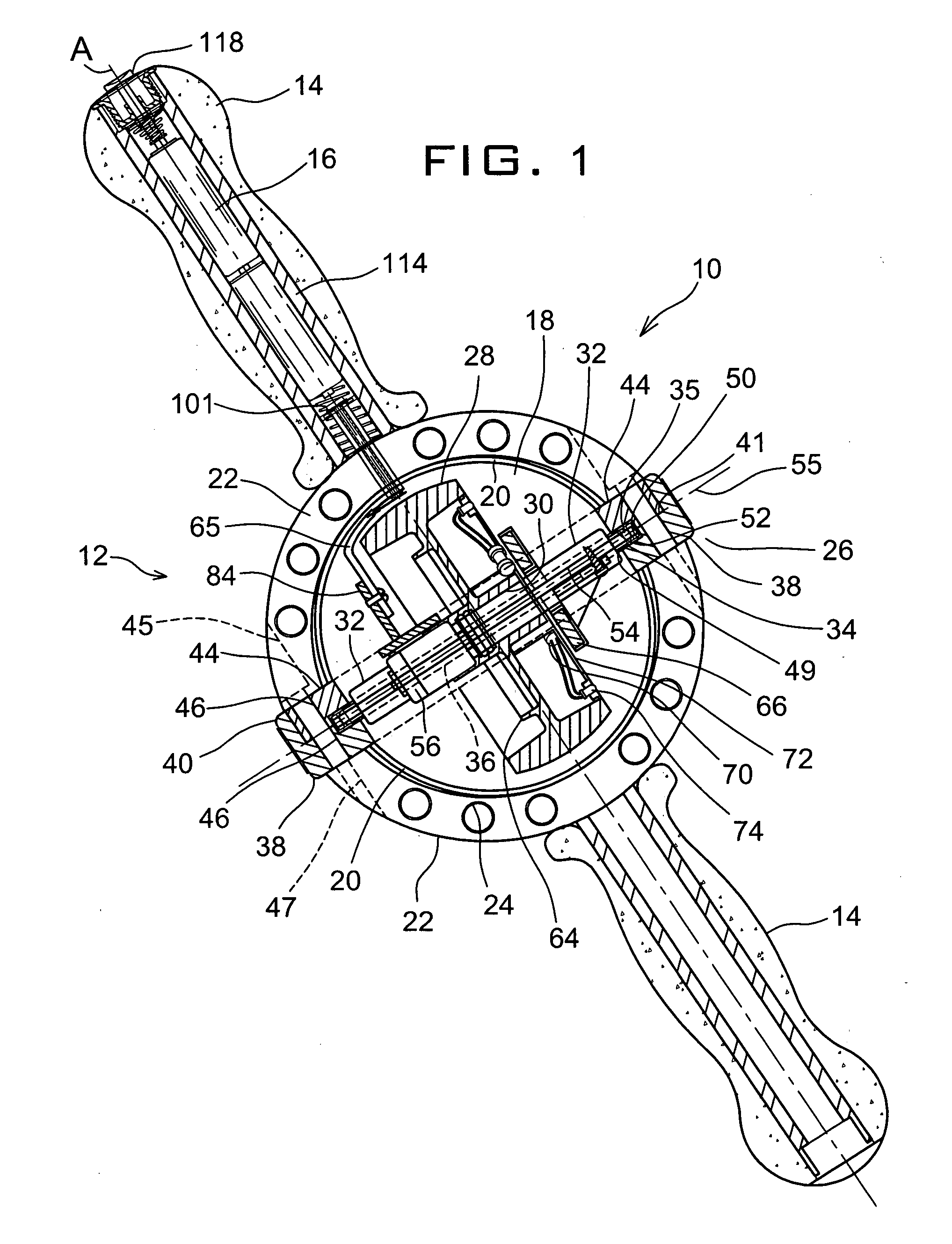

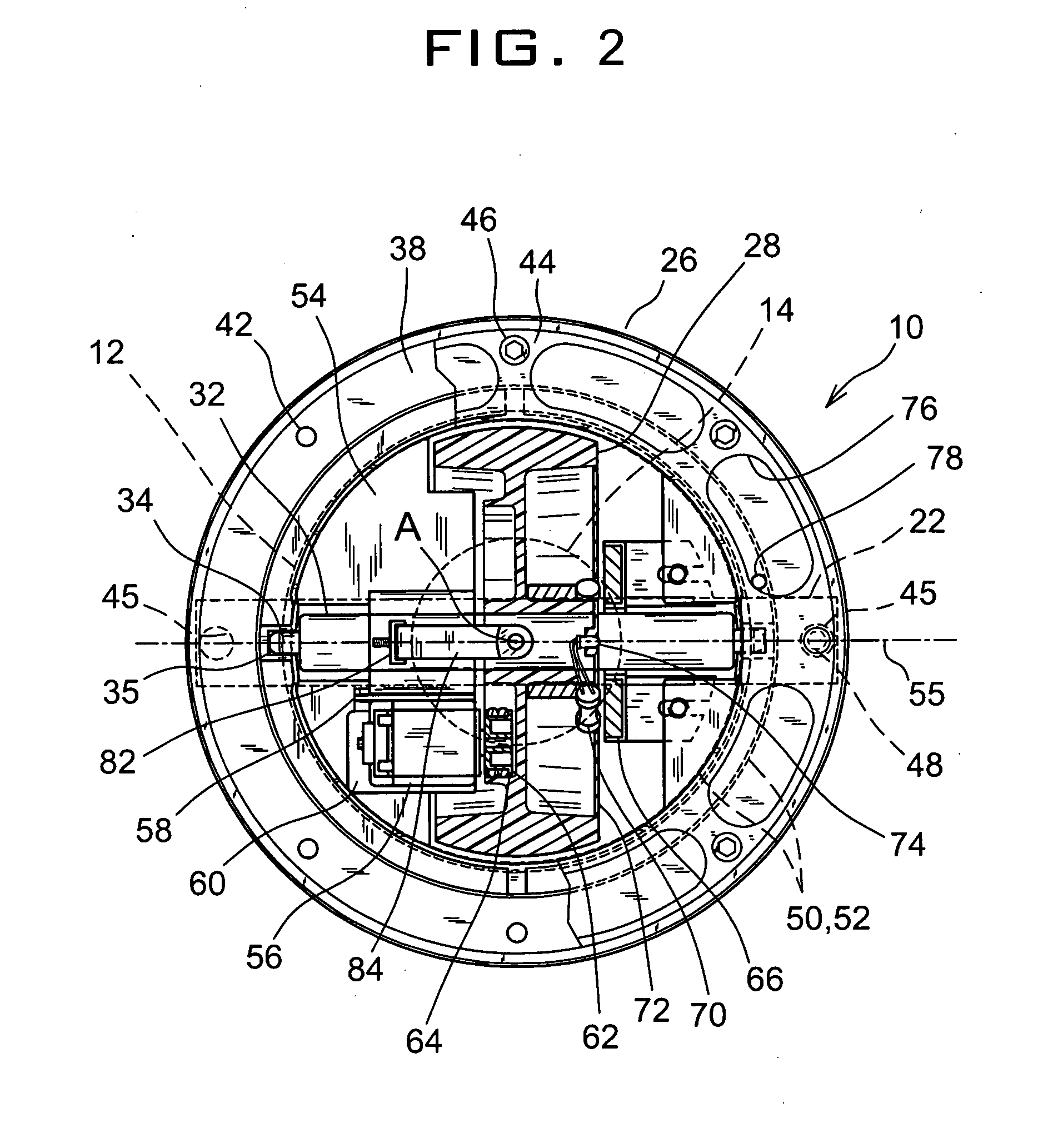

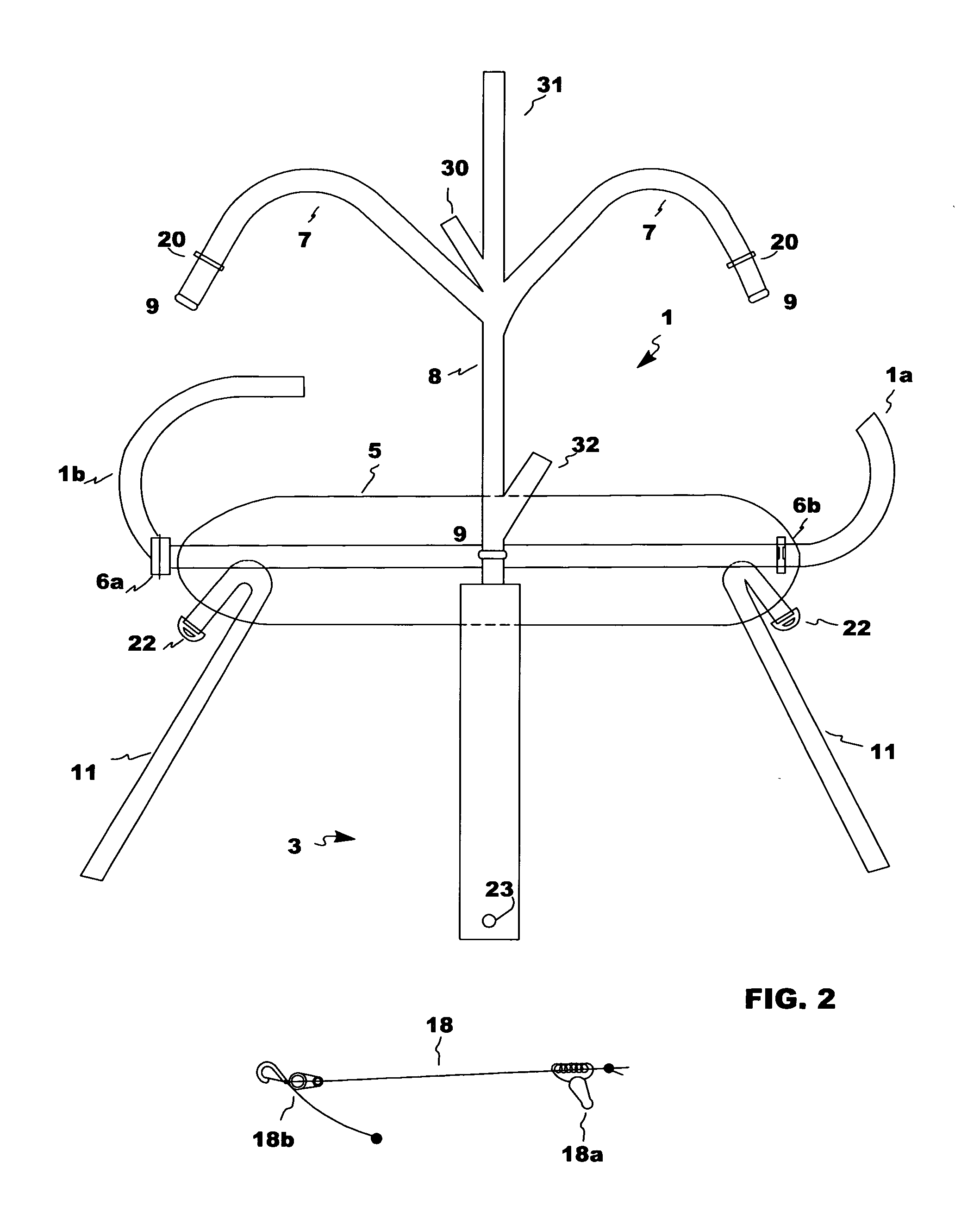

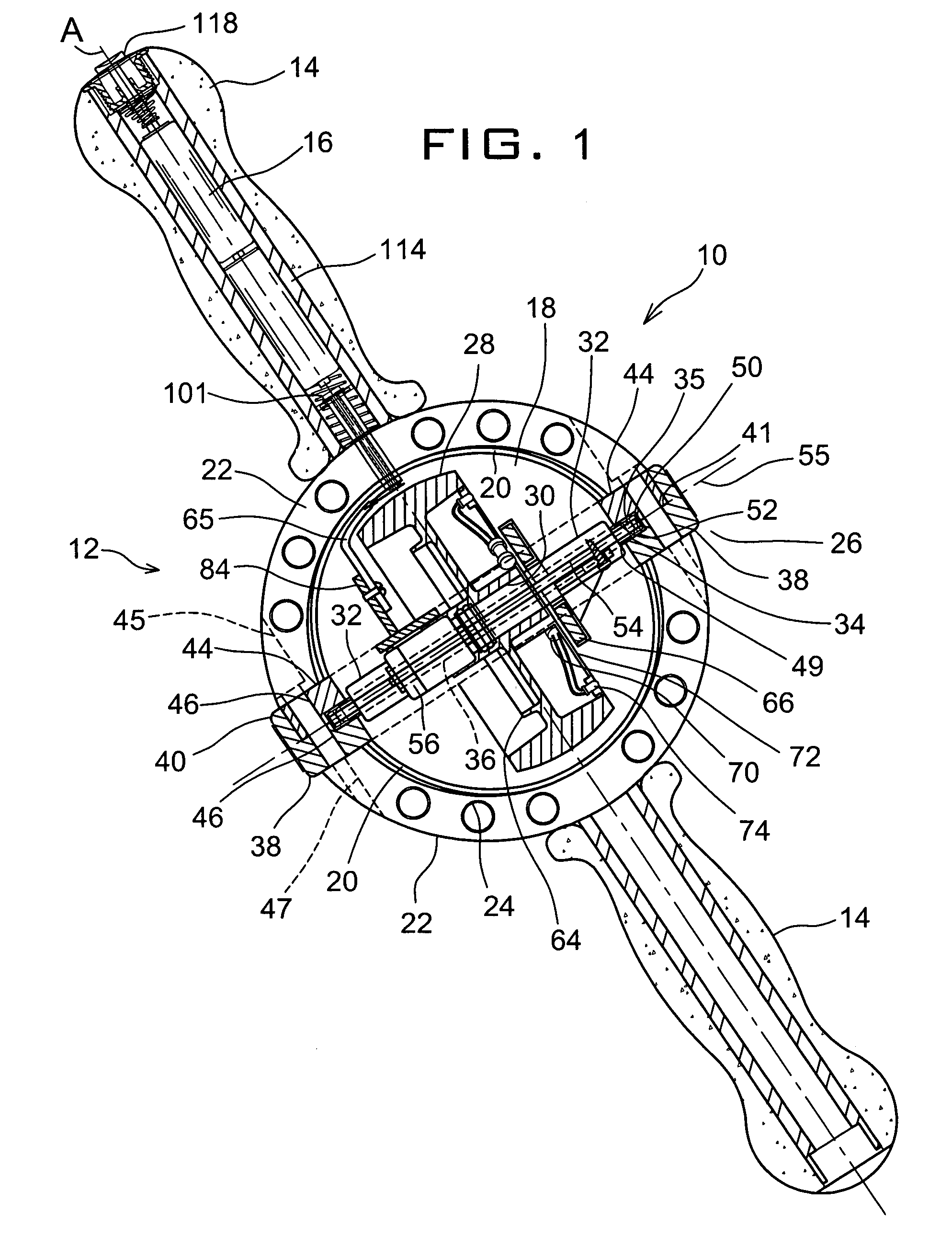

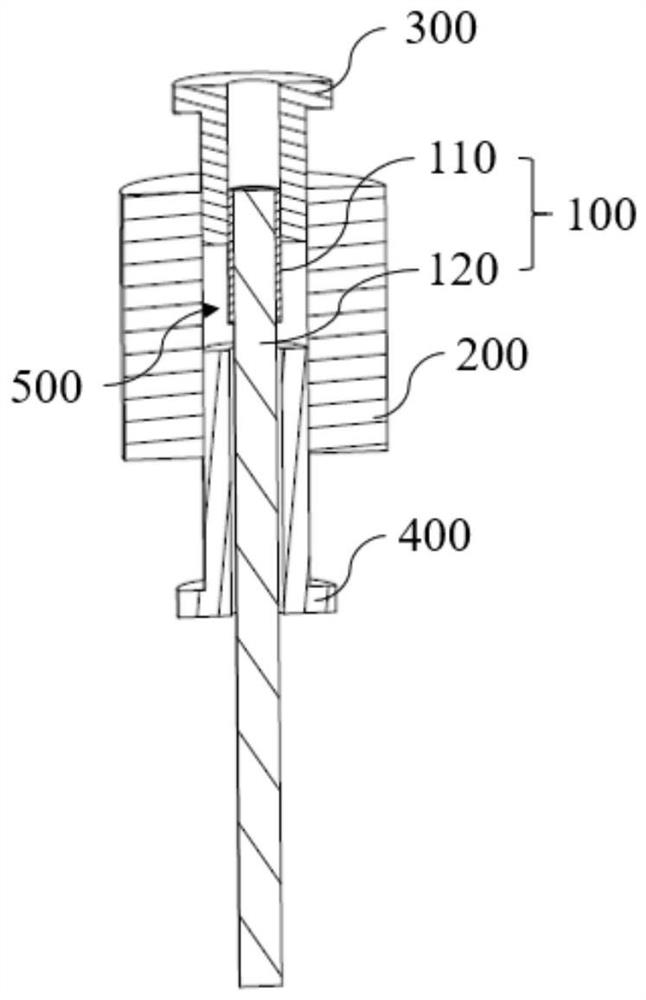

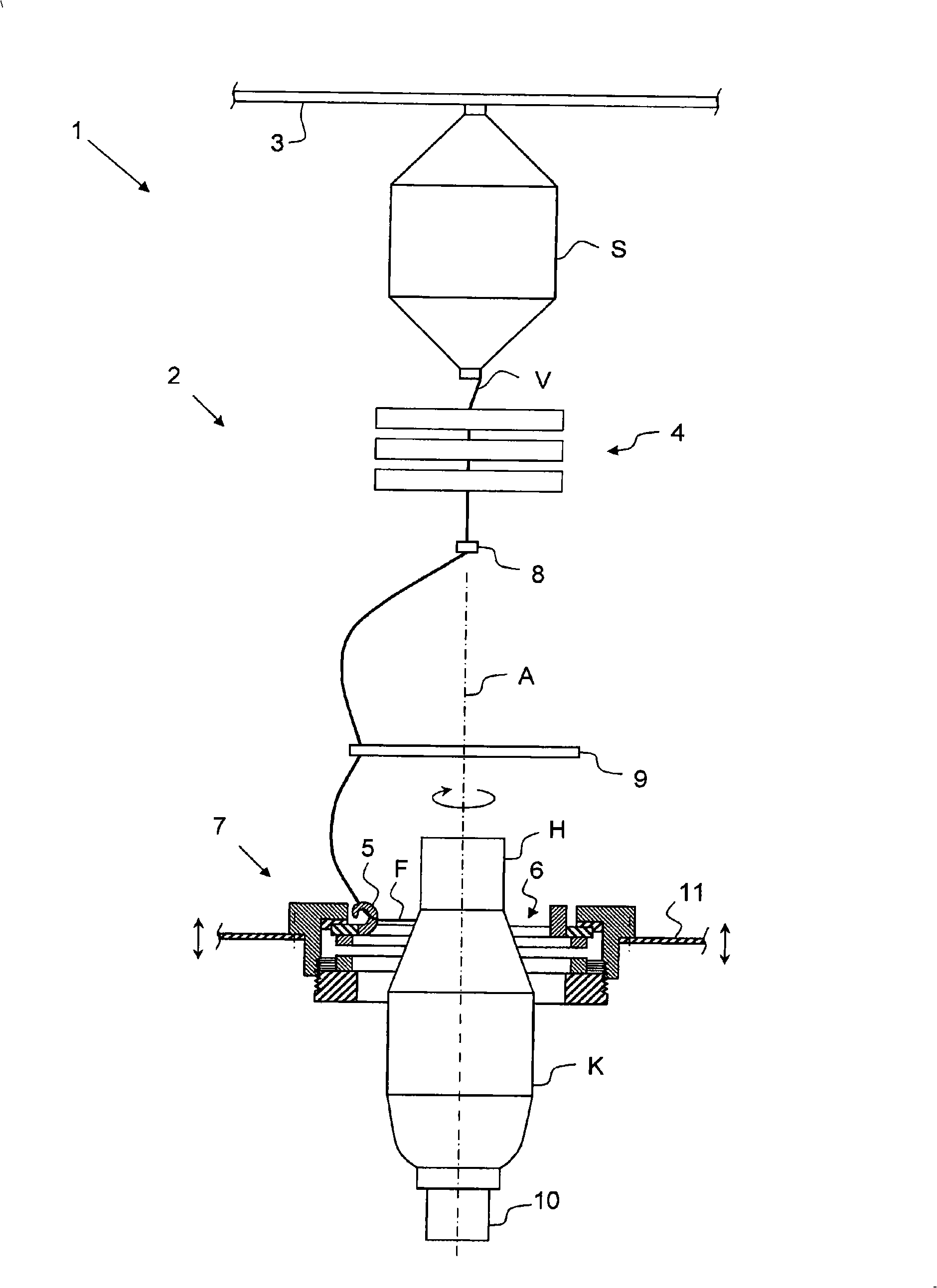

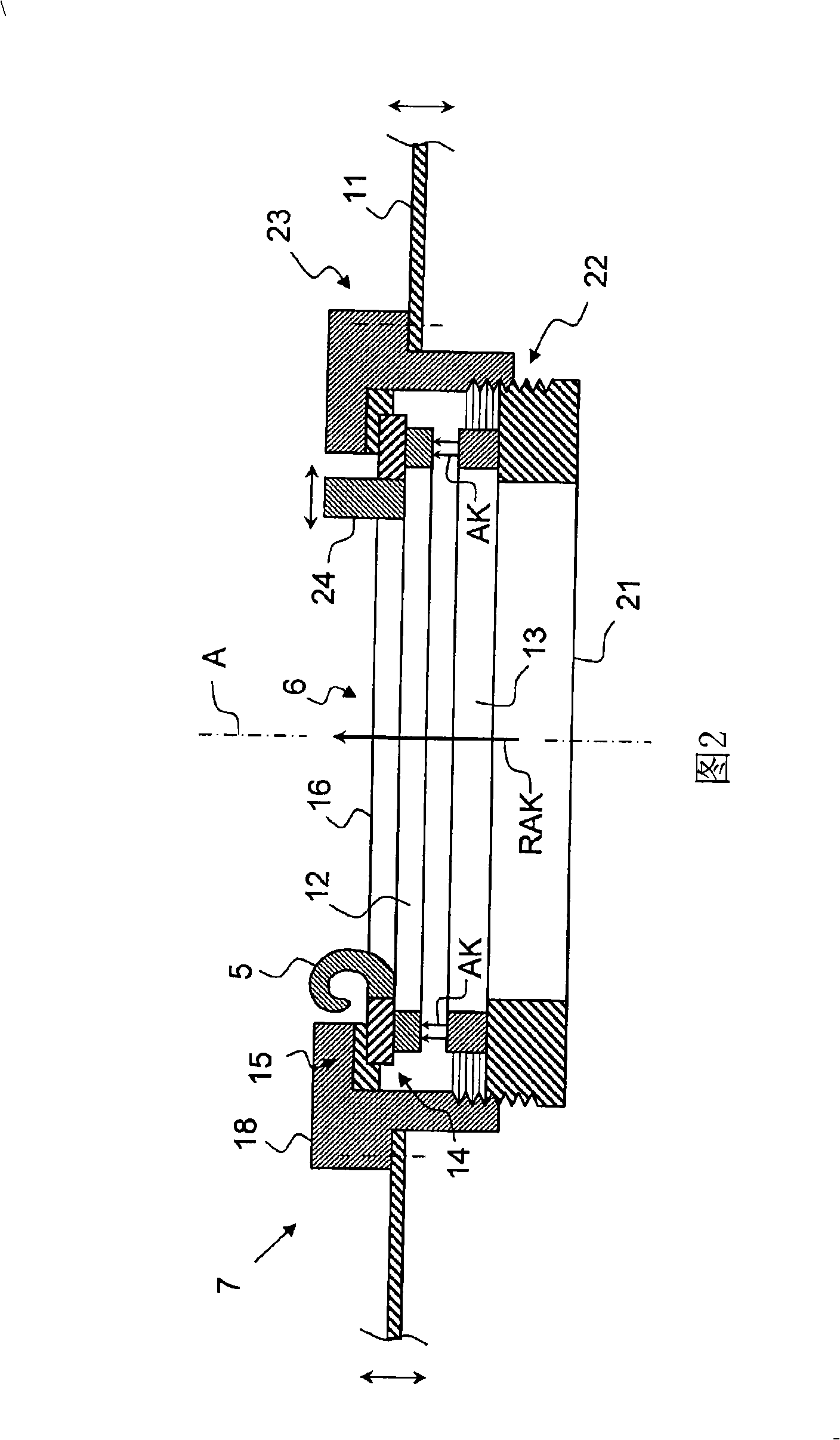

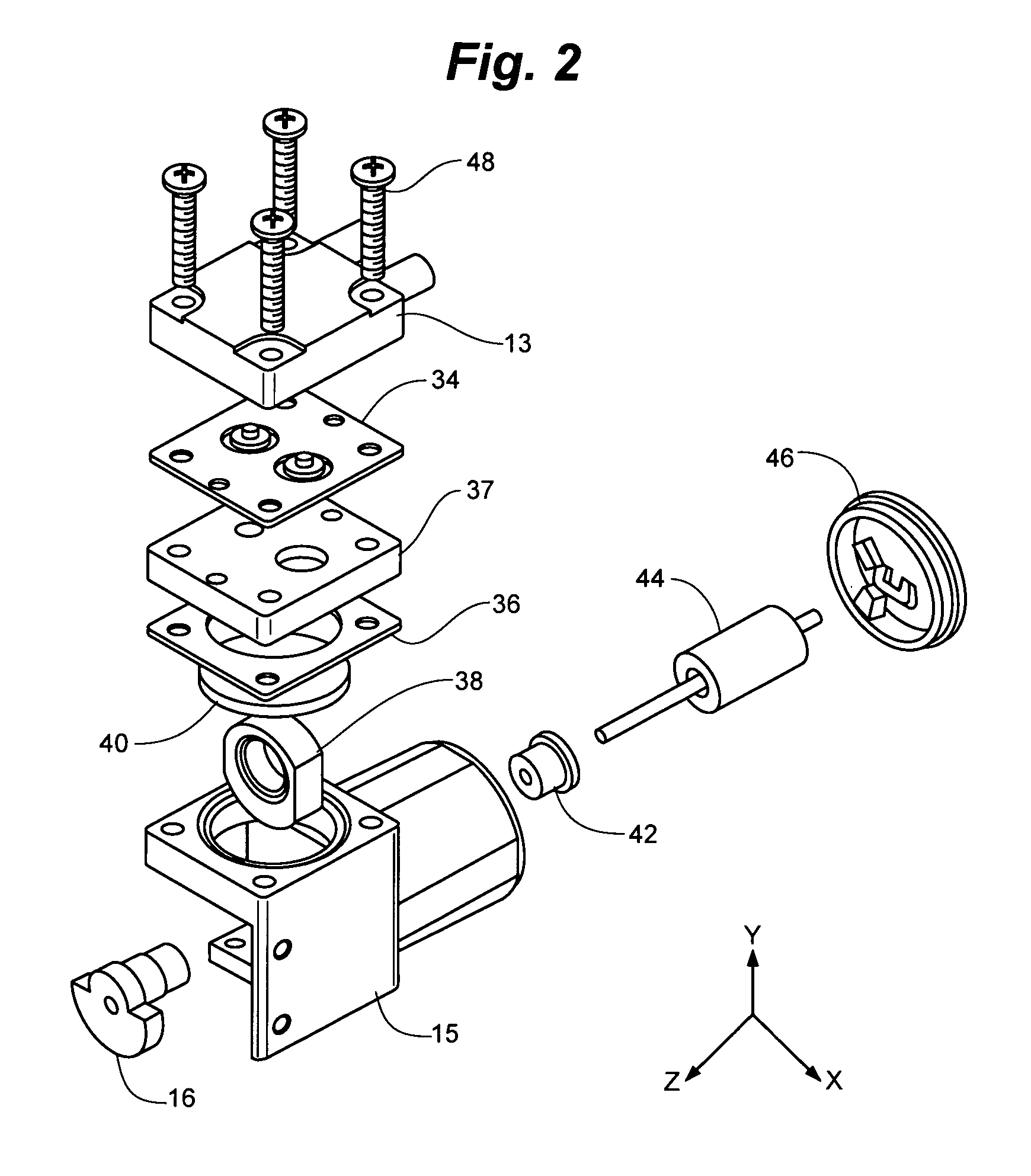

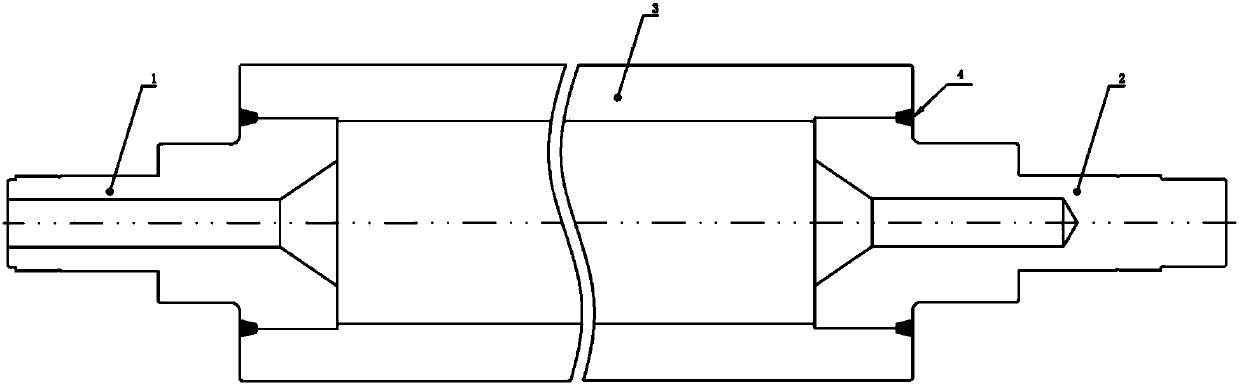

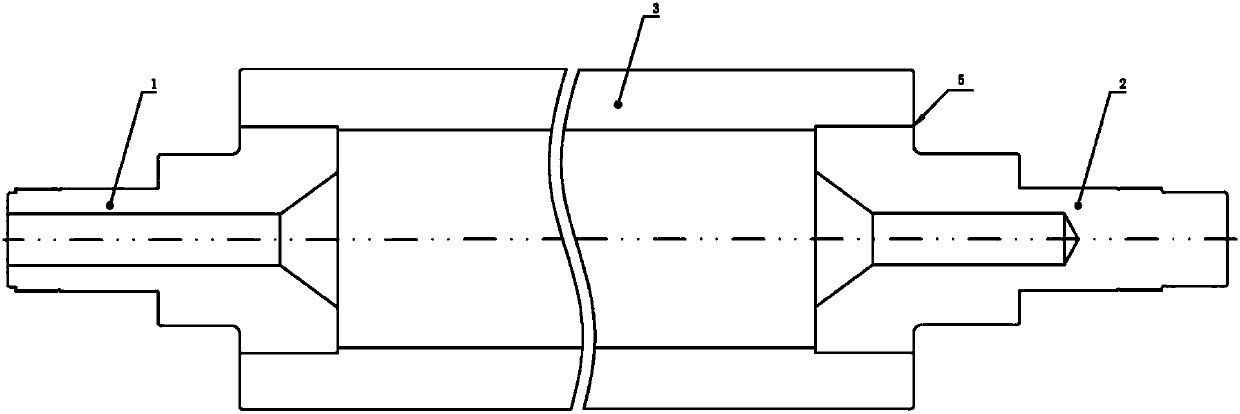

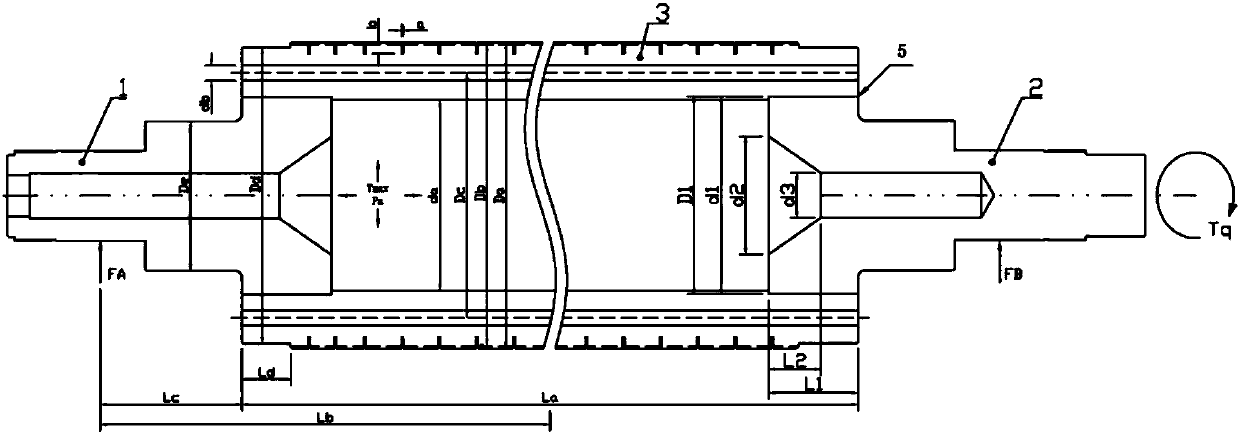

Fluid pump changeable in diameter, in particular for medical application

ActiveUS8944748B2Quiet and smooth operationPrevent penetrationPropellersRotary piston pumpsDrive shaftMedical treatment

