Linear moving system and laser processing device with linear moving system

A technology of linear movement and processing table, used in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unable to ensure smooth transportation of workpieces, affecting processing accuracy, affecting service life, etc., to achieve smooth transportation and improve processing accuracy. , the effect of increasing the time of the magnetic force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

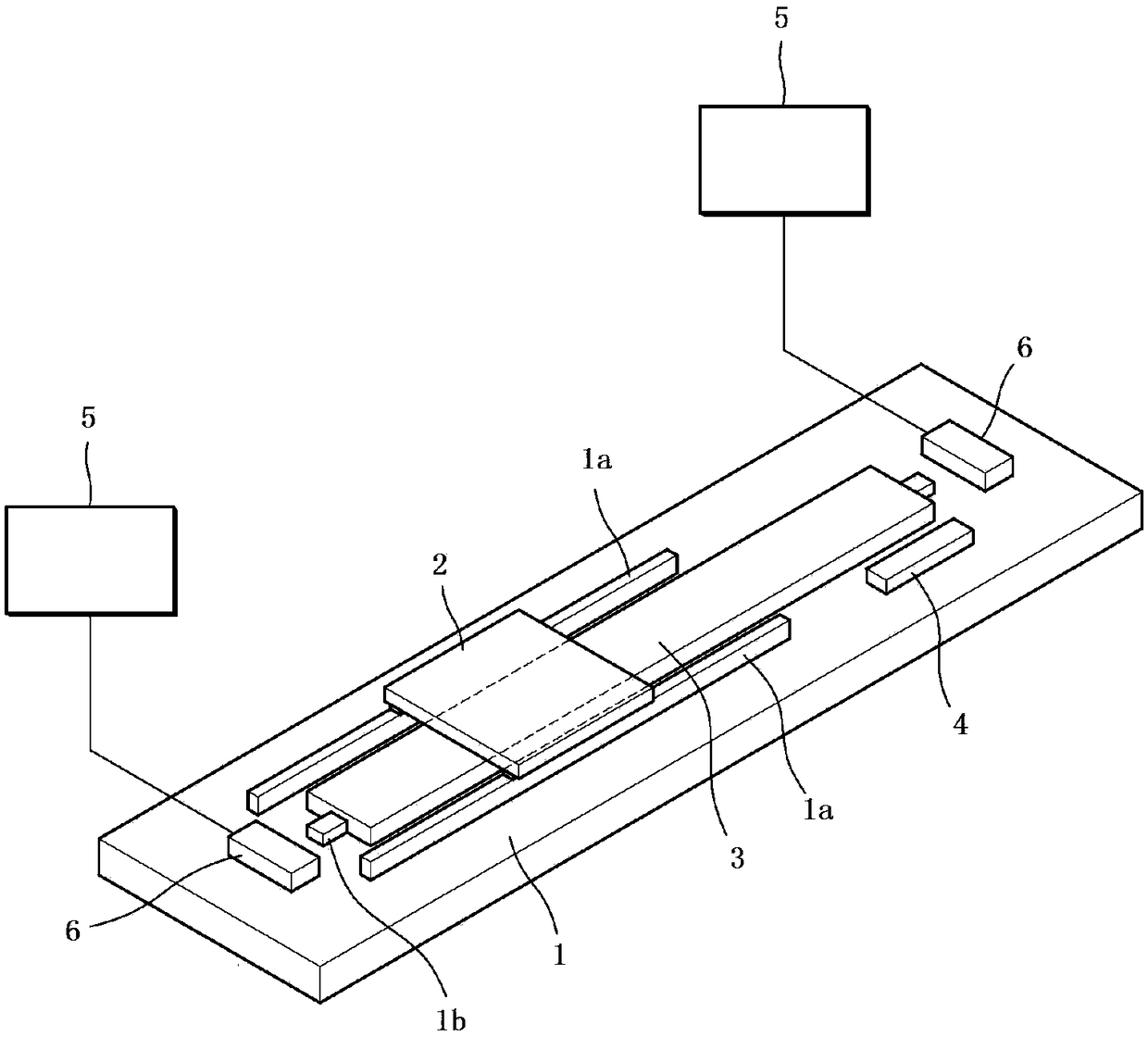

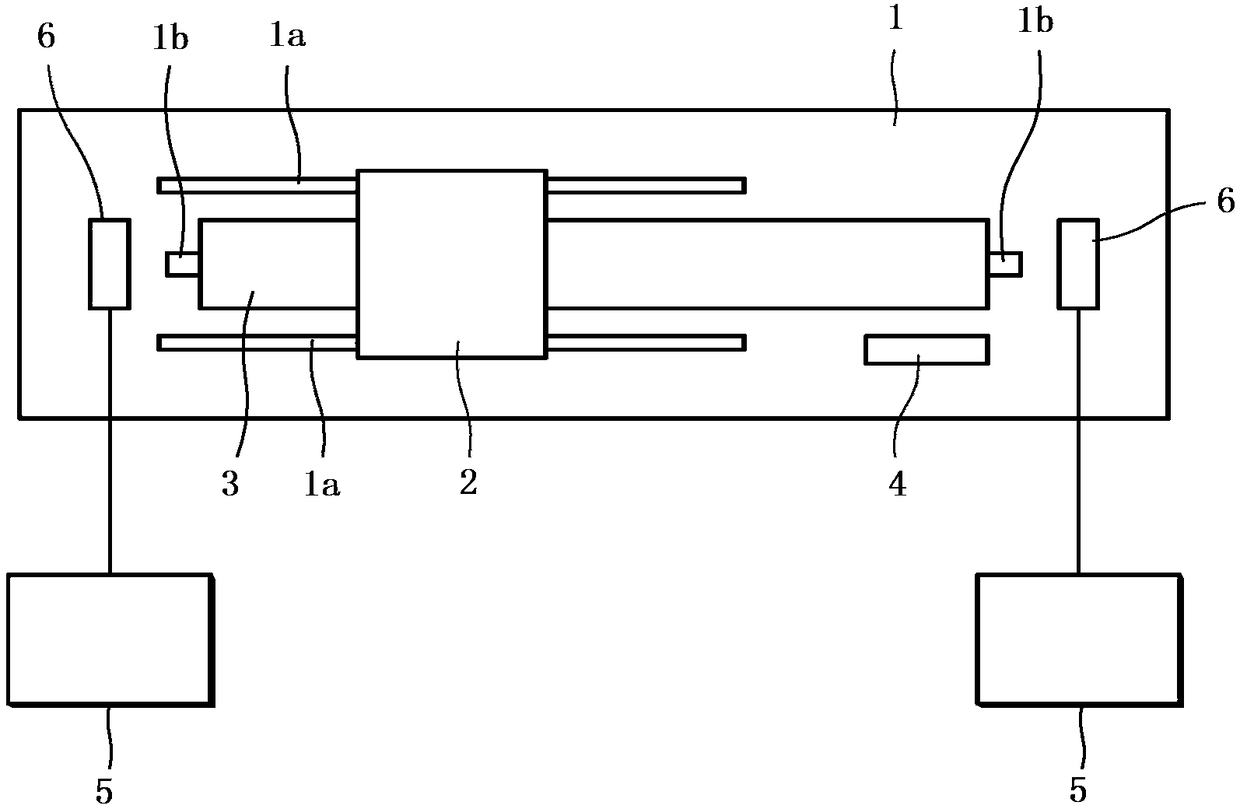

[0028] combine Figure 1 to Figure 4 Shown is the first specific implementation of a linear movement system and a laser processing device with the linear movement system of the present invention. First, the linear movement system includes a processing table 1 and a workpiece set on the processing table 1. Conveying plate 2 and magnetic force track 3, described magnetic force track 3 is arranged on the below of workpiece conveying plate 2, and described workpiece conveying plate 2 is provided with the first electromagnet that is used to produce reaction force between magnetic force track 3 to realize workpiece conveying Reverse movement of plate 2 and magnetic track 3.

[0029] The processing table 1 is provided with a first guide rail 1 a for guiding the movement of the workpiece conveying plate 2 and a second guide rail 1 b for guiding the movement of the magnetic rail 3 . The first guide rail 1a and the second guide rail 1b respectively extend along the length direction of ...

