Integrated pump and motor

a technology of integrated pumps and motors, which is applied in the direction of positive displacement liquid engines, pumping cylinders, machines/engines, etc., can solve the problems of not allowing vibration-free operation of pumps and not allowing quiet operation, so as to reduce the parts count of the overall device, simplify the motor construction, and reduce the effect of overall device parts coun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

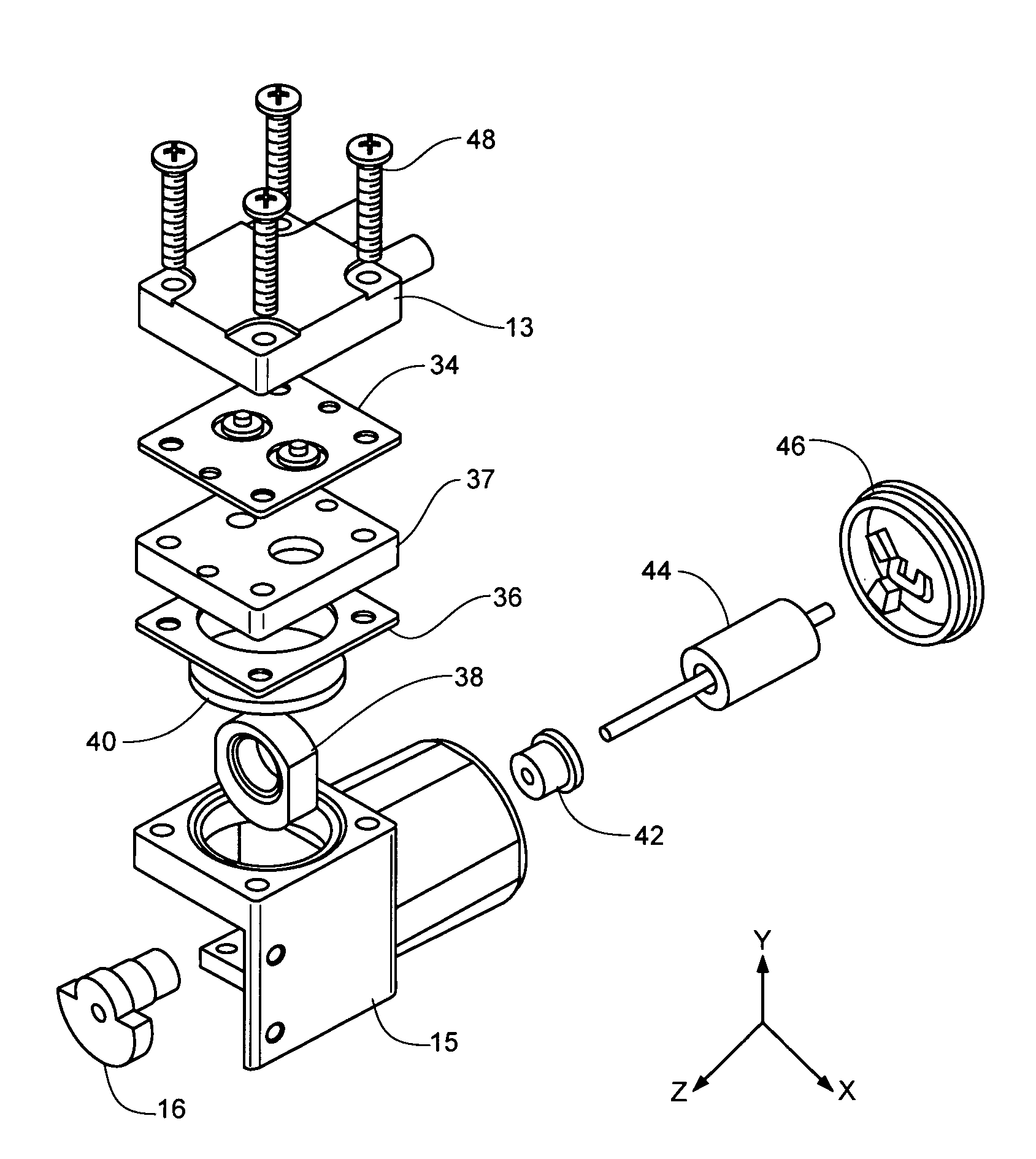

[0014]FIG. 1 shows the general layout of the motor / pump assembly 10. The pump portion is generally designated 32 while the motor portion is generally designated 30. In operation DC current is supplied to the motor and it drives the pump. Air is admitted through port 12 and emitted from port 14.