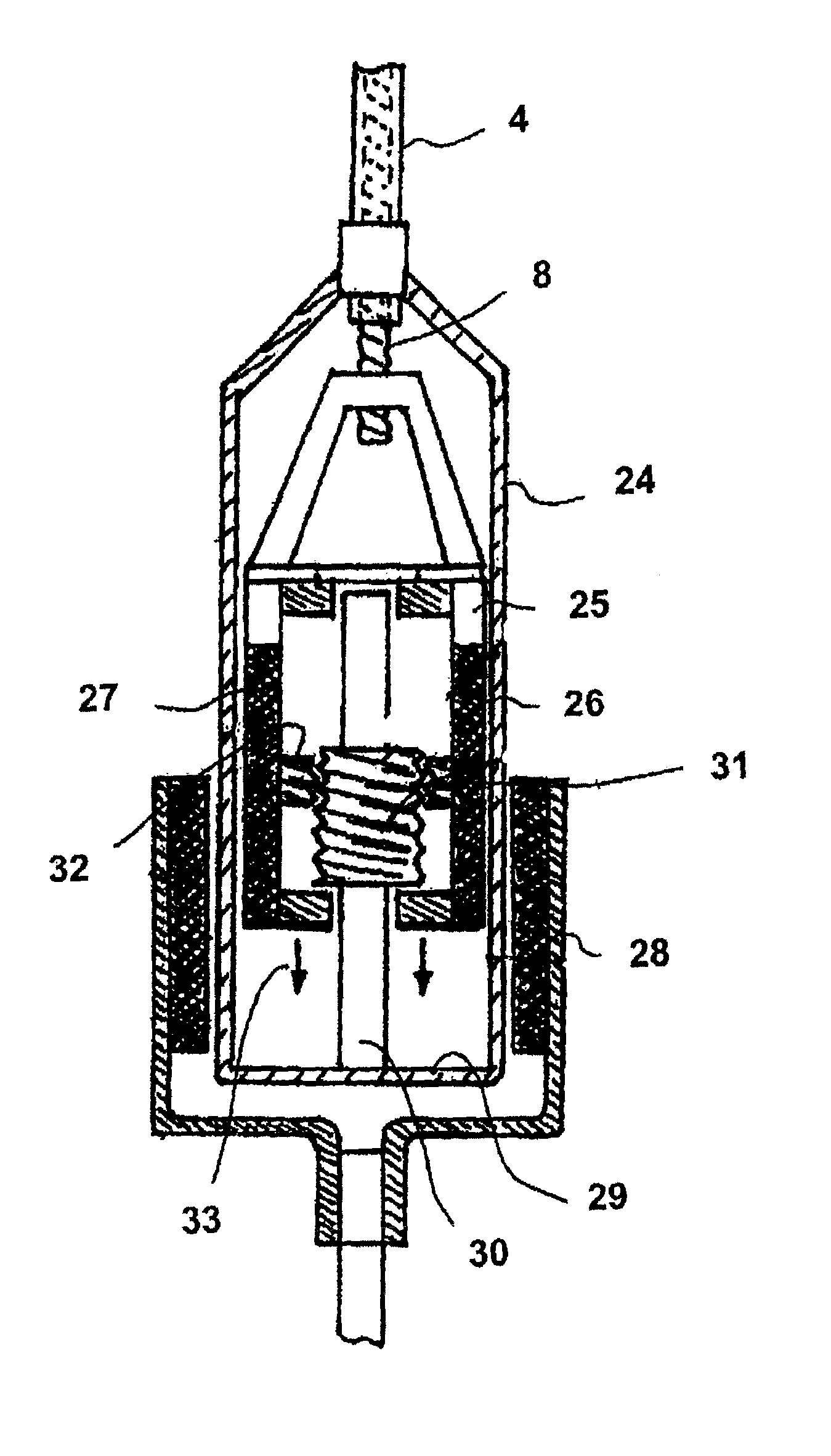

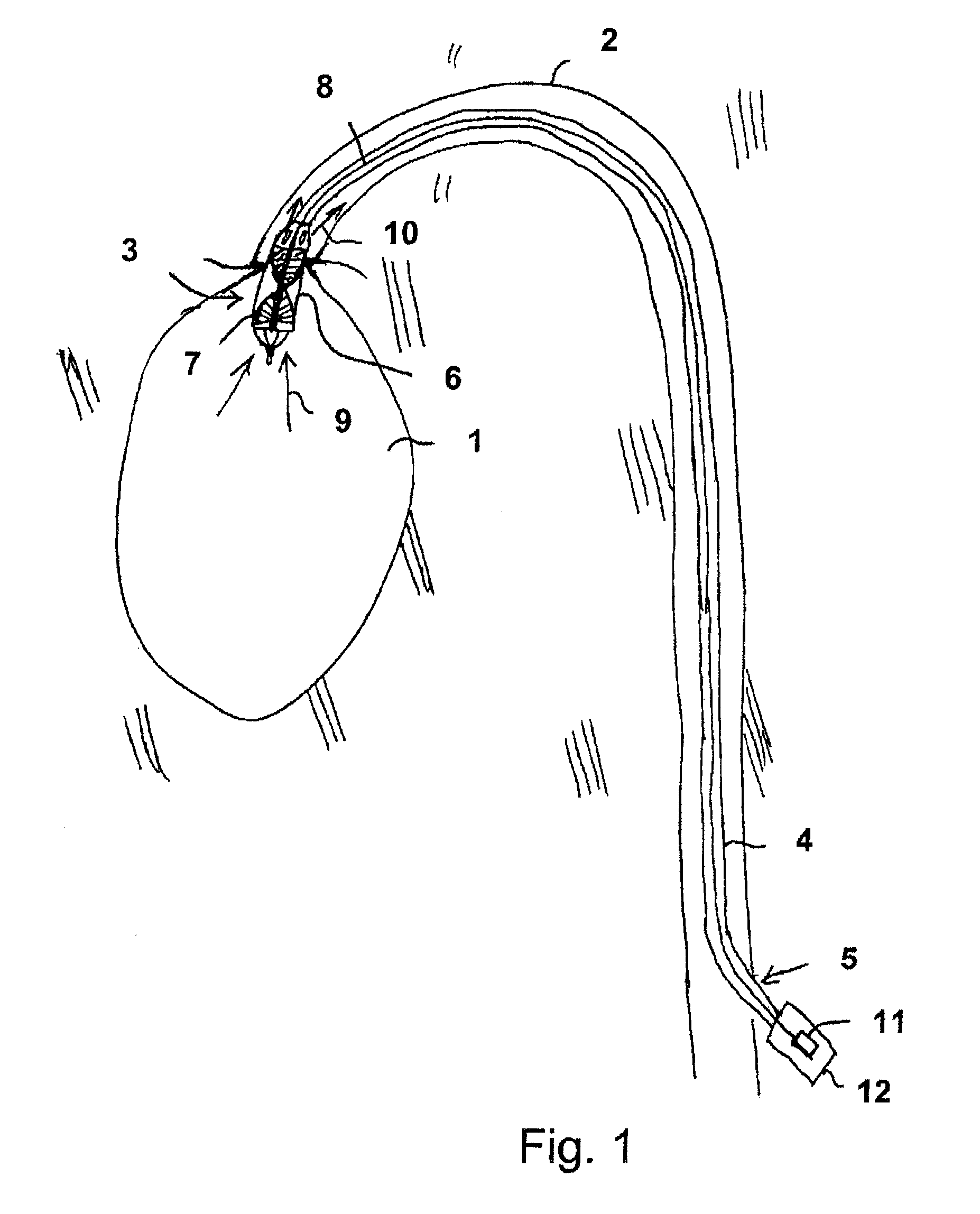

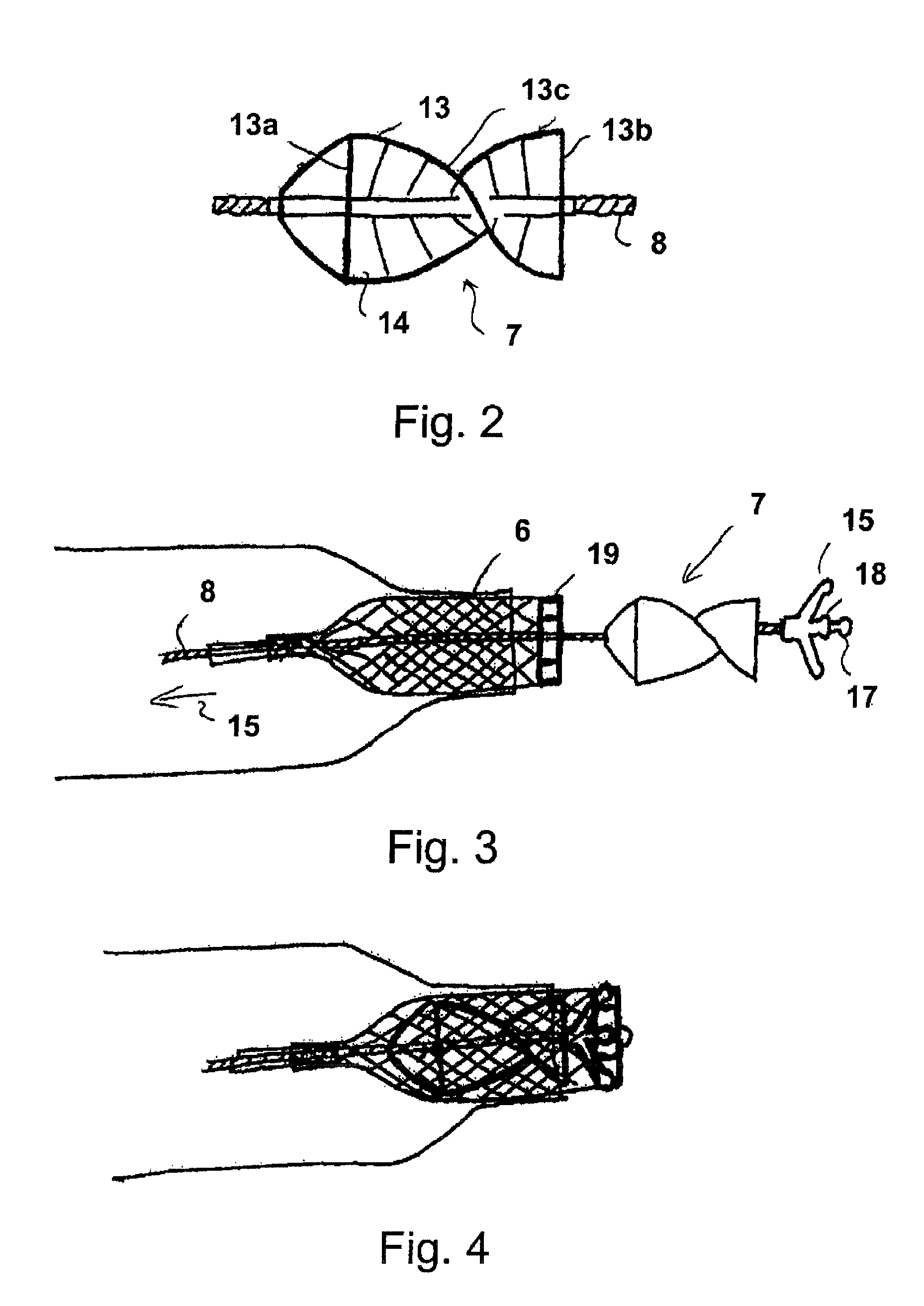

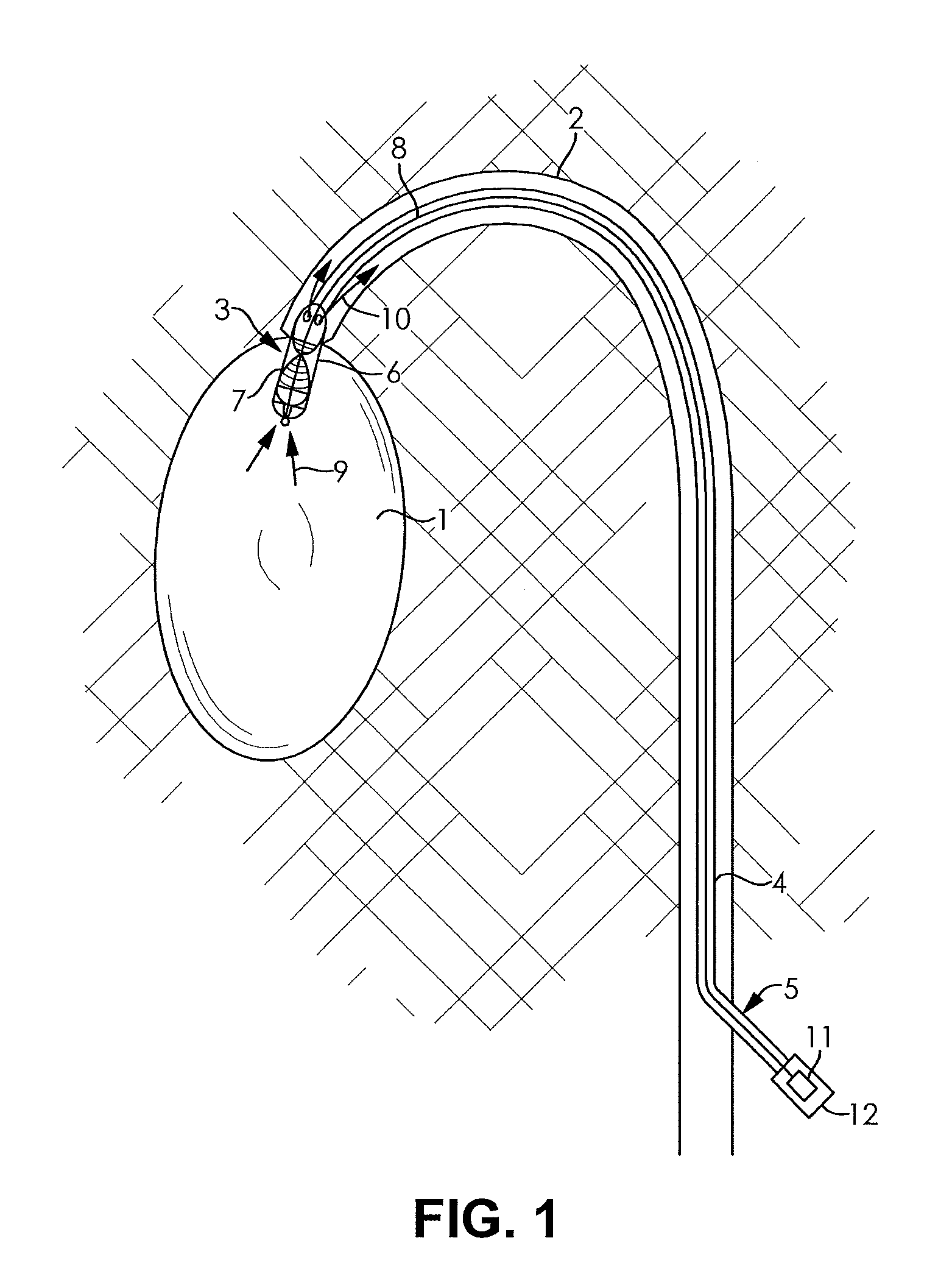

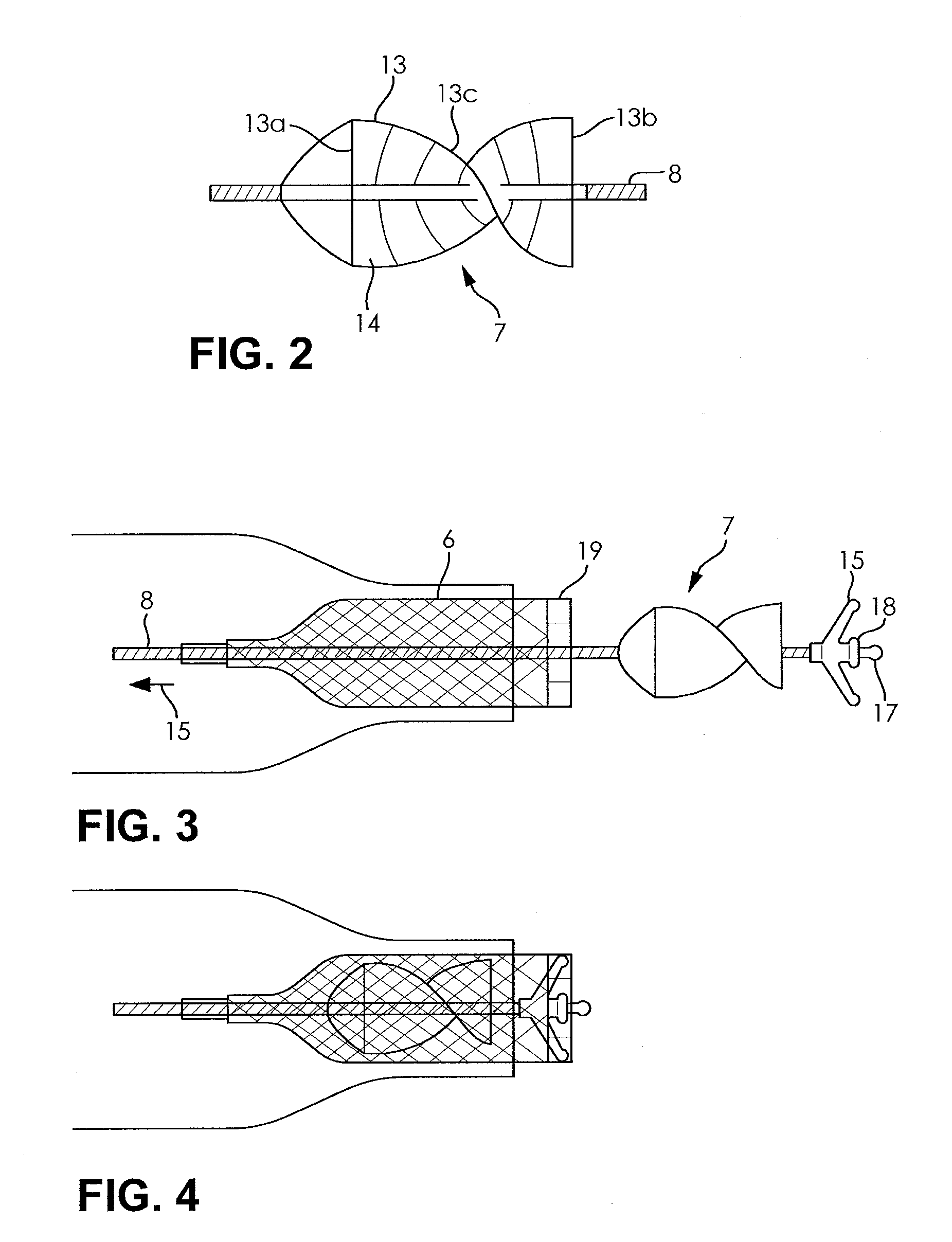

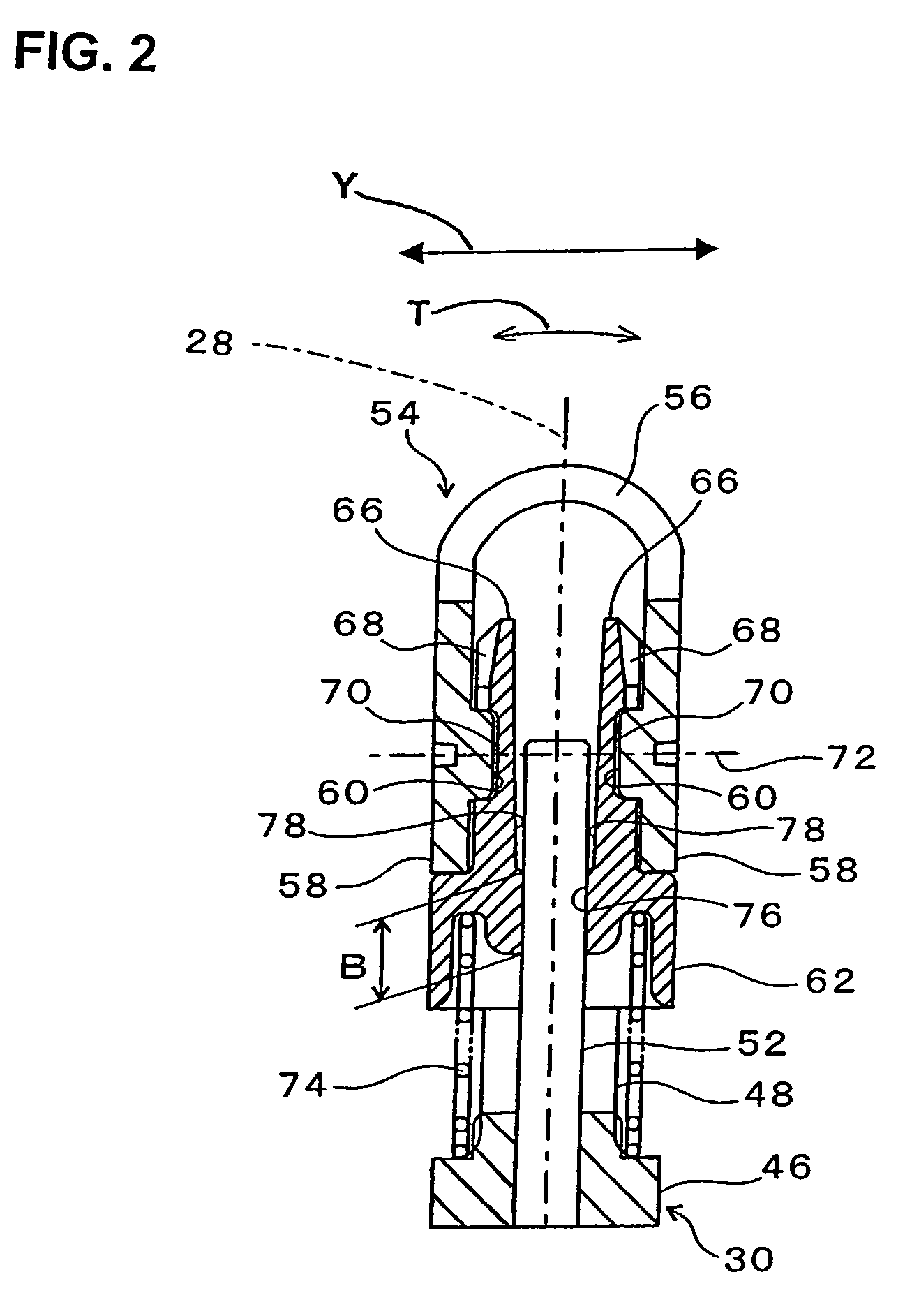

A fluid pump device, in particular for a medical application, is described having a compressible pump housing and rotor, as well as with a drive shaft which runs in a sleeve and on whose end the fluid pump is arranged. In order to utilize all possibilities of a space-saving arrangement of the respective pump housing of the rotor, which is compressible per se, and as the case a bearing arrangement, the mentioned elements are displaceable to one another in the axial direction compared to an operation position. In particular these elements may be end-configured by way of an axial movement of the drive shaft after the assembly.

Owner:ECP ENTWICKLUNGSGMBH

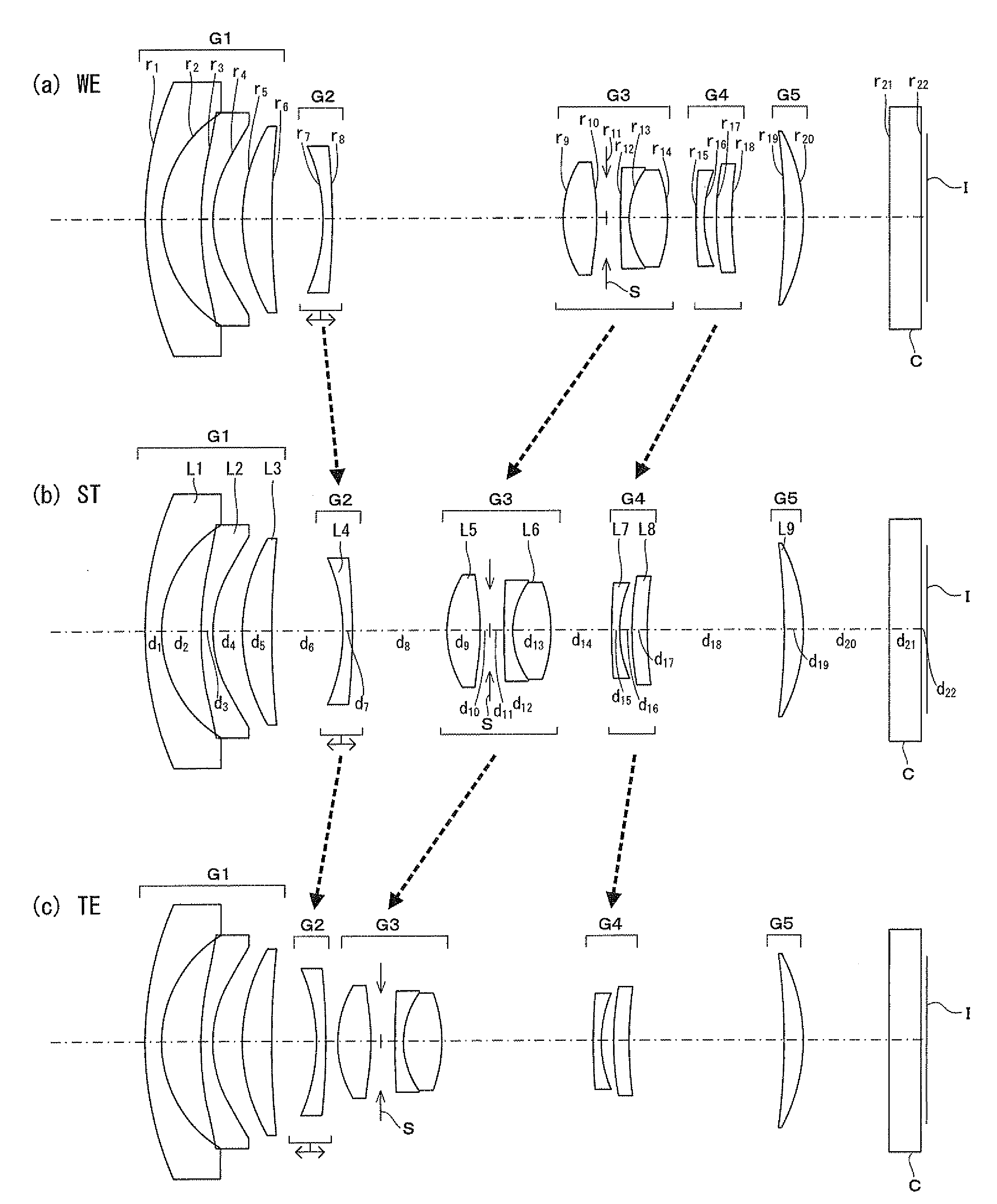

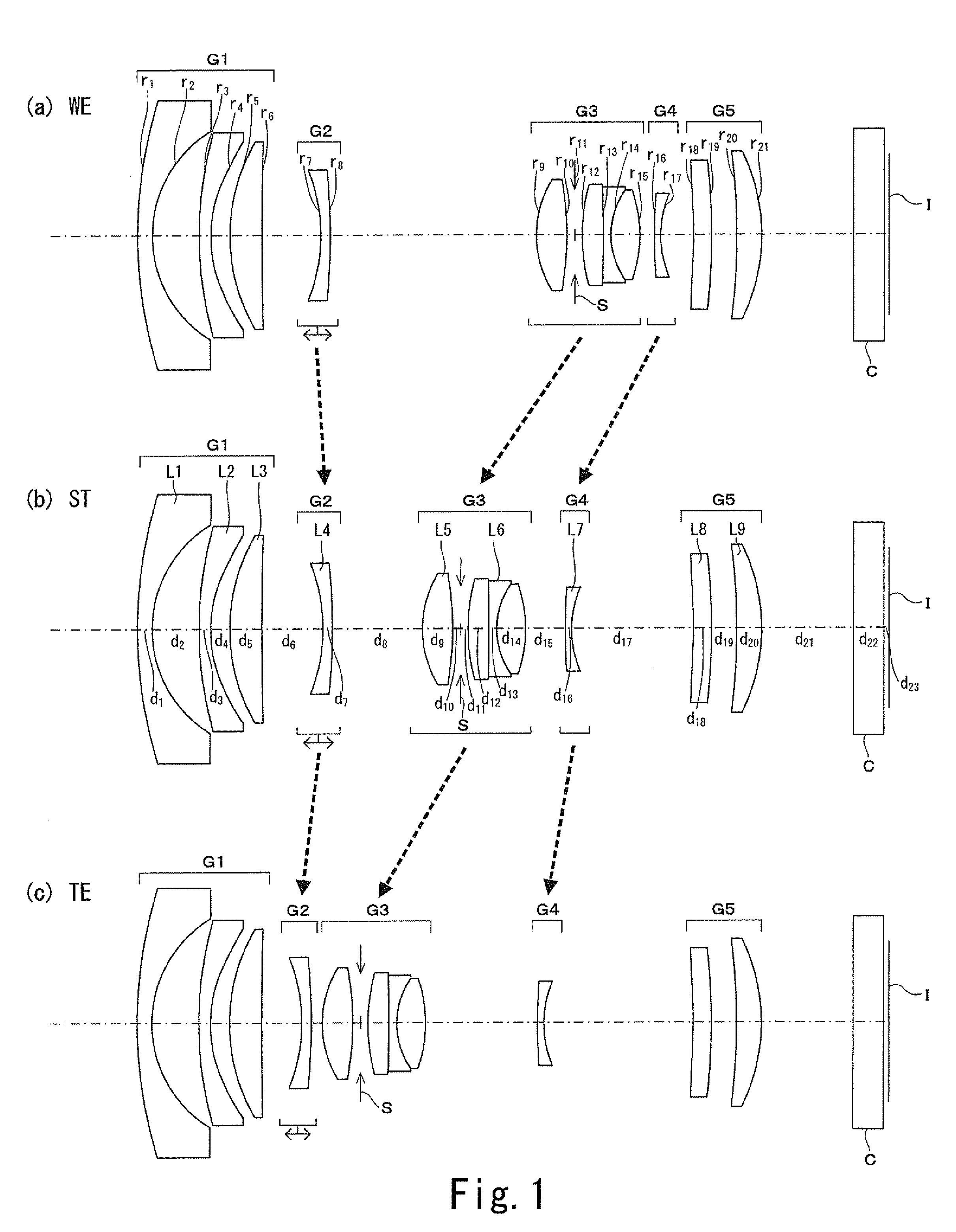

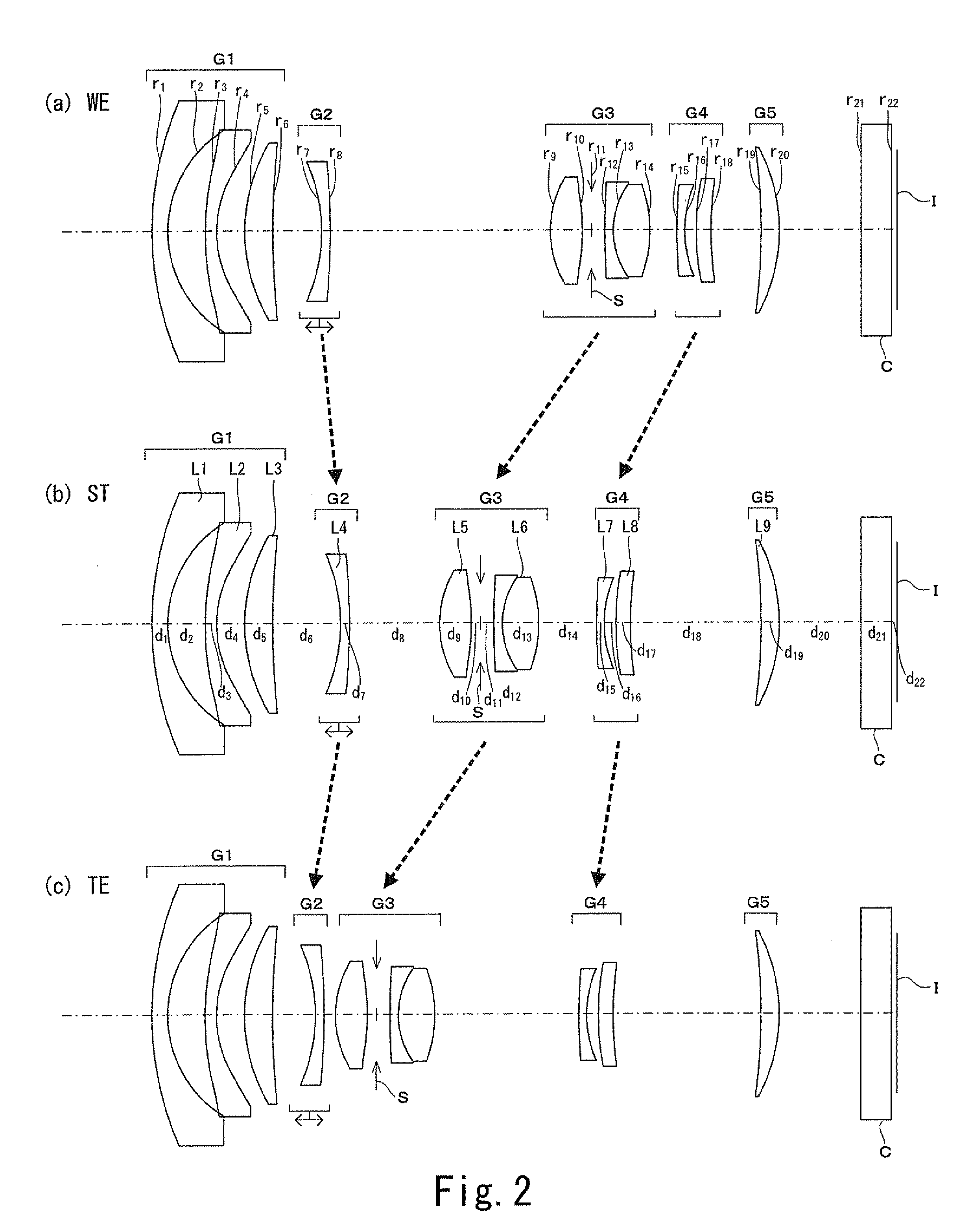

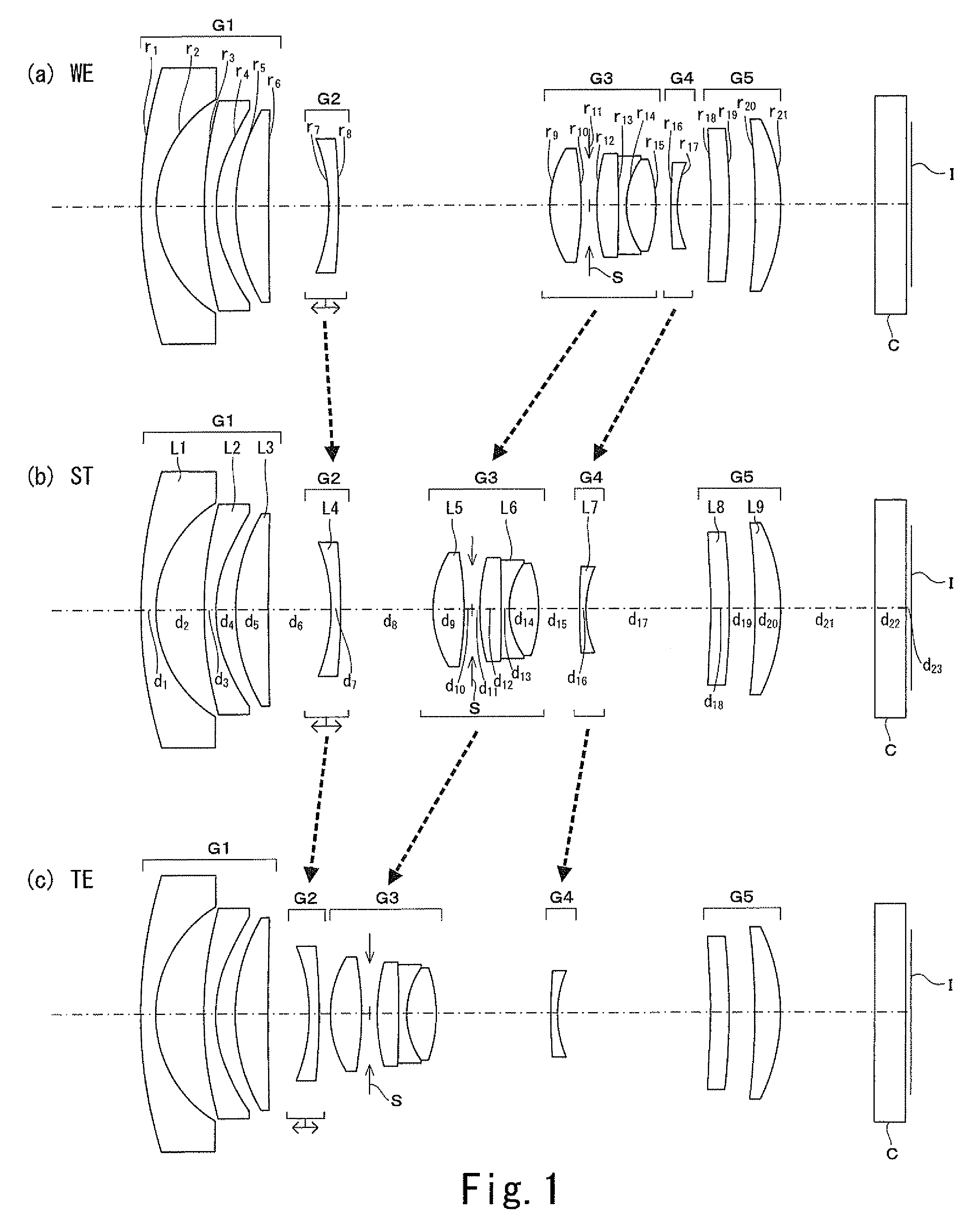

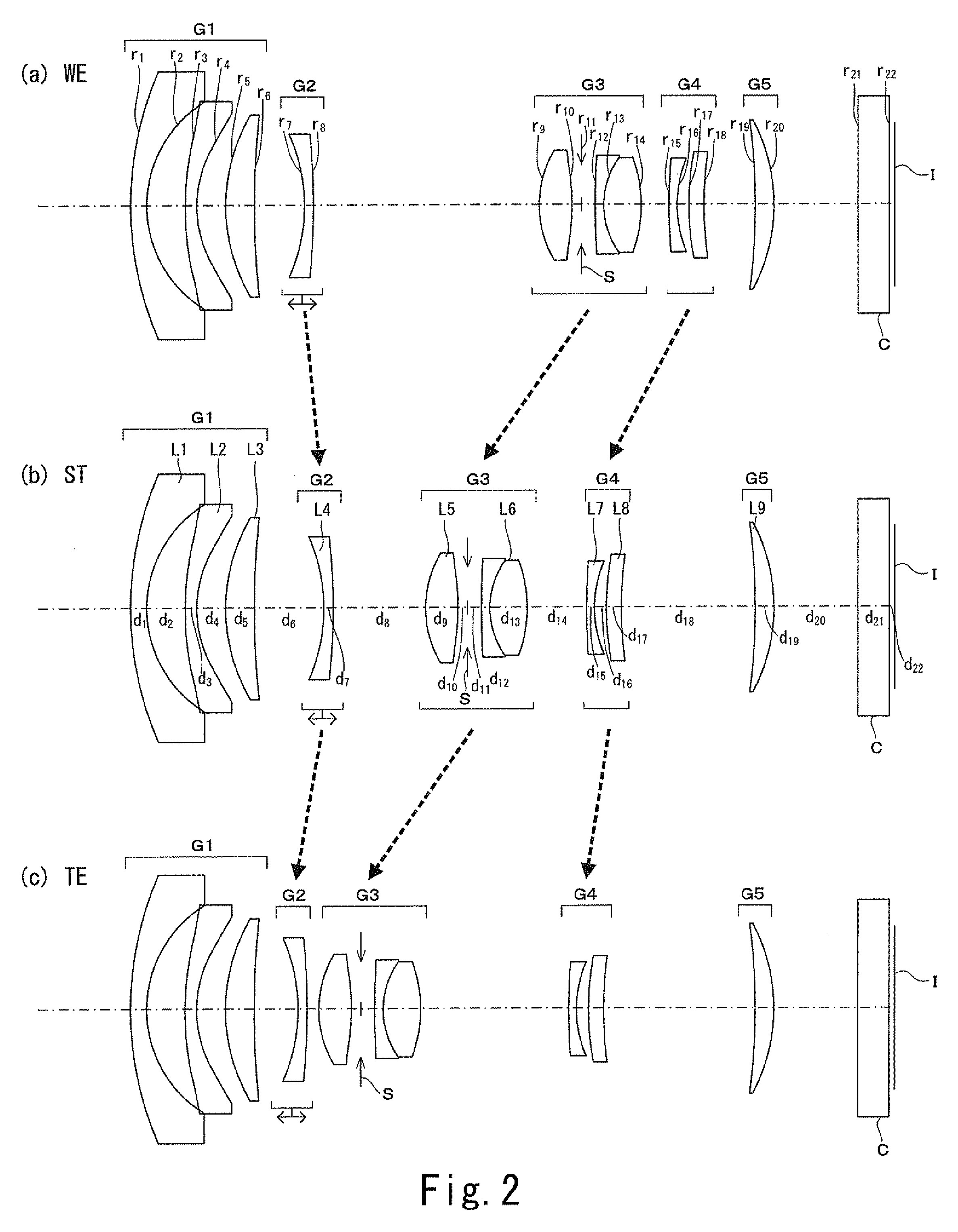

Zoom lens

In a zoom lens of a fixed total length, at the time of changing the magnification from the wide-angle end toward the telephoto end, the first lens group is anchored while the second lens group is moved, and the third and fourth lens groups are moved so as to be located at the object side of the telephoto end relative to the wide-angle end, such that: the interval between the second and third lens groups is decreased at the telephoto end relative to the wide-angle end; the interval between the third and fourth lens groups is increased at the telephoto end relative to the wide-angle end; and the interval between the fourth and fifth lens groups is increased at the telephoto end relative to the wide-angle end, and at the time of focusing a near object point from a remote object point, the second lens group is moved.

