Multifunctional cloth inspecting machine

A cloth inspection machine, multi-functional technology, applied in the field of cloth inspection machine, can solve the problems of wasting labor cost, heavy cloth weight, cumbersome operation, etc., and achieve the effect of improving quality, avoiding impact, and reducing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

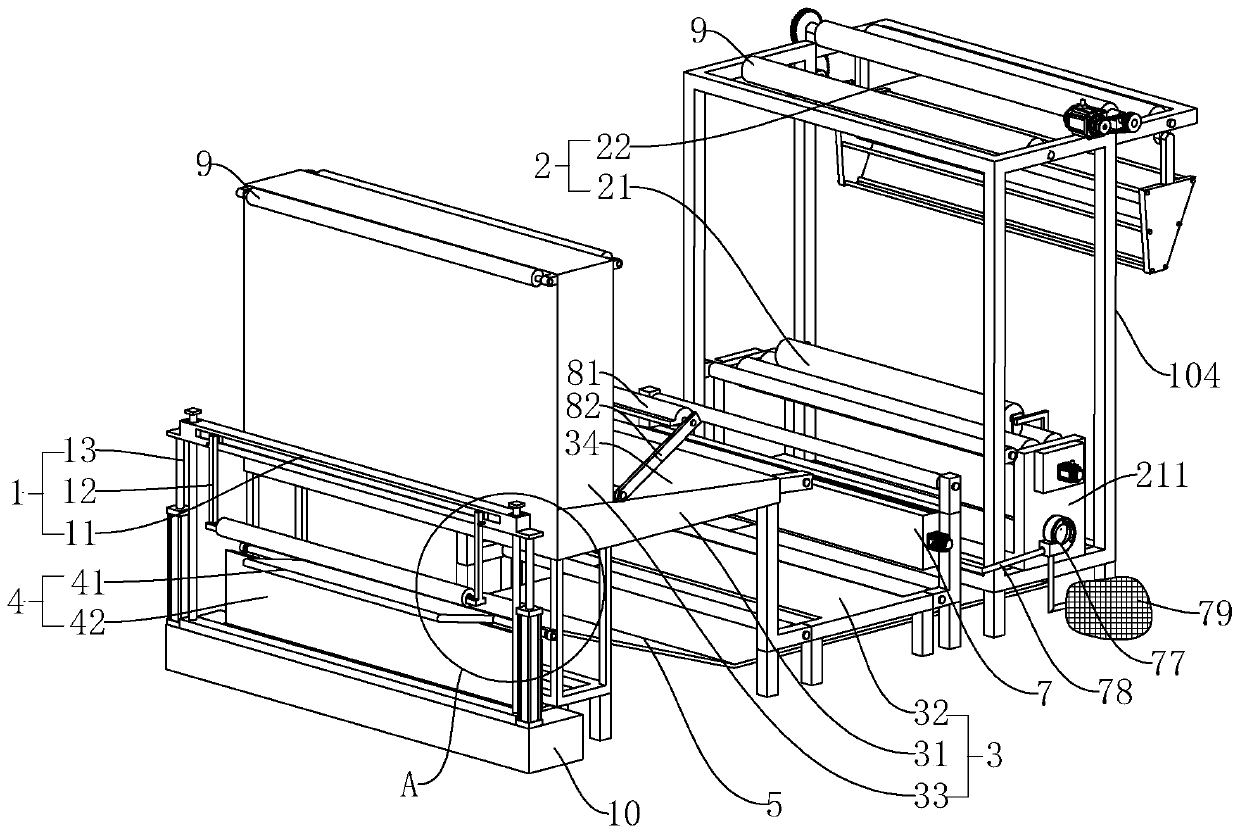

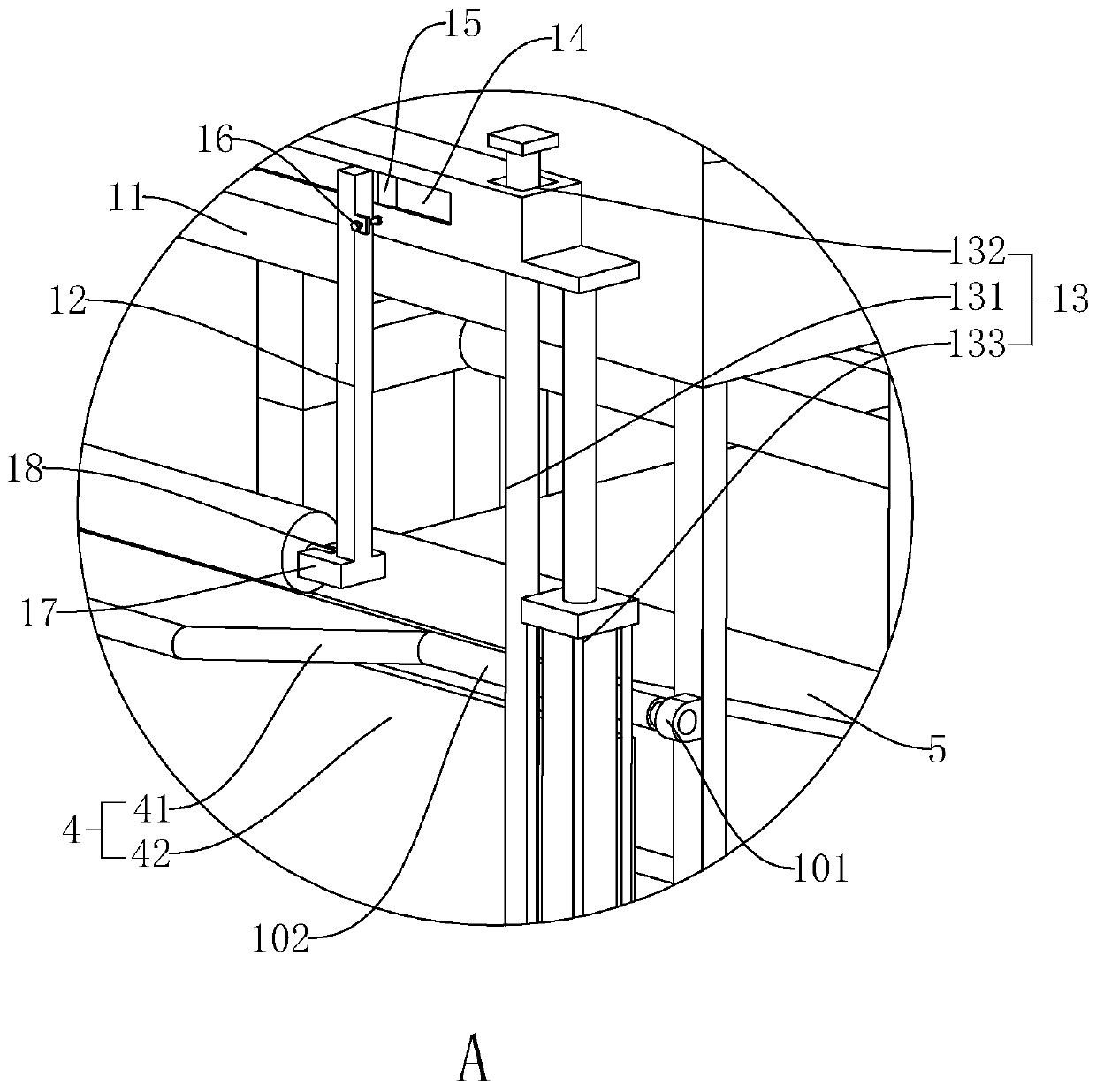