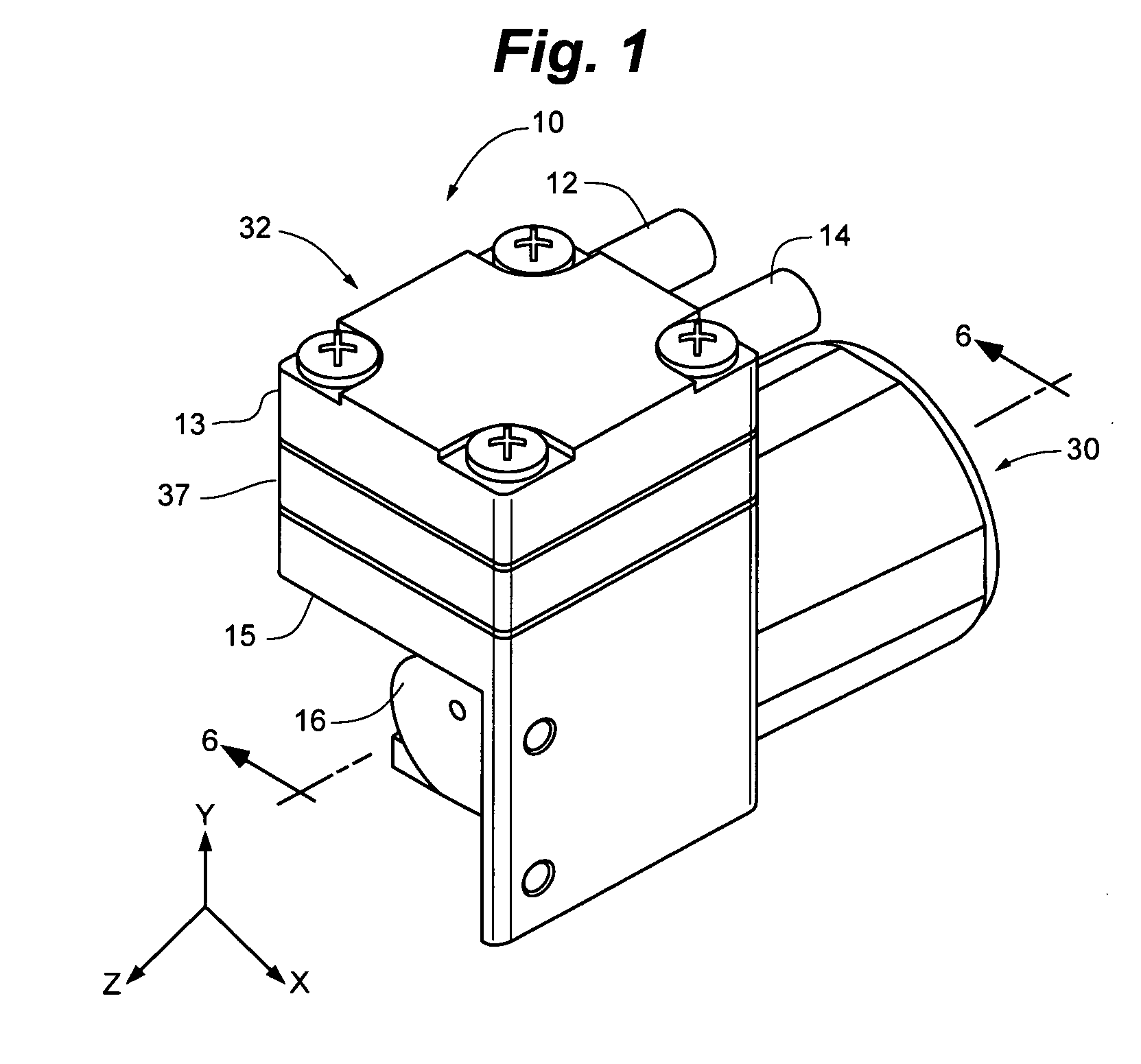

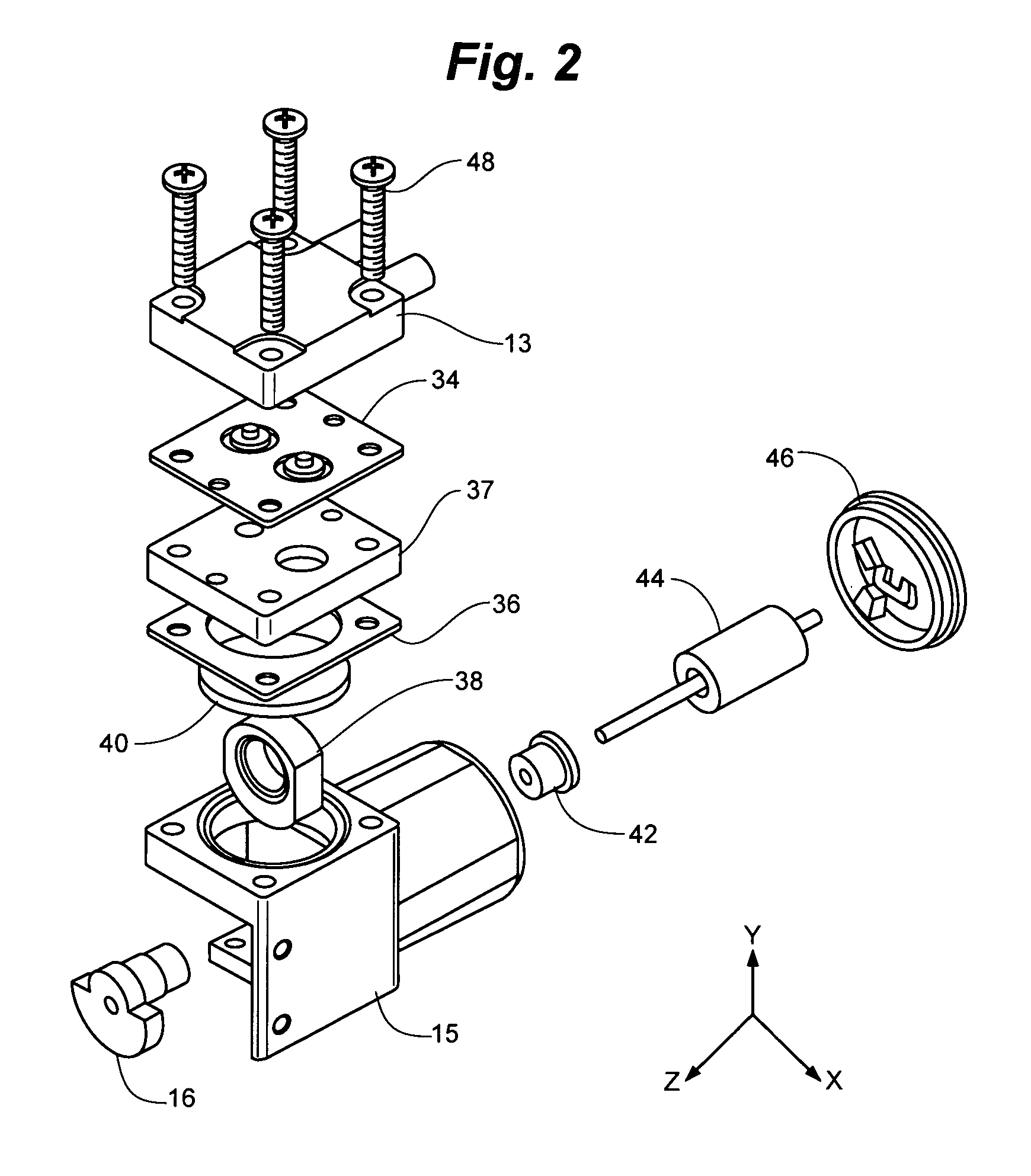

[0015]FIG. 2 shows the assembly 10 exploded to show the individual components. The pump portion includes the cylinder head 13, which sandwiches the flap valve sheet 34 between the cylinder head 13 and the cylinder plate 37. Screws typified by screw 48 holds the cylinder head valve plate 24 and cylinder to the to the motor / pump frame 15. The connecting rod / piston 38 is positioned in to the cylinder.

[0016]FIG. 3 shows the motor / pump frame 15 in isolation. FIG. 4 is a cross-section of the motor / pump frame 15 showing the stator assembly 56 that is placed in the mold and molded into position in the motor / pump frame 15. In the figure the axial motor shaft 20 is shown in isolation intersecting at 90°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com