Owner:OM DIGITAL SOLUTIONS CORP

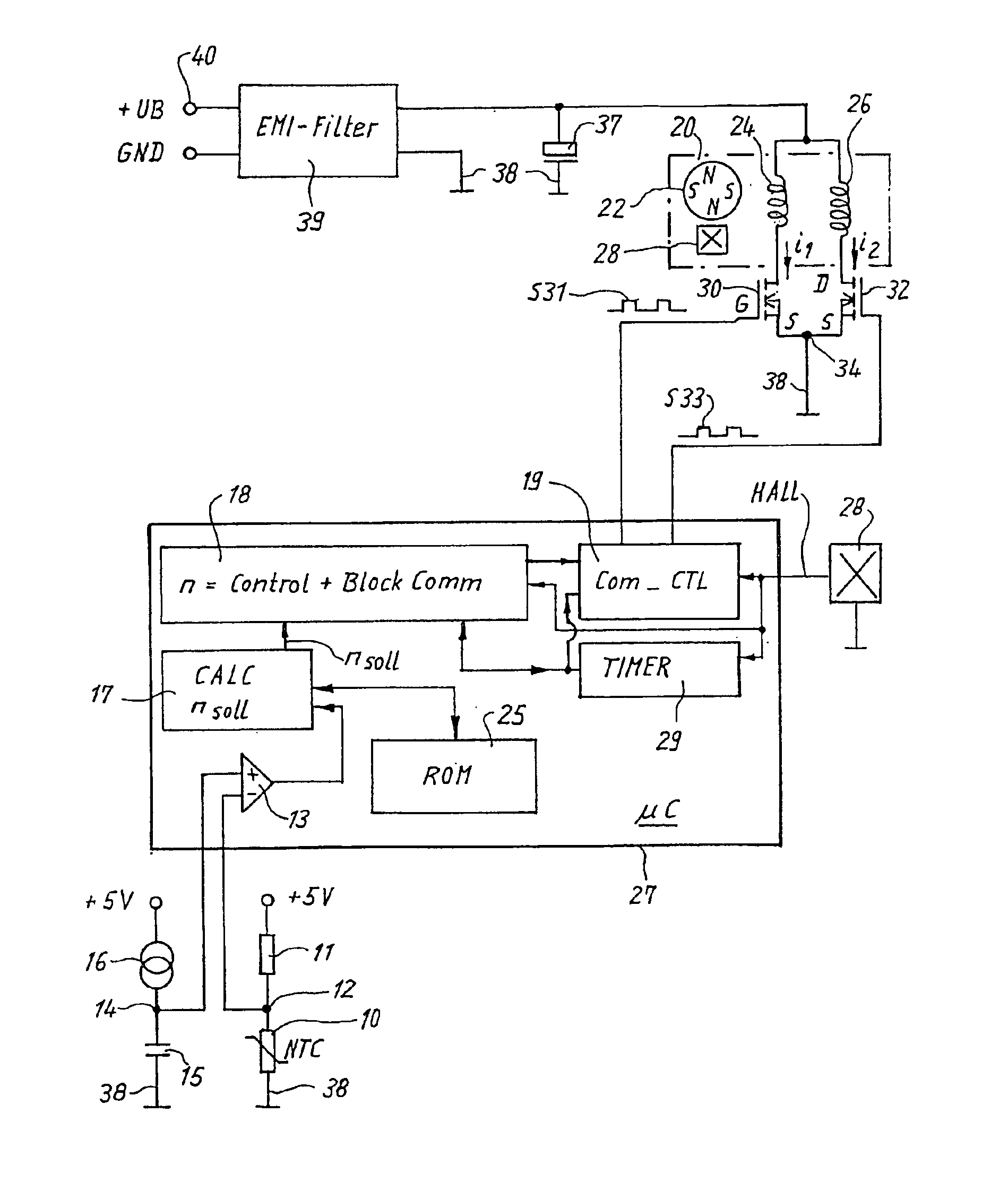

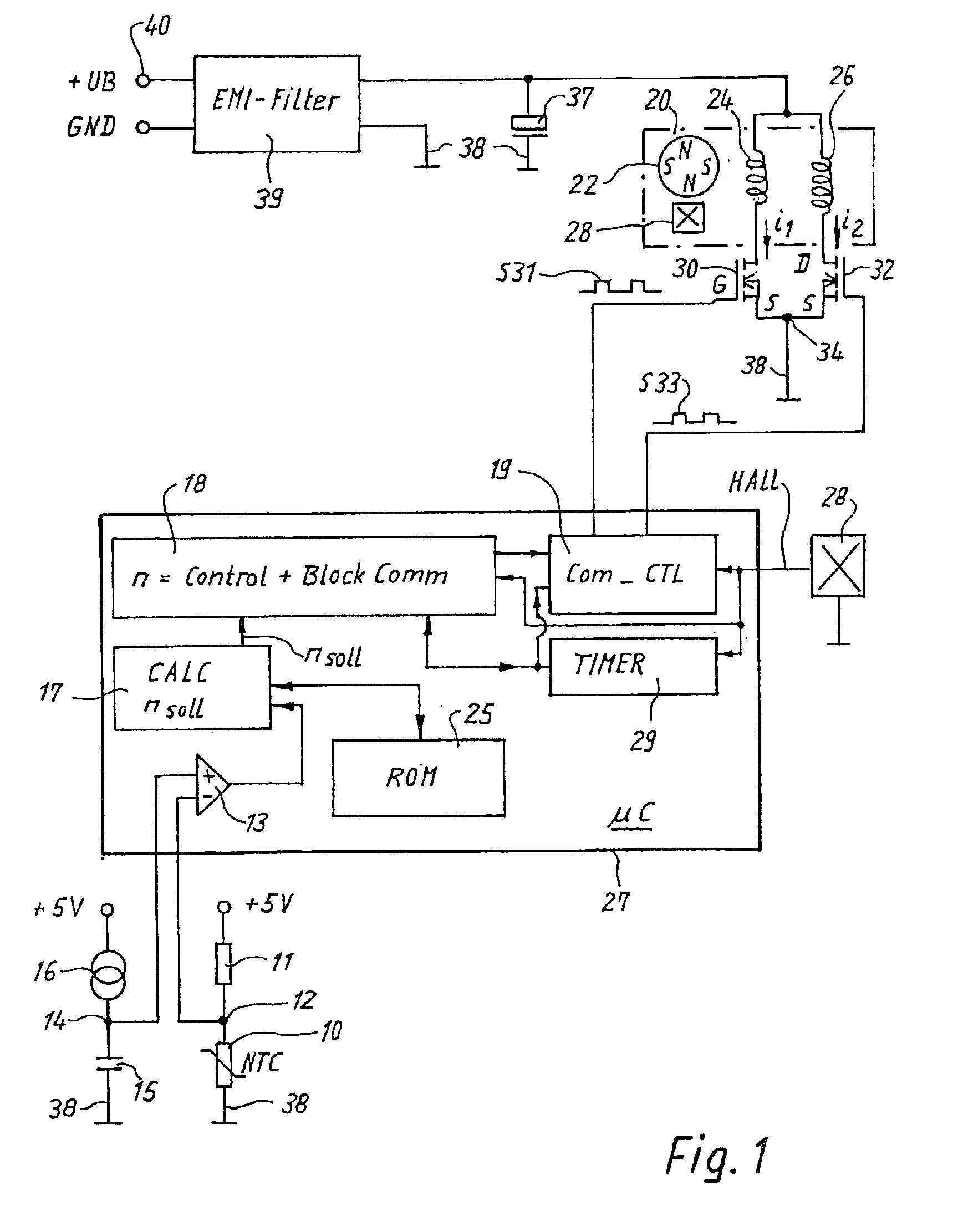

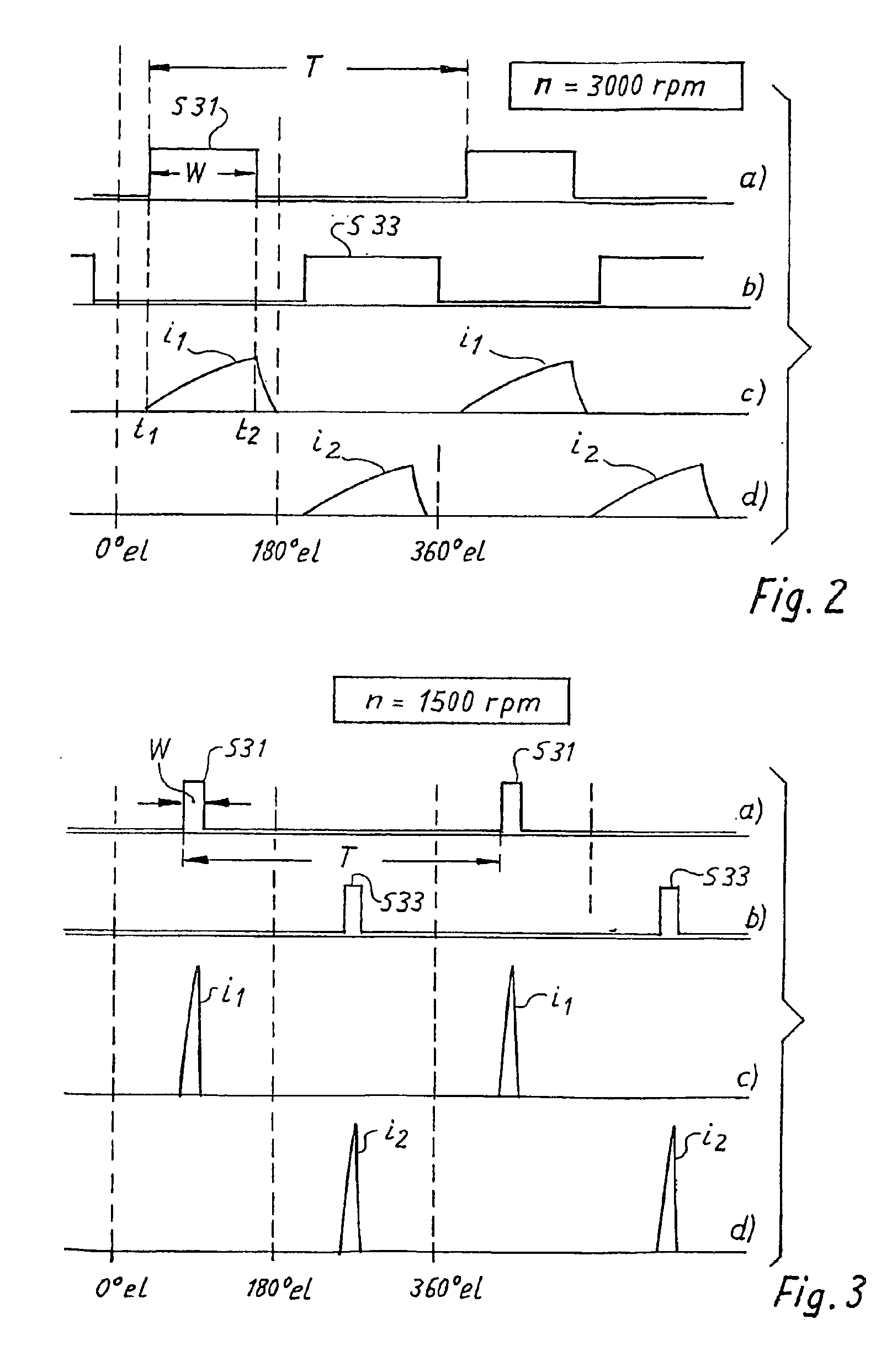

Method of controlling the commutation in an electronically commutated motor, and an electronically commutated motor for carrying out said method

InactiveUS6995534B2Improve efficiencyCurrent is limitedMotor/generator/converter stoppersAC motor controlPermanent magnet rotorCurrent limiting

A method is disclosed for controlling the commutation in an electronically commutated motor (20) which comprises a stator having at least one phase (24, 26), and a permanent-magnet rotor (22), and with which a current limiter (36, 58) and a controller (18) for regulating a motor variable are associated. The current limiter (36, 58) serves to limit the current (I) in the at least one phase (24, 26) to a setpoint value. The regulation by means of the controller (18) is accomplished by modifying the distance in time (W) between switching on (t1) and switching off (t2) of the current (i1, i2) in the at least one phase. In this method, the setpoint value to which the current limiter limits the current (i1, i2) in the relevant phase is modifiable. It is modified substantially as a function of a ratio of two times (W / T), namely as a function of the ratio of the distance in time (W) between switching on (t1) and switching off (t2) of the current (i1, i2) in the relevant phase (24, 26) to the time period (T) required by the rotor, at the instantaneous rotation speed, to rotate through a specified rotation angle. A decrease in noise at low rotation speeds is thereby made possible.

Owner:EBM PAPST ST GEORGEN & -

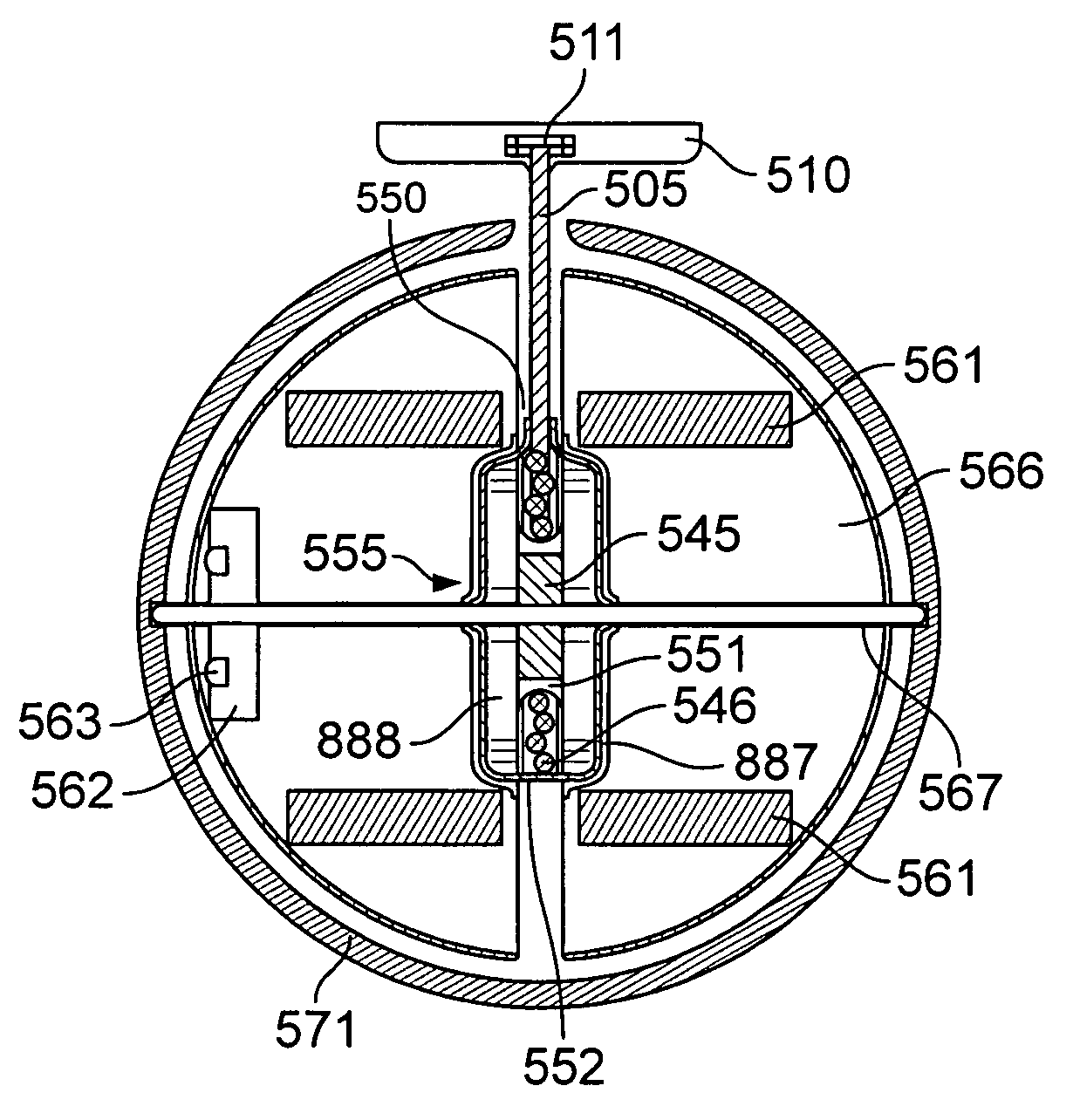

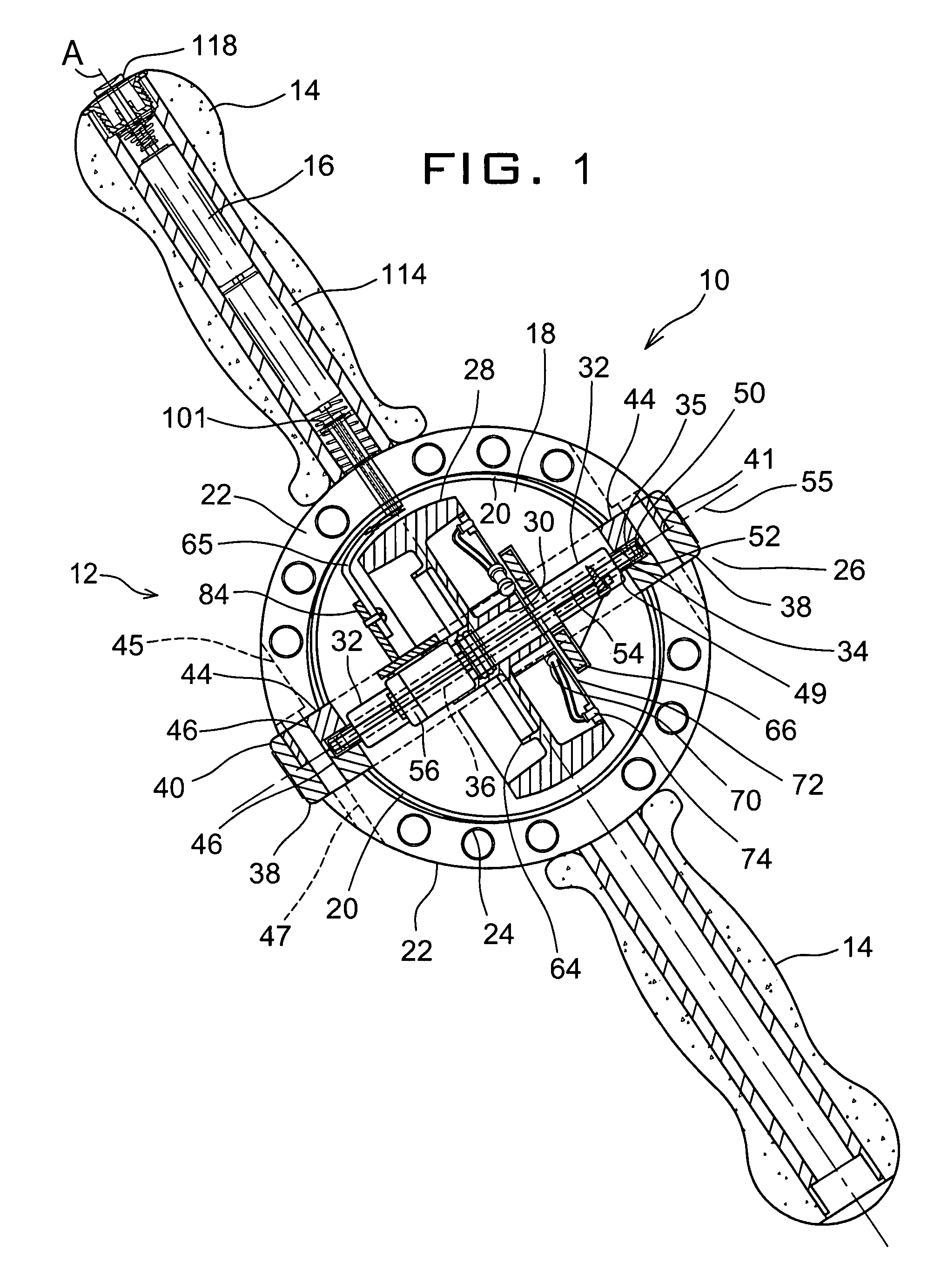

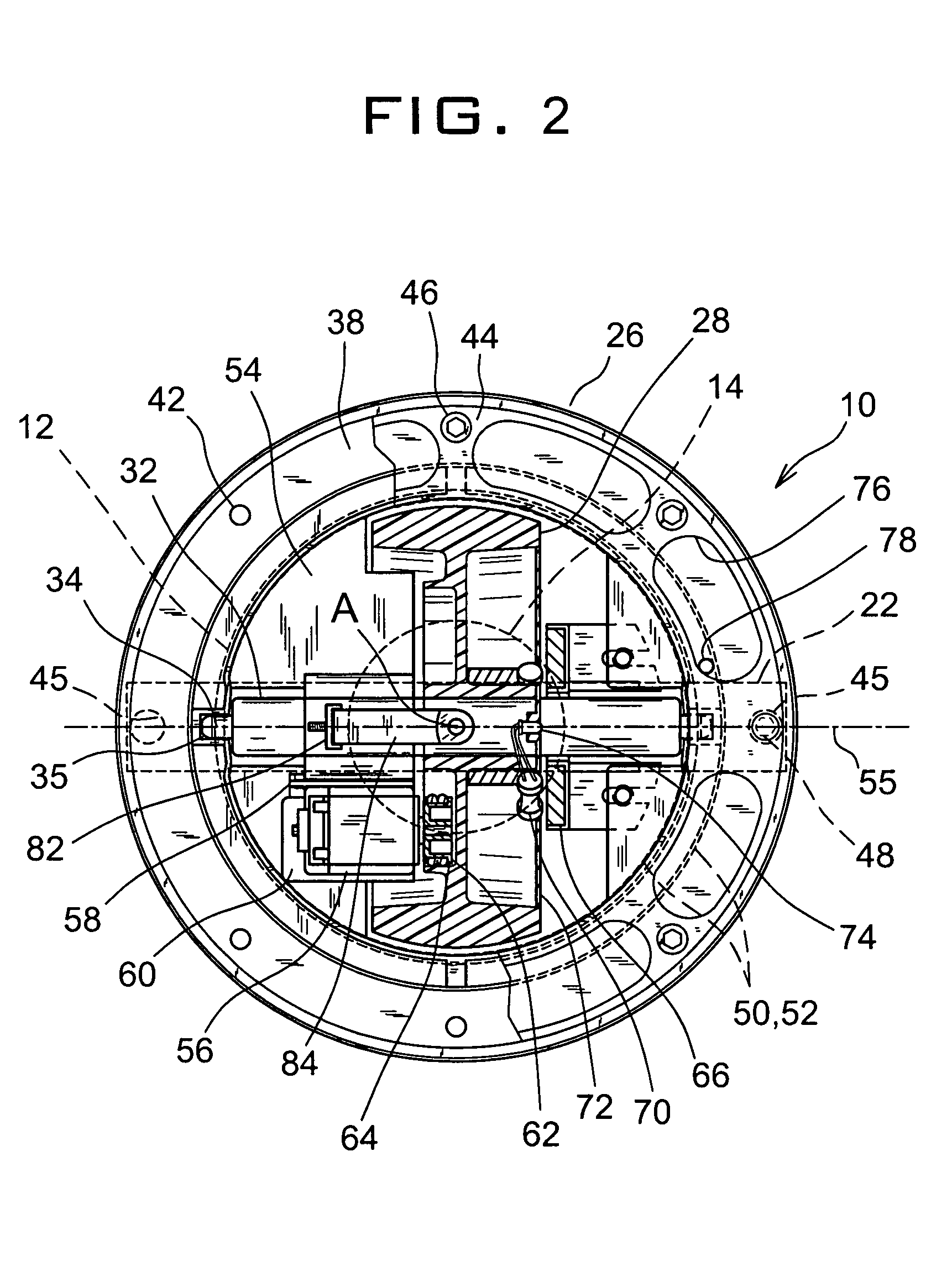

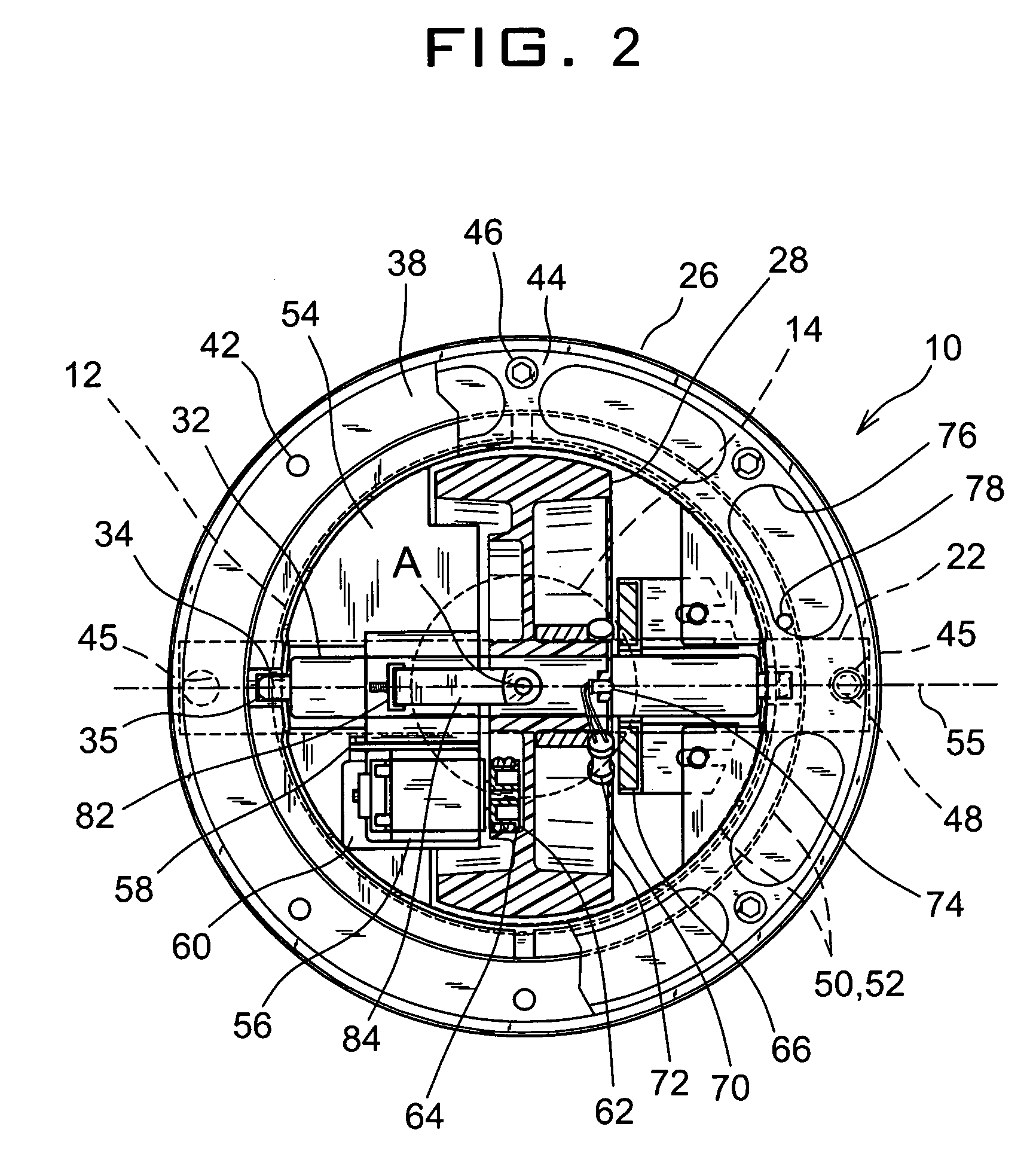

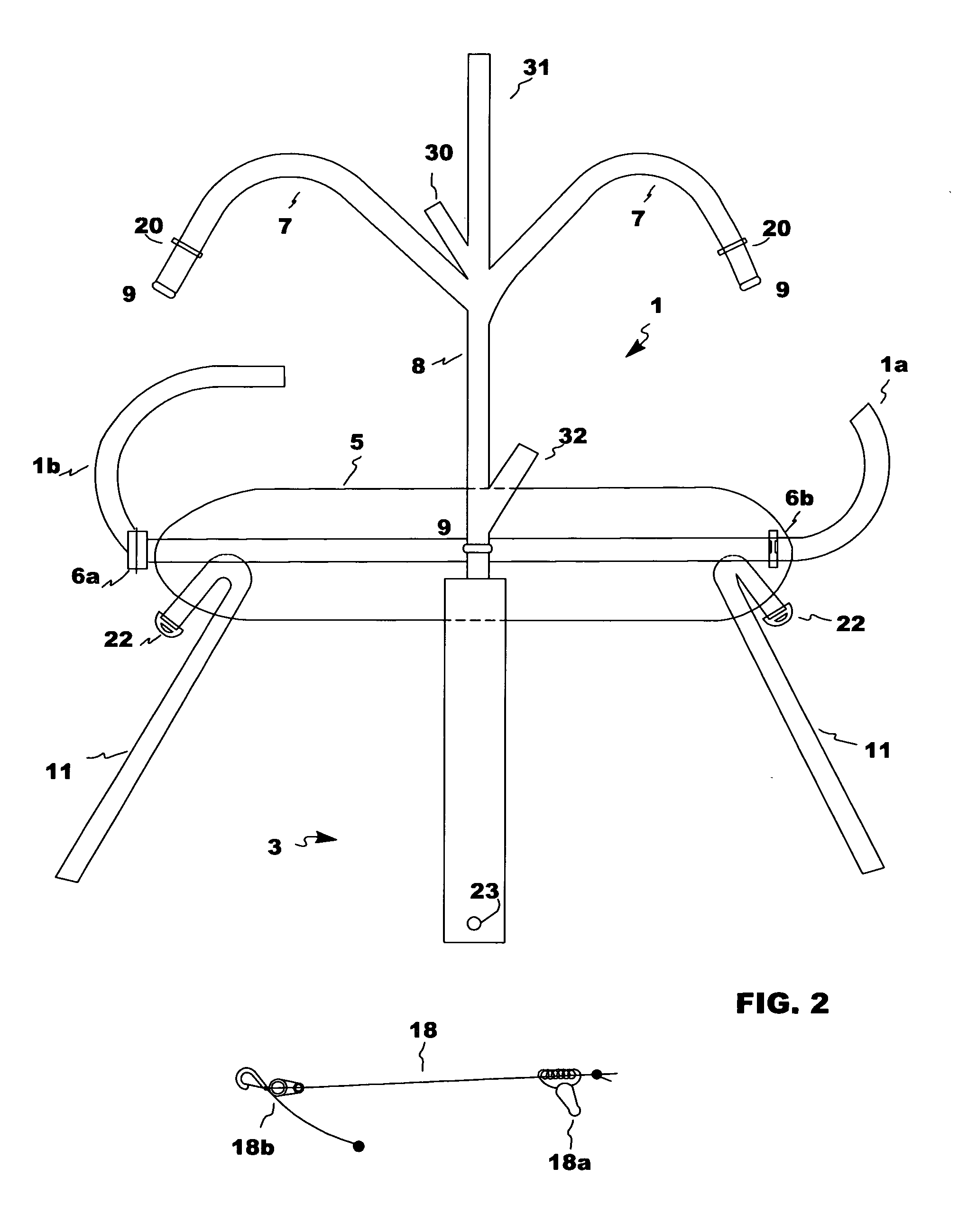

Gyroscopic total exerciser

ActiveUS20080242508A1Reducing idle weightQuiet and smooth operationMechanical apparatusSpeed measurement using gyroscopic effectsGyroscopePrecession

A gyroscopic exercise device has a pair of handles attached to a housing. A user holds and rotates the handles along cone-like paths causing precession of a rotor, which is rotating about its spin axis, to provide resistance to the user. The device has an axle disc that holds ends of an axle of the rotor. The periphery of the axle disc and the ends of the rotor axle are within a circular race in the housing. A motor attached to the axle disc has a wheel for rotating the rotor about a spin axis by a temporary supply of power from included batteries in one of the handles. The batteries are in between two opposite springs in one of the handles and normally biased away from an electrical contact until the user pushes them through an end pin to overcome the bias.

