Anisotropic inner circle orientation multi-pole magnetic ring and mold and preparation method thereof

A multi-pole magnetic ring, anisotropic technology, used in the manufacture of inductors/transformers/magnets, permanent magnets, electrical components, etc., can solve the problem of low magnetic field in inner circle orientation, and achieve stable and quiet operation, good concentricity, Assemble simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

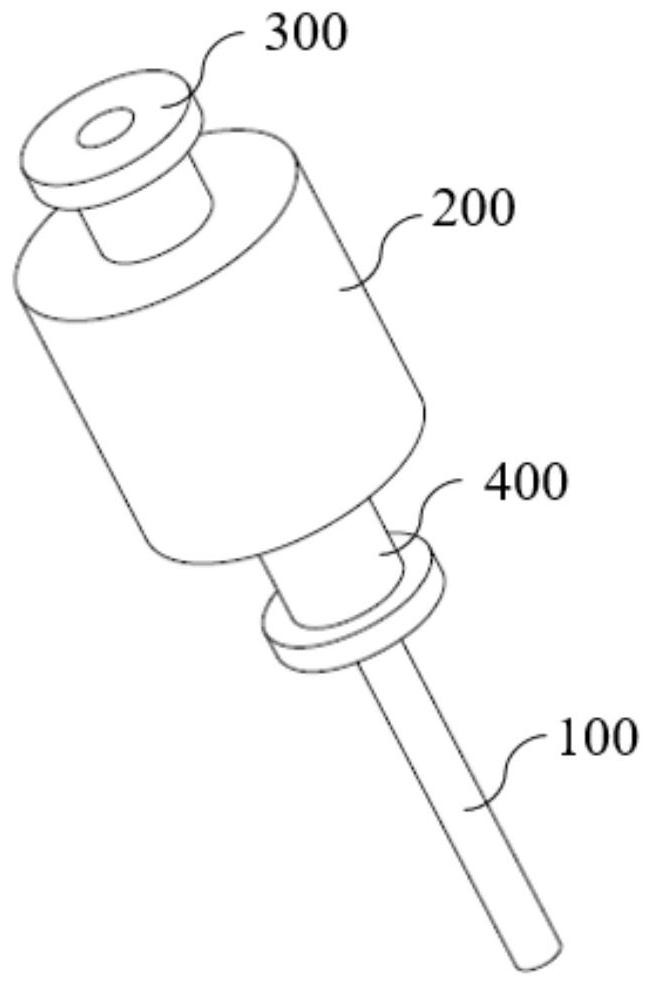

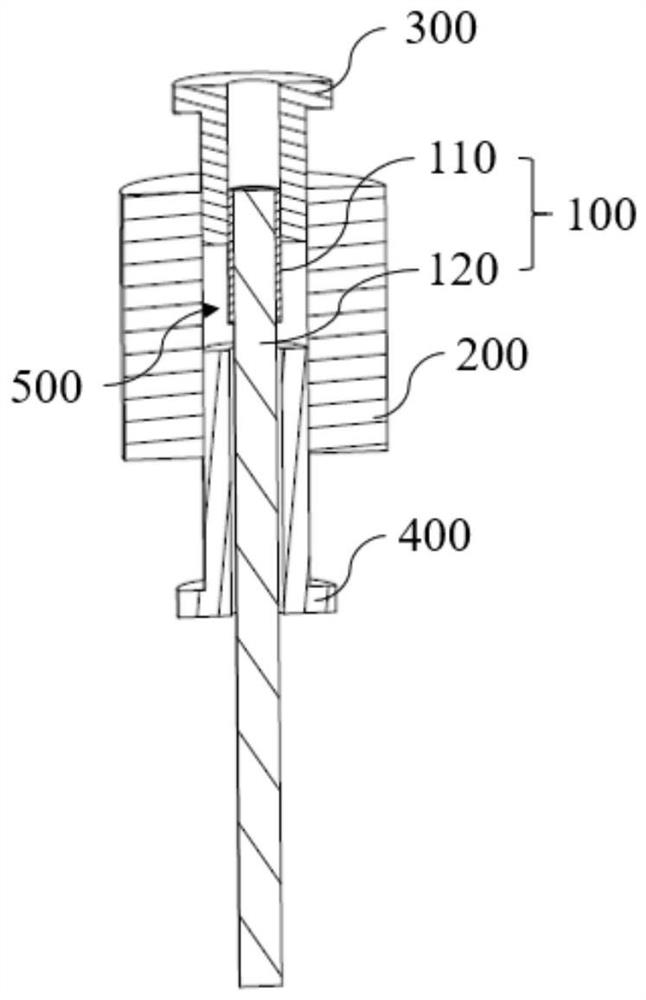

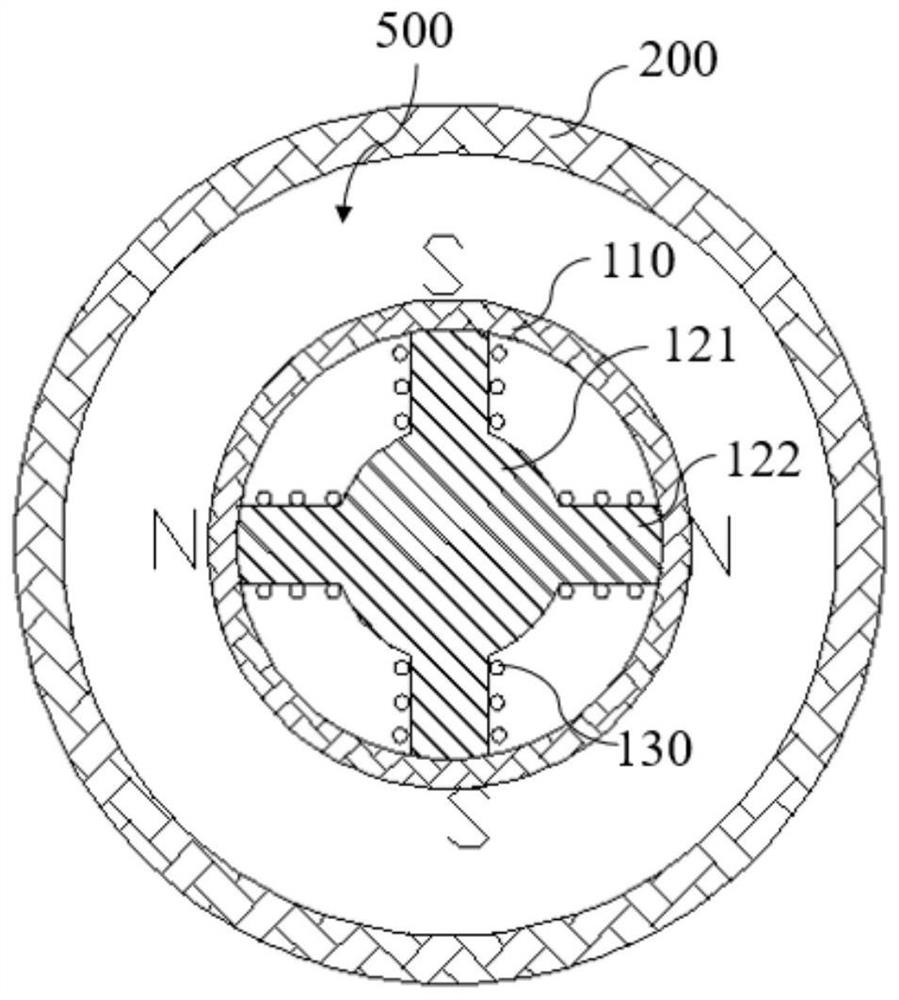

[0047] The mold for the anisotropic inner circle orientation multi-pole magnetic ring in this embodiment is an anisotropy for making D50*d30*H27-N4P (wherein: D means the outer diameter, d means the inner diameter, H means the height, and N means the inner circle orientation) A multi-pole magnetic ring filled with 4 poles, that is, the mold is provided with 4 protrusions 122, Figure 1-3 It is a schematic diagram of the mold structure of this embodiment.

[0048] The method for preparing the anisotropic inner circle oriented 4-pole magnetic ring of this embodiment using the above-mentioned mold is as follows:

[0049] (1) Powder making: The magnetic powder is made by uniformly mixing the primary formula and the secondary formula;

[0050] The primary formula is: 85 parts of iron oxide; 2.5 parts of calcium carbonate; 0.2 parts of silicon dioxide; 0.4 parts of boric acid; 1.2 parts of strontium carbonate, 5 parts of cobalt oxide, and 7 parts of lanthanum oxide;

[0051] The s...

Embodiment 2

[0058] The mold for the anisotropic inner circle orientation multi-pole magnetic ring in this embodiment is an anisotropy for making D37*d22*H15-N8P (where: D means the outer diameter, d means the inner diameter, H means the height, and N means the inner circle orientation) A multi-pole magnetic ring filled with 8 poles, that is, the mold is provided with 8 protrusions 122 .

