Driving structure of electric lifting table

A driving structure and a technology for lifting tables, which are applied to tables, service tables, and tables with variable table heights, etc., can solve problems such as poor synchronization, high production costs, and motor heat damage, so as to help balance output and improve market competition. The effect of low power and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

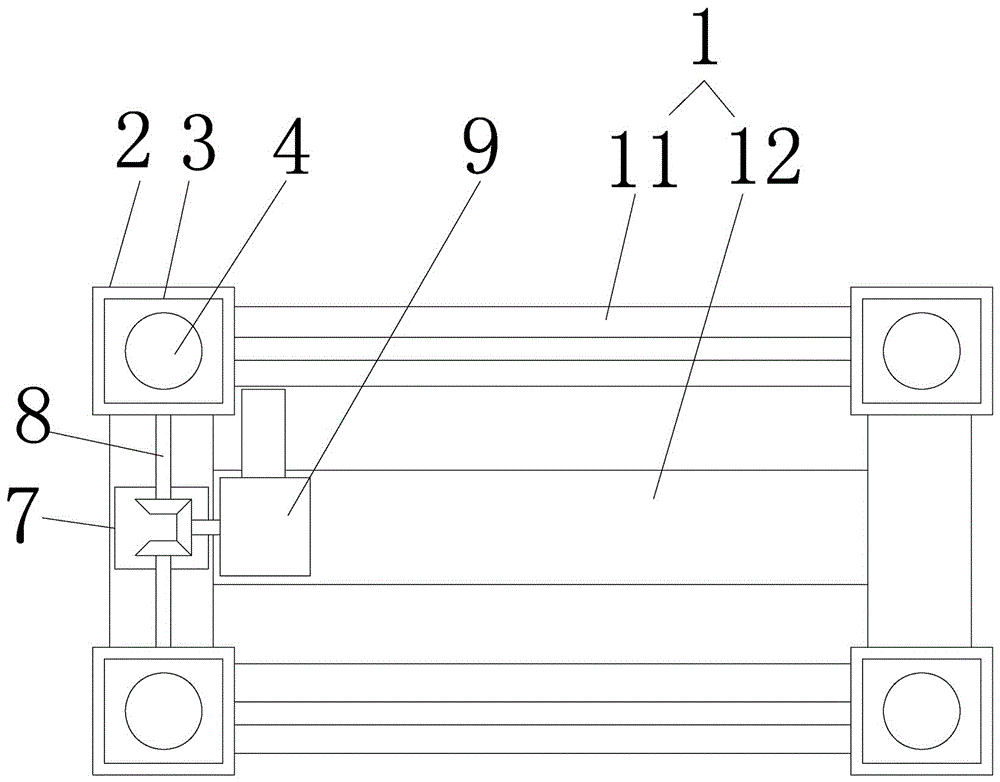

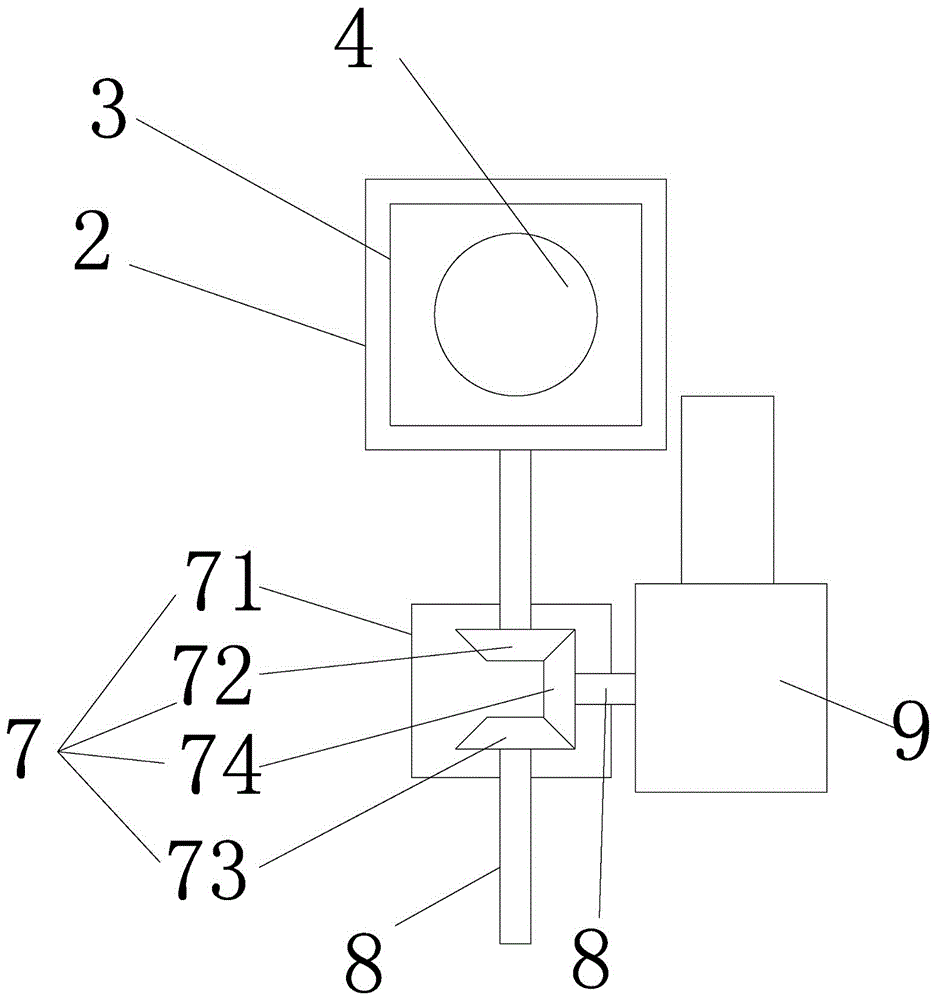

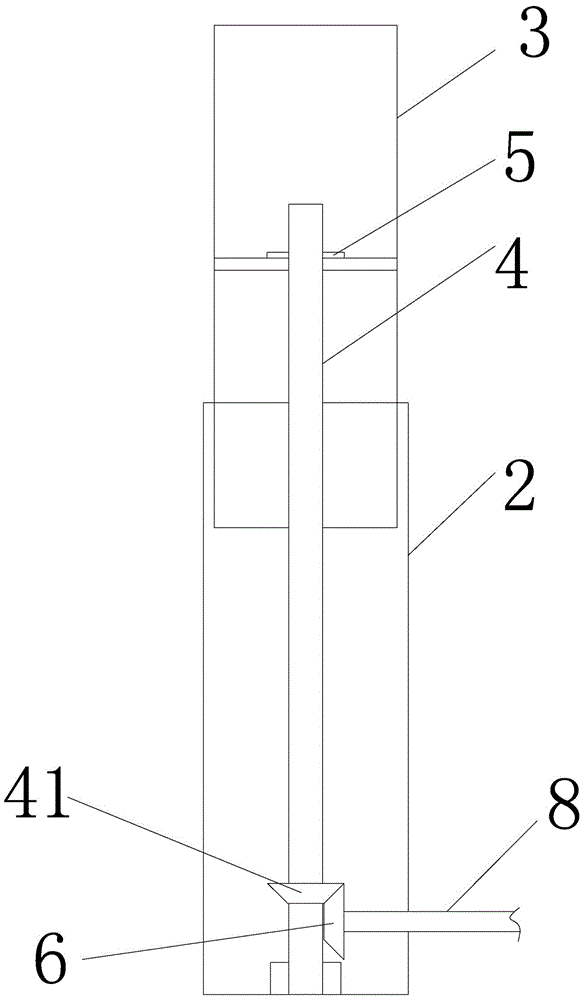

[0013] The present invention will be specifically and further described below in conjunction with the accompanying drawings. An electric lift table drive structure, characterized in that it includes a main bracket 1 and fixed legs 2 arranged at its four corners, the fixed legs 2 are provided with a lifting leg 3, and the fixed leg 2 is provided with a lifting screw 4 and a The nut 5 in the lifting leg 3 is screwed; the driven bevel gear 41 is installed on the lifting screw 4 to mesh with the driving bevel gear 6 in the fixed leg 2, and the main bracket 1 is provided with a gearbox 7. Transmission rods 8 extending from both sides of the gearbox are connected to the active bevel gears 6 in the left and right fixed legs, and the gearbox 7 is connected to the drive motor 9 through the transmission rods 8 .

[0014] The gearbox 7 is arranged at the midpoint of the left and right fixed legs 1, and the gearbox 7 is fixed on the main bracket 1.

[0015] Described gearbox 7 comprises ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com