Patents

Literature

79results about How to "Heat sensitive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic starch compositions incorporating a particulate filler component

InactiveUS6231970B1Reduce molecular weightAvoid hydrolysisProtein adhesivesPaper coatingParticulatesCross-link

Thermoplastic starch compositions that include a particulate filler, e.g. an inorganic filler component, and optional fibrous component The compositions include a thermoplastic phase comprising a thermoplastic starch melt that contains, at a minimum, starch blended with an appropriate plasticizing agent under conditions in order for the starch to form a thermoplastic melt. The thermoplastic phase may also include one or more additional thermoplastic polymers and other optional reactants, liquids or cross-linking agents to improve the water-resistance, strength, and / or other mechanical properties of the thermoplastic melt, particularly upon solidification. The inorganic filler component may affect the mechanical properties but will mainly be added to reduce the cost of the thermoplastic starch compositions by displacing a significant portion of the more expensive starch or starch / polymer melt. Fibers may optionally be included in order to improve the mechanical properties of the thermoplastic starch compositions. The thermoplastic starch compositions may be shaped into a wide variety of useful articles, such as sheets, films, containers, and packaging materials. Because the thermoplastic starch compositions will typically include a thermoplastic phase that is biodegradable, and because the other components will either constitute a naturally occurring mineral and optionally a natural fiber, the overall composition will typically be more environmentally friendly compared to conventional thermoplastic materials.