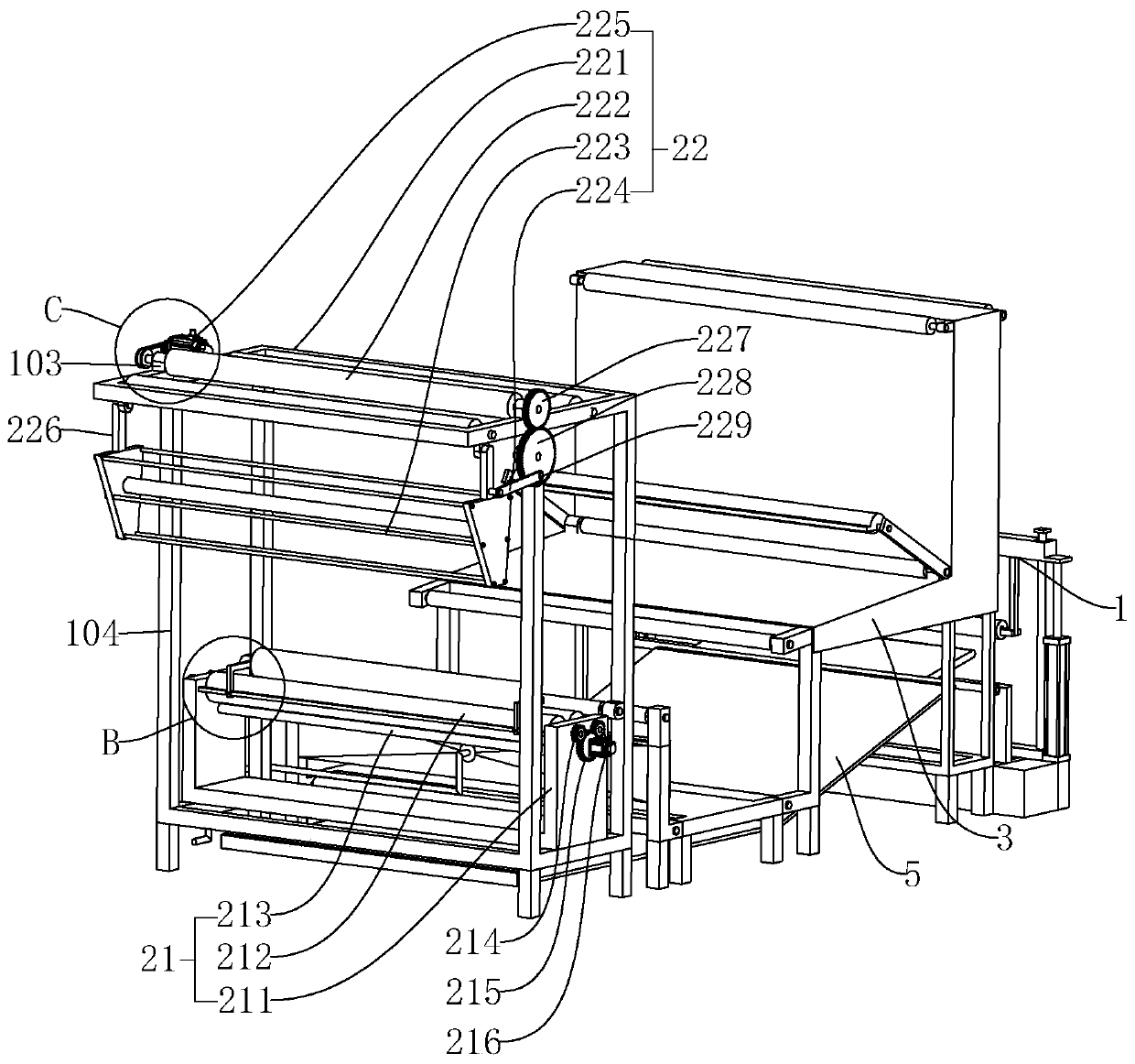

[0042] Refer to attached figure 1 , a multi-functional cloth inspecting machine, which sequentially includes a cloth releasing device 1, a machine platform 3, a cleaning assembly 7 and a cloth receiving device 2 along the direction of cloth running, and also includes multiple The cloth guide roller 9; wherein, the machine platform 3 includes a frame 31, a workbench 32 and a lamp panel 33, and the top of the frame 31 is fixedly provided with a working panel 34, and the lamp panel 33 is arranged on the working panel 34 near the cloth releasing device 1 On one side, the workbench 32 is fixed on the bottom of the frame 31 away from the cloth releasing device 1, and the lamp board 33 is used to provide light for the cloth; when working, the cloth is unwound by the cloth releasing device 1, and the cloth passes through the lamp board in turn 33 and the work panel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com