Device and thread guiding ring for a ring spinning machine or twisting machine

A technology of ring spinning and twisting machines, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc. It can solve problems such as thread damage, spinning speed not reaching the expected value, and variation. , to achieve the effect of quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

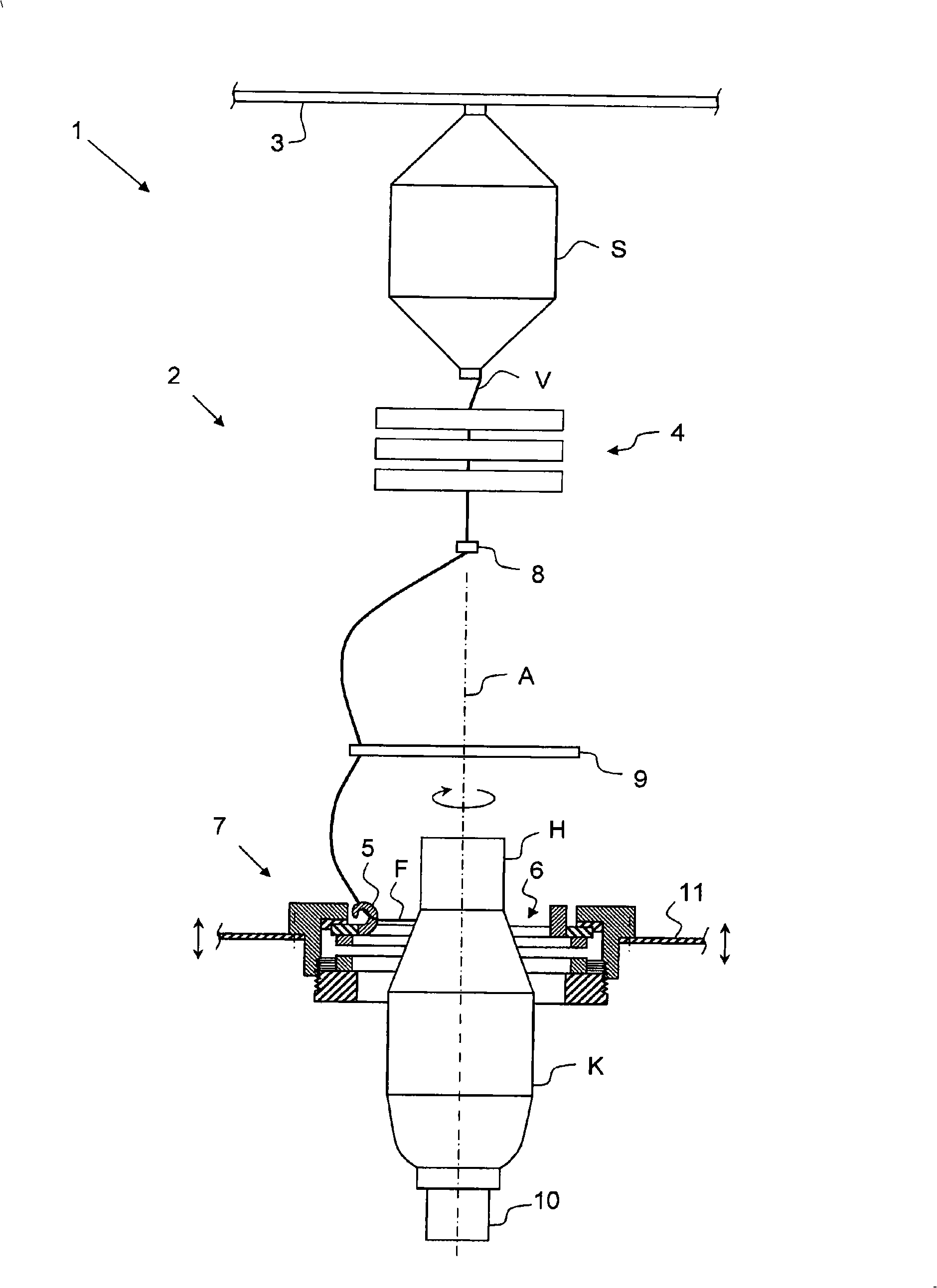

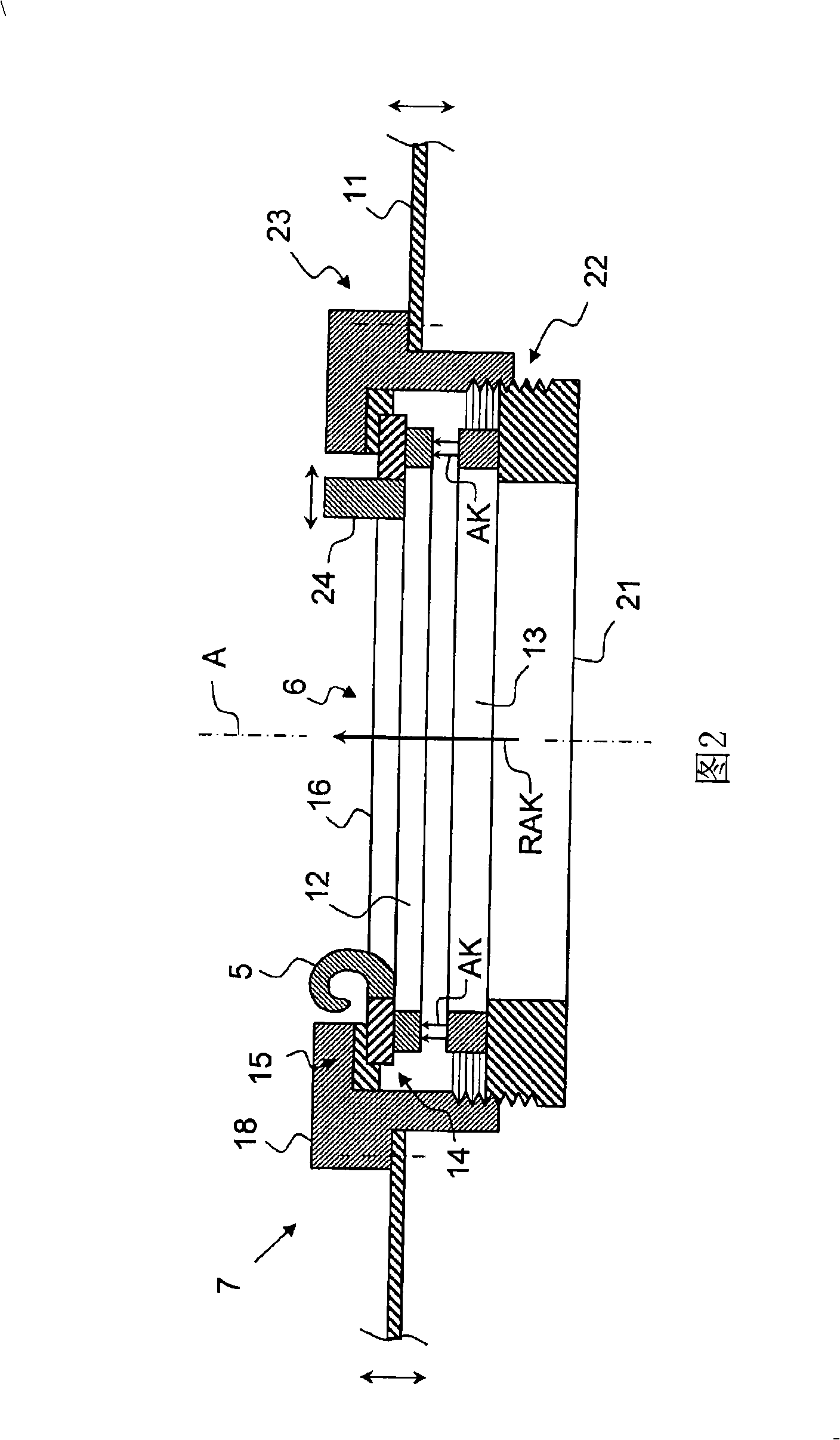

[0072] attached figure 1 A diagrammatic view showing the working position 2 of the ring spinning machine 1 . The ring spinning machine 1 comprises a number of further working units not shown as well as a large number of central devices.