Owner:BIO TEC BIOLOGISCHE NATURVERPACKUNGEN

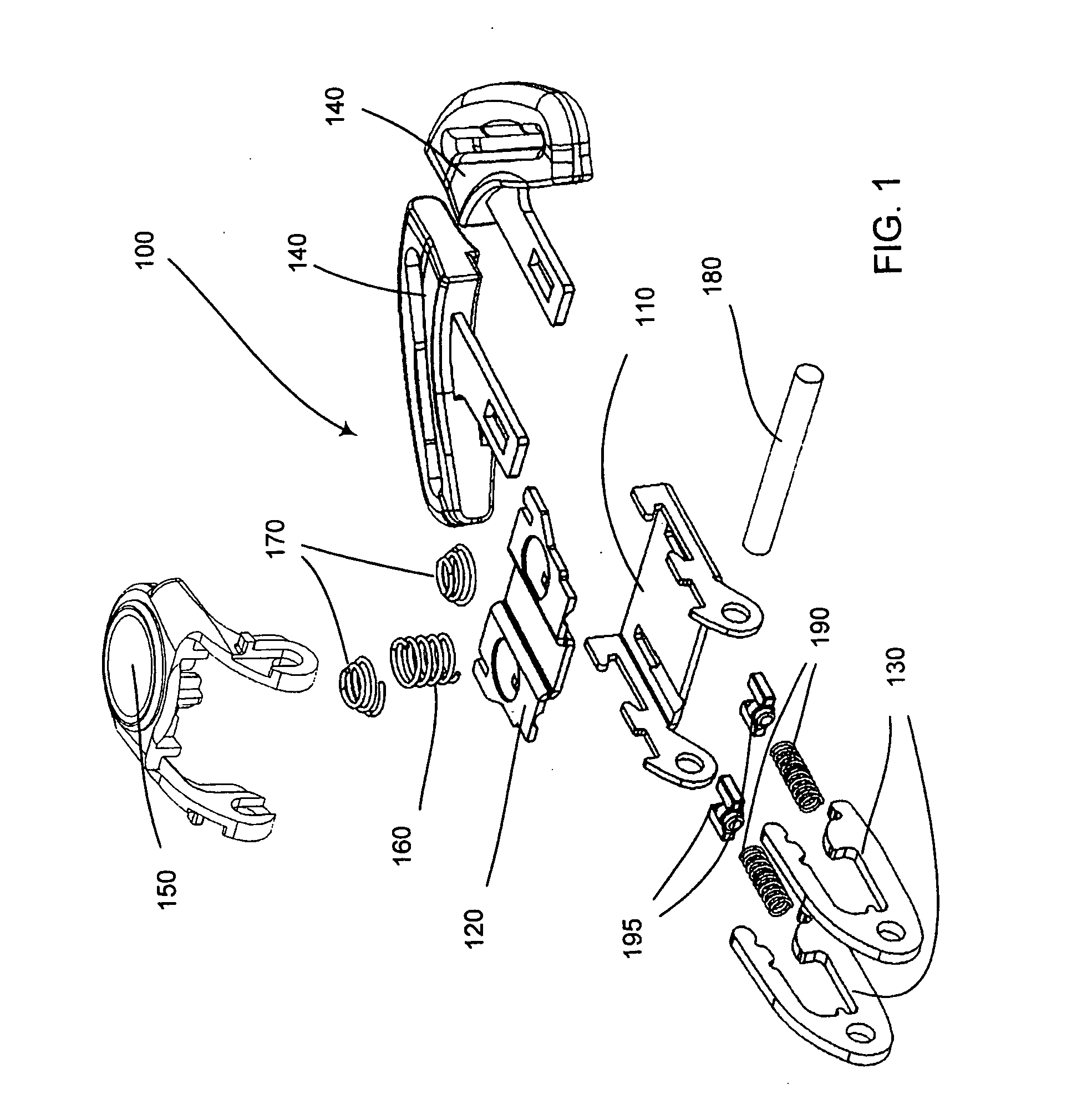

