Manufacturing process for weldless total-prefabricated rollers

A manufacturing process and no weld seam technology, applied in the direction of machining/deformation, can solve problems such as poor weldability, difficult rework, poor weldability, etc., to ensure connection strength and or air tightness, saving Cost of tempering heat treatment, effect of saving tempering heat treatment man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means realized by the present invention, technical features, reach the purpose and be easy to understand in effect, further elaboration will be done below in conjunction with preferred implementation process steps:

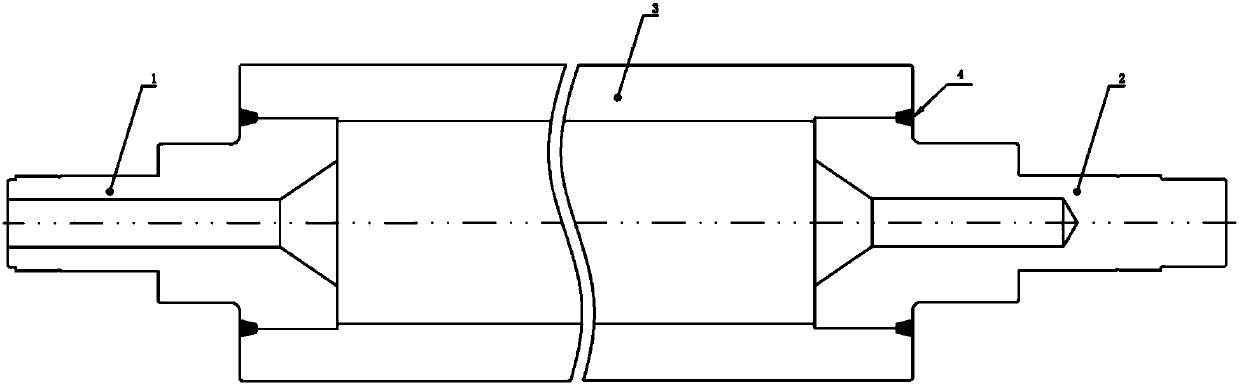

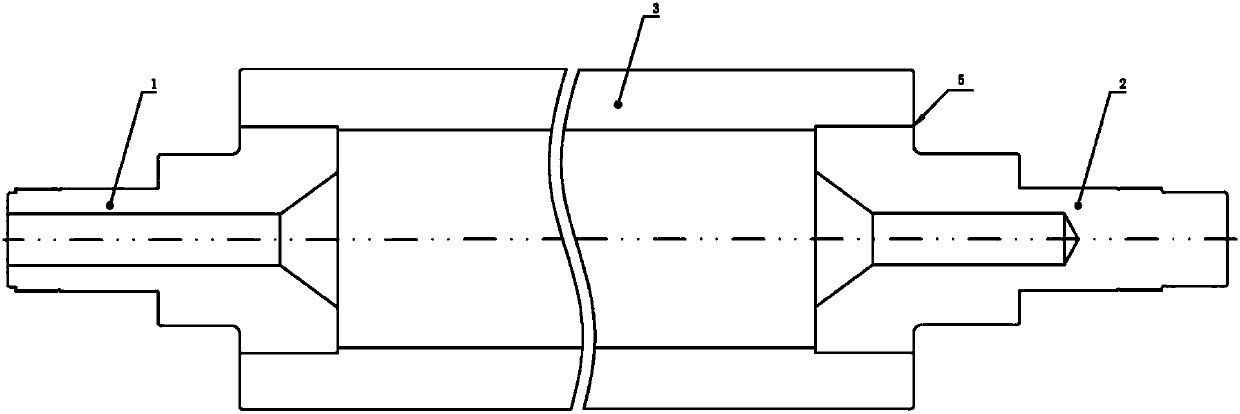

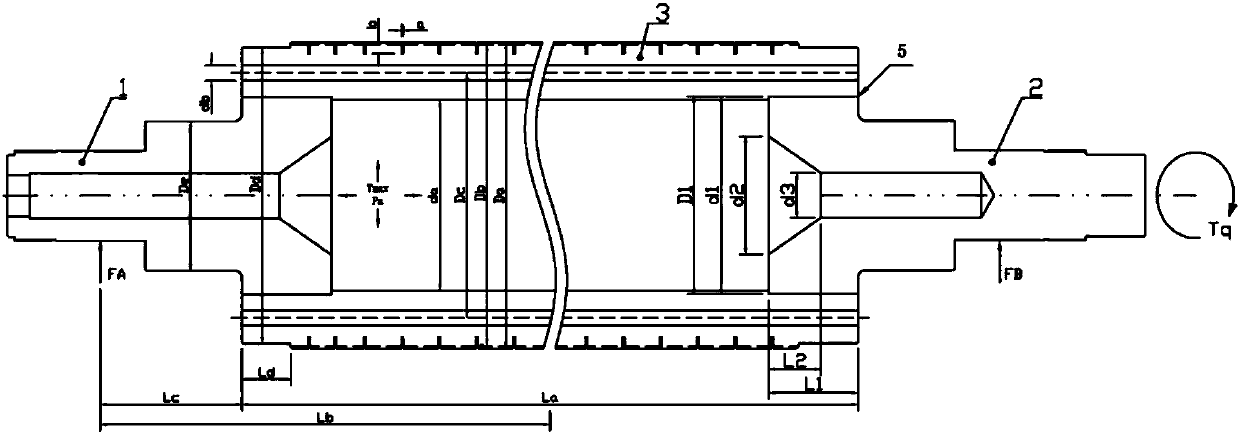

[0030] The first step, through a set of self-developed interactive computer programs, according to the functional structure dimensions Da, Db, Dc, Dd, De, da, db, a, b, La, Lb, Lc, Ld, etc. related to the roller, work Stress conditions FA, FB, Tq, etc., pressure Pa and maximum temperature Tmax of the medium in the cavity, etc., the respective performance conditions of the shaft head and roll body materials, and the dimensions of the shaft head and roll body D1, d1, d2, d3, L1, L2 and other parameters are used for design calculation and stress analysis, so that the bonding strength of the shaft head and the roller body after reliable interference assembly meets and guarantees the requirements for connection strength and / or air t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com