A self-adjusting cable tensioning device

A tensioning device, self-adjusting technology, applied in the direction of adjusting/maintaining mechanical tension, etc., can solve the problems of pulling the power rod, collapse, unable to self-adjust, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The invention will be described in detail below in conjunction with specific embodiments.

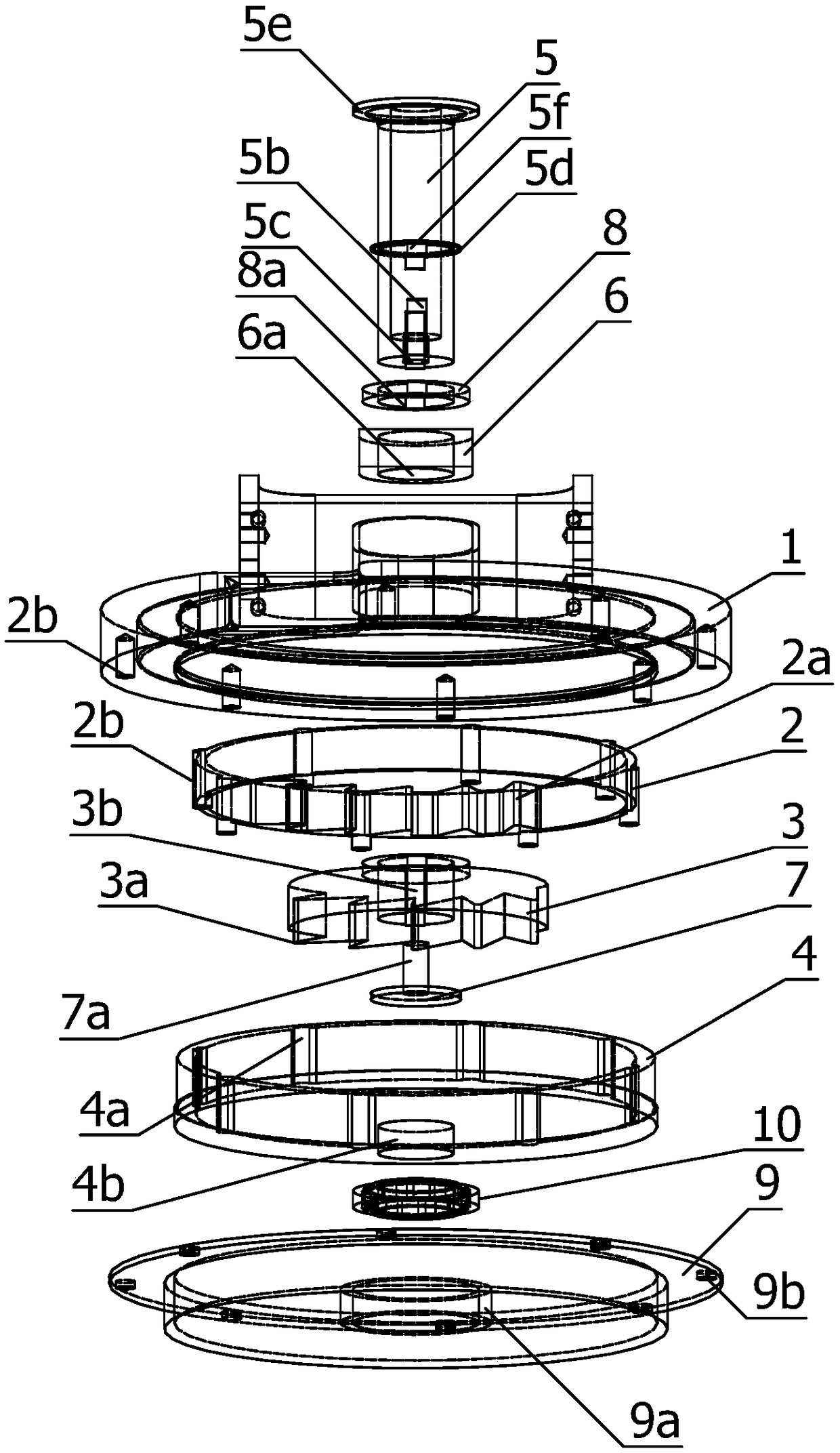

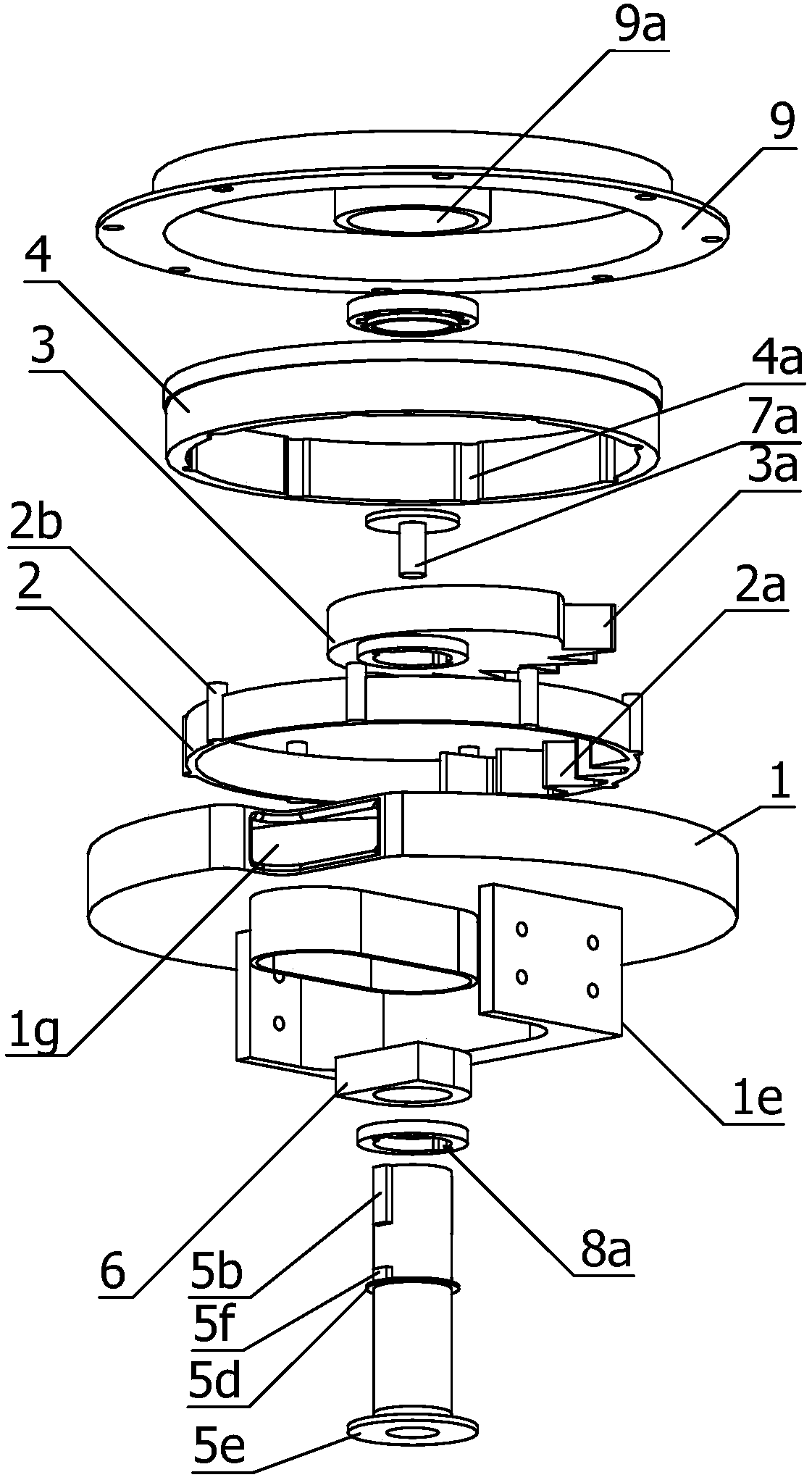