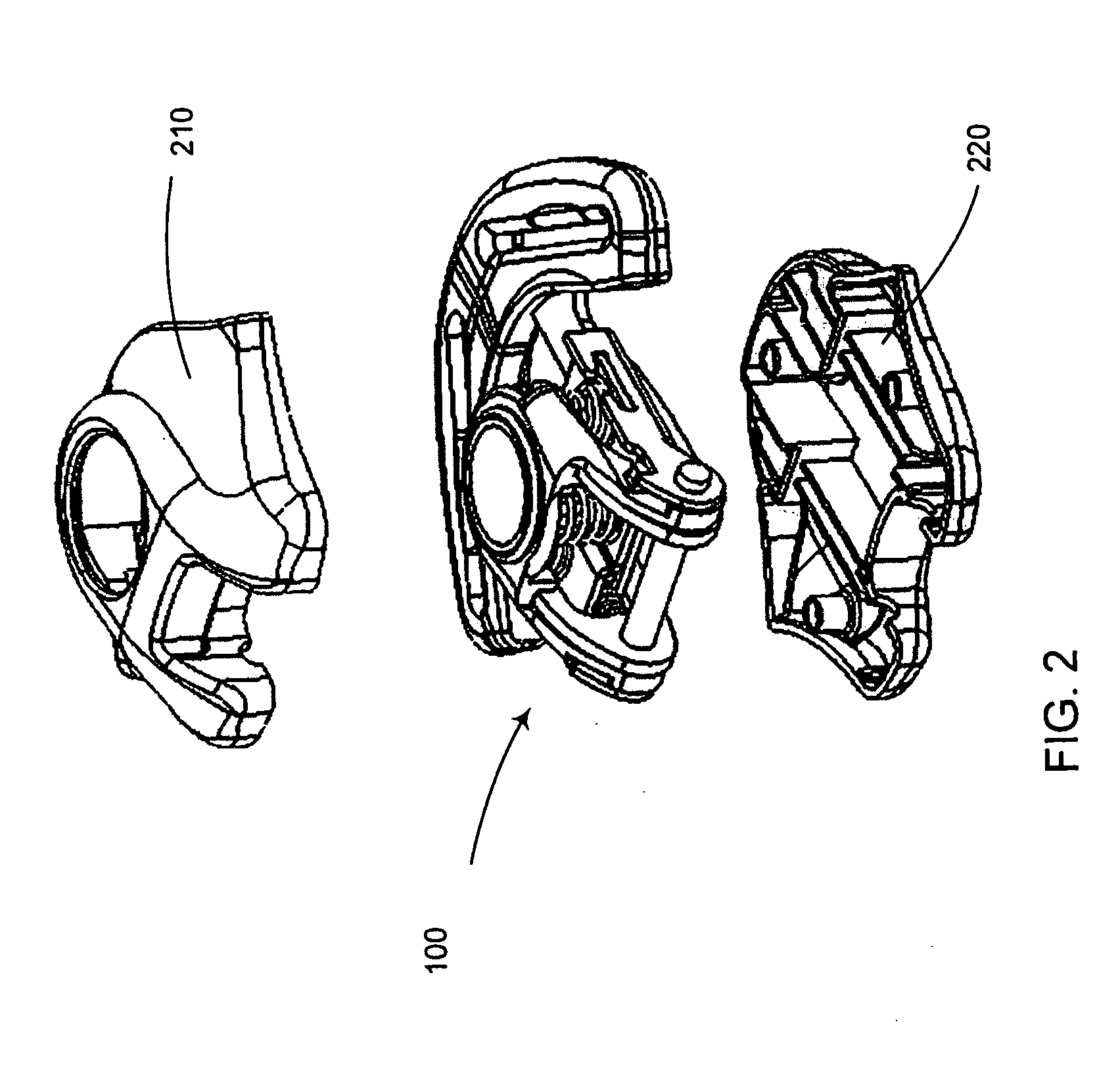

Seat belt arrangements for child safety seats

