Radial-axial bidirectional hybrid magnetic circuit frameless permanent magnet synchronous motor

A hybrid magnetic circuit and permanent magnet motor technology, applied to synchronous motors with stationary armatures and rotating magnets, synchronous machines, magnetic circuits, etc., can solve the problem of increasing copper loss and cannot meet the needs of direct drive tanks or self-propelled artillery turrets Horizontal rotation, complex structure and other issues, to achieve the effect of reducing copper consumption, small space, and simple motor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

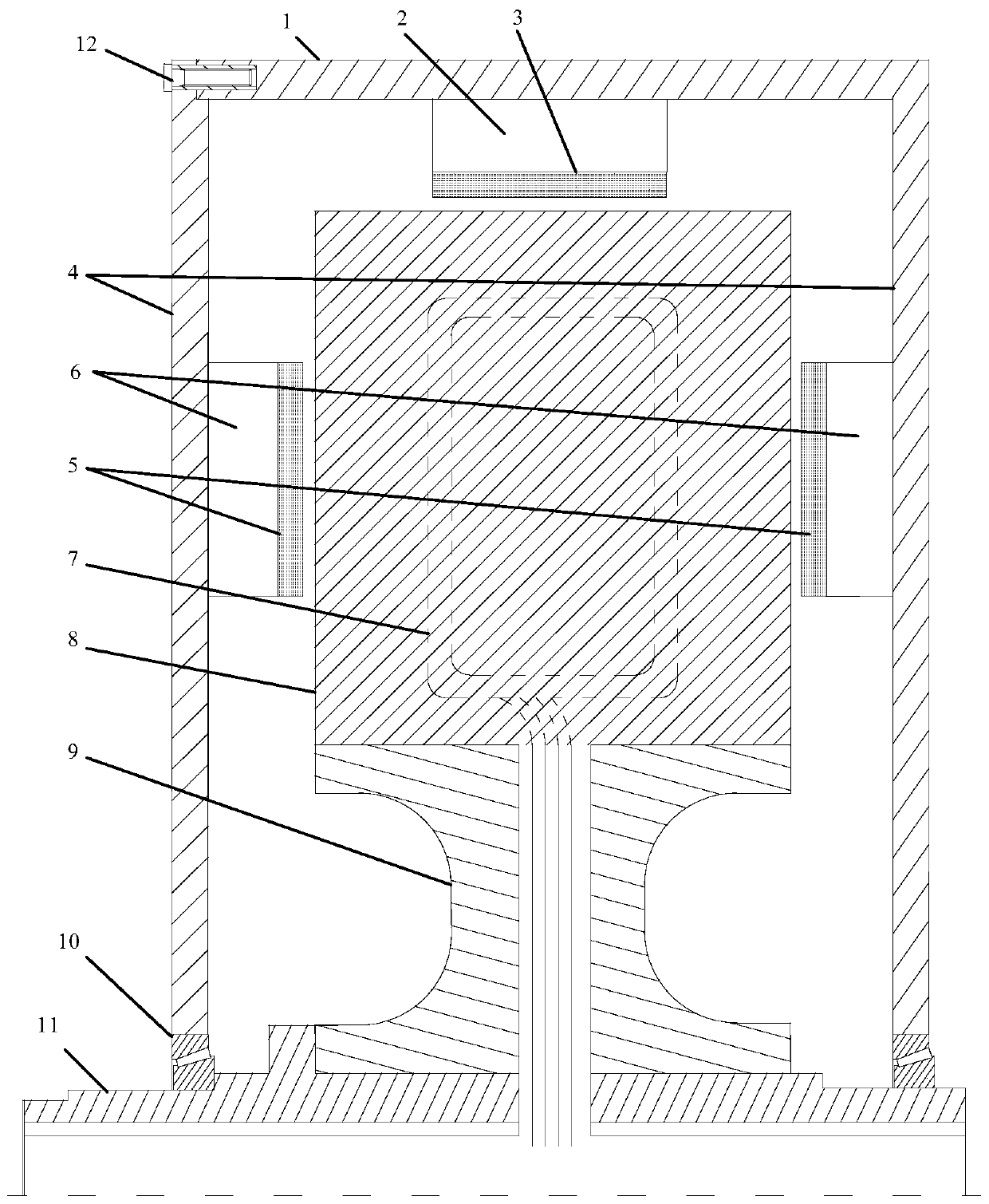

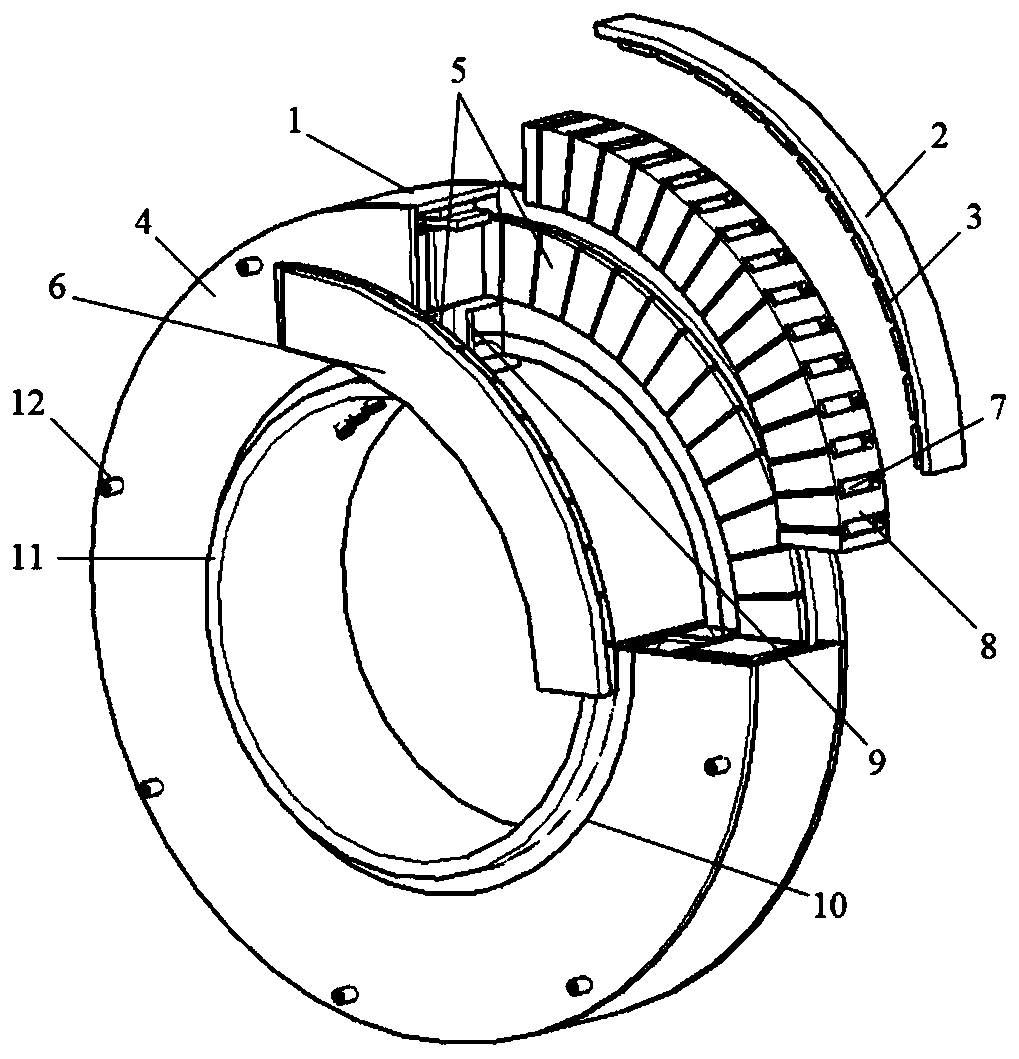

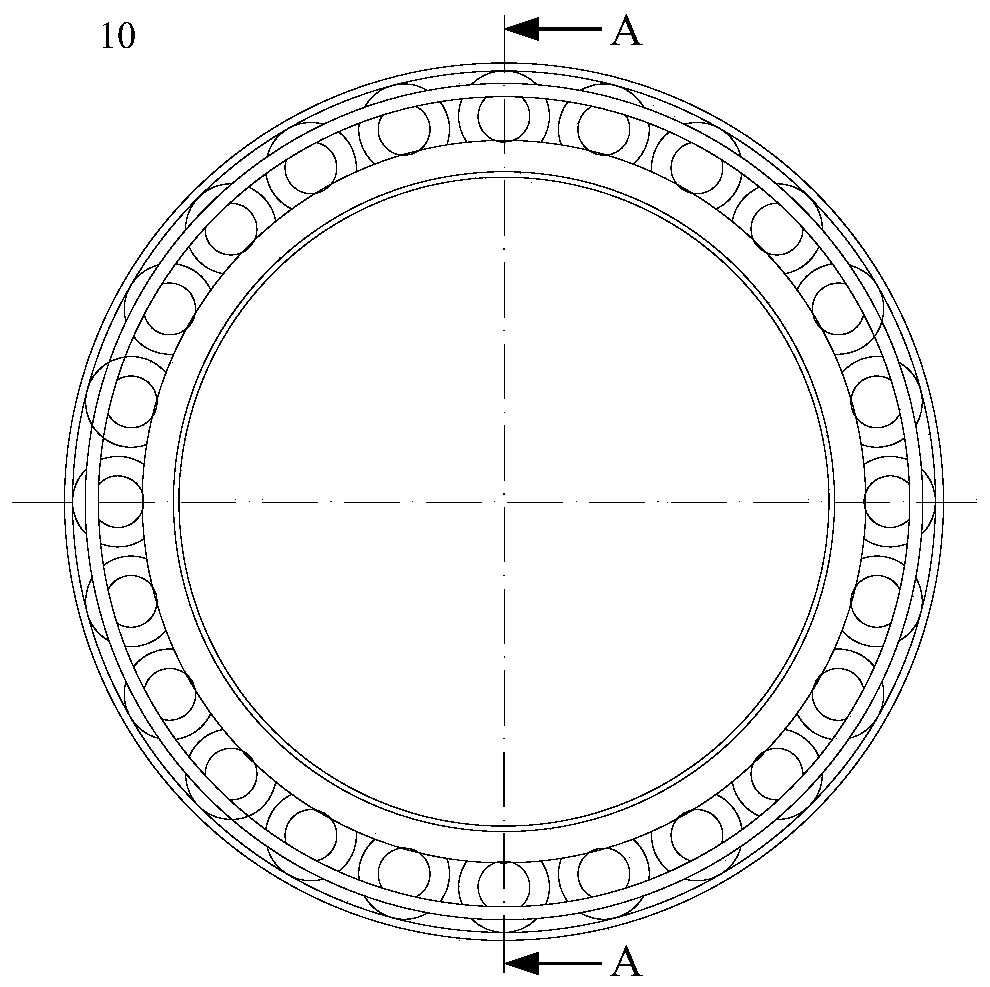

[0034] The radial-axis bidirectional hybrid magnetic circuit frameless permanent magnet motor of the present invention includes a stator and an inverted U-shaped rotor, wherein the stator part includes a stator core 8 and an armature winding 7, and the inverted U-shaped rotor includes a radial part and an axial part, the former Comprising a back yoke 2 in the shape of a thin cylinder, an outer casing 1 and a permanent magnet 3, the latter having two axial sides each containing a disc-shaped back yoke 6, an end cap 4 and a permanent magnet 5;

[0035] The stator part is between the disk-shaped back yokes 6 on both sides of the axial direction, and there are end covers 4 on the outer sides of both axial sides, and the end covers 4 on both axial sides and the radial outer casing 1 are closed as a A cavity, the stator part and the inverted U-shaped rotor are installed in the cavity, and the whole is set on the shaft wall of the hollow shaft 11;

[0036] A radial air gap is formed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com