Owner:SMITH TOM

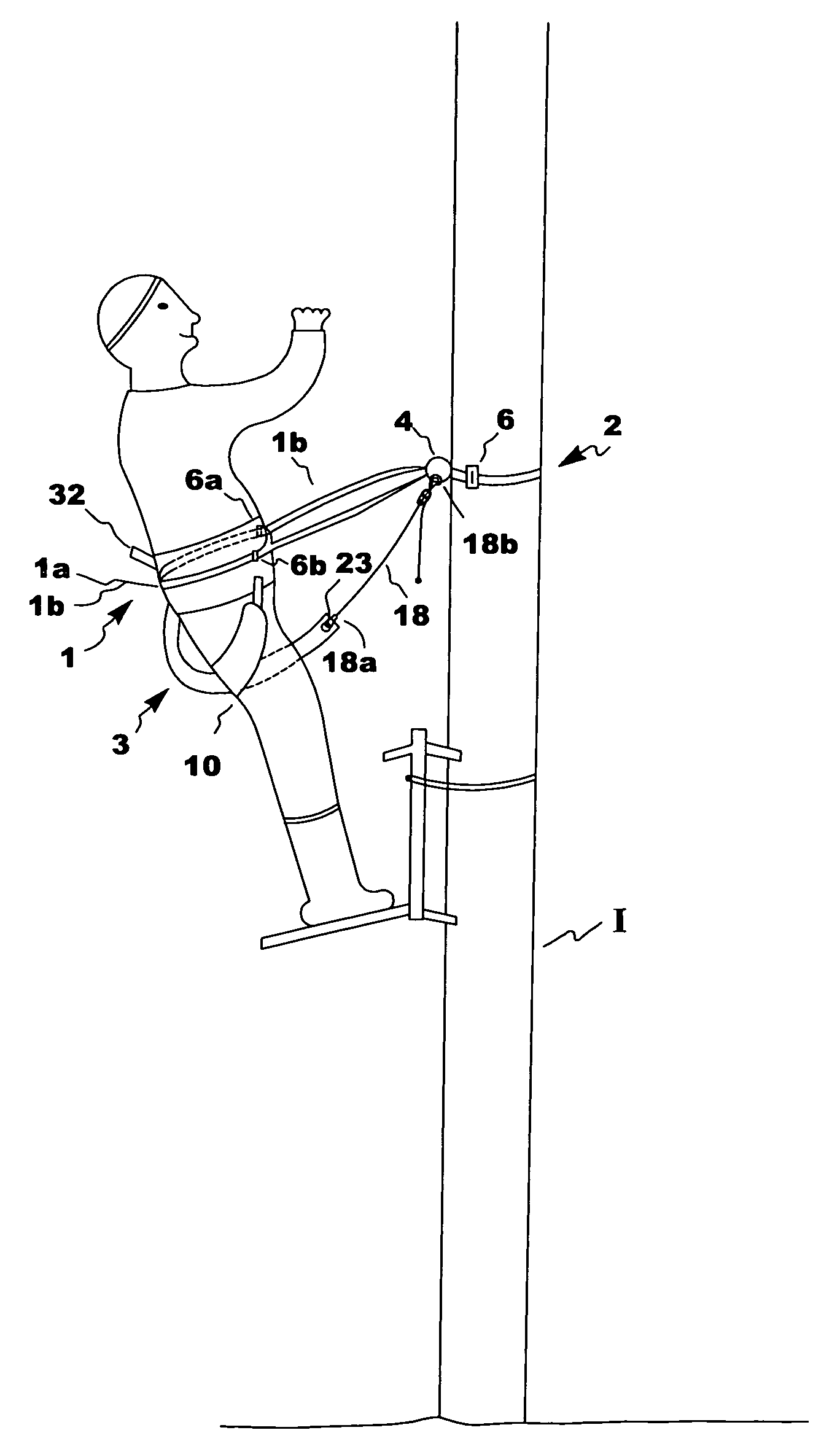

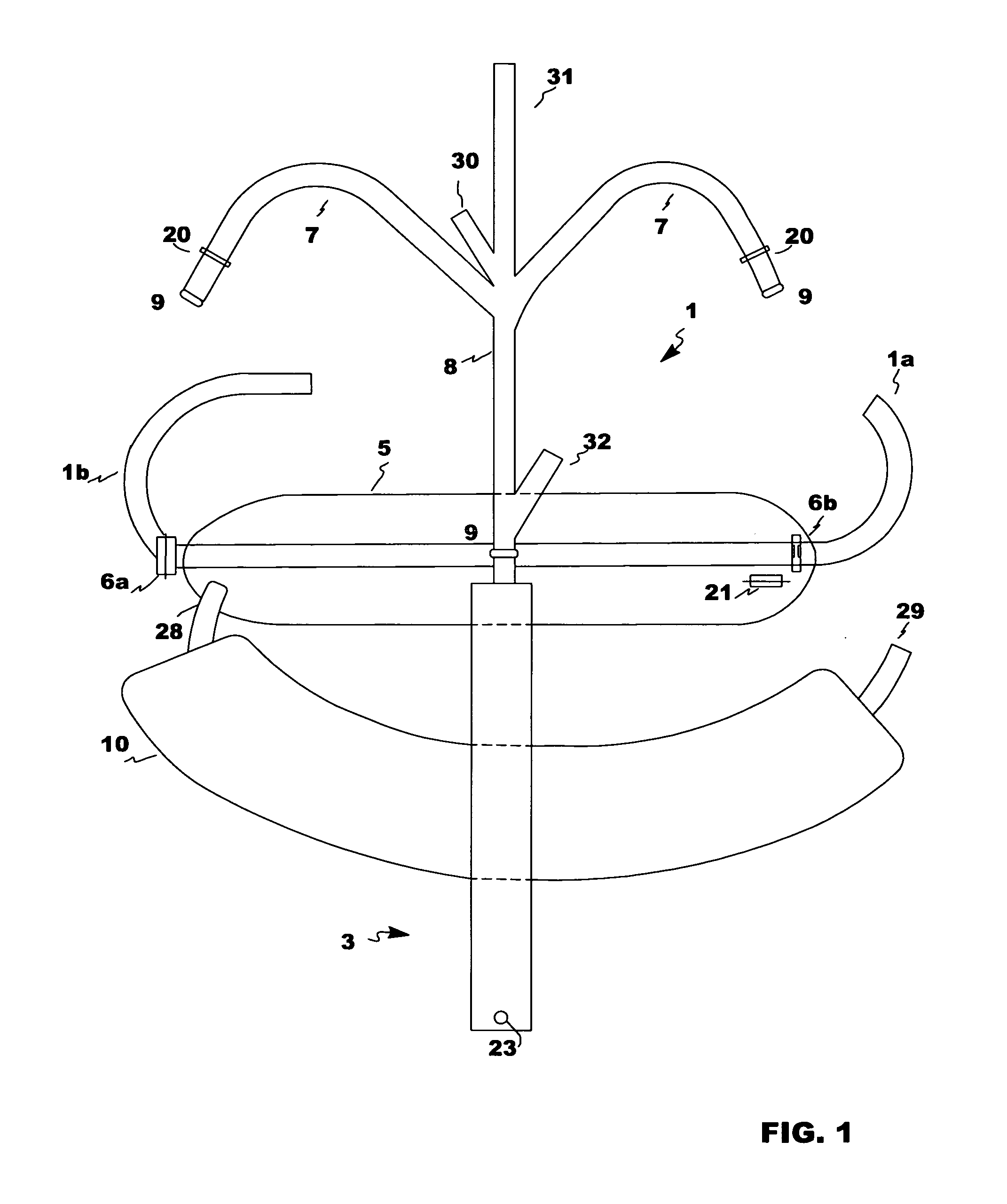

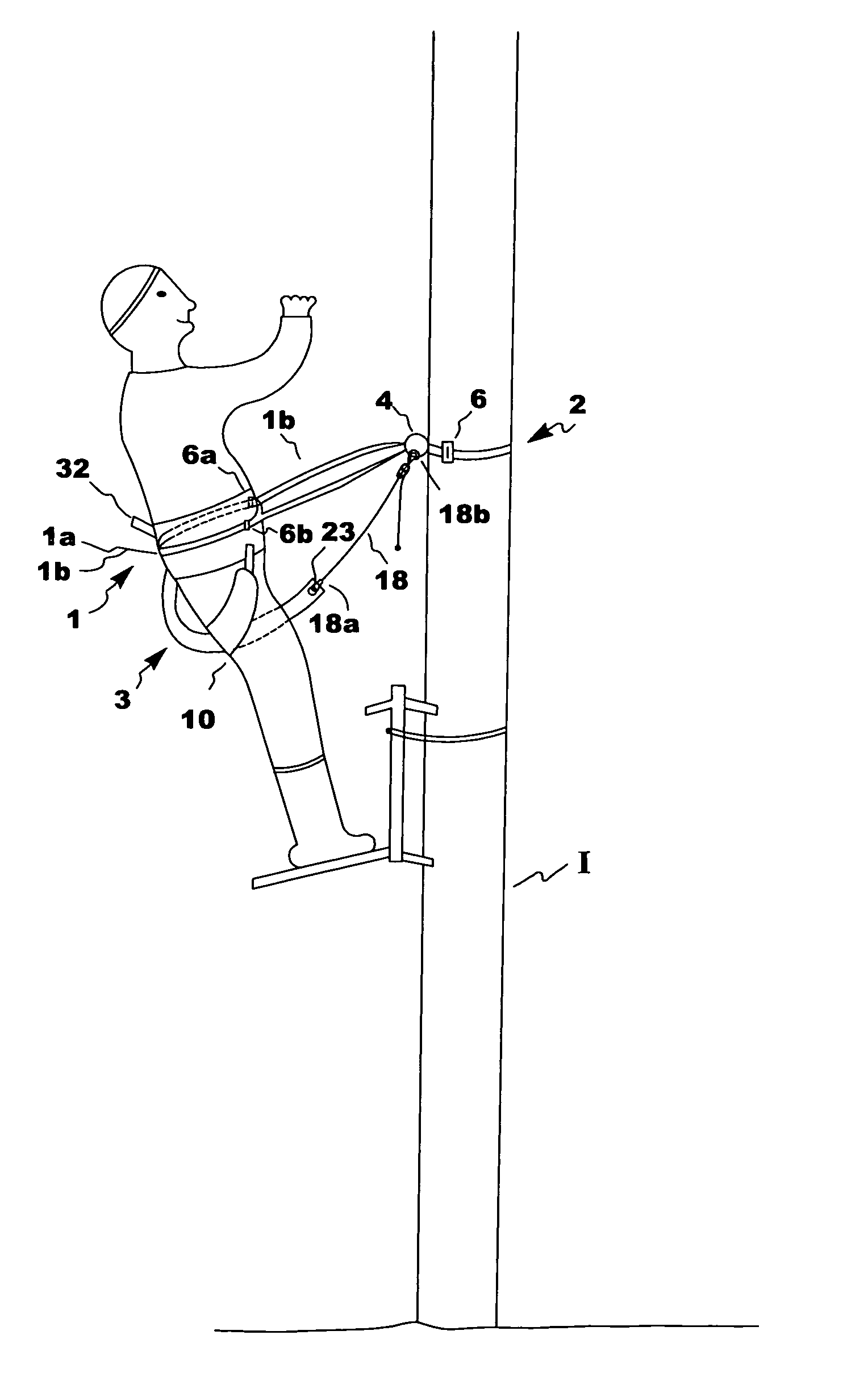

Safety harness

ActiveUS20080289903A1Smooth movementQuiet and smooth operationSafety beltsMountaineeringEngineeringBelt safety

The present invention generally relates to a safety restraint suitable for restraining the hunter to a tree in a deer stand. The safety harness of the invention comprises aiii) user member for connecting to the user,iv) an anchor member for attachment to a tree or other suitable generally vertical stand mounting member andiii) a connecting member which cooperatively connects the user and anchor members,wherein connected to said anchor member is a round and / or oval shaped ring sewn into the anchor strap material. The connecting member which is attached to the user member is connected to the D-ring or round and / or oval shaped ring attached to said anchor member.

Owner:KUHNERT BRADLEY A

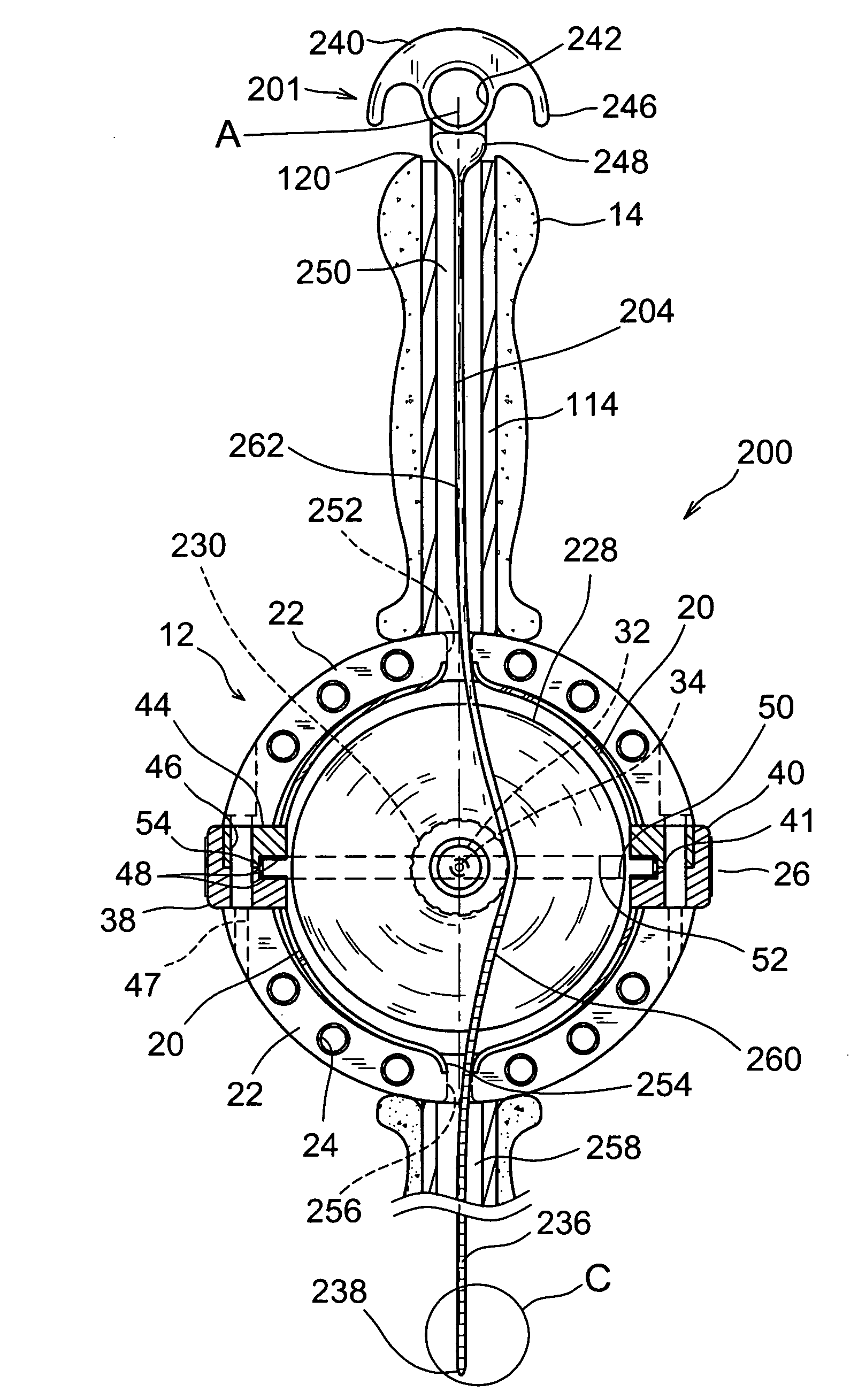

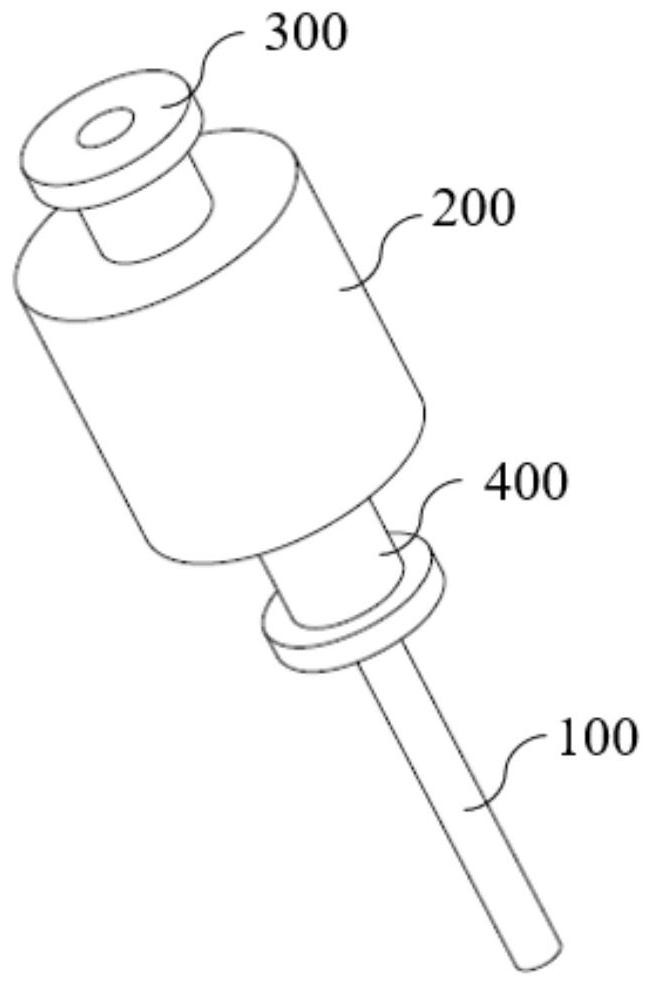

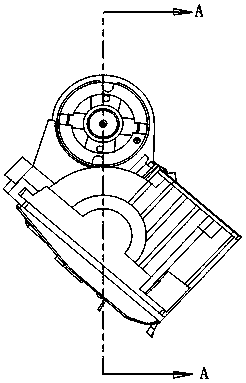

Fluid pump changeable in diameter, in particular for medical application

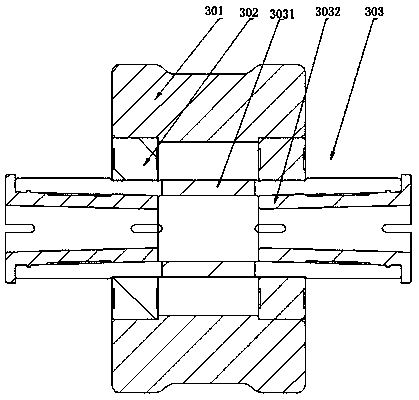

ActiveUS9512839B2Changeability of the diameterQuiet and smooth operationPump componentsBlood pumpsDrive shaftMedical treatment

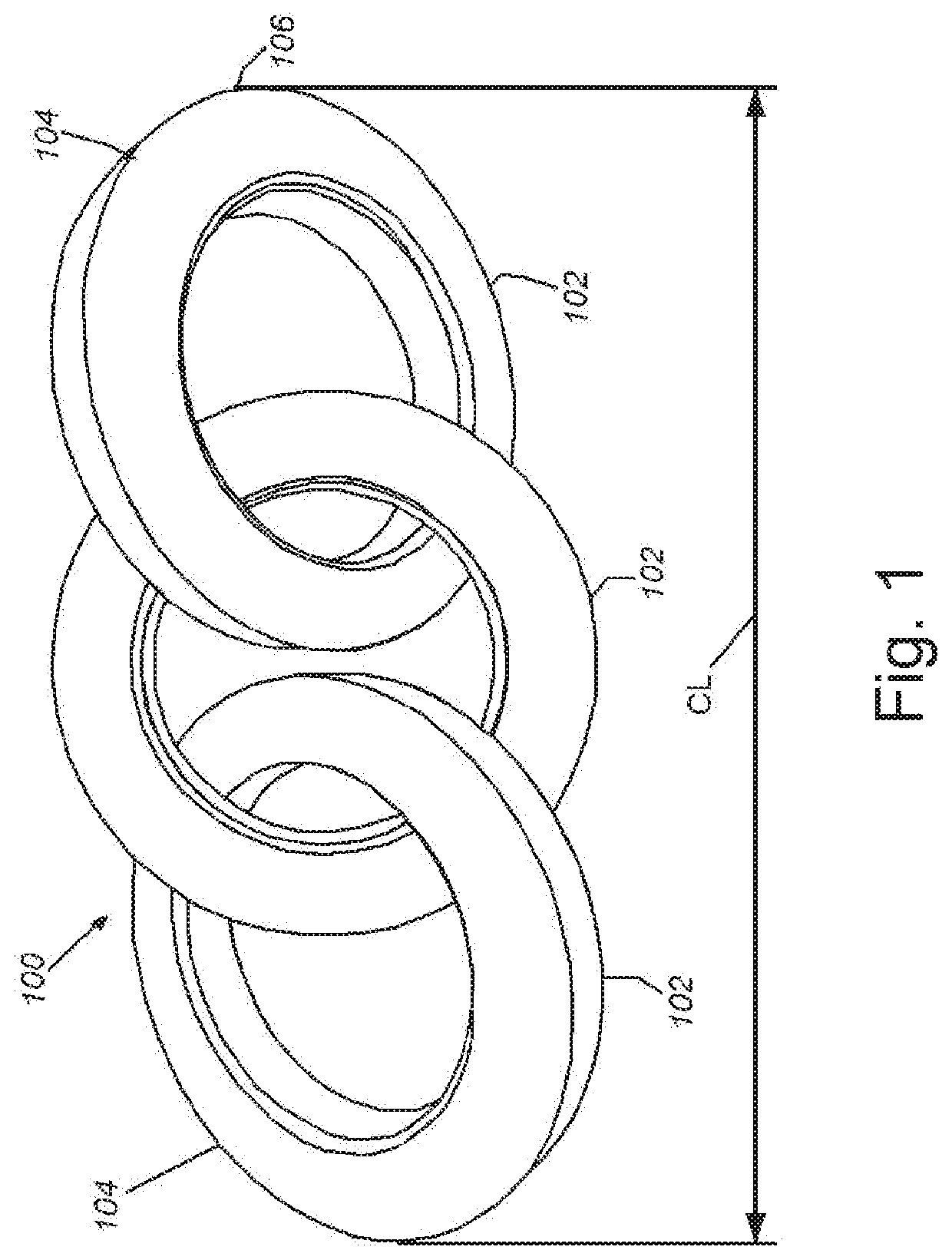

A fluid pump device changeable in diameter is provided. The device has a pump housing which is changeable in diameter and with a rotor which is changeable in diameter. The device has at least one delivery element for fluid, as well as a drive shaft on which the rotor is rotatably mounted. A bearing arrangement is arranged on the drive shaft or its extension, at the distal end of the drive shaft behind the rotor seen from the proximal end of the drive shaft. The bearing arrangement has struts, which elastically brace between a hub of the bearing arrangement and the pump housing.

Owner:ECP ENTWICKLUNGSGMBH

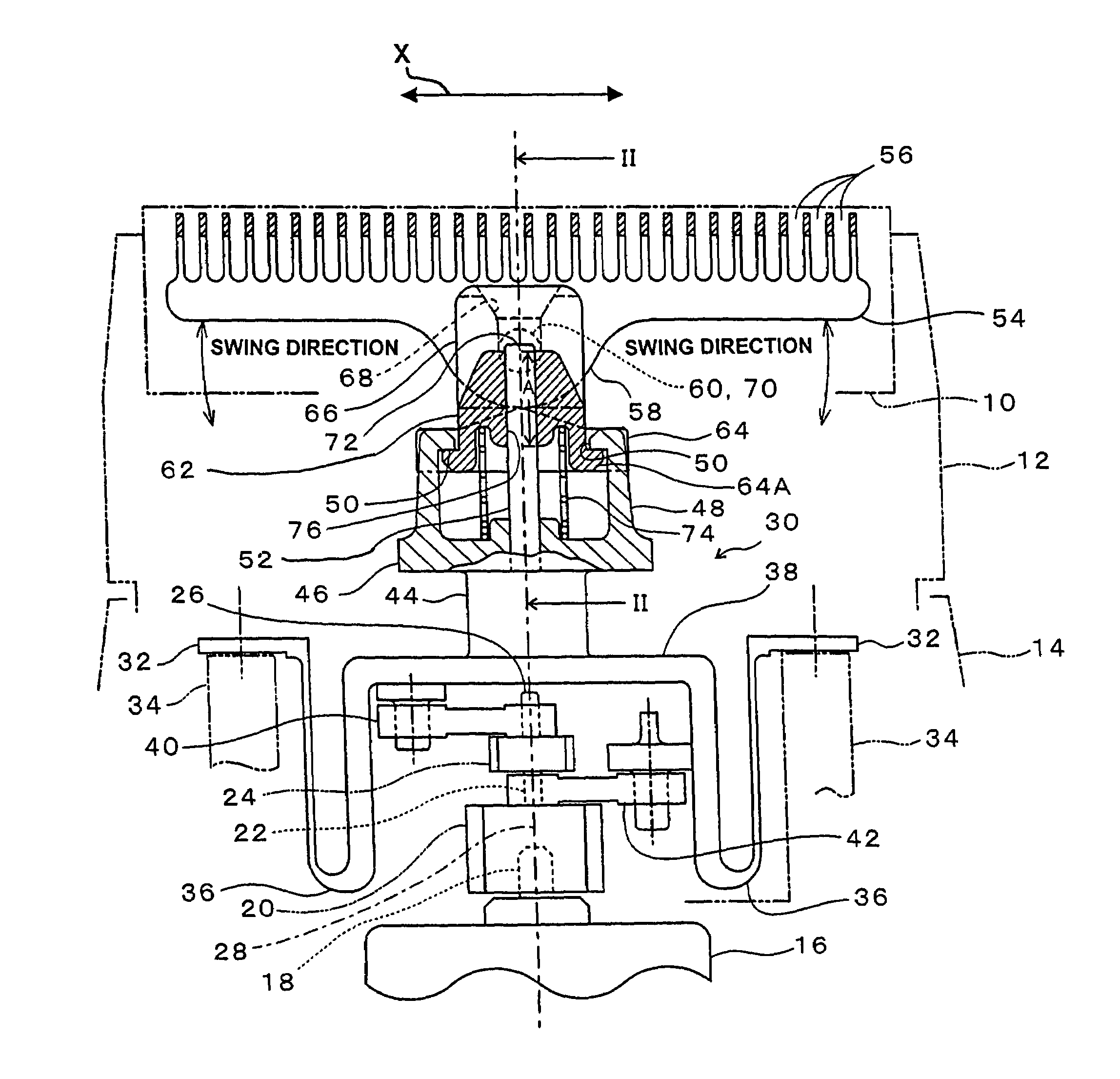

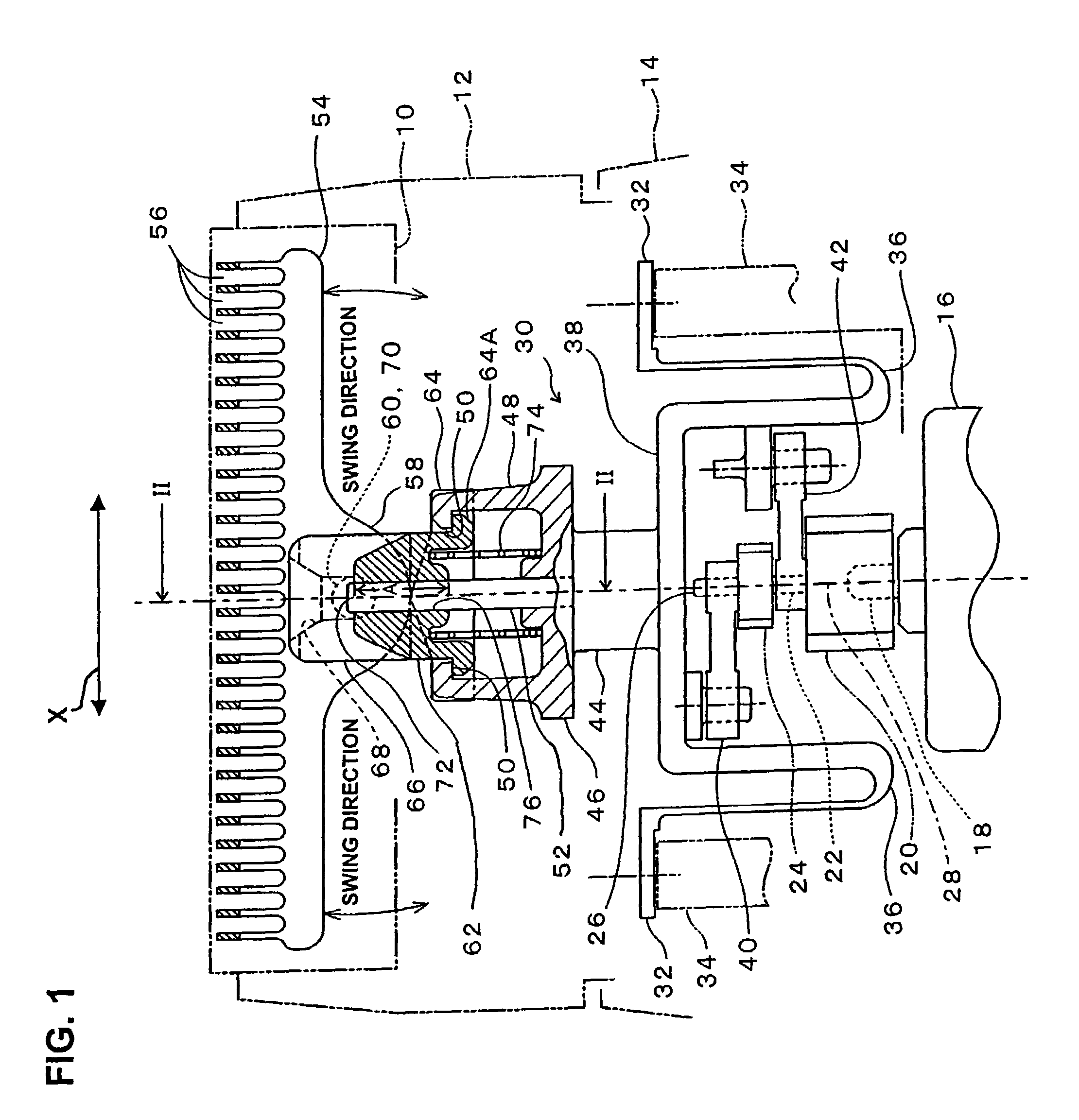

Reciprocating-type electric shaver

A reciprocating-type electric shaver including an outer cutter having an inverted U shape as seen from a side thereof and an inner cutter making a reciprocating motion while making sliding contact with an inside surface of outer cutter, and further including: an oscillator making a reciprocating motion by a motor installed inside the main body of the shaver; a central shaft provided in an upright position on the oscillator and rises toward the inside of the outer cutter; an inner cutter holder disposed in a slidable manner on the central shaft so that the inner cutter holder holds the inner cutter thereon and the inner cutter swings about a straight line that is perpendicular to the reciprocating direction of the inner cutter; and a spring compressedly installed between the oscillator and the inner cutter holder.

