An aluminum alloy conductor polypropylene insulated interlocking armored power cable

An aluminum alloy conductor, interlocking armoring technology, used in power cables, insulated cables, power cables with shielding/conducting layers, etc., can solve the problem of poor composite bonding strength, heavy material, impact resistance and resistance of insulation boards Poor cracking performance and other problems, to achieve the effect of reducing weight, improving mechanical strength, processing performance and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

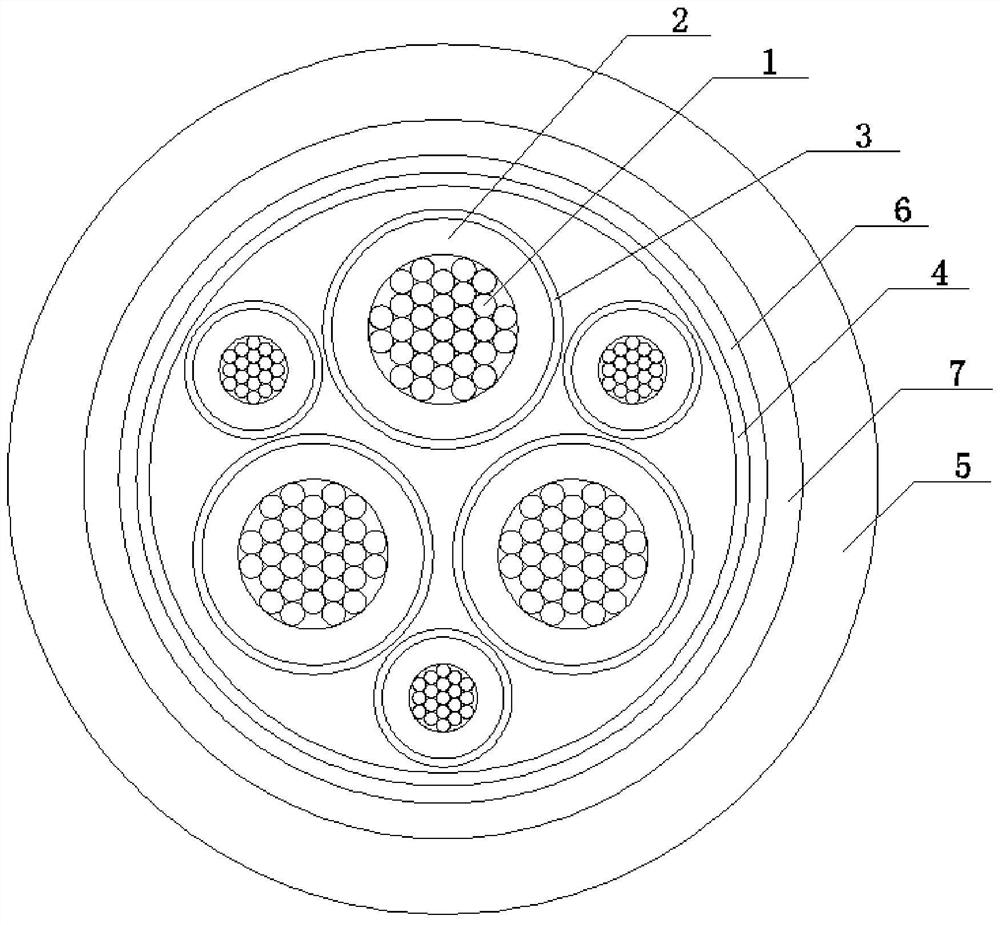

[0039] An aluminum alloy conductor polypropylene insulated chain armored power cable, comprising a conductor 1, an insulating layer 2, an inner shielding layer 3, a wrapping layer 4 and an armoring layer 5, the conductor 1 is provided with multiple groups, and the multiple groups of conductors 1 are provided with In the wrapping layer 4, the wrapping layer 4 is sequentially covered with an outer shielding layer 6 and a sheath layer 7 from the inside to the outside, and the sheath layer 7 is covered with an armor layer 5. The insulating layer 2 and the inner shielding layer 3 are covered.

