Mold

A mold and mold base technology, which is applied in the field of molds, can solve problems such as large deviations in machining accuracy, deformation of guide posts, and difficult stability of finished product forming, and achieve the effect of convenient installation and separation, and not easy to be displaced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

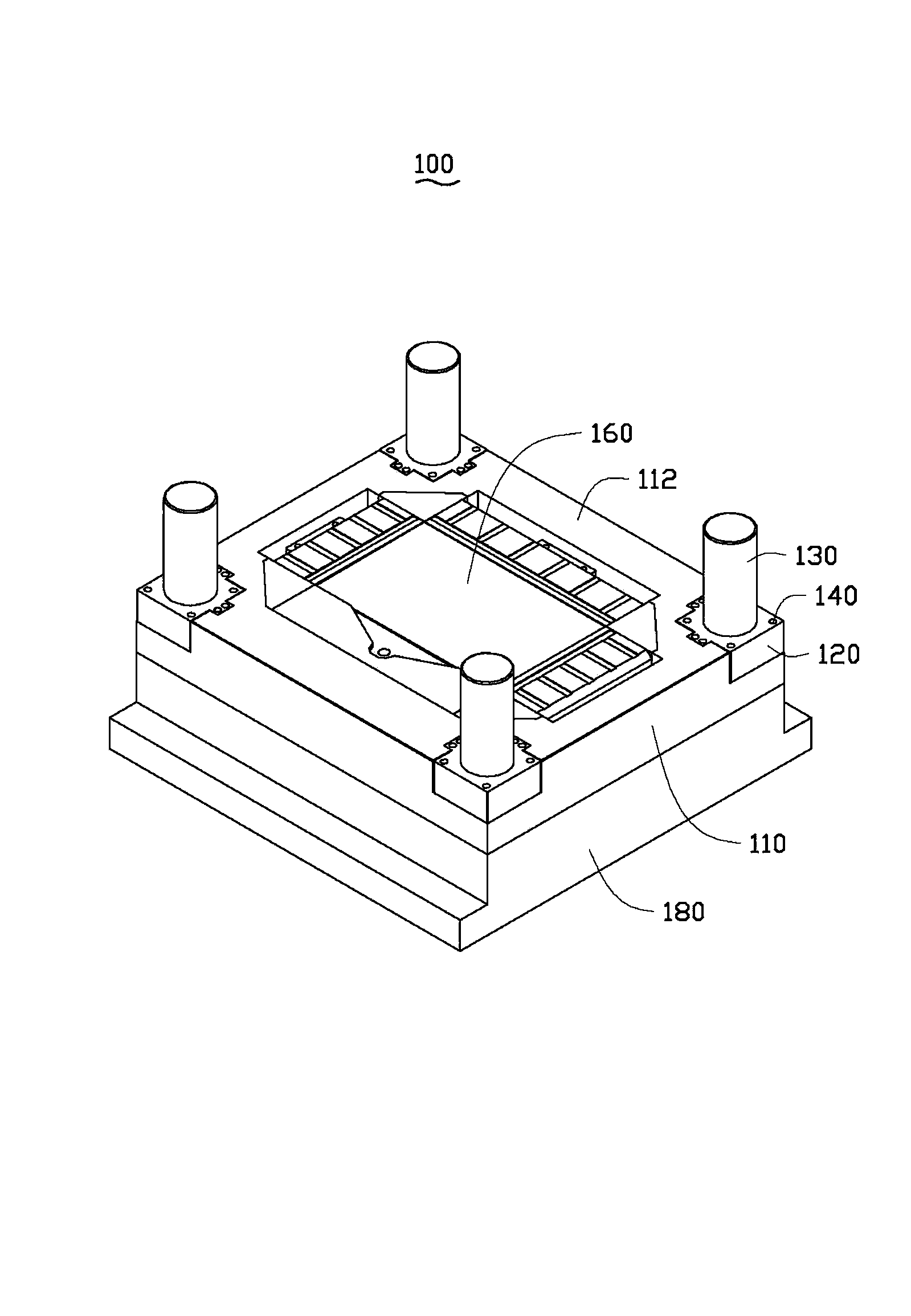

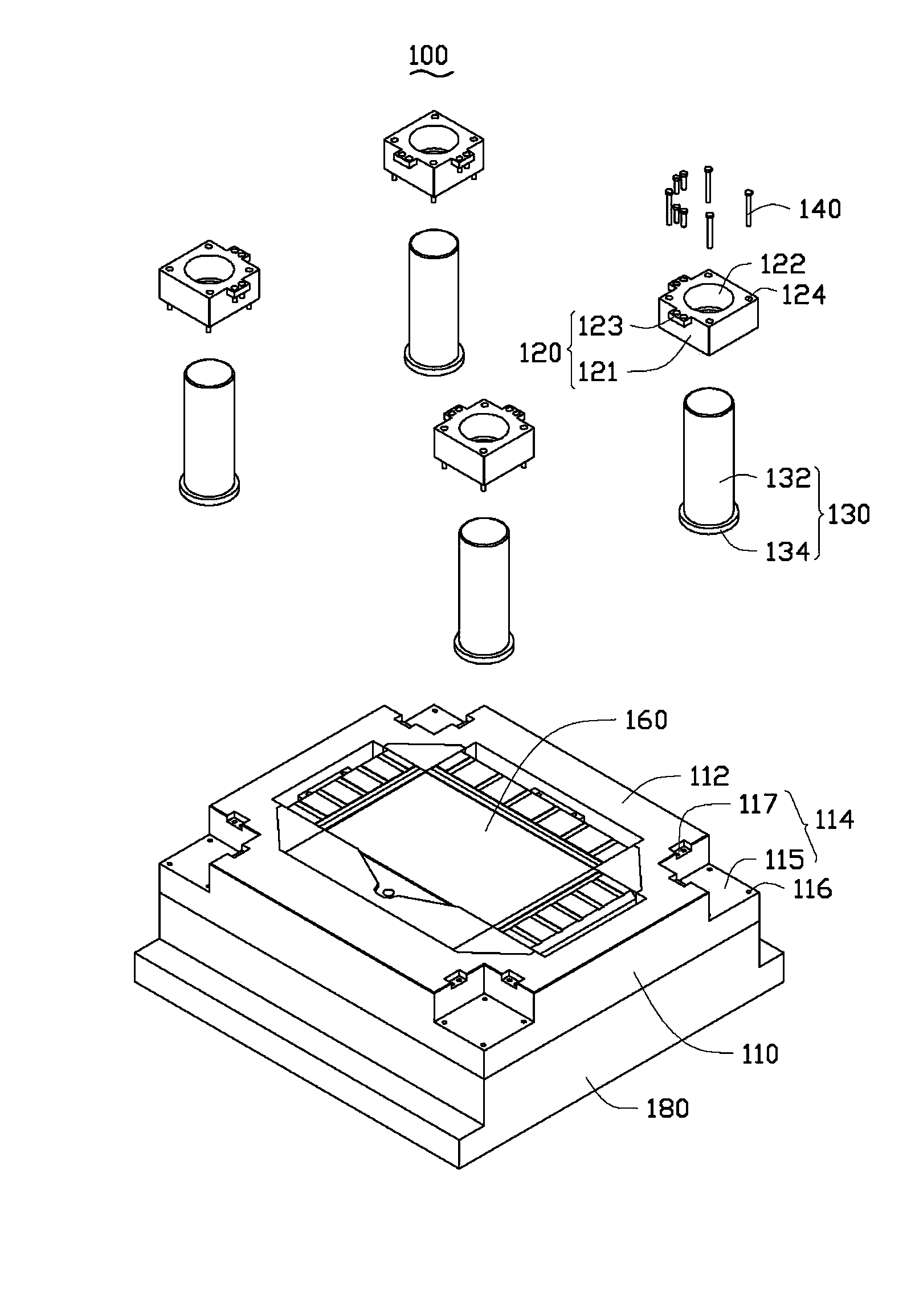

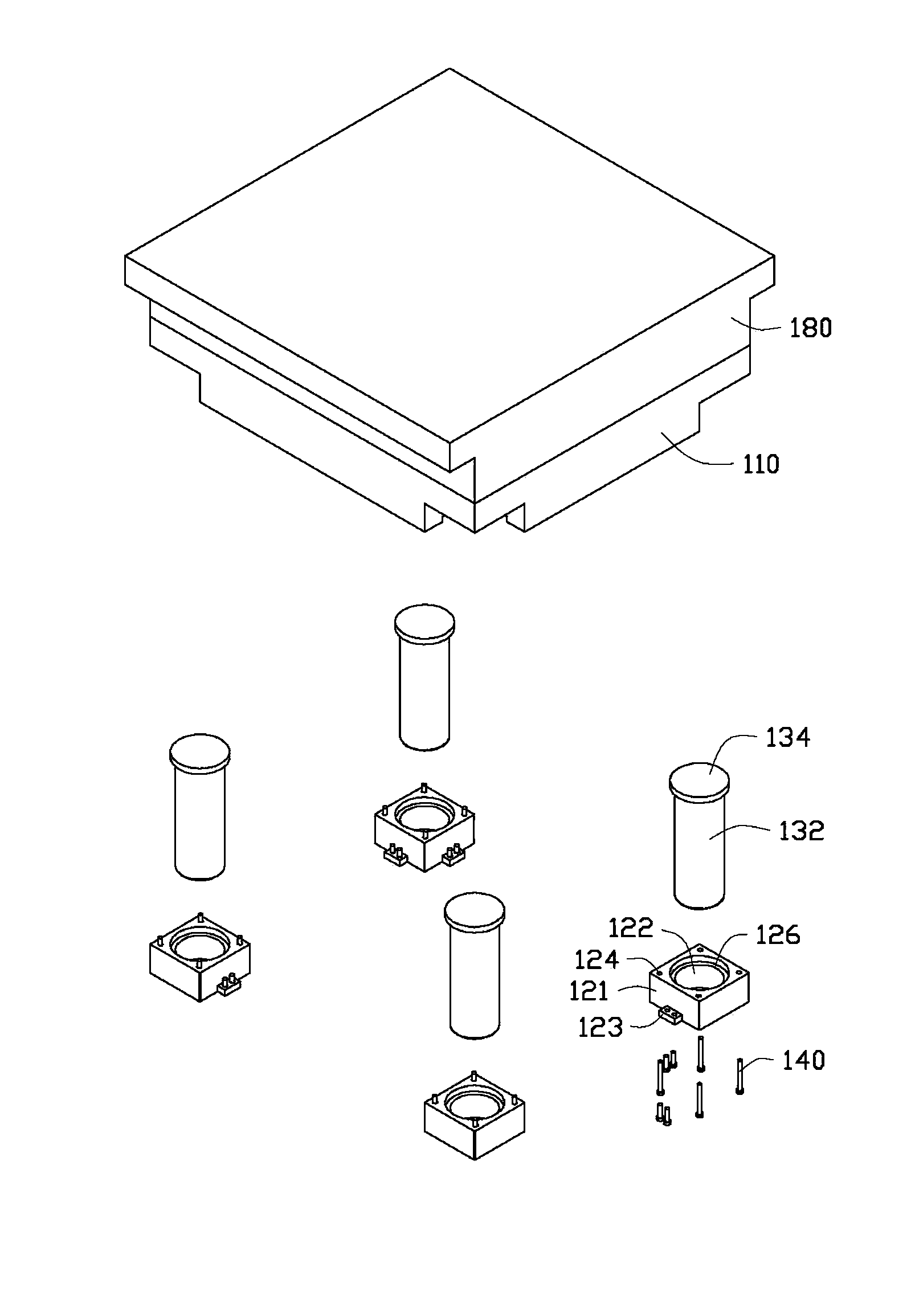

[0015] See Figure 1 to Figure 3 , The mold 100 provided by the embodiment of the present invention includes a mold base 110, a plurality of guide pillar fixing blocks 120, a plurality of guide pillars 130, and a plurality of screws 140. The mold 100 is used as a sub-mold. In injection molding, the mold 100 is usually used as a male mold, which is formed in cooperation with another sub-mold, that is, a female mold.

[0016] The mold base 110 has a parting surface 112 for separating products. A plurality of grooves 114 are formed on the edge of the parting surface 112. Each of the grooves 114 is provided with a plurality of screw fitting holes 116. In this embodiment, the parting surface 112 is rectangular, and the plurality of grooves 114 includes four grooves 114 located at four corners of the parting surface 112 and exposed to the side of the mold base 110. Each groove 114 includes a main groove 115 and two sub grooves 117 communicating with the main groove 115. Each of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com