Embodiment 2

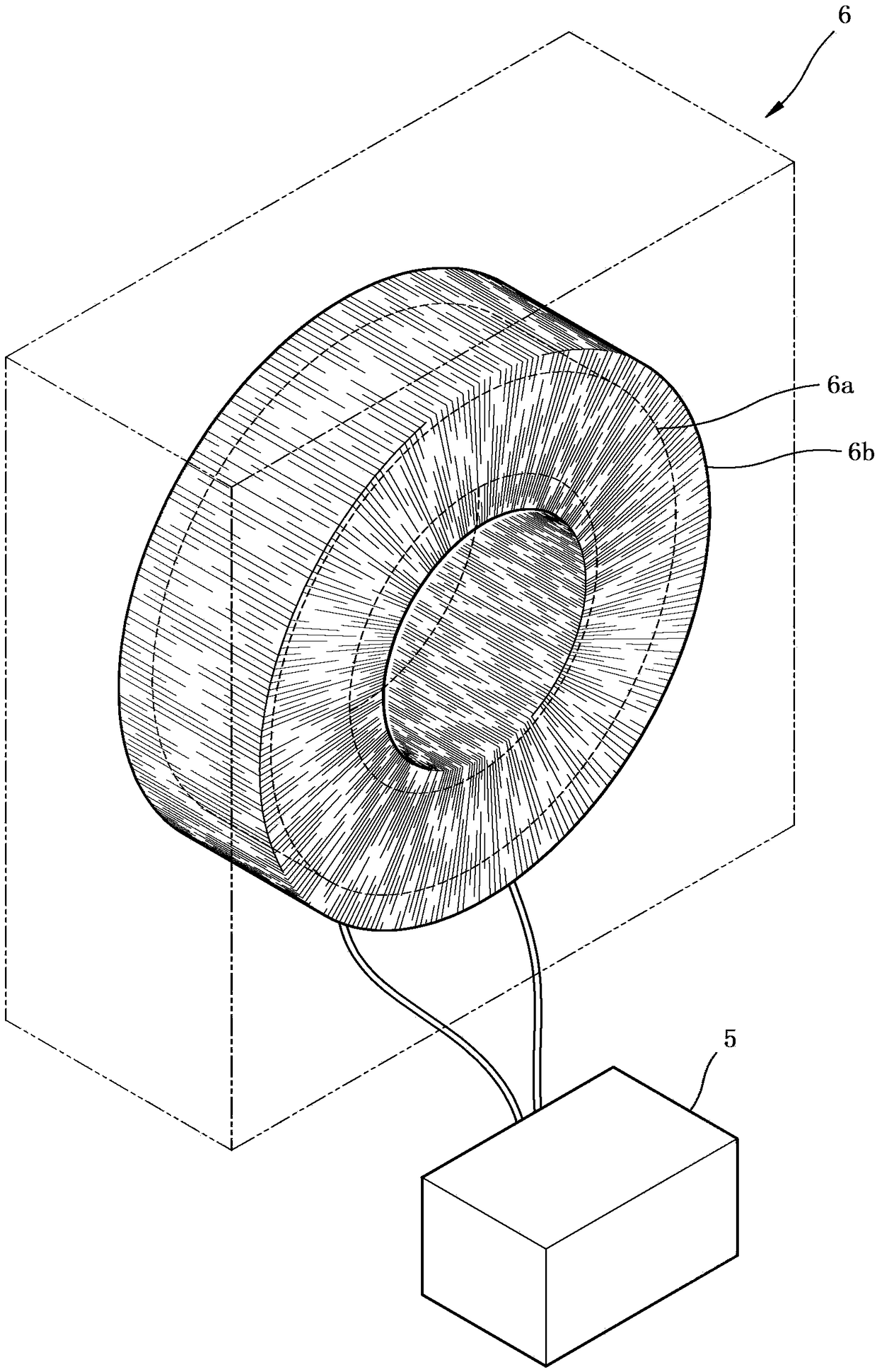

[0034] Embodiment 2: In this embodiment, combining Figure 5 to Figure 7 As shown, the difference from Embodiment 1 is that each reaction force compensation unit also includes a telescopic mechanism connected to the second electromagnet 6, and the second electromagnet 6 is realized by the telescopic mechanism and the magnetic track 3 same direction movement. Each telescopic mechanism includes an electromagnet support 7 installed on the processing table 1 , and a telescopic cylinder 8 or spring 9 is arranged between the electromagnet support 7 and the second electromagnet 6 . When the magnetic track 3 moves, the second electromagnets 6 at both ends provide the magnetic force opposite to the direction of motion for the magnetic track 3 and move in the same direction as the magnetic track 3, thereby increasing the second electromagnet 6 to provide magnetic force for the magnetic track 3. time to provide sufficient compensating force for the magnetic track 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com