[0040] The conductor 1 is formed by twisting multiple strands of aluminum alloy wires.

[0041] Among them, the insulating layer 2 is a thermoplastic polyurethane elastomer insulating layer; by setting the thermoplastic polyurethane elastomer insulating layer, the mechanical strength of the cable can be effectively improved, and it has high tear strength and bottom compression set, excellent...

Embodiment 2

[0049] An aluminum alloy conductor polypropylene insulated chain armored power cable, comprising a conductor 1, an insulating layer 2, an inner shielding layer 3, a wrapping layer 4 and an armoring layer 5, the conductor 1 is provided with multiple groups, and the multiple groups of conductors 1 are provided with In the wrapping layer 4, the wrapping layer 4 is sequentially covered with an outer shielding layer 6 and a sheath layer 7 from the inside to the outside, and the sheath layer 7 is covered with an armor layer 5. The insulating layer 2 and the inner shielding layer 3 are covered.

[0050] The conductor 1 is formed by twisting multiple strands of aluminum alloy wires.

[0051] Among them, the insulating layer 2 is a thermoplastic polyurethane elastomer insulating layer; by setting the thermoplastic polyurethane elastomer insulating layer, the mechanical strength of the cable can be effectively improved, and it has high tear strength and bottom compression set, excellent...

Embodiment 3

[0059] An aluminum alloy conductor polypropylene insulated interlocking armored power cable, comprising the following specific production steps:

[0060] Step 1, twisting multiple strands of aluminum alloy wire into conductor 1;

[0061] Step 2, extruding a thermoplastic polyurethane elastic insulating layer on the outer periphery of the conductor 1 to form the insulating layer 2;

[0062] Step 3, winding a layer of graphene composite high semi-conductive nylon tape on the outside of the insulating layer 2 to form the inner shielding layer 3;