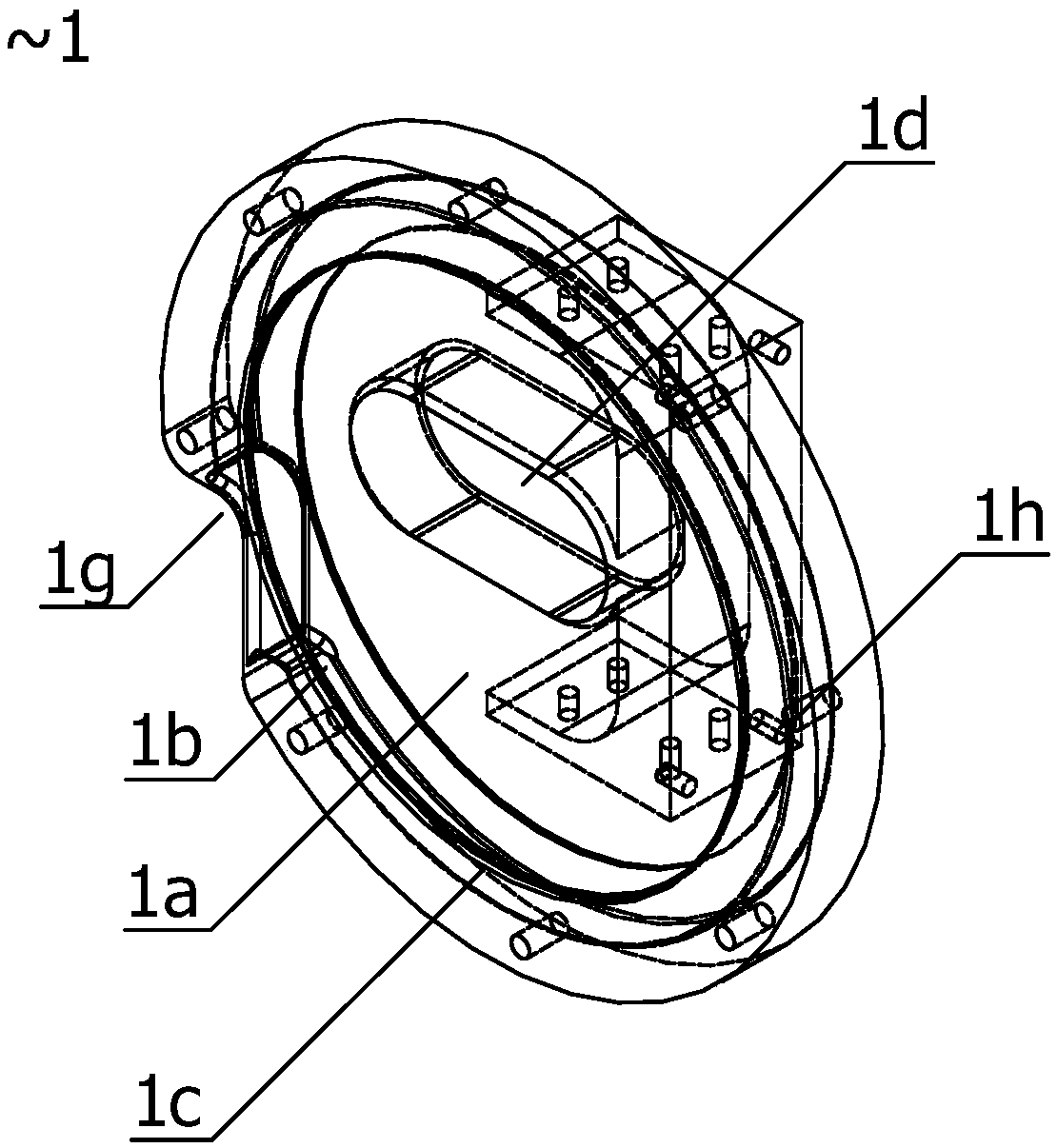

[0018] Such as Figure 1-Figure 4 As shown, a self-adjusting cable tensioning device of the present invention includes a mounting base 1 for connecting various structures, and a cylindrical mounting cavity 1a is provided inside the mounting base 1, and the edge of the mounting cavity 1a extends to the surroundings to install A winding groove 1b is formed inside the seat 1; in this embodiment, for the purpose of saving materials, the shape of the mounting seat in this embodiment is the same as the shape of the mounting cavity, but in fact its shape is based on actual needs and The state of the installation space can be set freely, including setting it as a block shape, a plate shape, etc. One end of the cylindrical installation chamber 1a passes through the installation seat 1 to form an installation opening 1c, and the bottom of the installation chamber 1a is dug with a strip-sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com