Hull bottom arthropod type suction grille

A technology of suction grilles and joints, which is applied to ship parts, ship construction, ships, etc., can solve the problems of lack of versatility, debris entering, and increased workload of workers, and achieve the effect of improving overall stability and versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

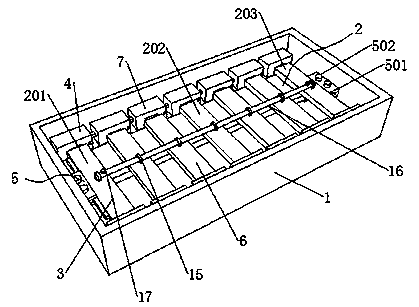

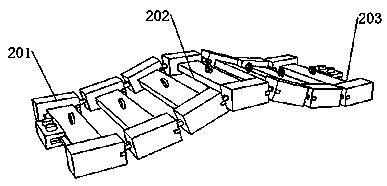

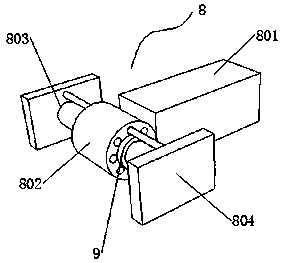

[0044] see Figure 1-9 , a bottom articulated suction grille, comprising a water inlet fixed frame 1, a grille plate group 2 is arranged in the water inlet fixed frame 1, and the grille plate group 2 includes a grille head 201, a grille body 202 and a grille The grid tail part 203, the grid body part 202 includes a plurality of joint grid plates distributed side by side, the joint grid plates include a second grid plate 6 and a pair of second connectors 7, and the joint between a pair of adjacent joint grid plates A connecting mechanism 8 is connected between them. The connecting mechanism 8 includes a fixed part and an active connecting part, which can realize multi-angle connection. The active connecting part includes a connecting rod 801 and a rotating connecting ring 802. The connecting rod 801 is connected to the second connecting head through the rotating connecting ring 802. The left end of 7 is fixedly connected, and the fixed portion includes positioning double rods 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com