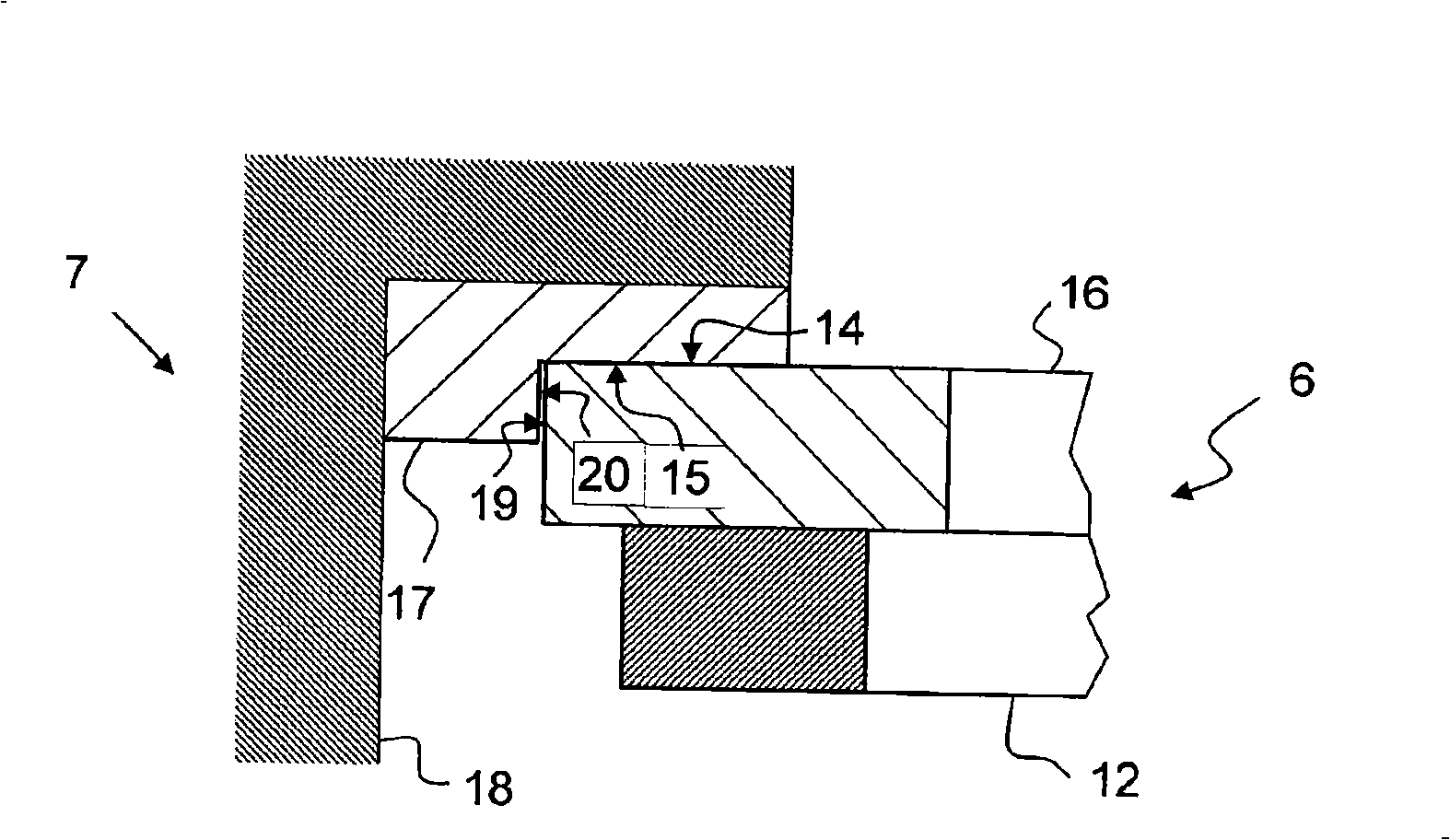

[0073] This working unit 2 comprises a creel 3 on which a bobbin S wound with a thread V is located. The thread V is usually a roving V made of, for example, what is known as a flyer, and carries only a slight protective twist. The thread V is drawn from the bobbin S and passed to a traction system 4, indicated only schematically. Although not visible in this illustration, the traction 4 is positioned at an angle for technical reasons. Its purpose is to pull out the thread V to its final fineness. In order to give strength to the not too thin thread V by twisting the thread V, and to wind the twisted thread F in an appropriate form, a thread guide member 5 is provided, and this is fixed to the thread guide ring spindle 6 . The yarn guide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com