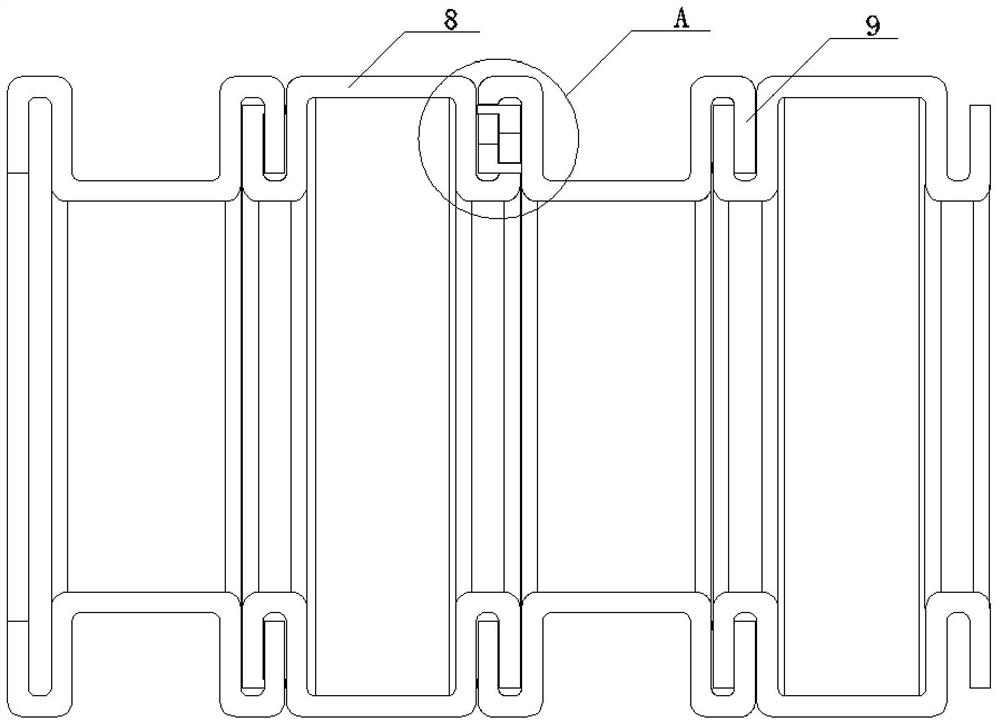

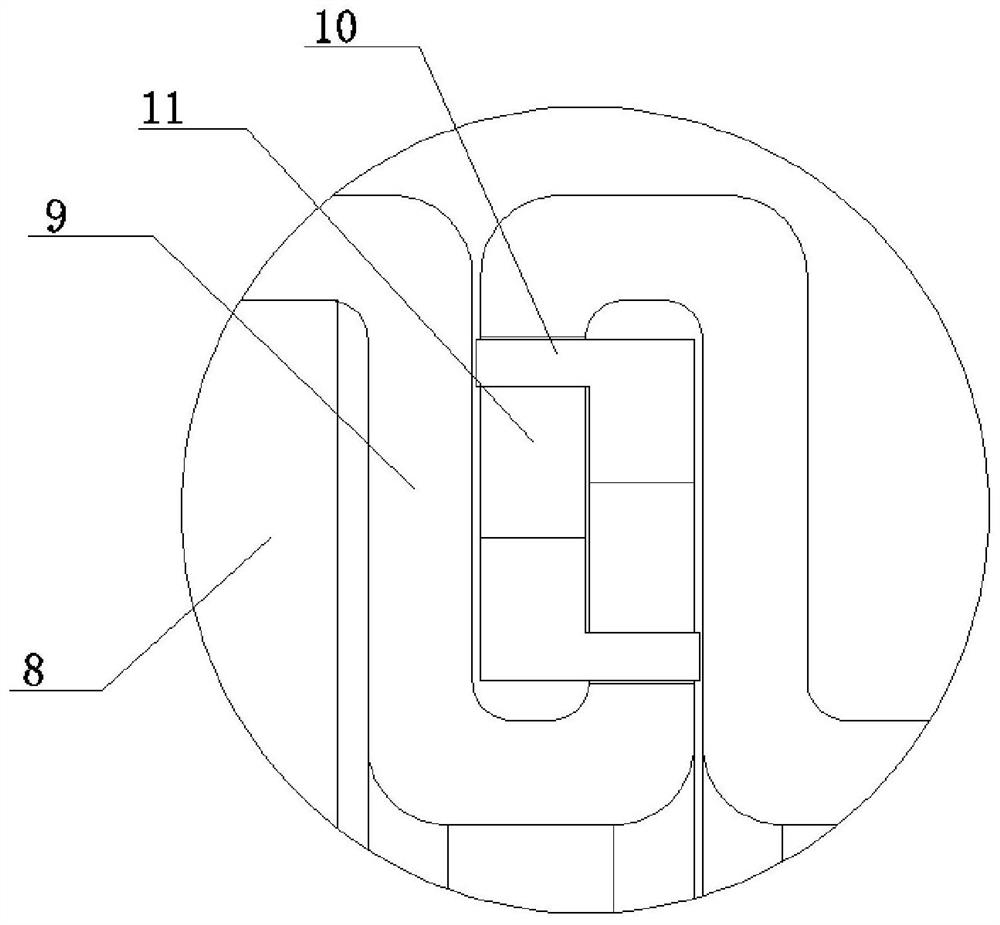

[0063] Step 4, twisting a plurality of conductors to form a package body and wrapping the conductive cloth tape to form a wrapping layer 4;

[0064] Step 5, covering the cladding layer 4 with a nickel-plated copper wire braided layer, and filling the nickel-plated copper wire braided layer with foamed rubber to form an outer shielding layer 6;

[0065] Step 6, extruding a layer of foamed thermoplastic elastomer on the outer shielding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com