Wide-width large-span hybrid beam extradosed cable-stayed bridge system and construction method thereof

A low-tower cable-stayed bridge and hybrid beam technology, which is applied to the wide-width and long-span mixed-girder low-tower cable-stayed bridge system and its construction field, can solve the problems of complex lateral force of the main girder, reduced mechanical performance of the main girder, and restricted development. , to achieve the effect of easy guarantee of construction quality, improvement of bearing capacity and increase of spanning capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

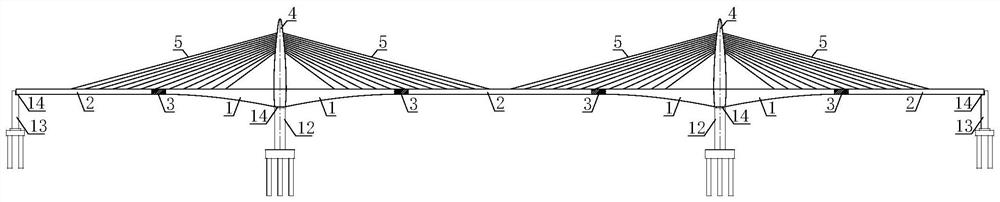

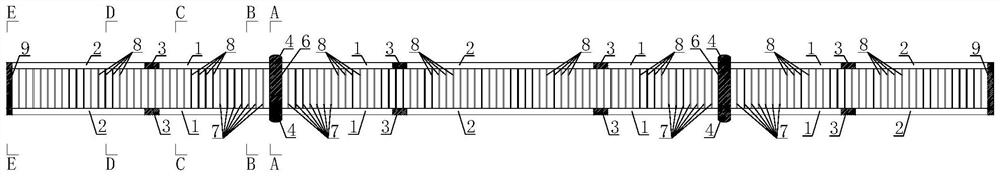

[0061] combine Figure 1-12 , the composite girder short-tower cable-stayed bridge span combination in this embodiment is (150+250+150) m, that is, the main span L of the short-tower cable-stayed bridge 0 =250m, the deck width of the bridge is 32.5m, arranged in a straight line.

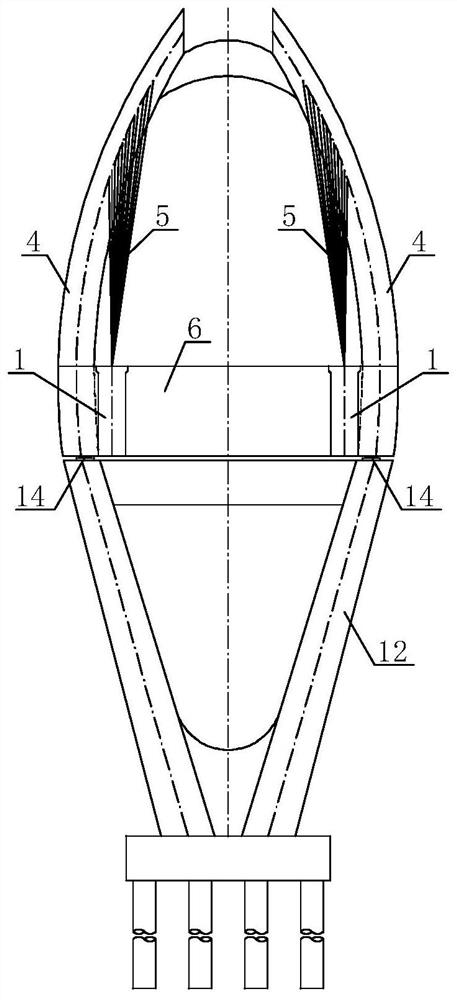

[0062]The hybrid girder low-tower cable-stayed bridge of this embodiment includes: a composite beam arranged on both sides of the cross bridge, which is composed of a concrete box girder 1, a corrugated web steel box-concrete composite beam 2, and a steel-concrete joint section 3, connecting the cross bridge The mid-pivot concrete beam 6, truss-type steel beam 7, I-shaped steel beam 8 and end beam 9 of the mixed beam on both sides, the cast-in-place bridge deck 10, prefabricated bridge deck 10-1 and Wet joints 10-2 of the bridge deck, the bridge tower 4 poured integrally with the composite beam at the middle fulcrum, the stay cables 5 connected between the bridge tower 4 and the composite beam, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com