[0059] Using the above-mentioned mold to prepare the anisotropic inner circle orientation 8-pole magnetic ring of this embodiment, the preparation method is as follows:

[0060] (1) Powder making: The magnetic powder is made by uniformly mixing the primary formula and the secondary formula;

[0061] The primary formula of magnetic powder is: 80 parts of iron oxide; 1 part of calcium carbonate; 0.1 part of silicon dioxide; 0.1 part of strontium carbonate; 0.2 part of polyvinyl chloride; 1 part of cobalt oxide and 3 parts of lanthanum oxide;

[0062] The secondary formula is: 0.2 part of calcium stearate;...

Embodiment 3

[0069] The mold of the anisotropic inner circle orientation multi-pole magnetic ring in this embodiment is an anisotropy for making D48*d40*H20-N6P (wherein: D means outer diameter, d means inner diameter, H means height, N means inner circle orientation) A multi-pole magnetic ring filled with 6 poles, that is, the mold is provided with 6 protrusions 122 .

[0070] The method for preparing the anisotropic inner circle oriented 4-pole magnetic ring of this embodiment using the above-mentioned mold is as follows:

[0071] (1) Powder making: The magnetic powder is made by uniformly mixing the primary formula and the secondary formula;

[0072] The primary formula of magnetic powder is: 90 parts of iron oxide; 5 parts of calcium carbonate; 1 part of silicon dioxide; 0.8 parts of boric acid; 2 parts of strontium carbonate; 1 part of polyvinyl chloride; 2.5 parts of cobalt oxide and 12 parts of lanthanum oxide;

[0073] The secondary formula is: 2 parts of calcium stearate; 1 part ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com