Self-balancing switched reluctance motor

A switched reluctance motor, self-balancing technology, applied in electrical components, electromechanical devices, etc., can solve problems such as high noise and vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further explained below in conjunction with the accompanying drawings.

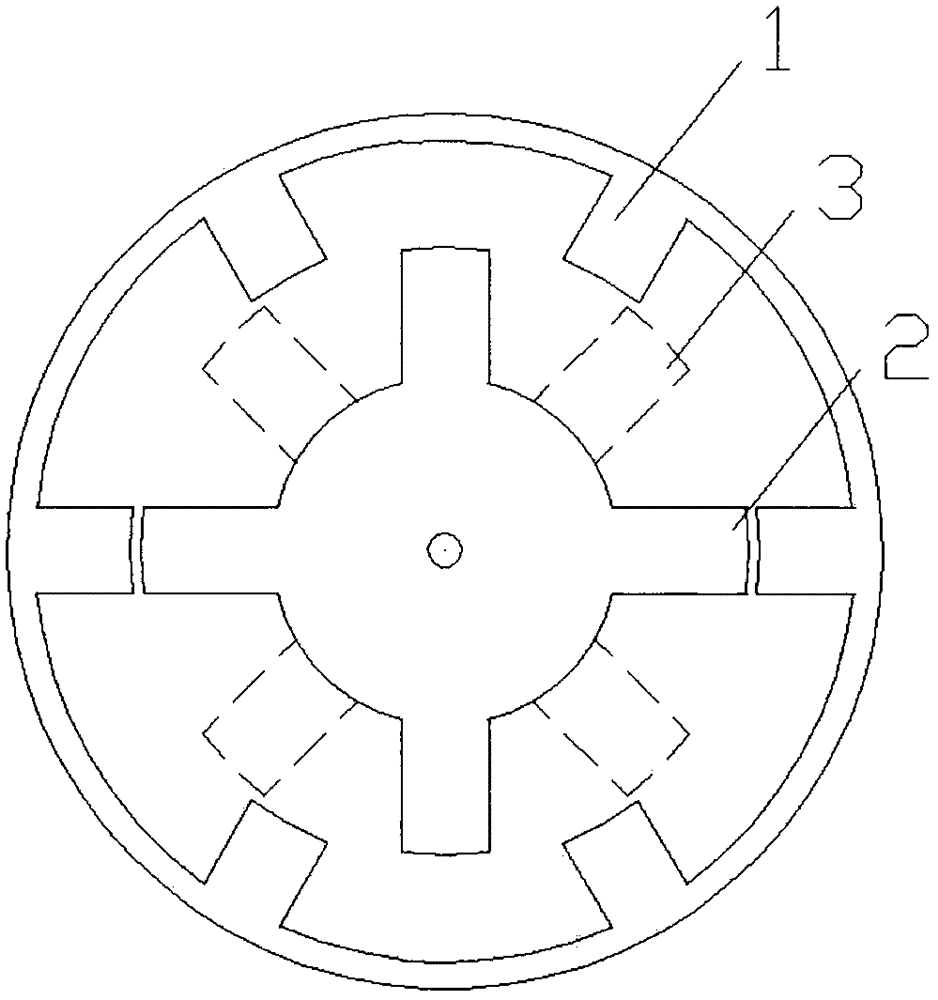

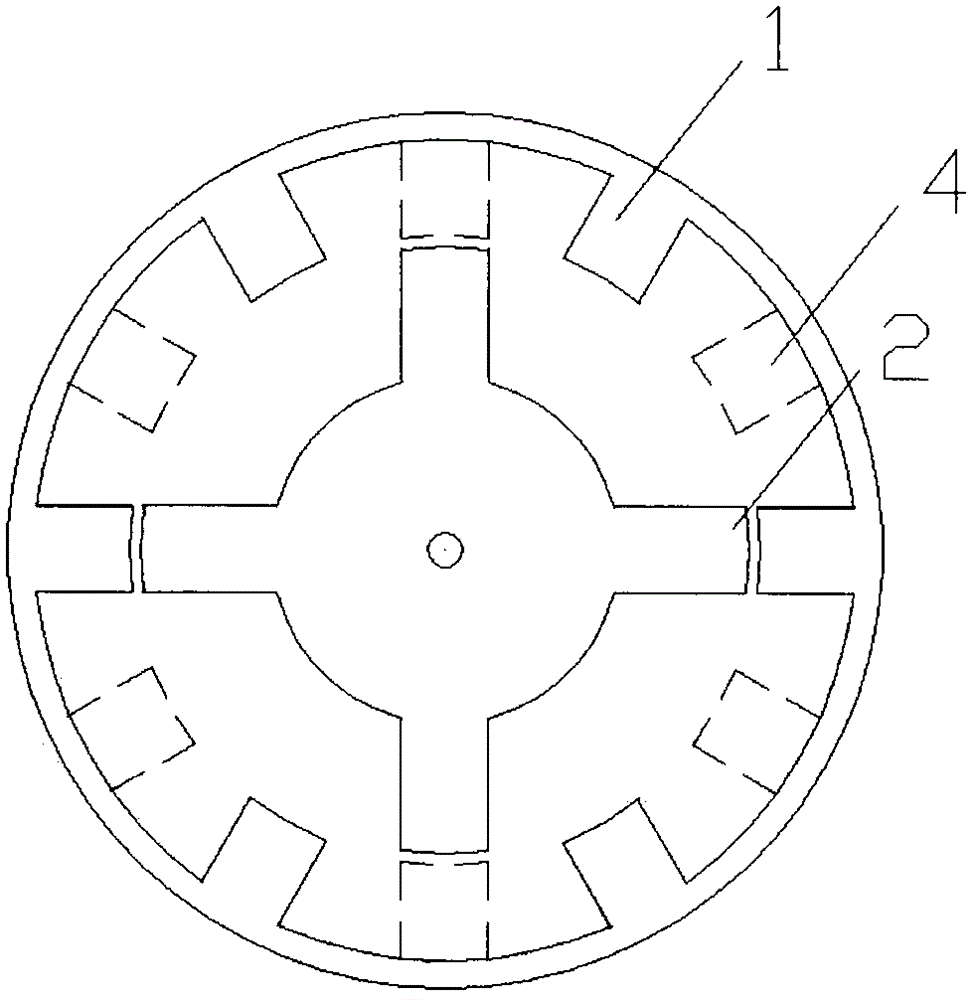

[0015] Such as figure 1 , figure 2 As shown, it is an embodiment of the present invention, the salient poles of the stator (1) are wrapped with coils, the rotor (2) and the rotor (3) are coaxially connected and separated by a certain distance, the rotor (2) and the rotor ( 3) The salient poles are staggered by 30°. A magnetic field is generated by controlling the on-off coil current on each pair of salient poles of the stator (1), and the rotor (2) and the rotor (3) are respectively driven by the magnetic field to rotate according to the principle of minimum reluctance. During the working process, the working state of the rotor (2) and the rotor (3) is just opposite. When the torque of the rotor (2) is the largest, the torque of the rotor (3) is just the minimum; when the torque of the rotor (2) is the minimum, the torque of the rotor (3) is just The torque is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com