Owner:IZUMI PROD CO

Gyroscopic exerciser

ActiveUS7935035B2Reducing idle weightQuiet and smooth operationMuscle operated startersMachines/enginesGyroscopePrecession

Owner:SMITH TOM

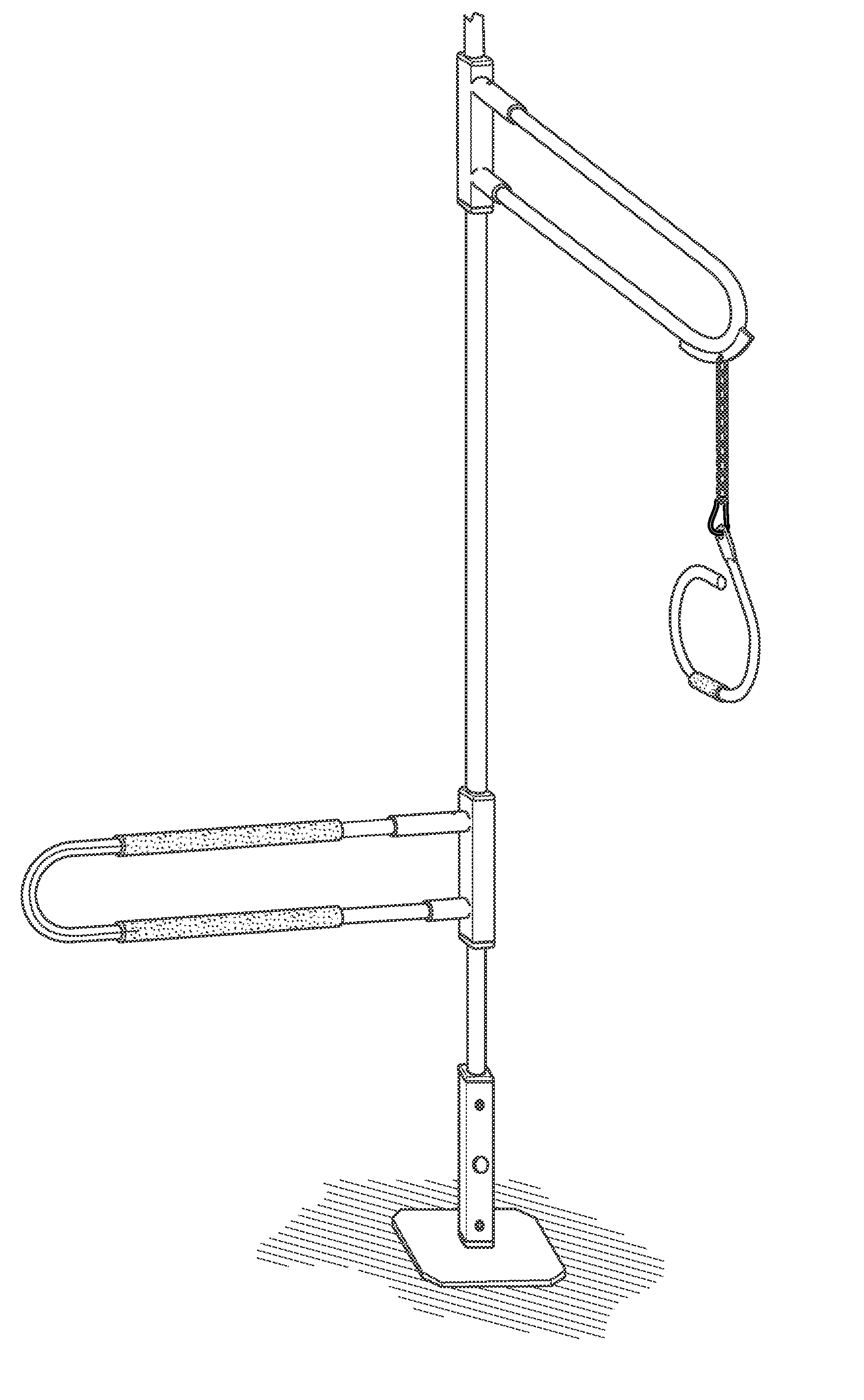

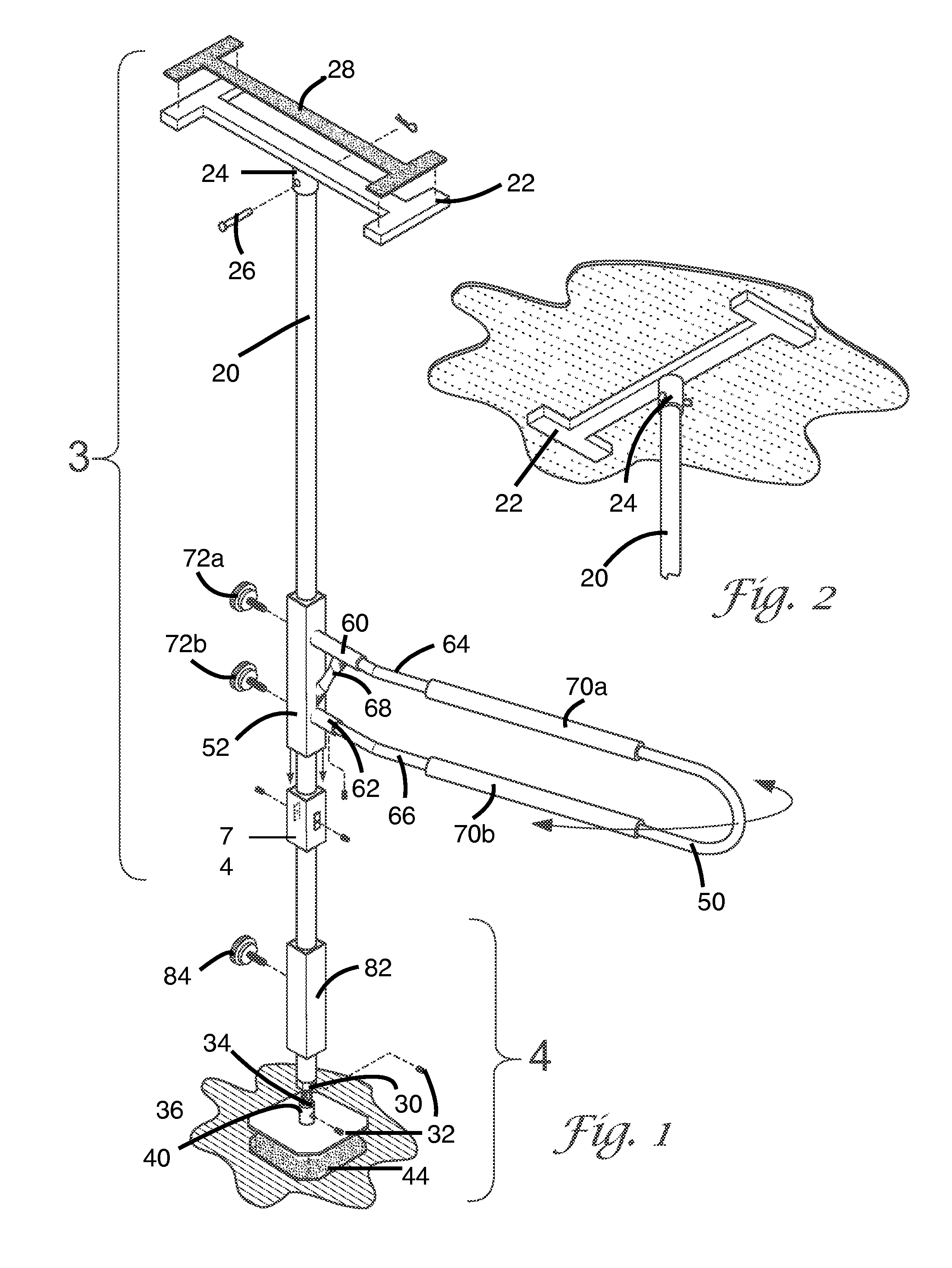

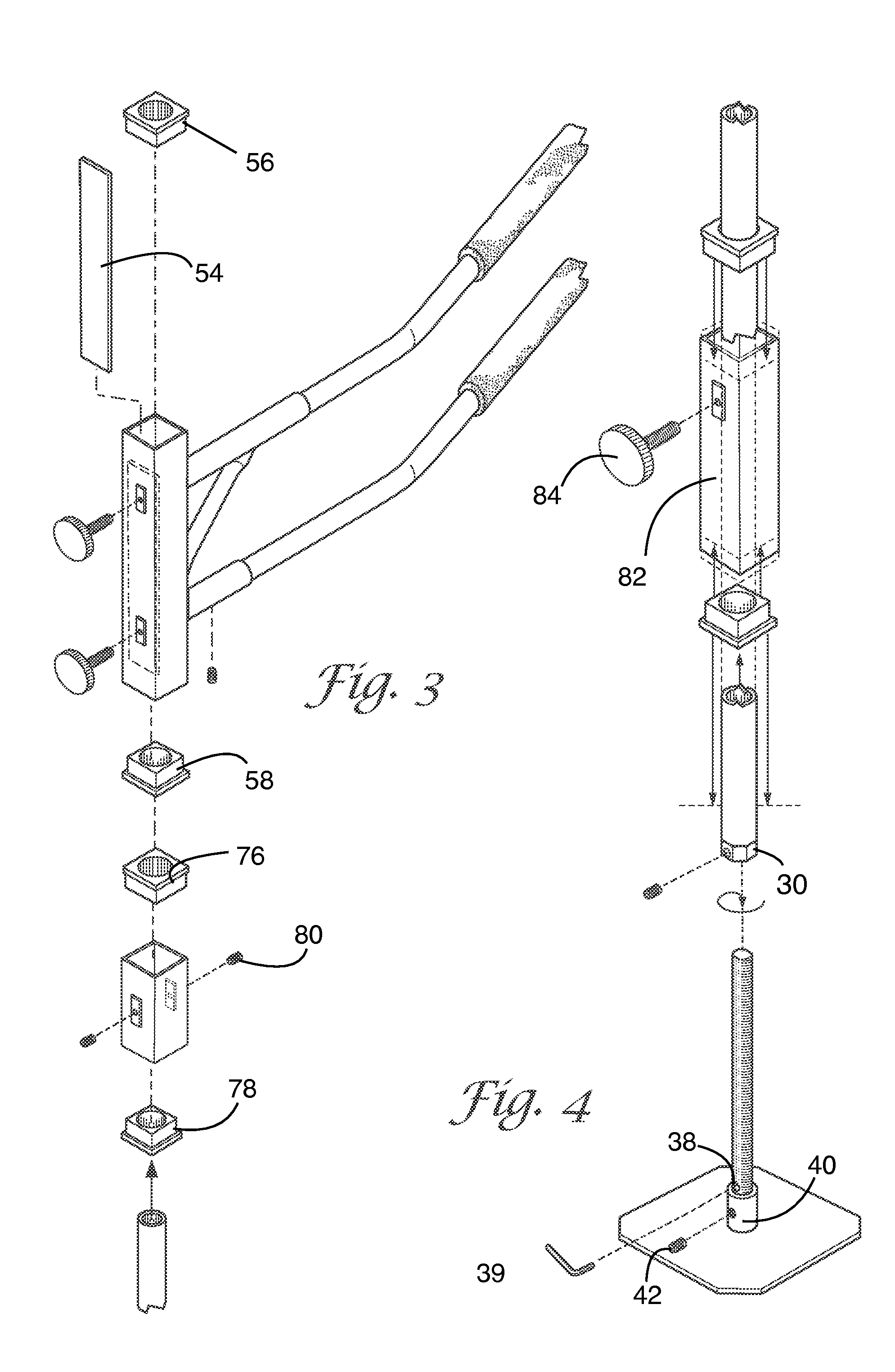

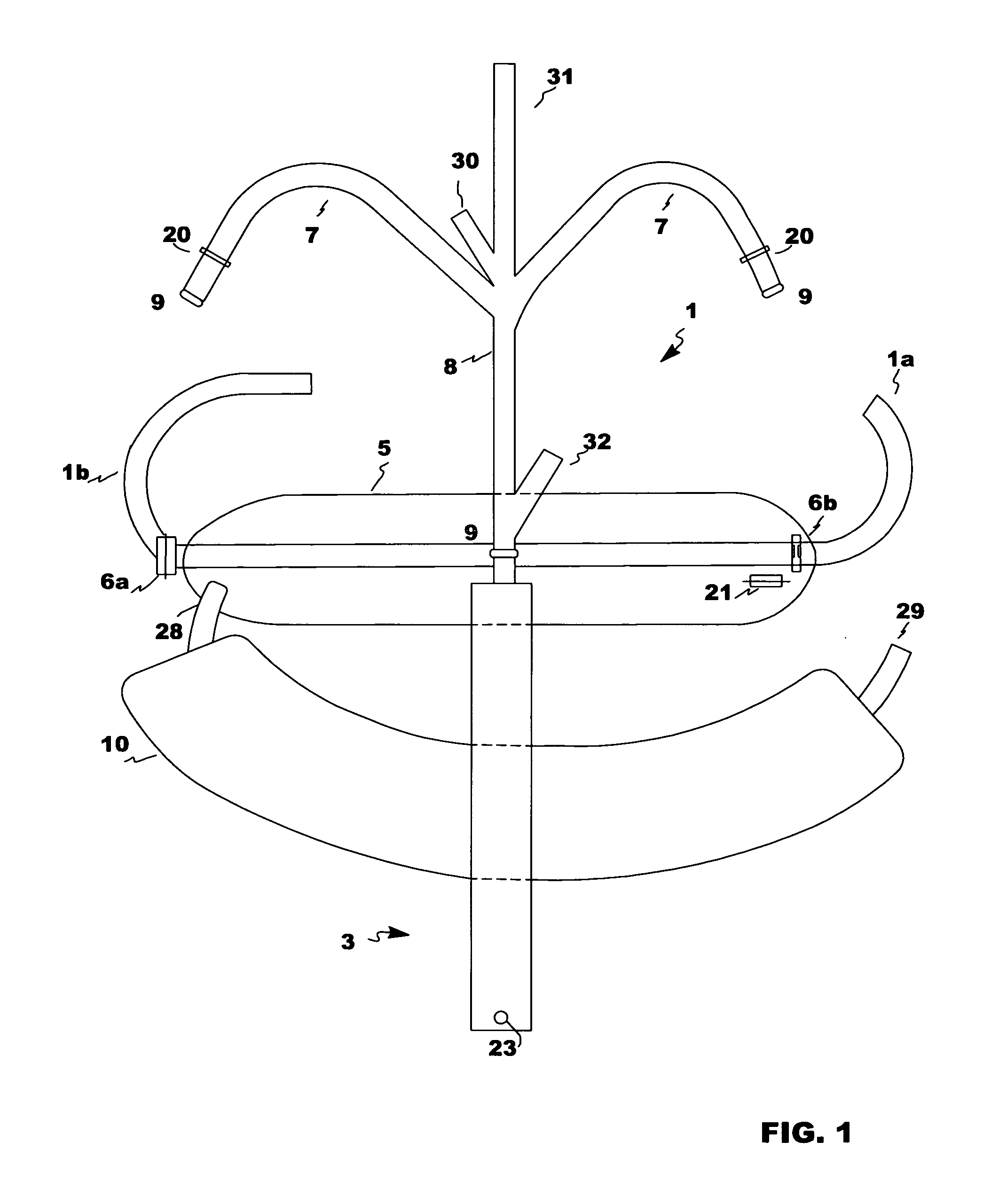

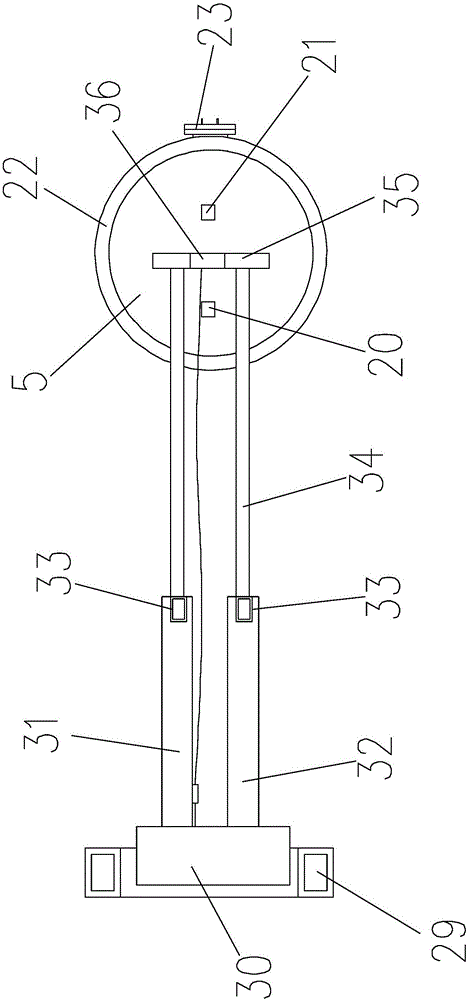

Physical Therapy and Patient Movement System

InactiveUS20160184164A1Quick disassemblyQuick installationWalking aidsNursing bedsEngineeringMovement system

A physical therapy and physical assist apparatus and system includes a vertical support pole with mount for ceiling and floor. A shaft in combination with the pole is used to adjust the height of the pole to fit the distance between ceiling and floor and mount the apparatus. At least one handle is attached to the vertical pole and via a rotating head and brake assembly. The brake assembly includes a brake pad for adjustment of resistance on a walk-around arrangement thereof. The handle includes a 25 degree kick out in the walk-around arrangement of the apparatus.

Owner:BROWNING JOHNNY C

Gyroscopic total exerciser

ActiveUS7563210B2Reducing idle weightQuiet and smooth operationMechanical apparatusMuscle exercising devicesGyroscopePrecession

A gyroscopic exercise device has a pair of handles attached to a housing. A user holds and rotates the handles along cone-like paths causing precession of a rotor, which is rotating about its spin axis, to provide resistance to the user. The device has an axle disc that holds ends of an axle of the rotor. The periphery of the axle disc and the ends of the rotor axle are within a circular race in the housing. A motor attached to the axle disc has a wheel for rotating the rotor about a spin axis by a temporary supply of power from included batteries in one of the handles. The batteries are in between two opposite springs in one of the handles and normally biased away from an electrical contact until the user pushes them through an end pin to overcome the bias.

Owner:SMITH TOM

Safety harness

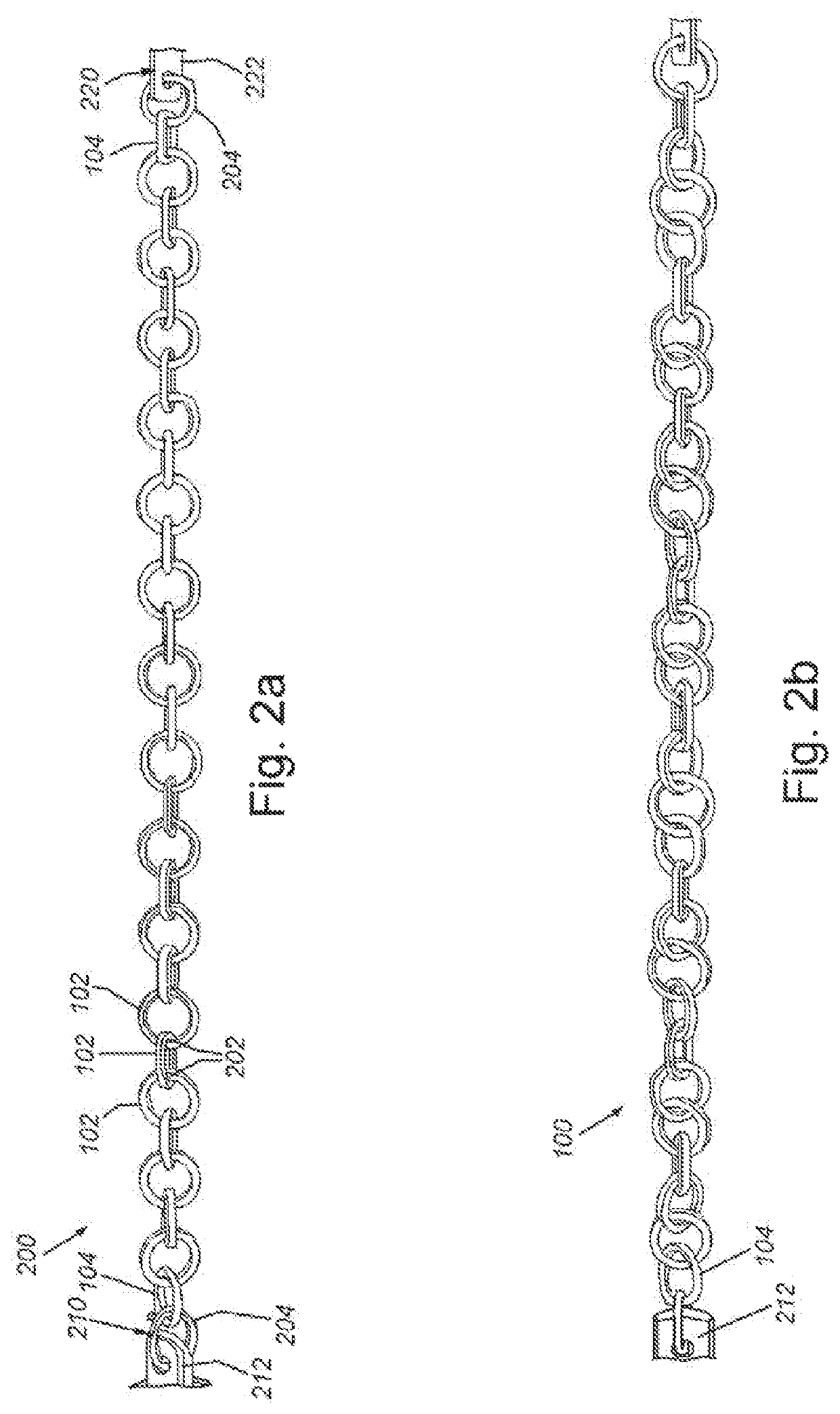

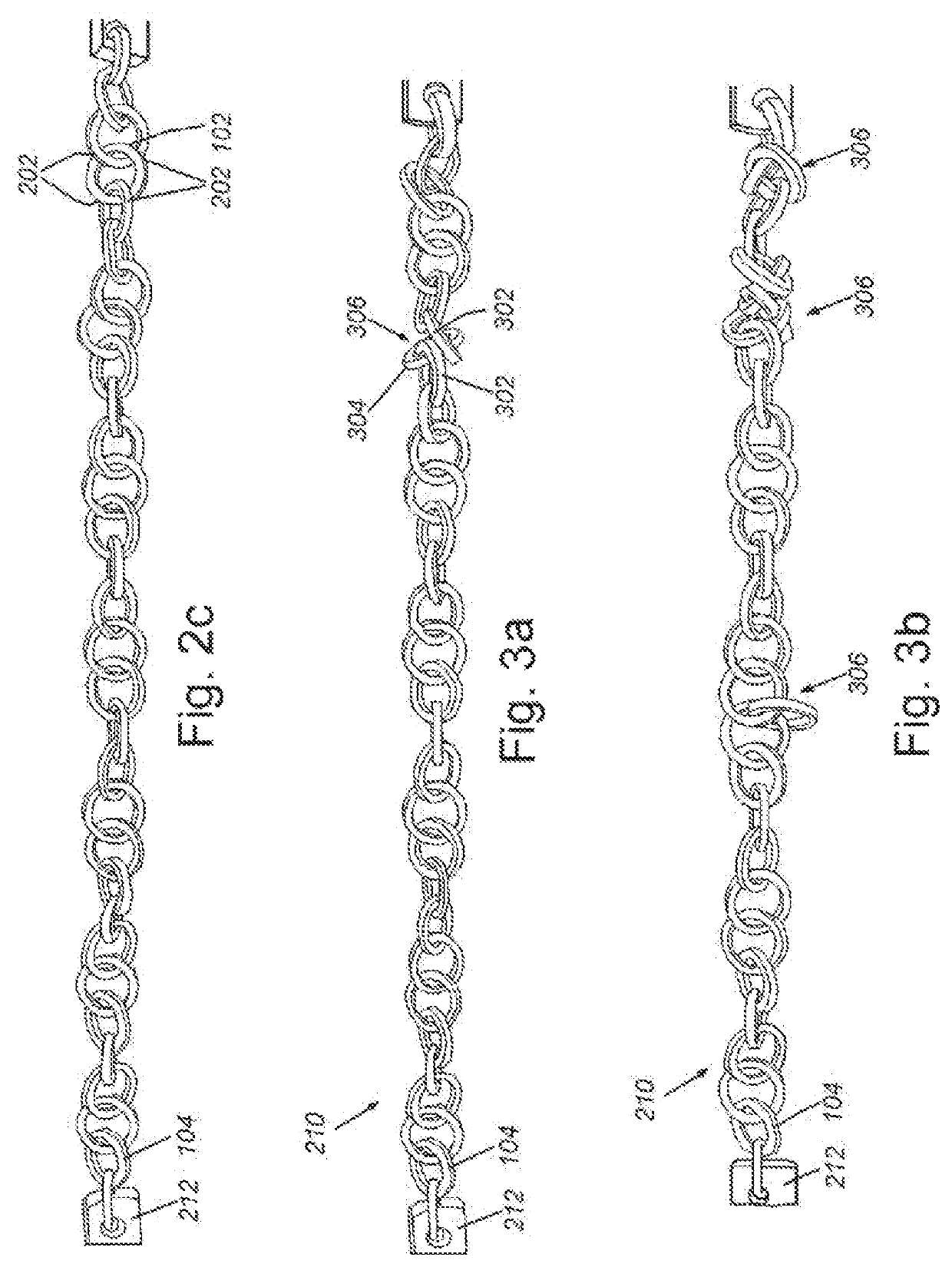

ActiveUS9162091B2Smooth movementQuiet and smooth operationSafety beltsMountaineeringEngineeringMechanical engineering

The present invention generally relates to a safety restraint suitable for restraining the hunter to a tree in a deer stand. The safety harness of the invention comprises aiii) user member for connecting to the user,iv) an anchor member for attachment to a tree or other suitable generally vertical stand mounting member andiii) a connecting member which cooperatively connects the user and anchor members,wherein connected to said anchor member is a round and / or oval shaped ring sewn into the anchor strap material. The connecting member which is attached to the user member is connected to the D-ring or round and / or oval shaped ring attached to said anchor member.

Owner:KUHNERT BRADLEY A

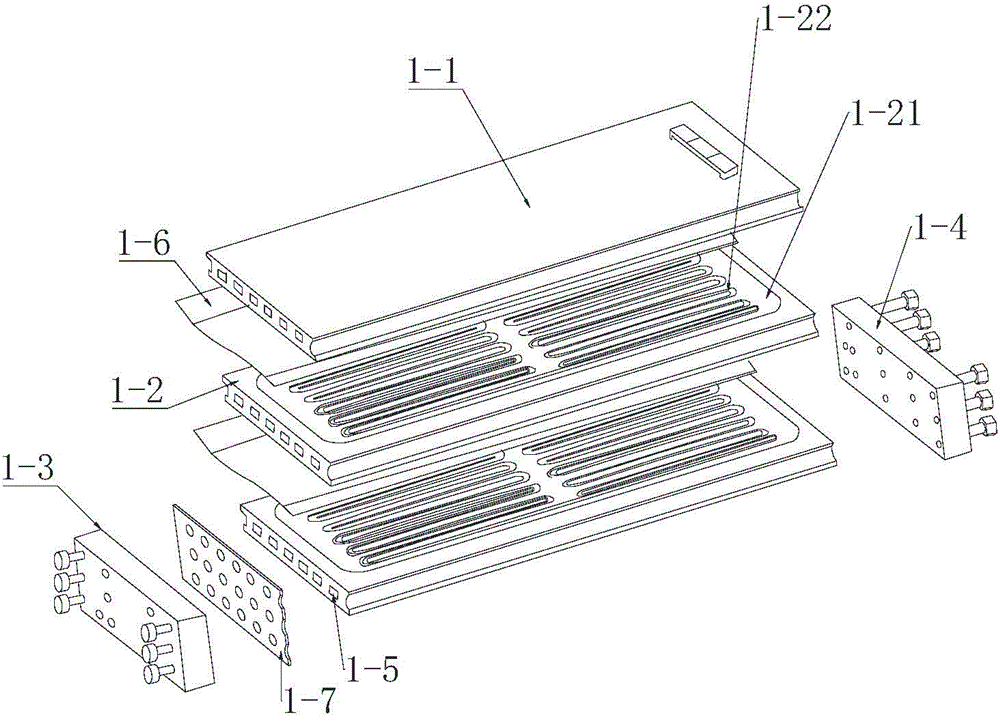

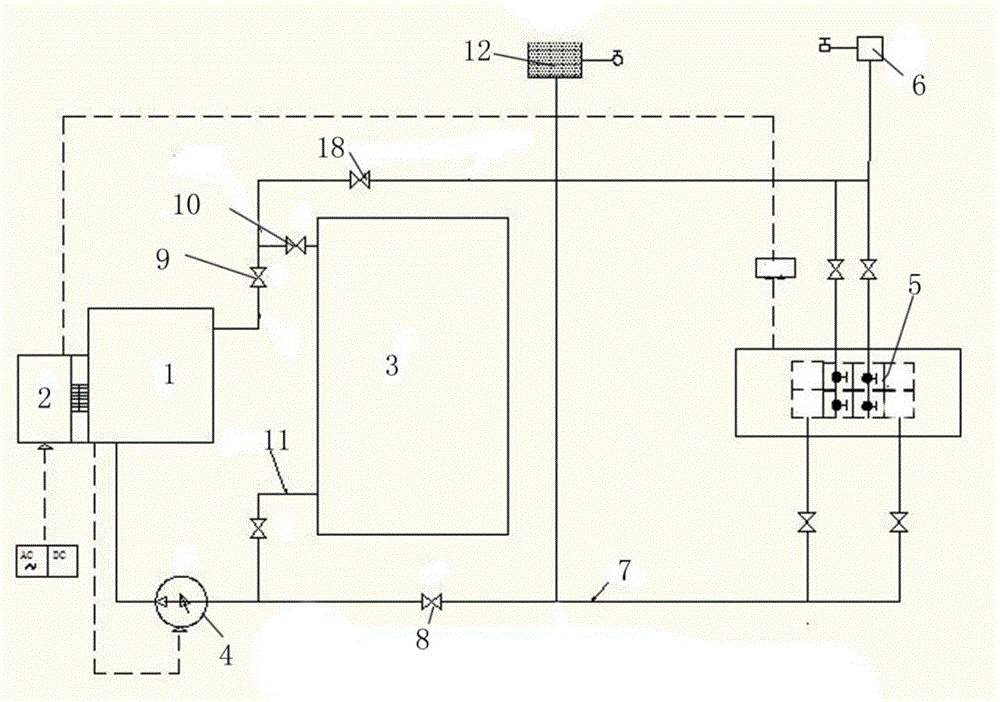

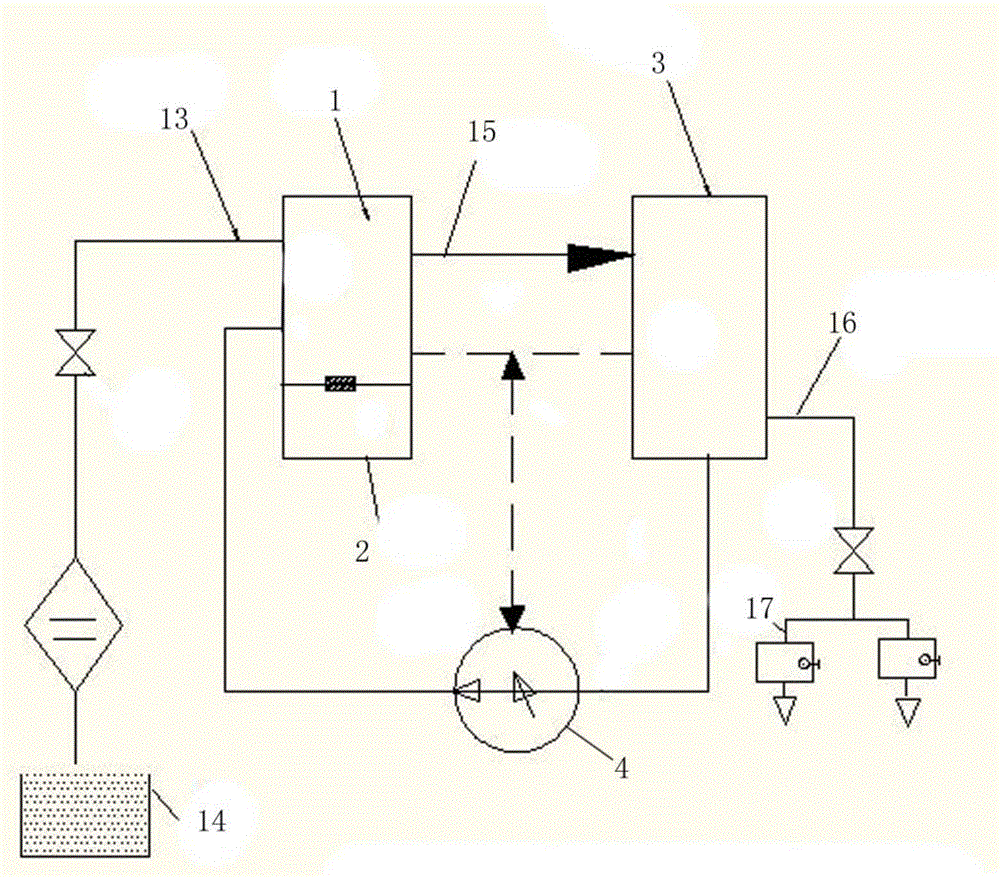

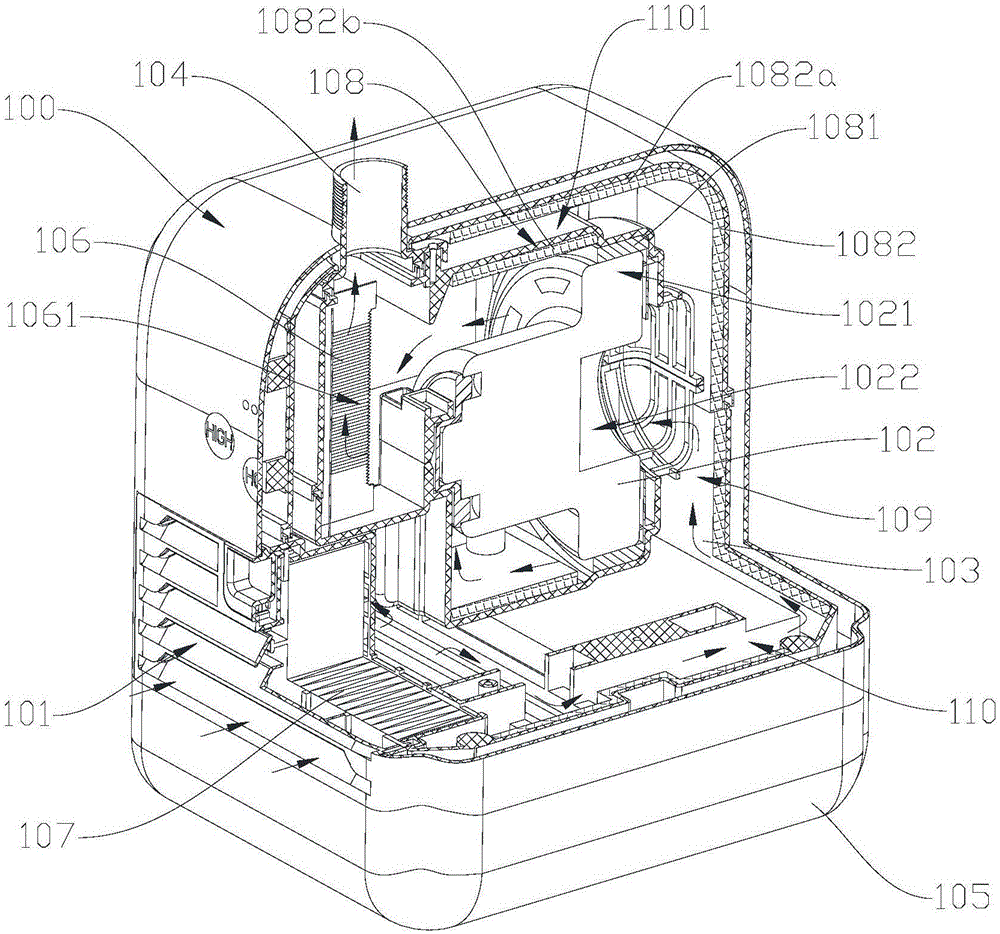

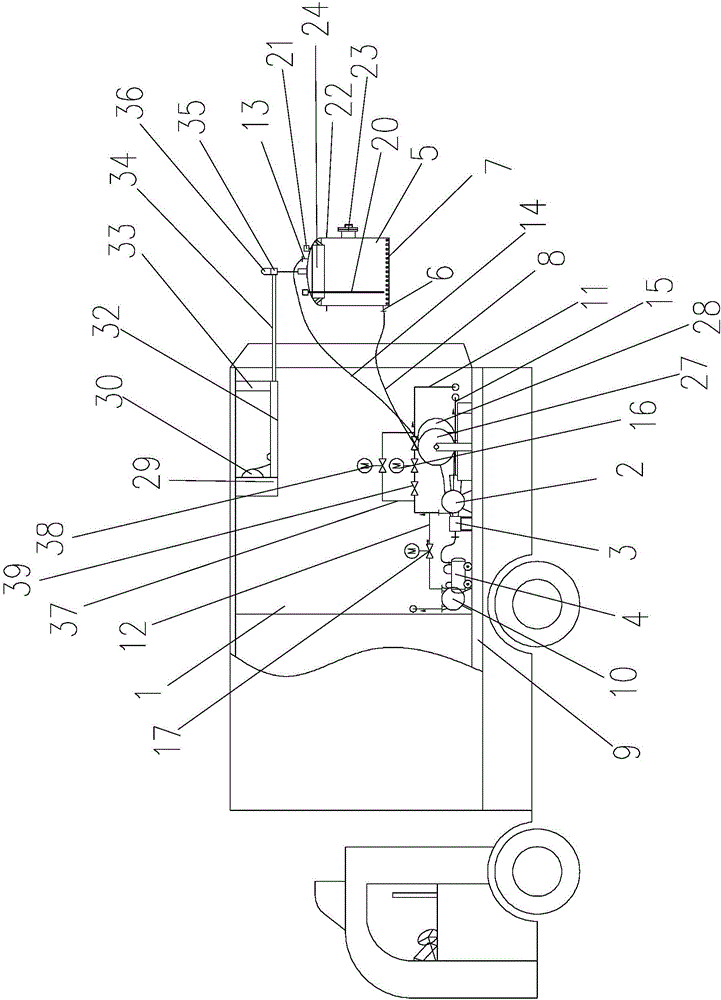

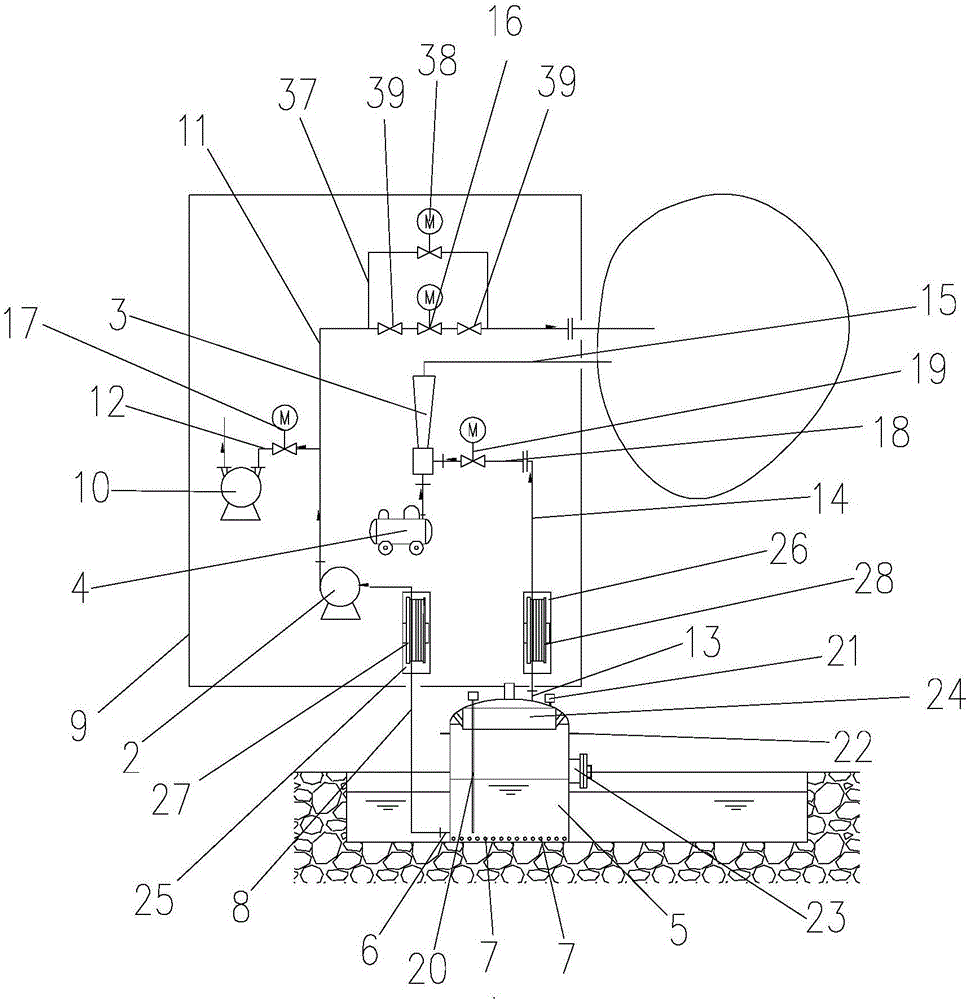

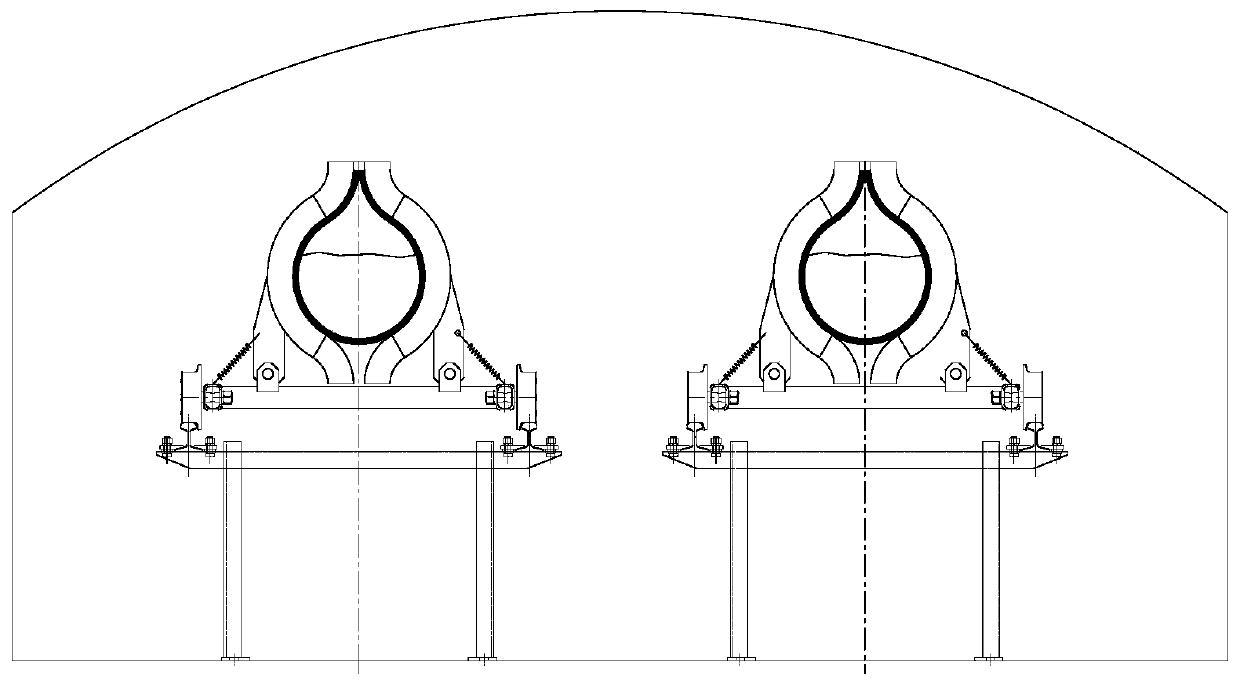

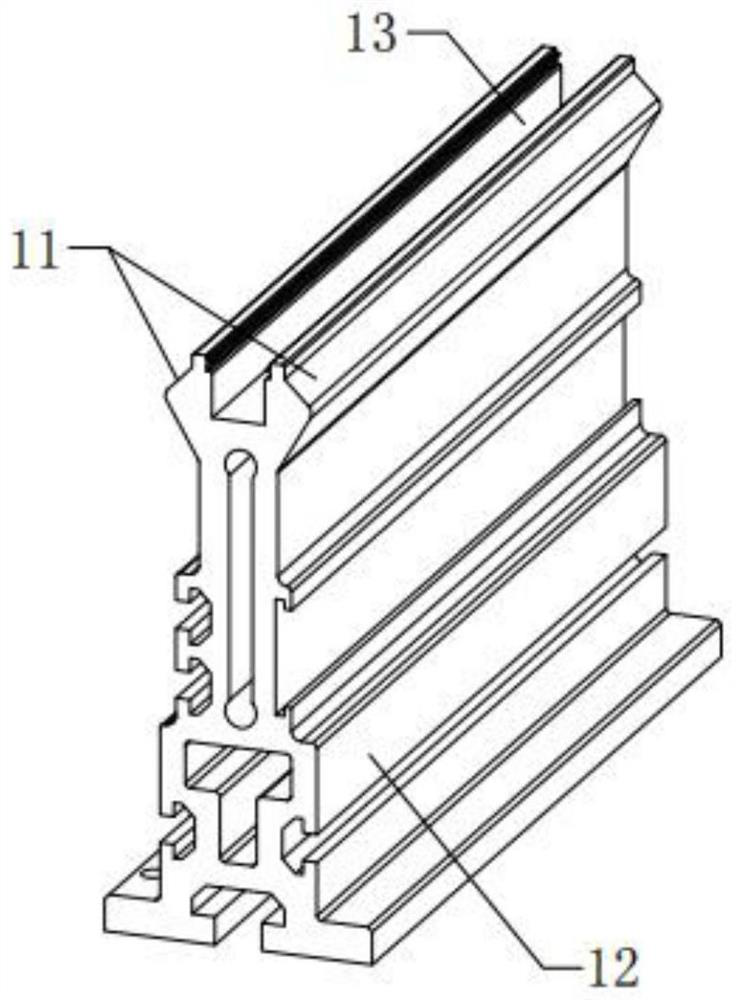

Modularized combined intelligent heat collector system

ActiveCN104832967AImprove thermoelectric conversion efficiencyReduce manufacturing costWaste gas energySpace heating and ventilation detailsCollector deviceEngineering

The invention discloses a modularized combined intelligent heat collector system, which is characterized in that the system comprises a PTCR-xthm electric heating chip heat source host, a data control template, a constant-temperature and constant-pressure device and a variable frequency pump, wherein the variable frequency pump and the PTCR-xthm electric heating chip heat source host are connected with the data control template; the outlet end of the PTCR-xthm electric heating chip heat source host is connected with the constant-temperature and constant-pressure device; the outlet end of the constant-temperature and constant-pressure device is connected with the PTCR-xthm electric heating chip heat source host through the variable frequency pump; the PTCR-xthm electric heating chip heat source host directly leads out a user heating pipeline; and / or the PTCR-xthm electric heating chip heat source host leads out the user heating pipeline through the constant-temperature and constant-pressure device, and a heat exchanger connected with a user water heater. Source water is heated to a set temperature when passing through the PTCR-xthm electric heating chip heat source module once a machine is started, and waiting is not needed. The water temperature can be adjusted and controlled within 100 DEG C, the saturation temperature can be adjusted and controlled within 180 DEG C, and the device also has the advantages of general structure, zero pollution, zero emission, high efficiency, energy saving, safety, reliability, high cost performance, small size, low cost and intelligent control.

Owner:GUANGDONGSHENG YUCHEN ELECTRONICS & TECH CO LTD

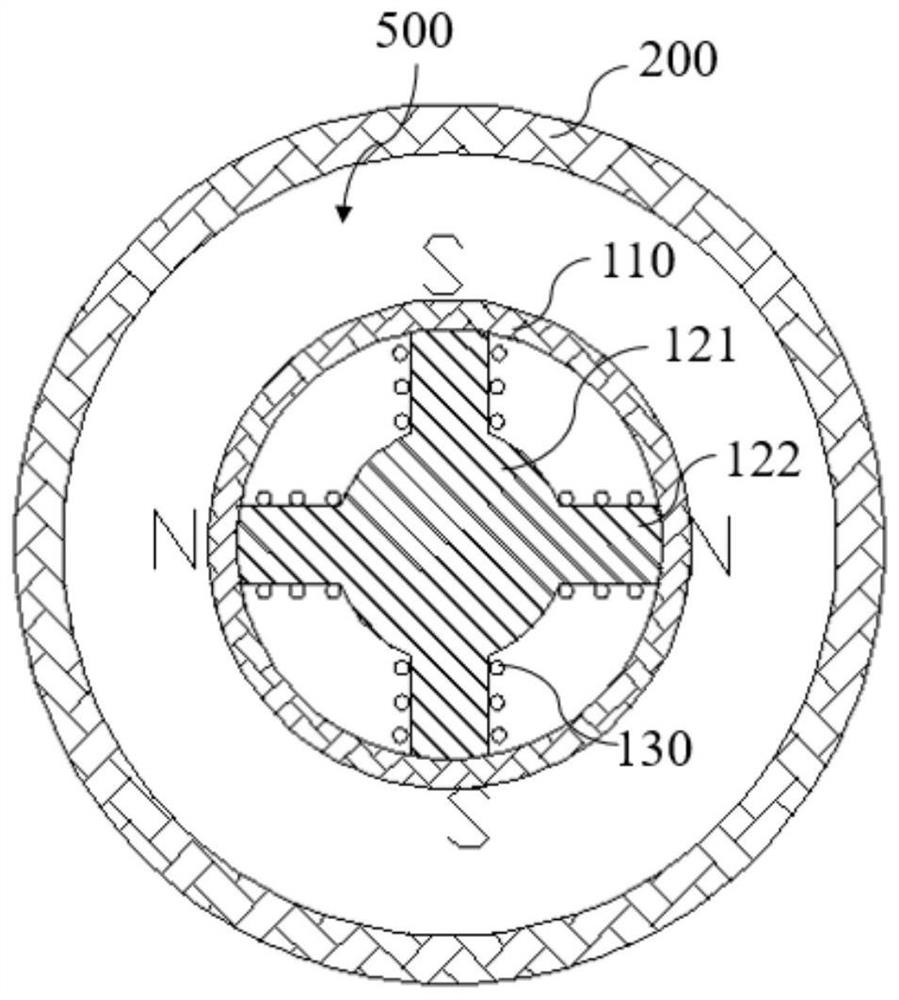

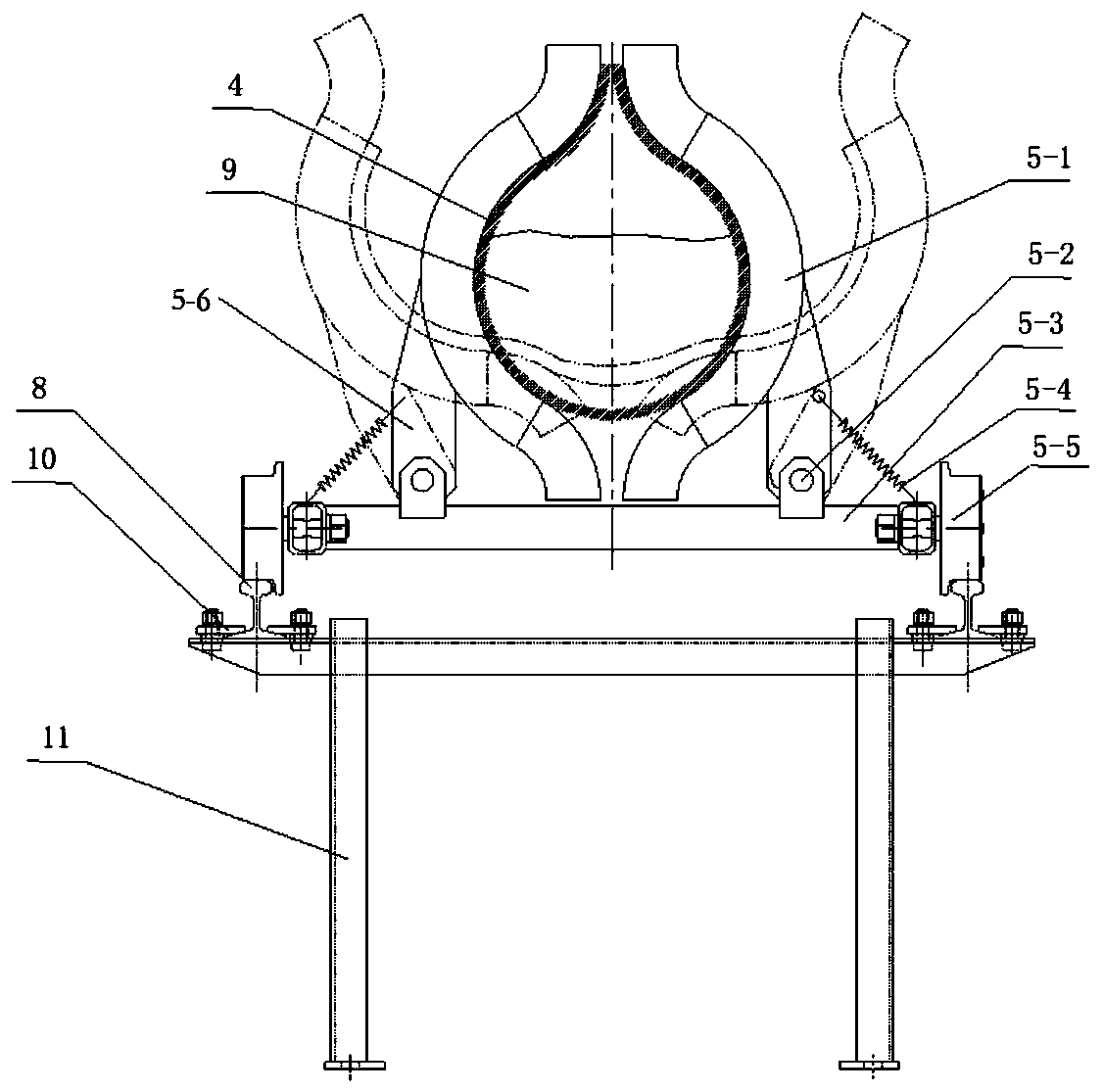

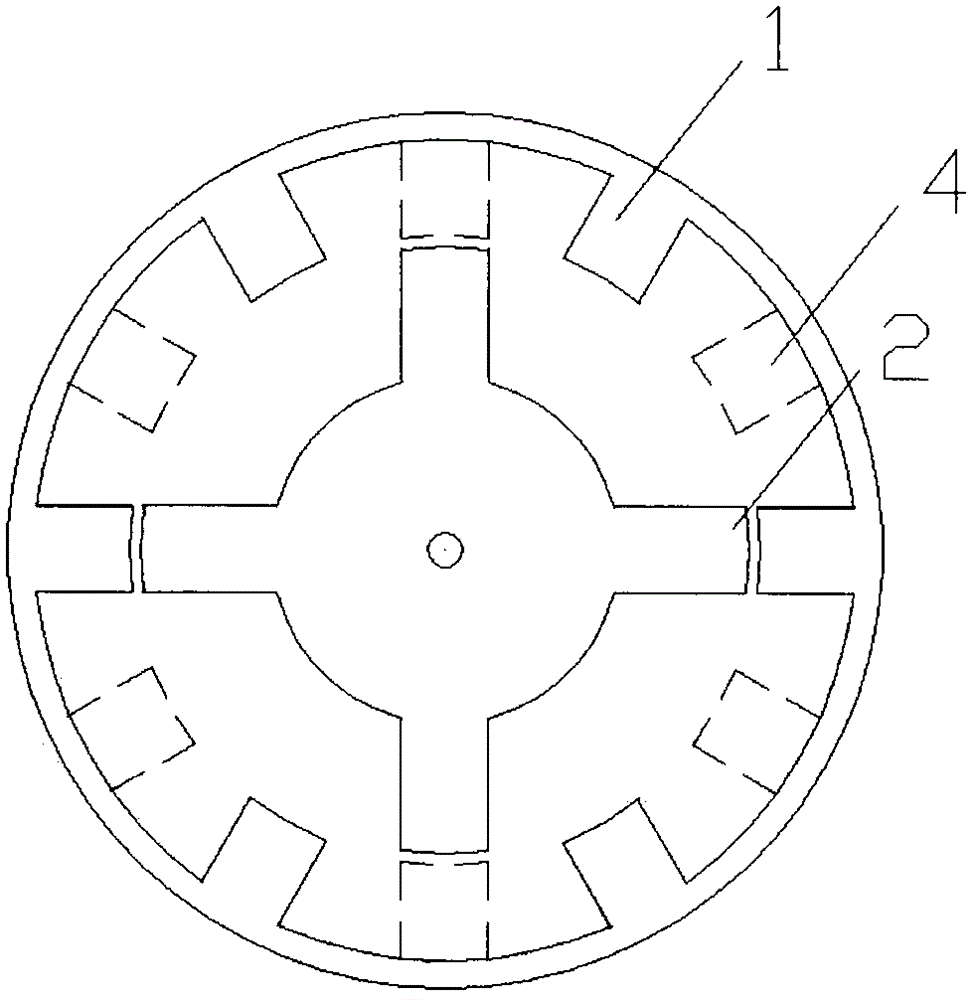

Anisotropic inner circle orientation multi-pole magnetic ring and mold and preparation method thereof

InactiveCN112086259ANo flux leakageQuiet and smooth operationPermanent magnetsInductances/transformers/magnets manufactureCopper wireElectric machinery

The invention discloses an anisotropic inner circle orientation multi-pole magnetic ring and a mold and a preparation method thereof, and belongs to the field of magnetic ring manufacturing. The multi-pole magnetic ring is an anisotropic 2n-pole magnetic ring with an oriented inner circle, n is a natural number, and the waveform of a magnetic circuit on the surface of the inner circle of the magnetic ring is a sinusoidal waveform; the mold comprises a core rod, an outer cylinder, an upper pressing head and a lower pressing head, and the core rod, the upper pressing head, the lower pressing head and the outer cylinder are matched and sleeved to form a mold cavity. The core rod comprises a sleeve and a magnet yoke, the magnet yoke comprises a base body and protruding parts, 2n protruding parts are distributed on the side face of the end, stretching into the upper pressing head, of the base body in the circumferential direction, copper wires are wound around the protruding parts respectively, and the protruding parts are sleeved with the sleeve in a matched mode. The preparation method comprises the following steps of: filling magnetic powder into the mold cavity, pressing the magnetic powder, electrifying a copper wire, applying a direct-current or pulsed magnetic field to the magnetic powder, orienting the magnetic powder, sintering, grinding and magnetizing to obtain the anisotropic inner circle orientation multi-pole magnetic ring. The multi-pole magnetic ring is directly manufactured into an integral stator magnetic ring, and stable and quiet operation of a motor is facilitated.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD +1

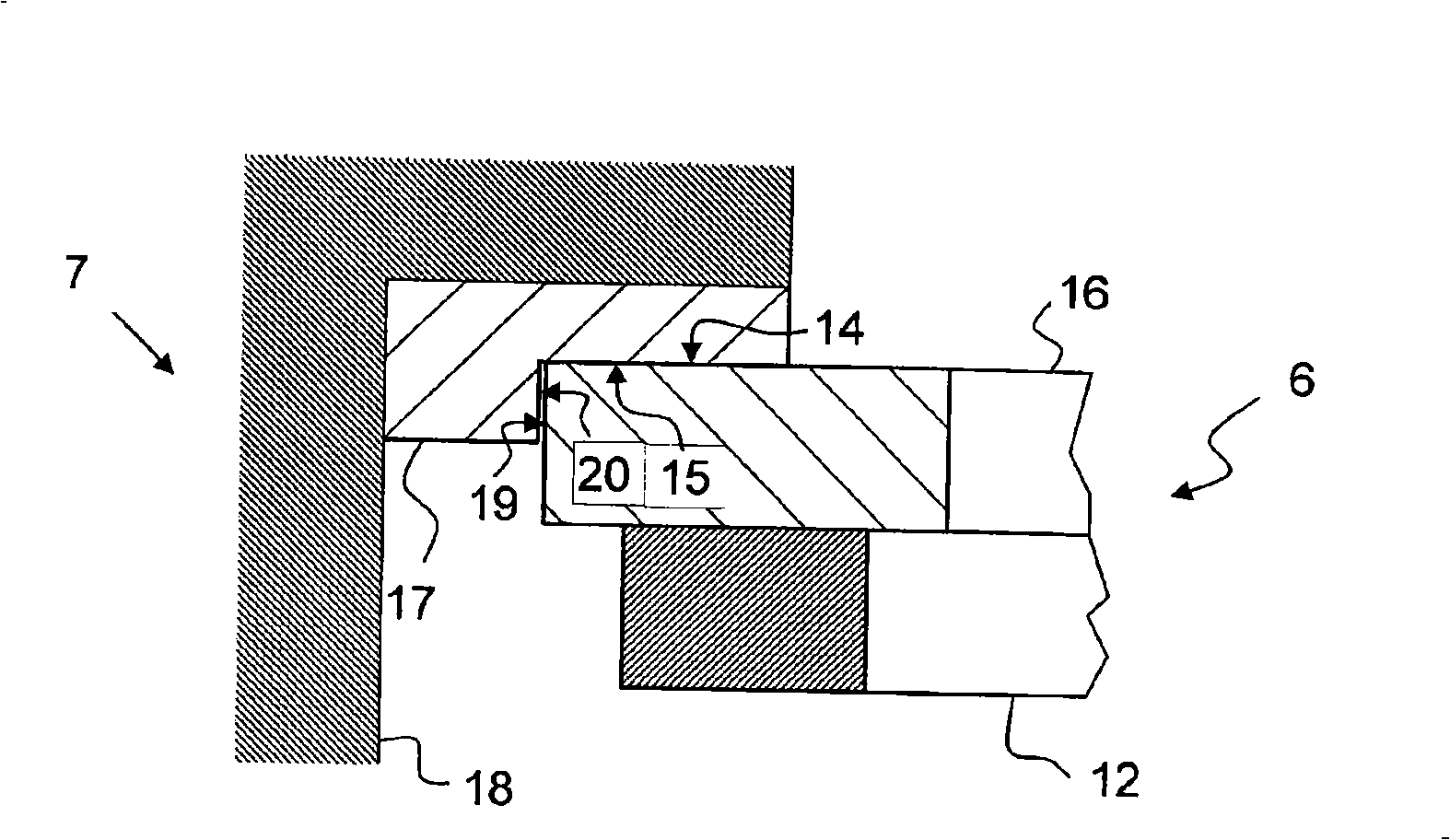

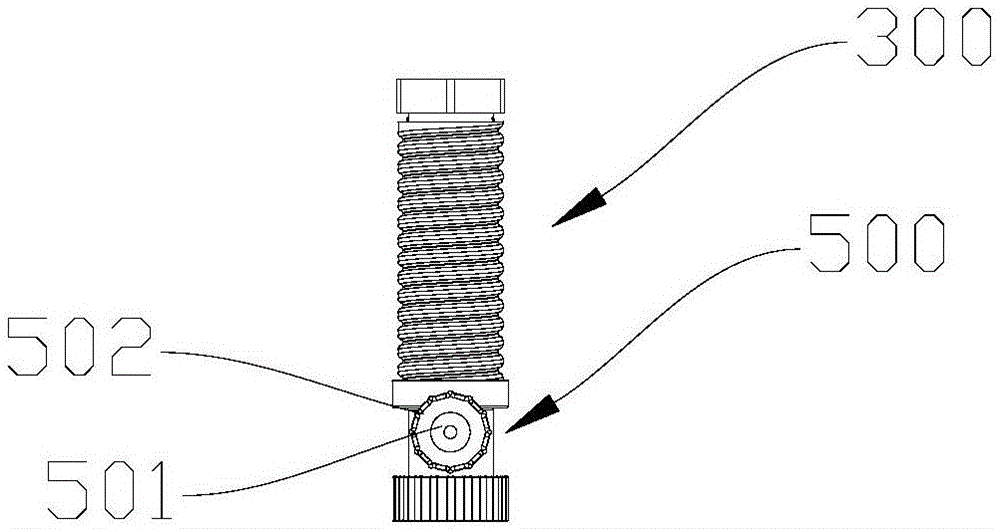

Device and thread guiding ring for a ring spinning machine or twisting machine

The invention relates to a device for ring spinning or twisting machine which is provided with a guide eye (6) the guide parts (5, 5') of which are used for twisting and veer silking (F), and a holding unit (7), the guide eye (6) is arranged on the holding unit (7) and rotates with a given spin axis (A), wherein force generating devices (12, 13; 12', 13'; 28) are used between the axial force (AK) to the guide eye (6), when the device is operated by continuous acting of the force generating devices, a first sliding section (14) formed on the guide eye (6) is bunted on a second sliding section (15)formed on the holding unit (7), thereby providing axial support to the guide eye (6) in that way. The invention also relates to the ring spinning or twisting machine and the guide eye thereof.

Owner:斯图加特德国纺织、纤维研究所

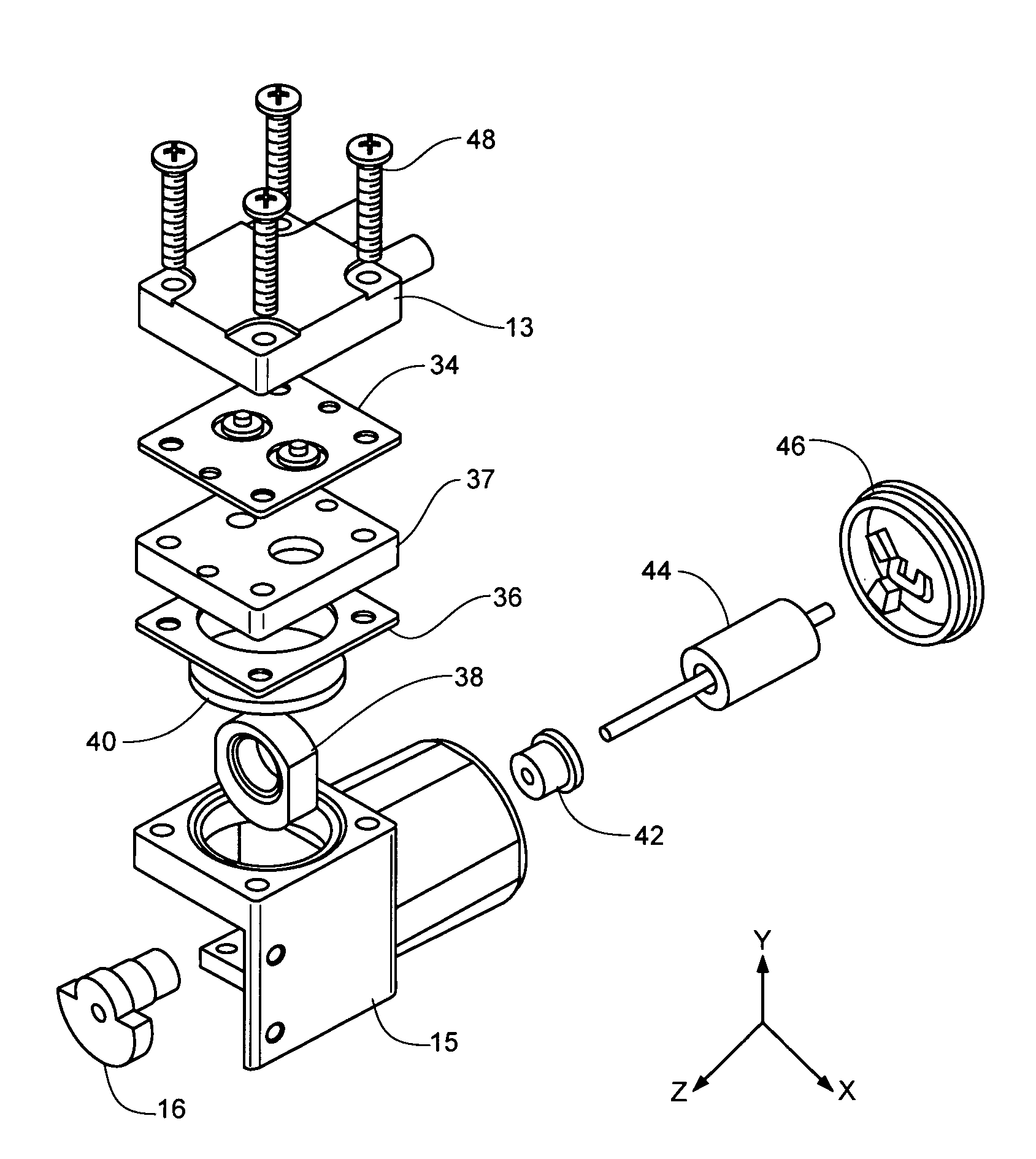

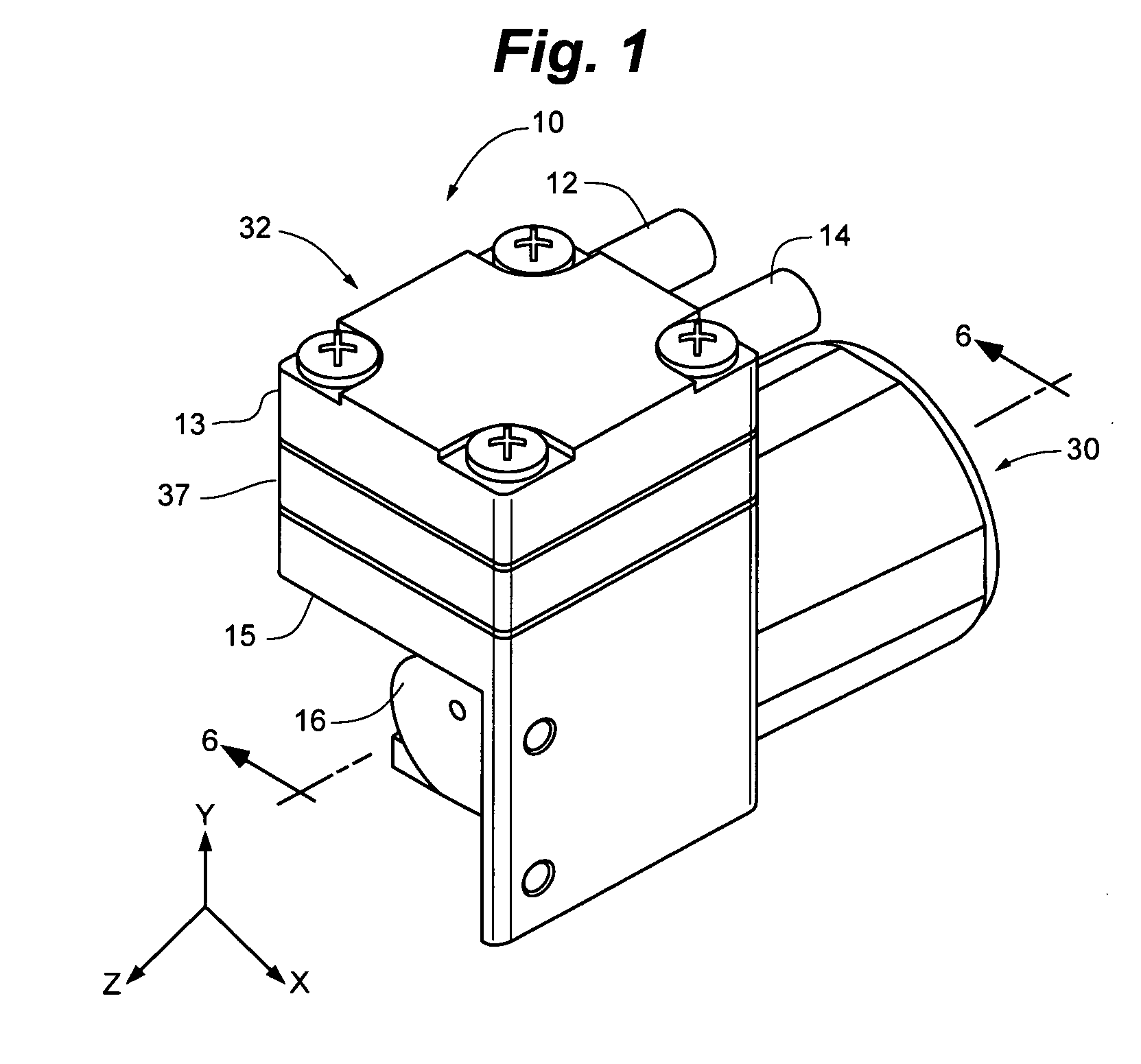

Integrated pump and motor

InactiveUS20080260556A1Simplify the motor structureReduce the number of partsFlexible member pumpsPiston pumpsElectric machineMedical device

Owner:HOFFMAN LESLIE +1

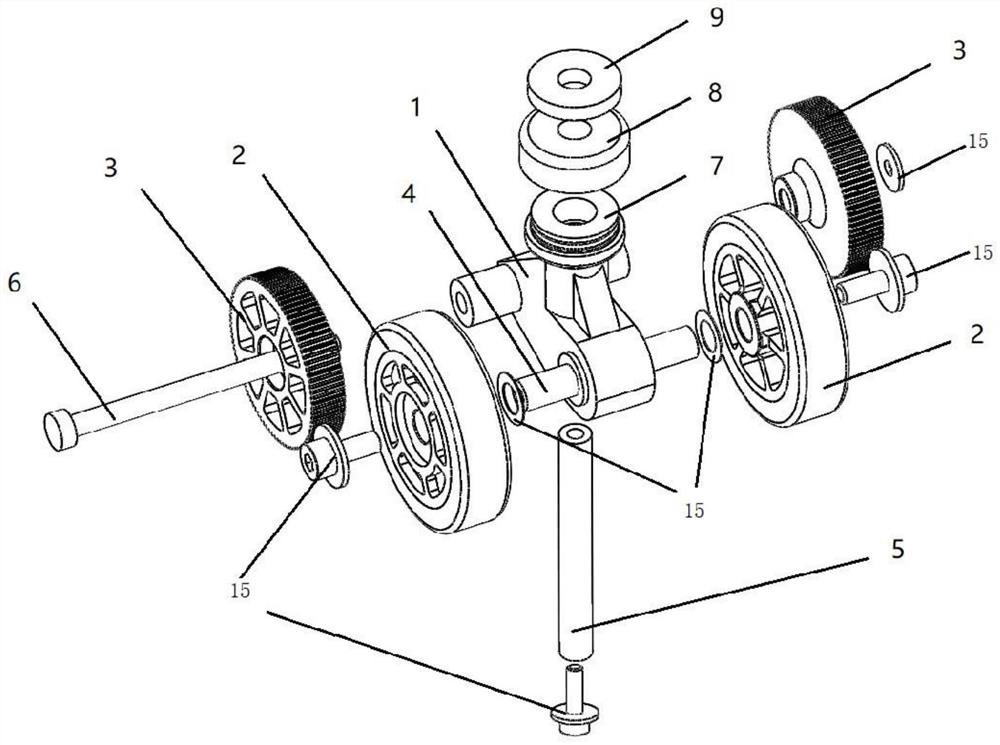

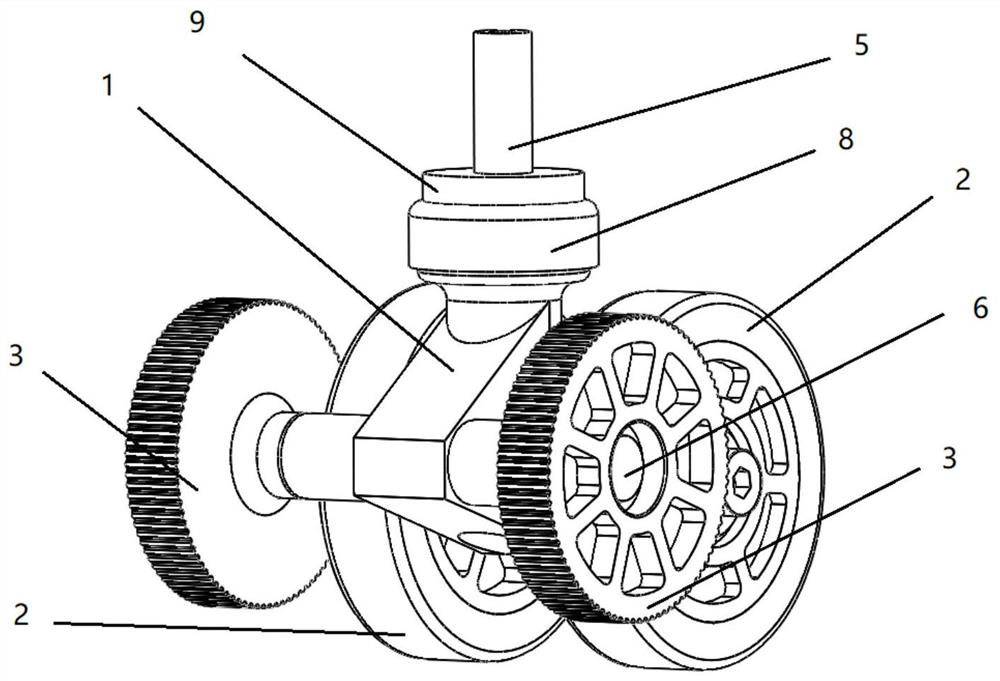

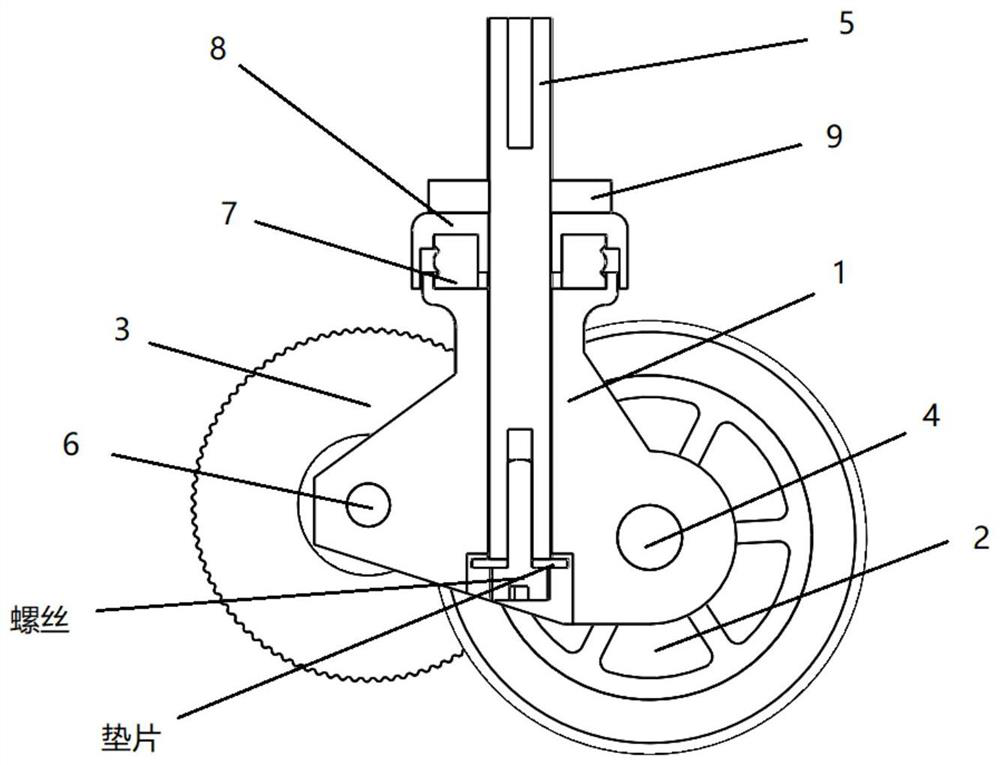

Obstacle crossing assembly and obstacle crossing device

The invention relates to the field of roller advancing structures, in particular to an obstacle crossing assembly and an obstacle crossing device. The obstacle crossing assembly comprises a wheel carrier, more than one driven wheel and more than one obstacle crossing wheel, wherein the driven wheels and the obstacle crossing wheels are rotationally installed on the wheel carrier. The obstacle crossing wheels are arranged in front of the advancing direction of the driven wheels, and the bottoms of the obstacle crossing wheels are higher than those of the driven wheels. The obstacle crossing wheels firstly contact with an obstacle, and the obstacle crossing wheels are easy to jump up the obstacle due to the high bottom surface, so that the driven wheels originally contacting with the groundare lifted to be separated from the ground, and the obstacle crossing effect is achieved. Through the assembly, the obstacle crossing performance is improved on the premise that the diameter of the driven wheel is not increased.

Owner:BEIJING BOOCAX TECH CO LTD +2

System and method for conversion of rotational motion into linear actuation by mechanical stacking or unstacking of connected links

ActiveUS10967524B1Shorten the lengthReduce power consumptionProgramme-controlled manipulatorGripping headsRobotic armClassical mechanics

A Link Stacking Actuator is a scalable device that will contract or expand upon the application of rotational force. This rotational force is converted into linear force in contraction and this contraction can be released for expansion. Contraction and expansion are determined by the relative direction of rotational force applied. The device only generates linear force when contracting. Expansion is simply a relaxation of the device. The conversion of rotational force to contraction is achieved by mechanical stacking of interconnected links that fold or stack into a structure when rotational torsion is applied from a motor against a fixed mount-point or another counter-rotating motor. When used in oppositional pairs, these devices can be used to actuate hinged beams such as robotic arms, legs, and fingers. The device can also be used for direct lift applications when configured in multiple parallel sets.

Owner:MORGAN JAMES P

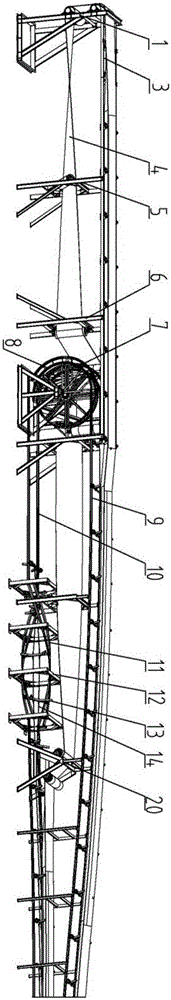

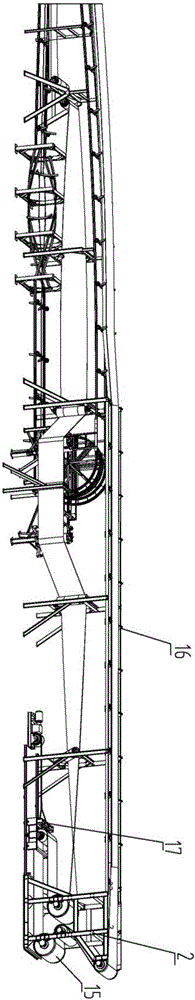

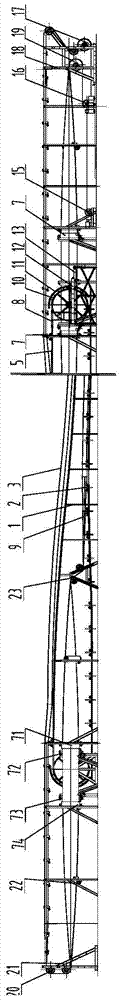

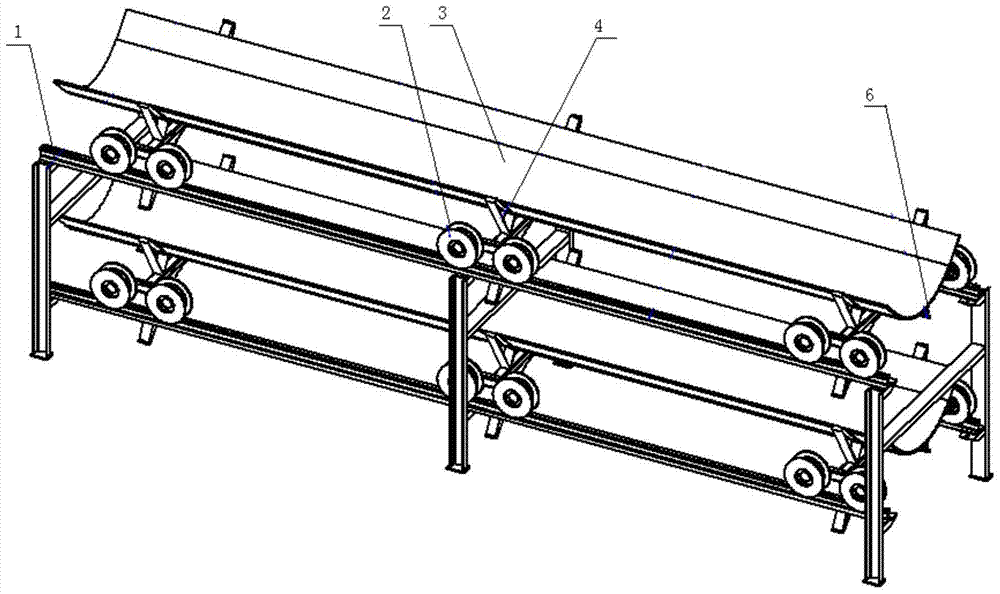

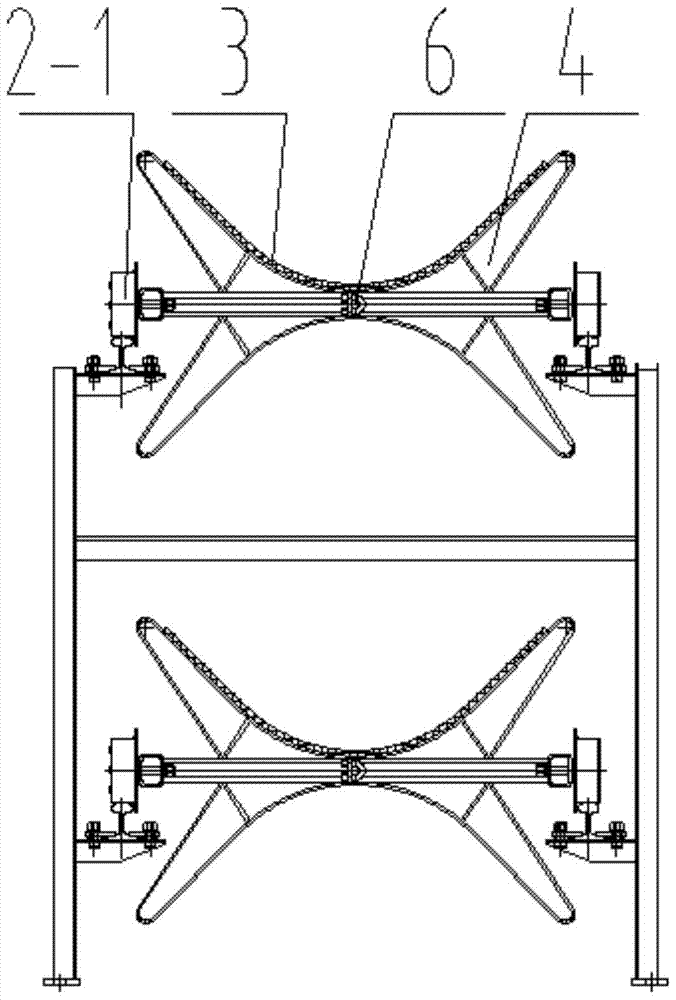

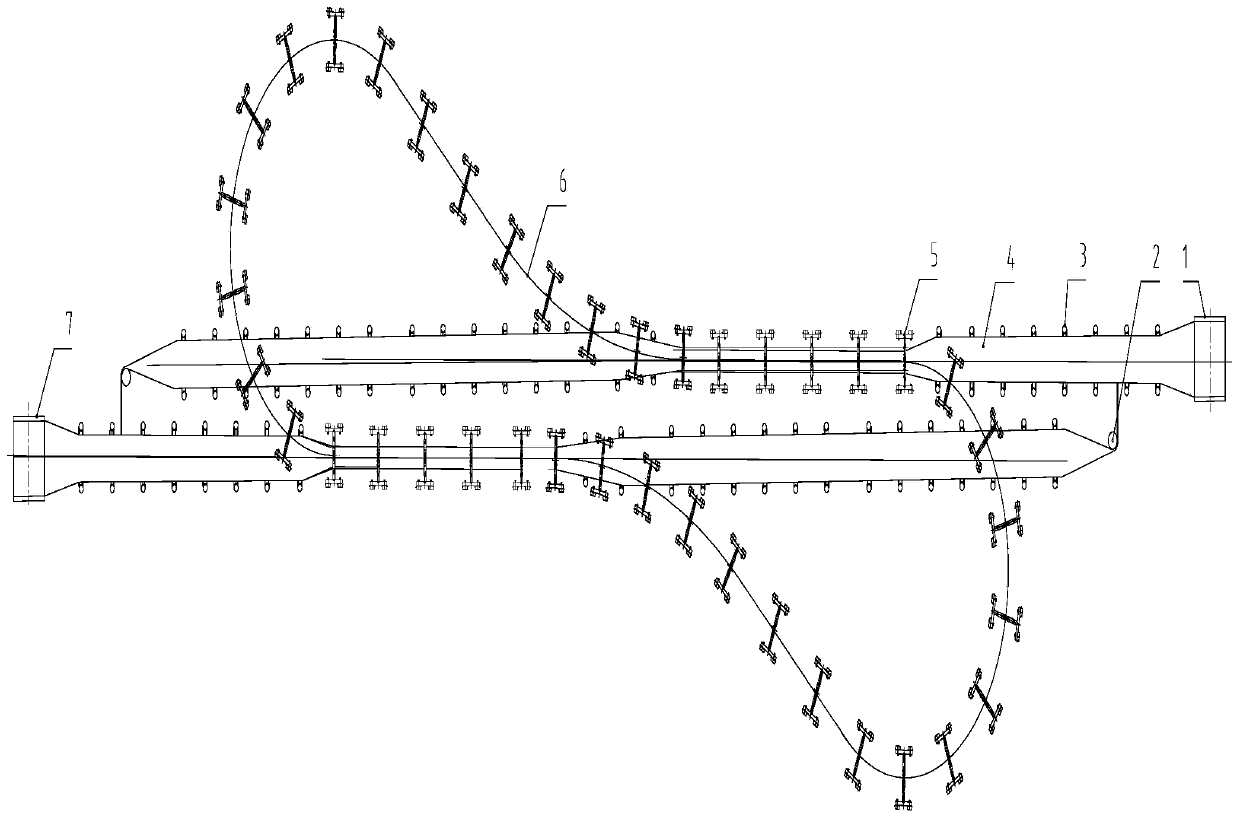

Rail belt-type conveyor with rotary wheel structures

InactiveCN105692068AAchieve structural optimizationStrong complementarityConveyorsHeadframeEngineering

The invention relates to a rail belt-type conveyor with rotary wheel structures. The rail belt-type conveyor comprises a support, a headstock, a tailstock, an upper guide rail, a lower guide rail, the rotary wheel structures, spiral steering mechanisms, towing trolleys, a tape, a steel wire rope, a driving roller, steering racks and vertical racks, wherein the tape is arranged on support roll groups on two ends of the support for rotation in a surrounding manner; the towing trolleys are separated from the tape or are in contact with the tape on the middle part of the support through the rotary wheel structures and the spiral steering mechanisms; the upper guide rail and the lower guide rail are both arranged on the support through pressing plates; the headstock is arranged on the head part of the support; the tailstock is arranged on the tail part of the support; and the steering racks and the vertical racks are arranged between the tailstock and the headstock. The rail belt-type conveyor has the advantages that the structure of the conveyor is optimized, and the use cost is lowered, so that complementary advantages are realized; the operation cost is greatly lowered; a part of ordinary support rolls are replaced by the towing trolleys, so that the cost and assembly cost are lowered; and revolutionary innovation is brought to bulk material transportation.

Owner:LIBO HEAVY MACHINE TECH

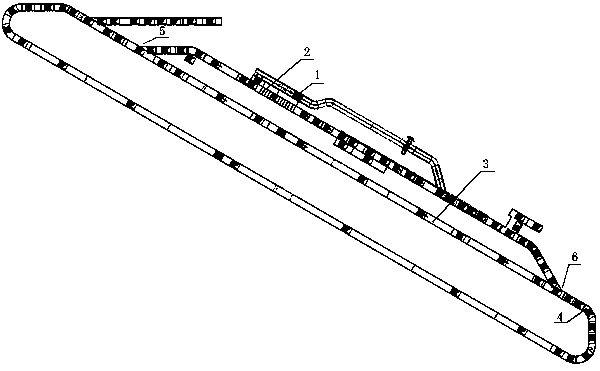

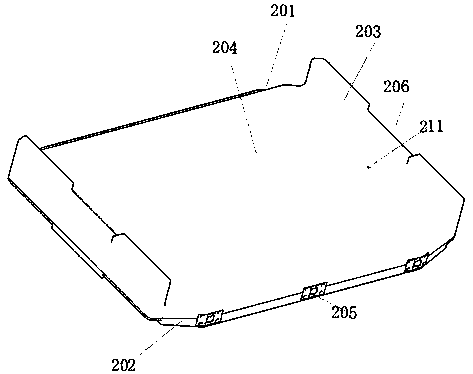

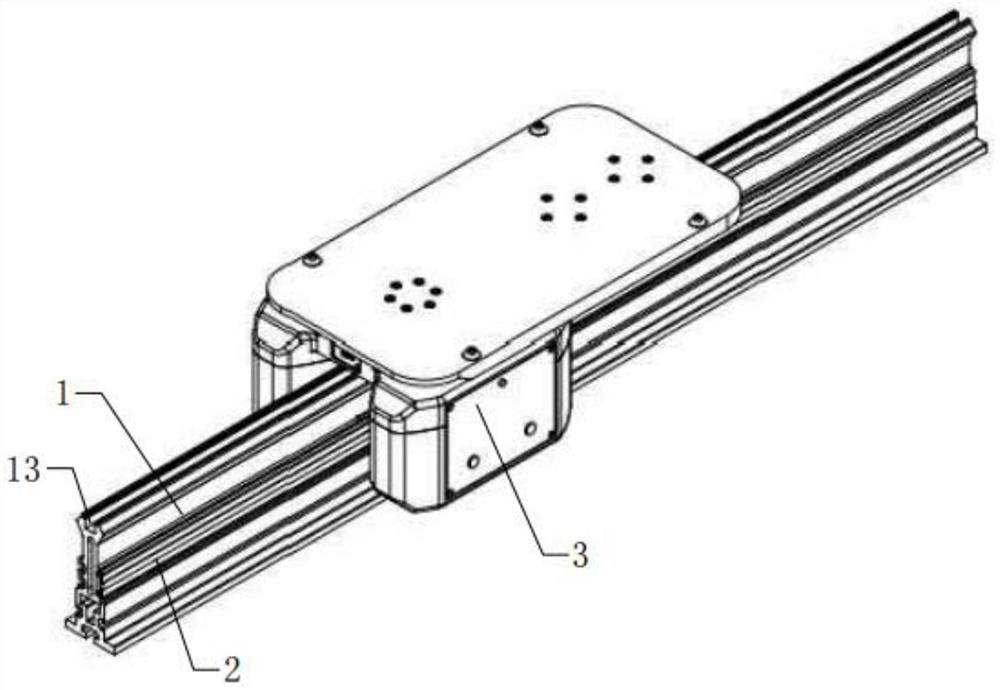

Airport luggage high-speed conveying and sorting system

ActiveCN109160251AImprove stabilityEnsure safetyConveyor partsMechanical conveyorsLogistics managementEngineering

The invention belongs to the civil aviation logistics application field, and particularly relates to an airport luggage high-speed conveying and sorting system. The system comprises a track part, a dynamic sorting device and a luggage high-speed conveying tray; the luggage high-speed conveying tray is used for conveying the luggage on the track part, and the dynamic sorting device is used for carrying out high-speed sorting on the luggage; the track part comprises a straight track, a turning conveyor, at least one section of rapid shunting conveying device and at least one section of rapid confluence conveying device; and a supporting wheel device capable of realizing rapid dismounting and mounting is arranged on the track part. According to the system, high-speed conveying and sorting ofthe airport luggage can be realized; and the whole system is rearranged, a conveying part and a luggage sorting part in the system are mainly improved, so that the speed of conveying the luggage of the whole system can be up to 10 m / s, the stability of the luggage sorting part in the system during tipping is improved, so that the safety and stability when the luggage is conveyed and tipped can beguaranteed on the premise that the system guarantees that the luggage can be conveyed at a high speed.

Owner:CIVIL AVIATION LOGISTICS TECH

Manufacturing process for weldless total-prefabricated rollers

InactiveCN107755985AEasy to processReduce welding man-hoursMechanical working/deformationManufacturing cost reductionInterference fit

The invention provides a manufacturing process for weldless total-prefabricated rollers, and relates to the technical field of processing and manufacturing of rollers. The manufacturing process for weldless total-prefabricated rollers is technically characterized in that a position where a shaft head is connected with a roller does not have weld, and requirements of stress of the roller and / or airtightness and processing precision of the roller are met and ensured by bonding strength generated by reliable interference fit between the shaft head and the roller completely. After the shaft headand the roller are assembled, welding, stress-relieving heat treatment, heat treatment such as medium-frequency hardening, processing such as finish turning of the shaft head and dynamic balance emendation of the roller are not required, a technological process can be greatly shortened, processing procedures can be greatly reduced, processing time can be greatly shortened, processing difficulty can be greatly relieved, manufacturing costs can be greatly reduced, and perfect dynamic balance grade and manufacturing precision are realized. Therefore, a series of configuration and matching of machine tool equipment, change and innovation of technical requirements, change and innovation of fixtures, workshop planning and layout and change and innovation of a technology of the manufacturing process for rollers can be further initiated.

Owner:抚顺东旭精工制辊科技有限公司

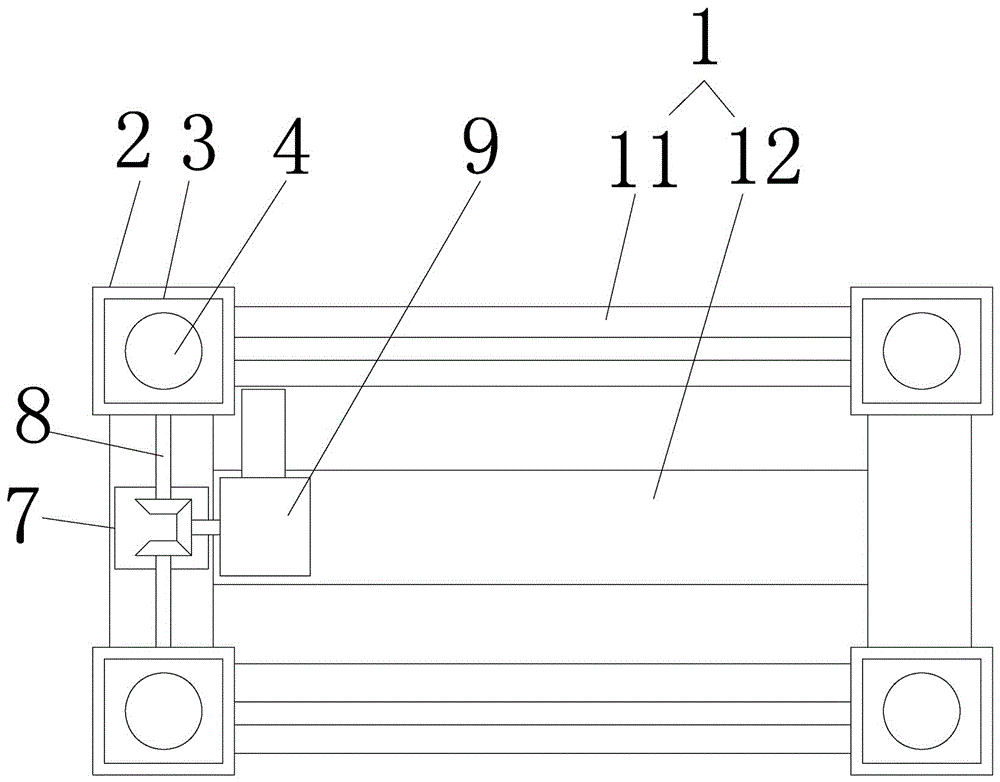

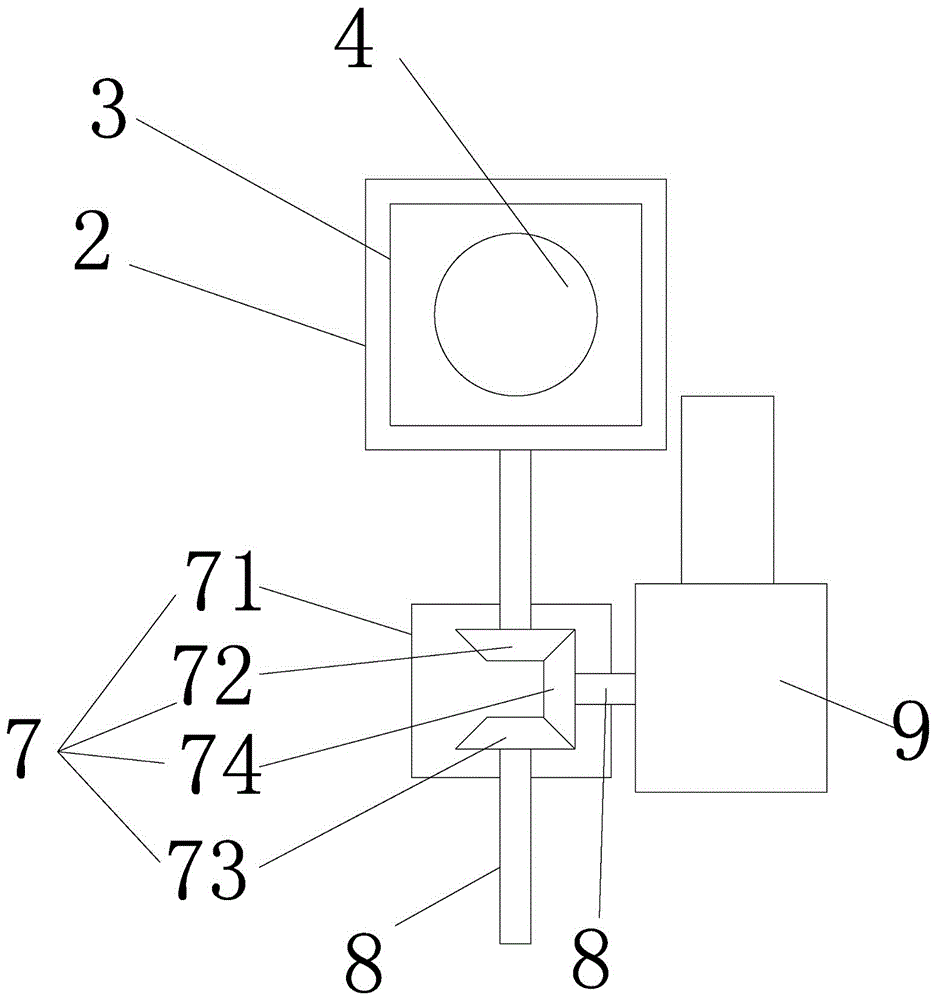

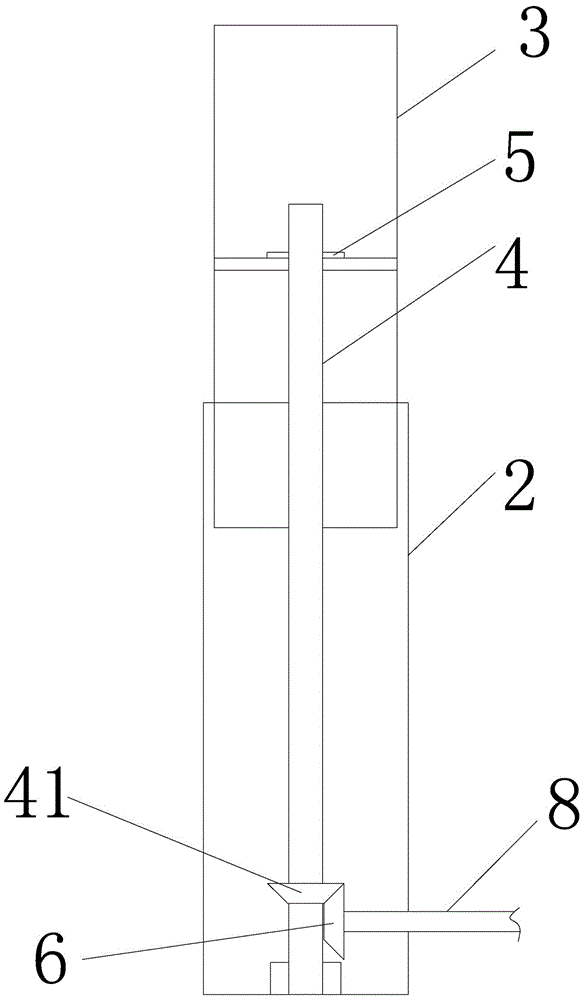

Driving structure of electric lifting table

PendingCN106617667ASimple structureReduce manufacturing costServing tablesVariable height tablesElectric machineryDrive motor

The invention provides a driving structure of an electric lifting table. The driving structure includes a main support 1 and fixing legs arranged at the four corners of the main support, lifting legs are arranged in the fixing legs in a sleeving mode, and the fixing legs are internally provided with lifting screw rods which are in threaded connection with nuts arranged in the lifting legs; the lifting screw rods are provided with conical driven gears which are meshed with conical driving gears arranged in the fixing legs; a transmission gearbox is arranged on the main support, the two sides of the transmission gearbox extend out of transmission rods to be connected with the conical driving gears in the left fixing leg and the right fixing leg, and the transmission gearbox is connected with a driving motor through the transmission rods. The driving structure of the electric lifting table has the advantages that a reducer is arranged between the motor and driving screw rods and can effectively reduce the operation resistance of the motor and make a lifting device run smoothly and quietly; the reducer is arranged between the left fixing leg and the right fixing leg and located in the main support, and accordingly installation with a housing is convenient to achieve, and balanced output of power is easily achieved.

Owner:黄顺贤

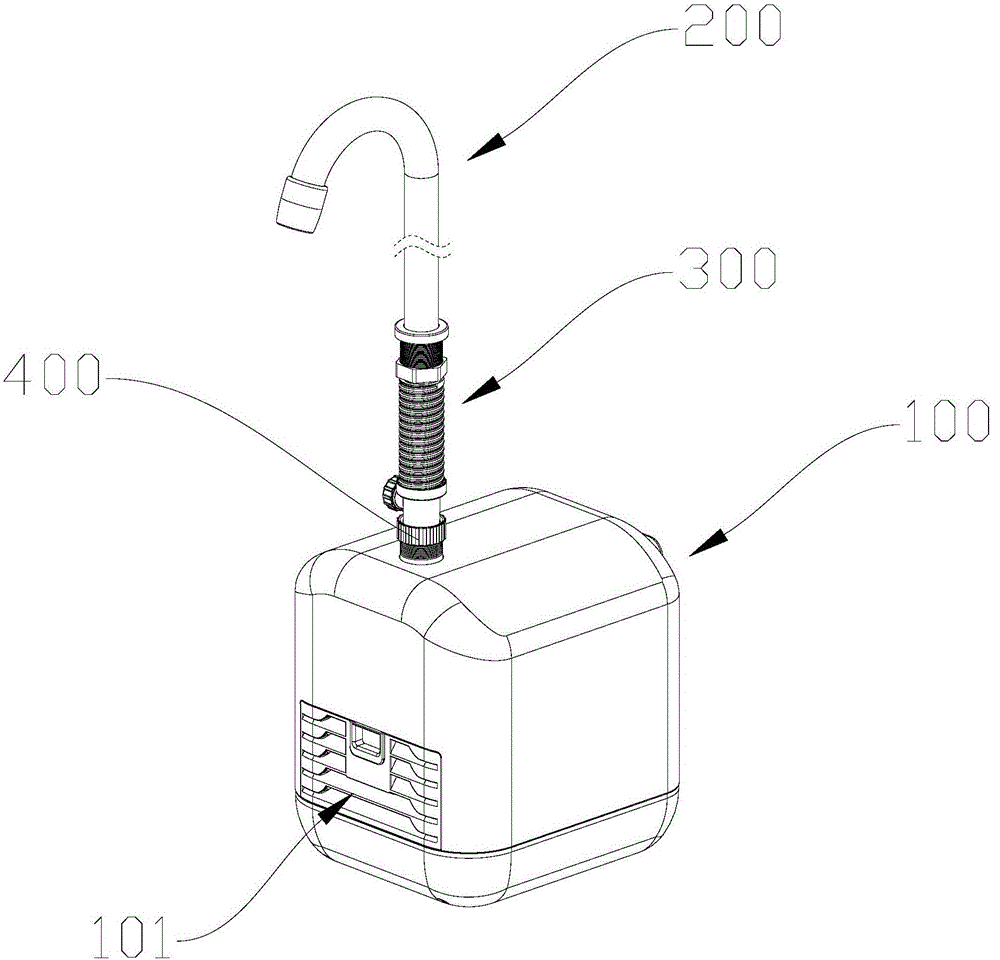

Faucet-type air blower

The invention relates to a kitchen ware, and discloses a faucet-type air blower, which comprises an air pump component, an air faucet component and a connecting component which is used for communicating the air pump component and the air faucet component, wherein the air pump component and the connecting component are located on one side of an operation surface; one end of the connecting component, connected to the air faucet component, passes through the operation surface above the air pump component; and the air faucet component, after passing through the operation surface, is used for venting gas in a direction away from the operation surface obliquely downwards. The air blower disclosed by the invention has the advantages that an air source can be used as a kitchen cleaning device, and the air blower has the characteristics of being convenient and rapid and being convenient in installation; and the air blower is quite in running, and is suitable for daily household use.

Owner:ZHEJIANG AIKE APPLIANCE

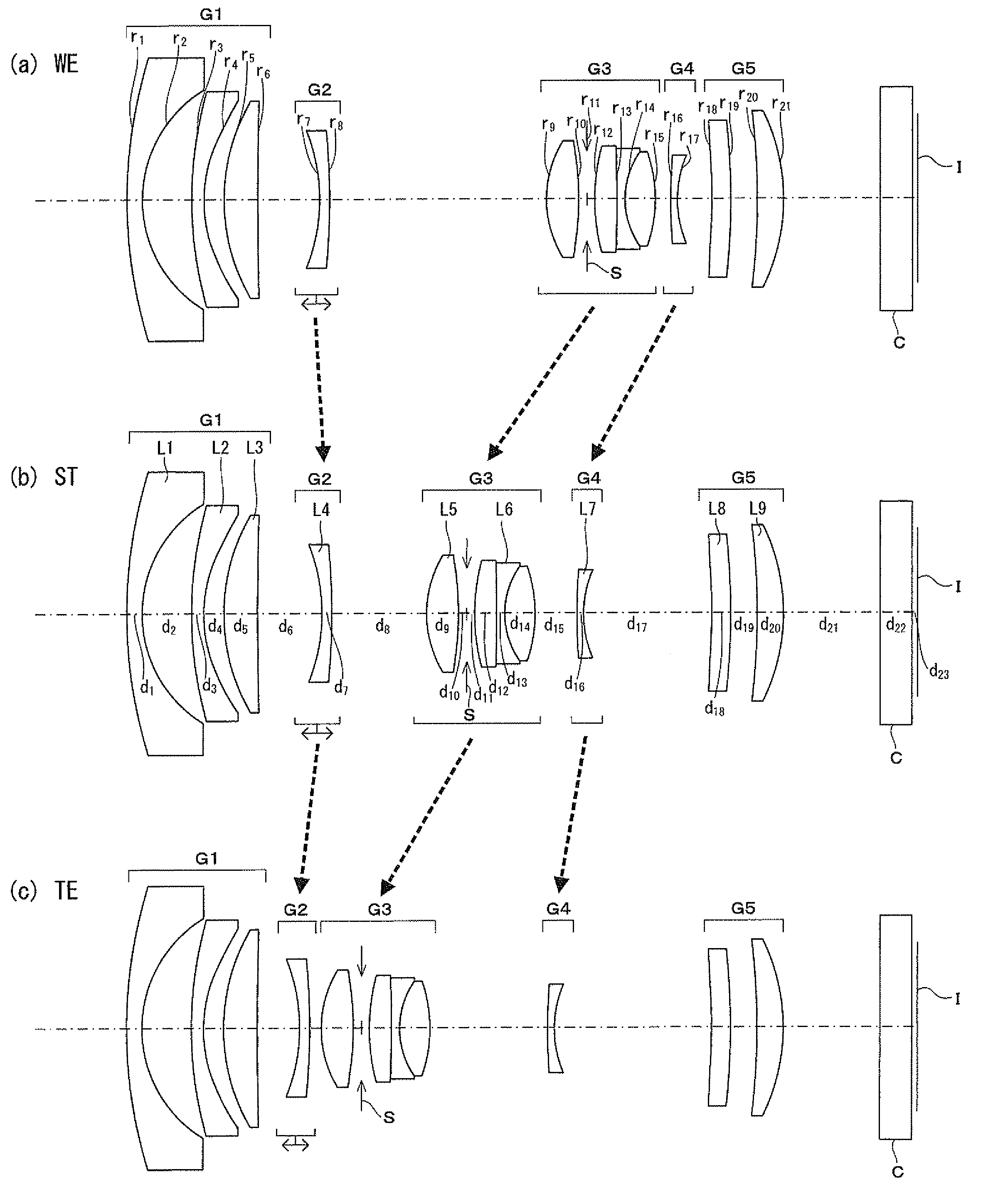

Zoom lens

InactiveUS8711489B2Reduce motor loadObstruction is producedOptical elementsObject pointMagnification

In a zoom lens of a fixed total length, at the time of changing the magnification from the wide-angle end toward the telephoto end, the first lens group is anchored while the second lens group is moved, and the third and fourth lens groups are moved so as to be located at the object side of the telephoto end relative to the wide-angle end, such that: the interval between the second and third lens groups is decreased at the telephoto end relative to the wide-angle end; the interval between the third and fourth lens groups is increased at the telephoto end relative to the wide-angle end; and the interval between the fourth and fifth lens groups is increased at the telephoto end relative to the wide-angle end, and at the time of focusing a near object point from a remote object point, the second lens group is moved.

Owner:OM DIGITAL SOLUTIONS CORP

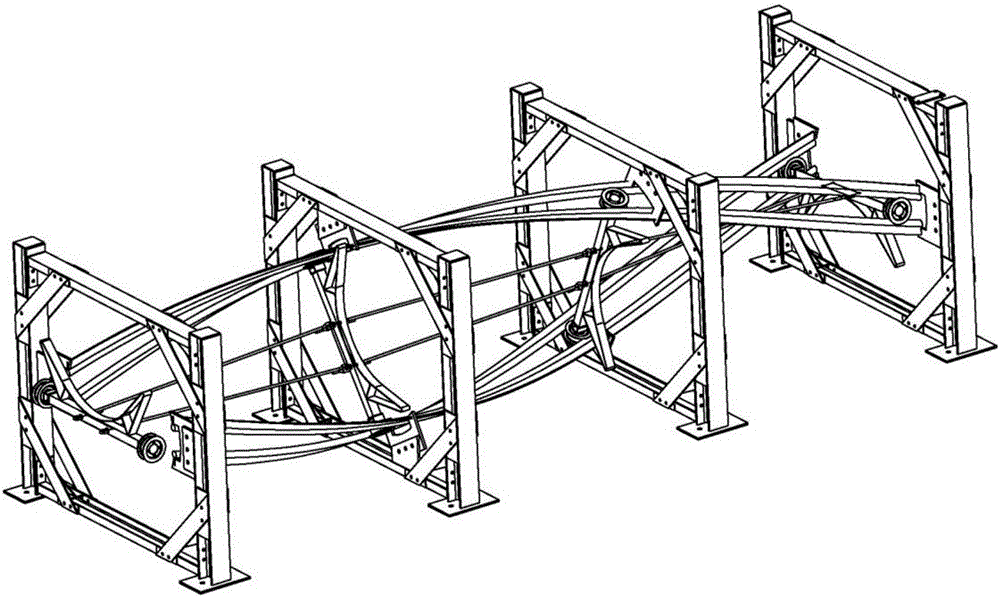

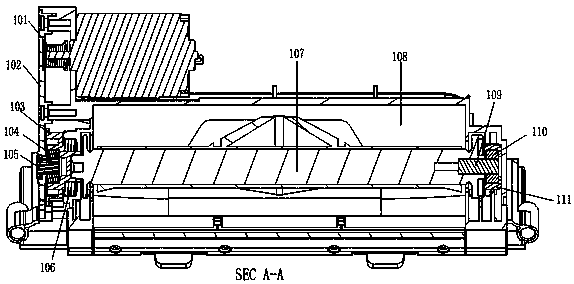

Track Belt Conveyor

ActiveCN105416993BAchieve structural optimizationStrong complementarityConveyorsHeadframeClosed loop

The invention relates to a rail type belt conveyor. The rail type belt conveyor comprises a support, a machine head frame, a machine tail frame, an upper guide rail, a lower guide rail, a towing trolley, a rubber belt, a steel wire rope, closed-loop systems, a driving roller, an elevating supporting roller set, a redirection frame and a triangular frame. The elevating supporting roller set is mounted at the position, close to the machine head frame, of the support, the redirection frame is mounted on the machine tail frame, a redirection drum is arranged on the machine head frame, and a tensioning vehicle is arranged at the position, close to one side of the redirection drum, of the support; and the triangular frame is arranged at the position, between the two closed-loop systems, of the support, and the rubber belt is wound around the elevating supporting roller set, the redirection drum, the tensioning vehicle, a supporting roller on the redirection frame and a supporting roller on the triangular frame. The rail type belt conveyor has the beneficial effects that a traditional rubber belt machine structure is removed, a supporting belt trolley is used for replacing a part of a common supporting roller, the cost and the mounting cost are reduced, and revolutionary innovation is brought to bulk conveying.

Owner:LIBO HEAVY MACHINE TECH

High-reliability emergency drainage vehicle

PendingCN106585470AExtended service lifeQuiet and smooth operationSewerage structuresItem transportation vehiclesWater flowHigh pressure

The invention belongs to the technical field of rescue vehicles and specifically relates to a high-reliability emergency drainage vehicle. The high-reliability emergency drainage vehicle comprises a vehicle cabin, the vehicle cabin is internally provided with a chassis, the chassis is provided with a water pump, a Venturi injector, an inflator and a vacuum pump, a water storage pot is arranged in the vehicle cabin, the bottom of the water storage pot is provided with a water pumping port and a water inlet, the water pumping port communicates with an inlet of the water pump through a first flexible pipe, and an outlet of the water pump communicates with the outside of the vehicle cabin through a drain pipeline; the drain pipeline communicates with an inlet of the vacuum pump through a first branch; and the top portion of the water storage pot communicates with a mixing chamber of the Venturi injector through a second flexible pipe, a high-pressure gas inlet of the Venturi injector communicates with the inflator, and the Venturi injector communicates with the outside of the vehicle cabin through an injection pipeline. The high-reliability emergency drainage vehicle has the following advantages: each apparatus is integrated on the chassis, the water pump does not have to be moved, and maintenance and repair are convenient; and water currents in the water pump are stable, the operation of a pump body is quiet and stable in an application process, there is neither noise no vibration, the service life of the water pump is long, and the reliability is high.

Owner:NANJING NANQI CHANGTONG ROAD MACHINERY

Novel low-resistance circular tube belt conveyor

ActiveCN109941689AImprove reliabilityExtended service lifeMechanical conveyorsClosed loopEngineering

The invention relates to a novel low-resistance circular tube belt conveyor which comprises a machine frame, a driving roller, redirecting roller groups, a carrier roller group, a conveying belt, a plurality of moving trolleys, a steel wire rope and a tail roller, wherein the driving roller, the redirecting roller groups, the carrier roller group, the conveying belt, the moving trolleys, the steelwire rope and the tail roller are installed on the machine frame; the driving roller and the tail roller are respectively positioned at two ends of the machine frame; the two redirecting roller groups are arranged at the end, close to the driving roller, of the machine frame and the end, close to the tail roller, of the machine frame respectively; the conveying belt surrounds the driving roller,the redirecting roller groups and the tail roller to be connected end to end to form a closed loop, and the conveying belt is further supported by the carrier roller group; and the plurality of movingtrolleys are arranged on the steel wire rope at equal distances. The novel low-resistance circular tube belt conveyor has the advantages that the reliability of the conveyor is improved, and the service life of the conveyor is prolonged. The moving trolleys and the conveying belt are combined to operate, so that the structural optimization of the conveyor is achieved, the using cost is reduced, and the complementation of advantages is achieved.

Owner:LIBO HEAVY MACHINE TECH

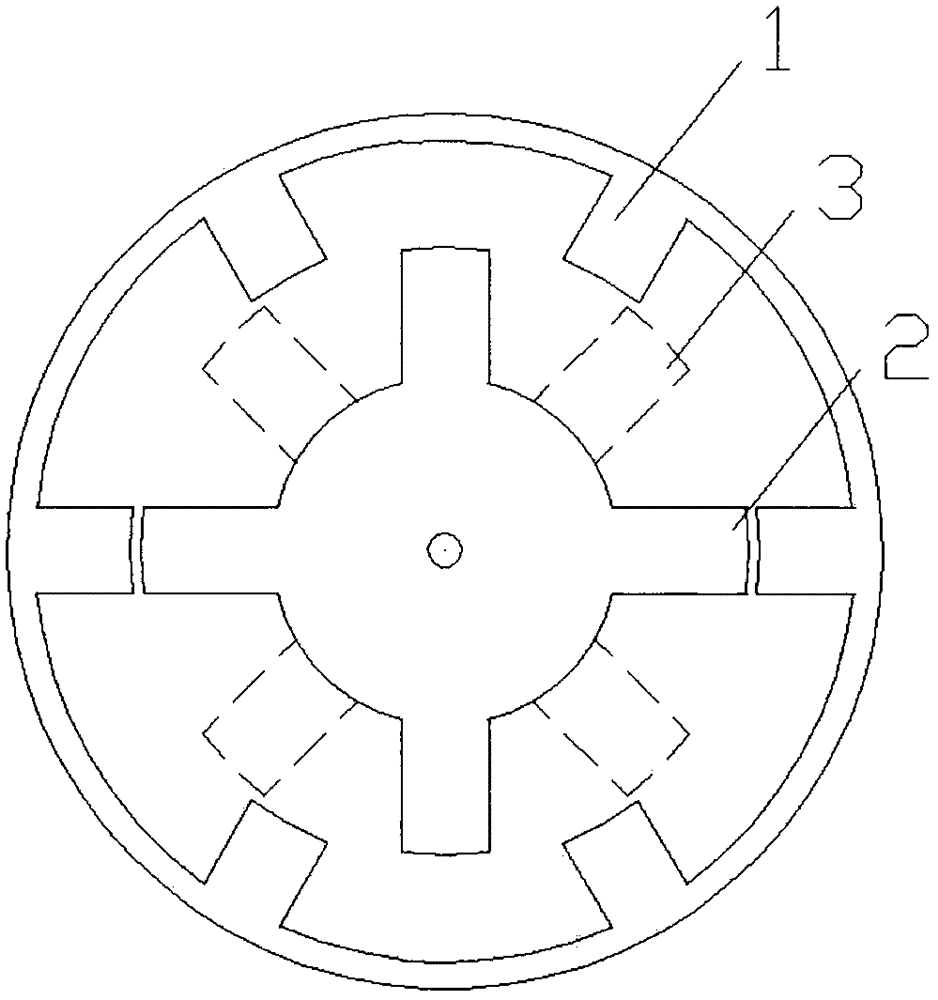

Self-balancing switched reluctance motor

InactiveCN106160376AGuaranteed uptimeQuiet and smooth operationDynamo-electric machinesReluctance motorOperational stability

The invention relates to a switched reluctance motor which overcomes the shortcomings of large pulsating torque and vibration and high noise of a current switched reluctance motor. A plurality of stators and a plurality of rotors are combined to form a plurality of switched reluctance sub-motors, a plurality of rotors share a rotating shaft to collectively output power, the switched reluctance sub-motors are mutually and serially connected, stators or rotors of each switched reluctance sub-motor are distributed according to a certain rule, the switched reluctance sub-motors are mutually balanced by the aid of pulsating torques of the switched reluctance sub-motors, and stable and quiet operation is achieved. As the switched reluctance sub-motors collectively output the power, and the self-balancing switched reluctance motor has the advantages of operational stability and quietness, stronger power and the like.

Owner:韦翔

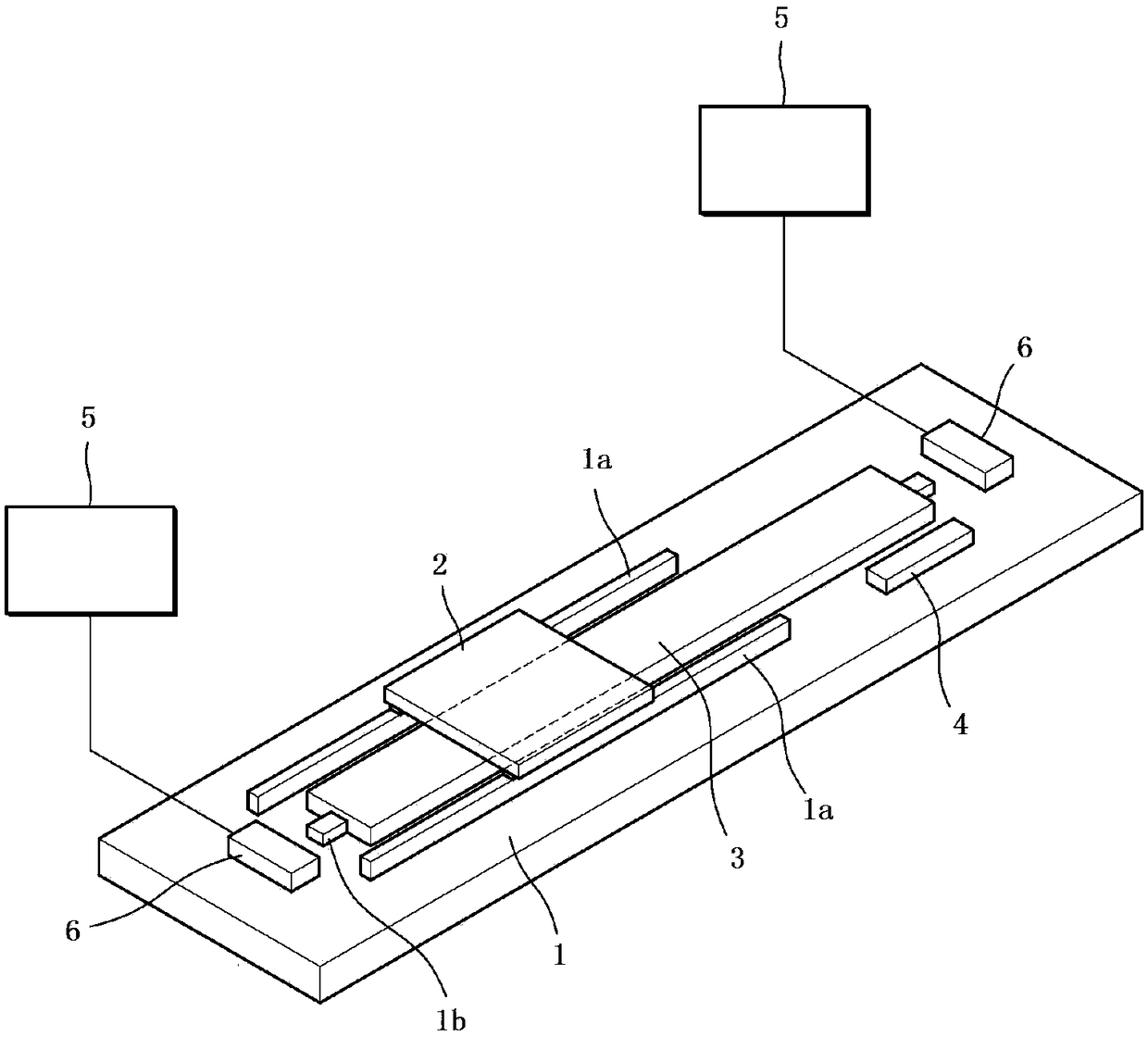

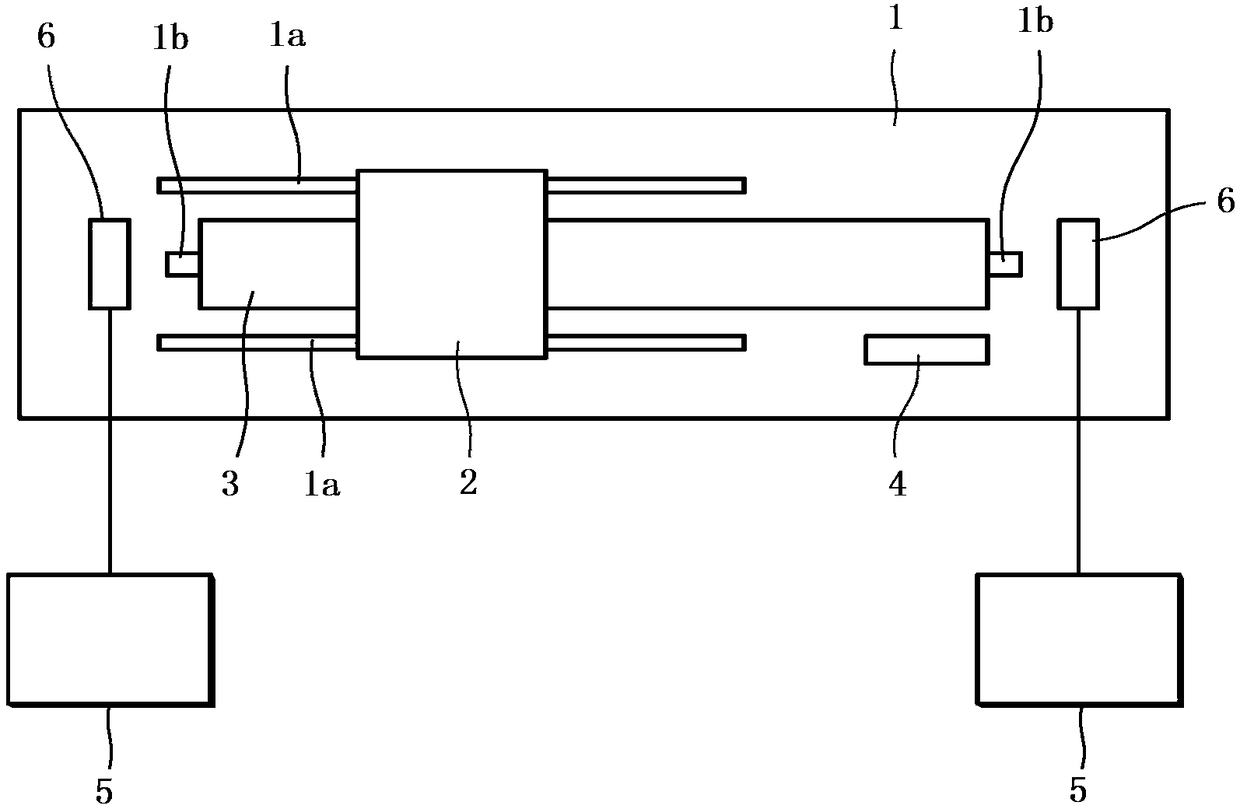

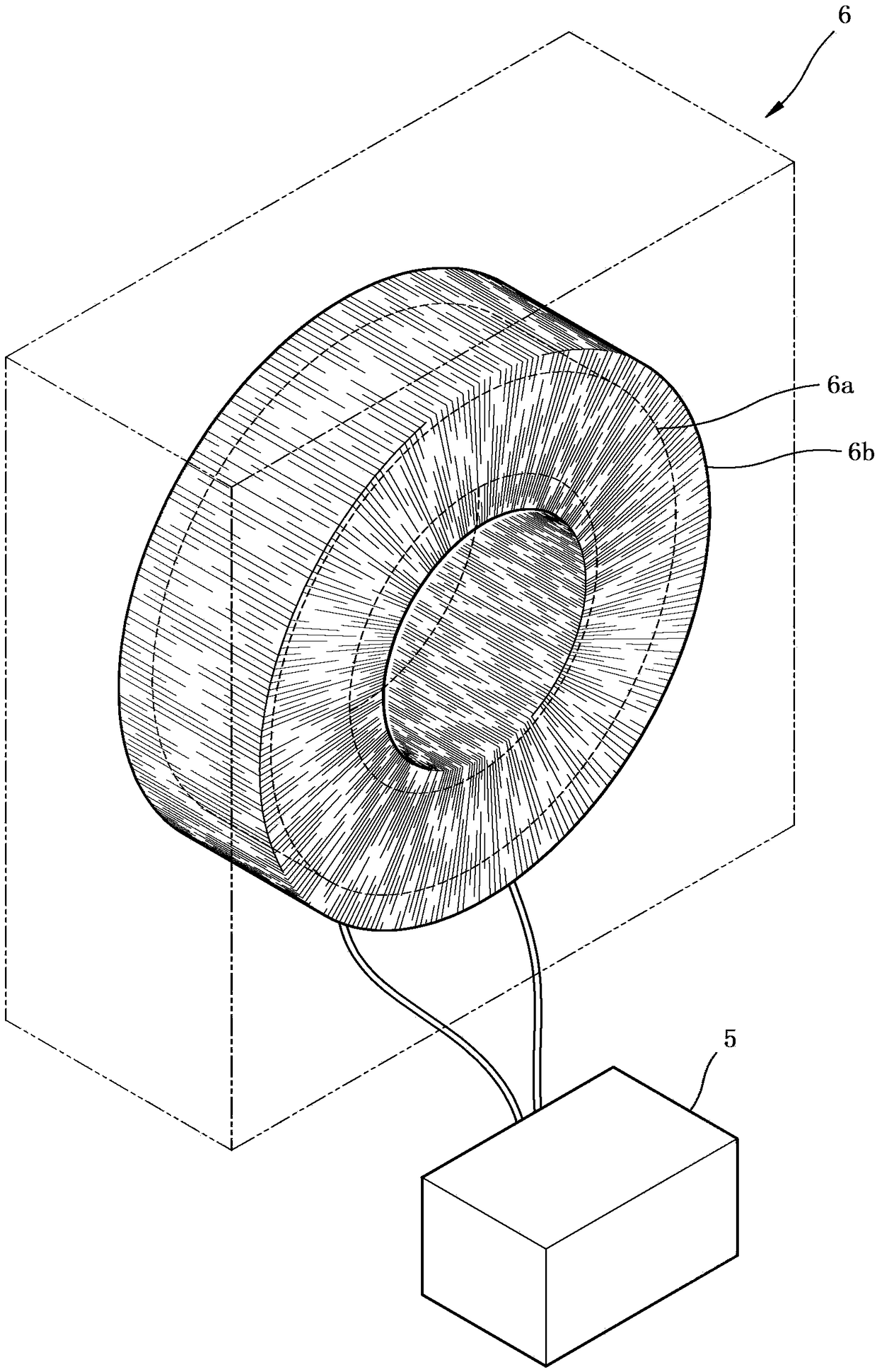

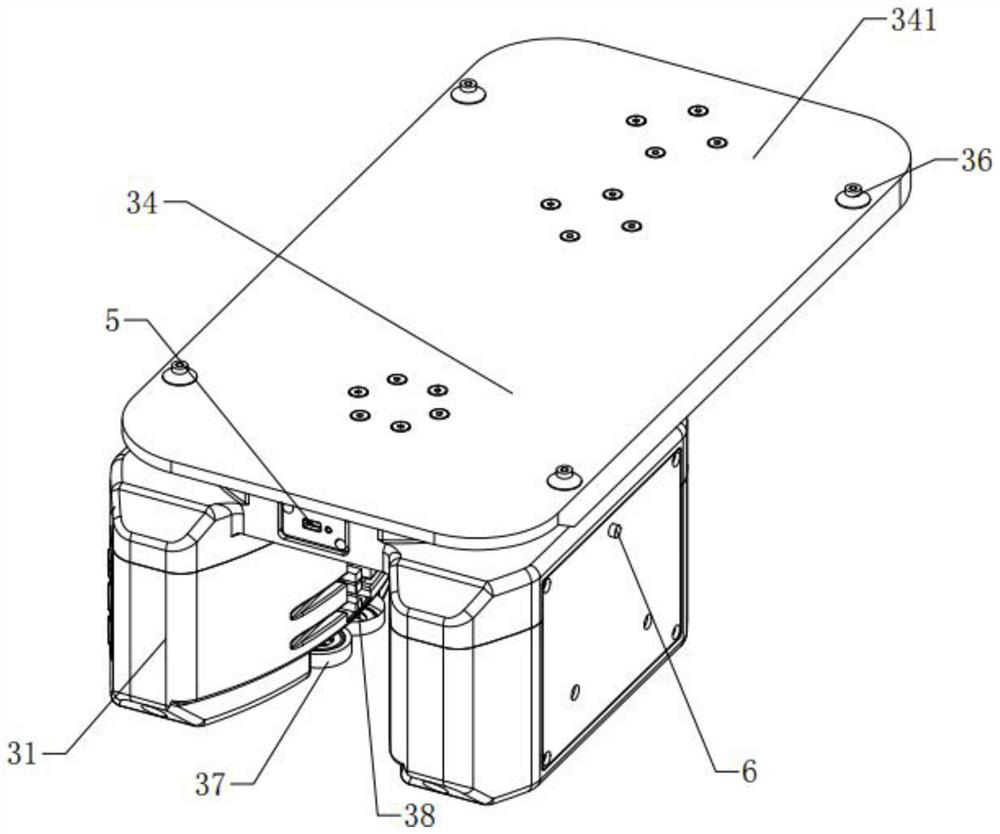

Linear moving system and laser processing device with linear moving system

ActiveCN108406142ASimple structureEasy to implementLaser beam welding apparatusLaser processingEngineering

The invention discloses a linear moving system and a laser processing device with the linear moving system. The linear moving system comprises a processing table, a workpiece conveying plate and a magnetic rail, wherein the workpiece conveying plate and the magnetic rail are arranged on the processing table; the workpiece conveying plate is provided with a first electromagnet, and at least two reaction force compensation units arranged in the movement direction of the magnetic rail are arranged on the processing table; each reaction force compensation unit comprises a second electromagnet, thelinear moving system further comprises a detection sensor, and current adjusting parts connected with the second electromagnets; and the laser processing device comprises the linear moving system, and further comprises a laser irradiating portion and a moving table used for allowing the workpiece to be placed, the moving table is installed and fixed on the workpiece conveying plate to synchronously move, and a laser beam emitted by the laser irradiation portion is used for processing the workpiece. The linear moving system and the laser processing device with the linear moving system has theadvantages that the structure is simple, the implementation is easy, the noise is avoided, the smooth conveying of the workpiece can be guaranteed, and the processing precision is greatly improved.

Owner:伊欧激光科技(苏州)有限公司

Multi-bearing rolling brush assembly and cleaning robot

PendingCN109549571AQuiet and smooth operationAvoid noiseCarpet cleanersFloor cleanersBrush toothEngineering

The invention discloses a multi-bearing rolling brush assembly and a cleaning robot. The rolling brush assembly comprises a rolling brush tooth box work box, a power box, a rolling brush tooth box fixing shaft assembled on a cover face of a rolling brush tooth box, a first dust-proof part, a second dust-proof part and a third dust-proof part, wherein a wheel type structure is assembled between therolling brush tooth box work box and the power box, the wheel type structure sleeves in an assembly groove position at one end of a rolling brush shaft, a rotation ring of the first dust-proof part and a rotation ring of the second dust-proof part are in interference contact with the corresponding side faces of the wheel type structure, a fixed ring of the first dust-proof part sleeves the rolling brush tooth box fixing shaft, and a fixed ring of the second dust-proof part is fixed on the cover face of the brush tooth box work box; and a rotation ring of the third dust-proof part is assembledon a rotation shaft at the other end of the rolling brush shaft, and a fixed ring of the third dust-proof part is fixed on the rolling brush cover face of the rolling brush tooth box when the rollingbrush shaft is assembled in the rolling brush tooth box, so that the rolling brush assembly runs stably and quietly.

Owner:DONGGUAN XINSU TECH CO LTD

Special rail trolley for friction rolling on rail

InactiveCN113071872AQuiet and smooth operationNot easy to deviateControl devices for conveyorsMechanical conveyorsClassical mechanicsElectric machinery

The invention discloses a special rail trolley for friction rolling on a rail. Two opposite inclined surfaces are arranged at the top of the rail; the upper ends of the two inclined surfaces are close to each other; the lower ends of the two inclined surfaces are far away from each other; a copper strip is arranged on the rail in the length direction; the rail trolley comprises a trolley body; a motor and an even number of inclined surface rollers are arranged in the trolley body; the inclined surface rollers are uniformly distributed on the two sides of the rail and are respectively propped against the two inclined surfaces; the motor drives the inclined surface rollers to roll along the inclined surfaces; an electric brush in contact with the copper strip is arranged on the trolley body; the electric brush is used for supplying power to the motor; a tail plate is arranged on the top surface of the trolley body; the tail plate comprises an extension portion which extends in the same direction or the opposite direction of the running direction of the trolley body; and an even number of supporting rollers are arranged below the extension portion. The rail trolley is driven to move through the friction force between the inclined surface rollers and the inclined surfaces, so that the rail trolley runs more quietly and stably, and the processing requirement is low.

Owner:安徽艾灵科工业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com