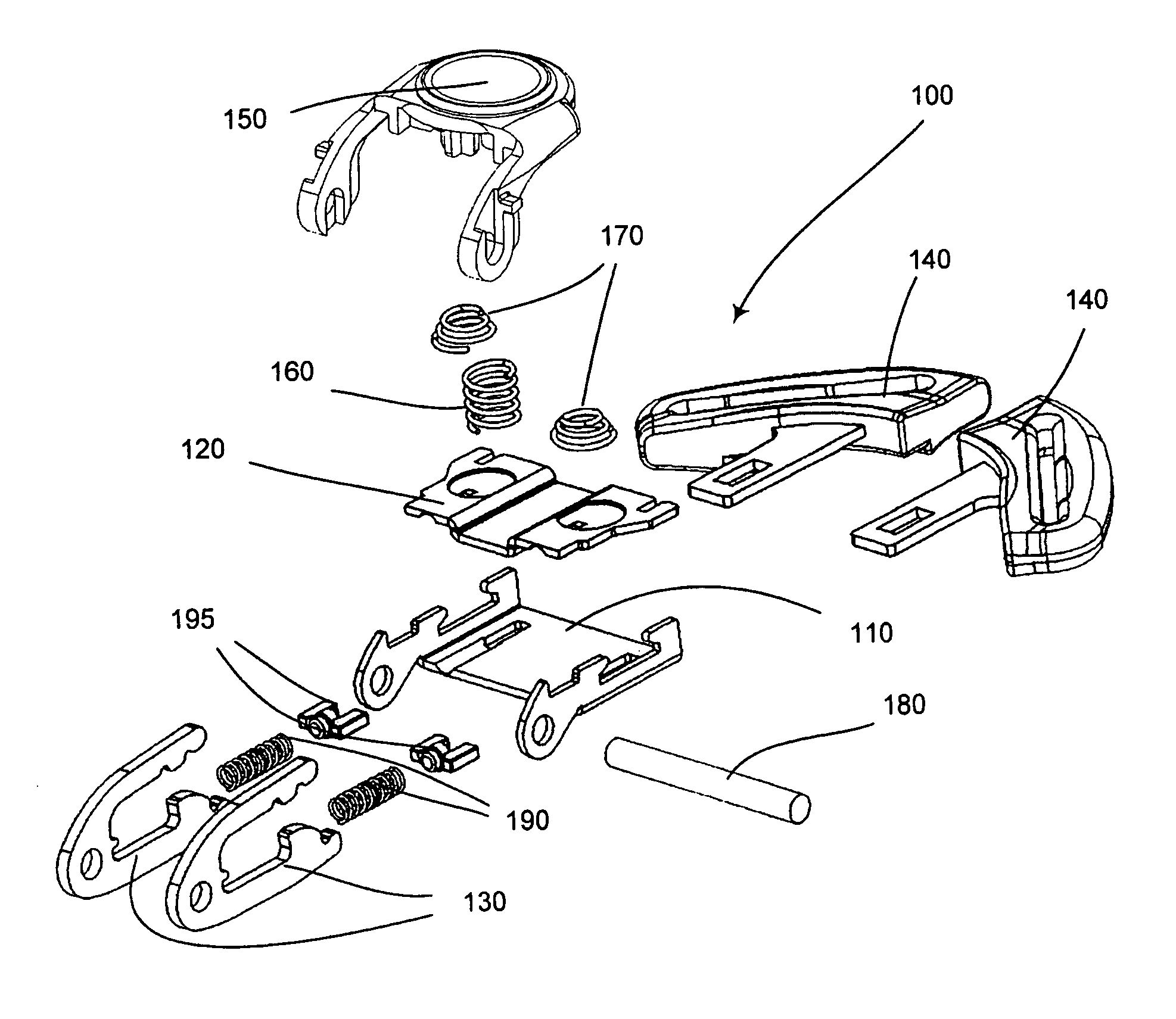

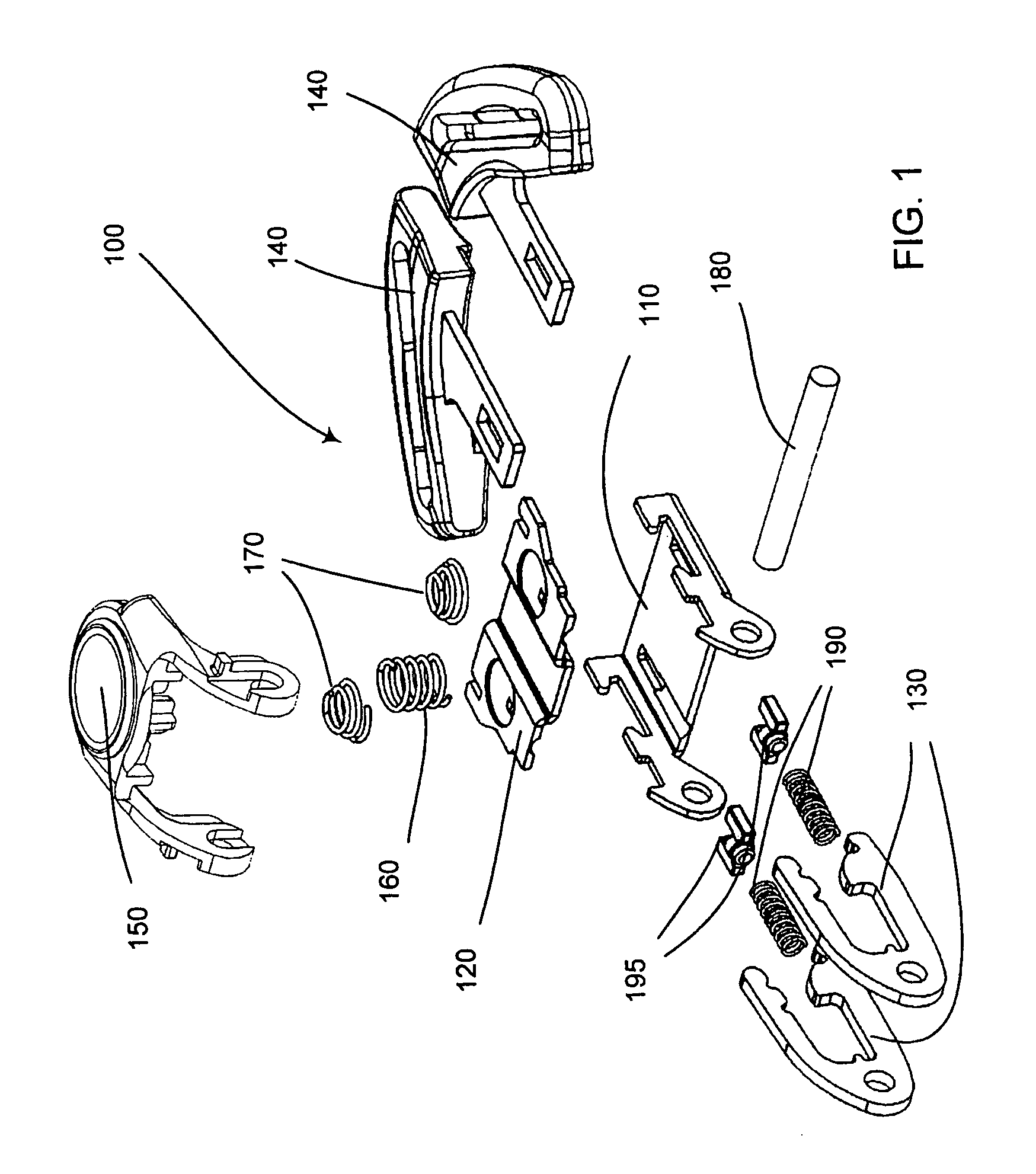

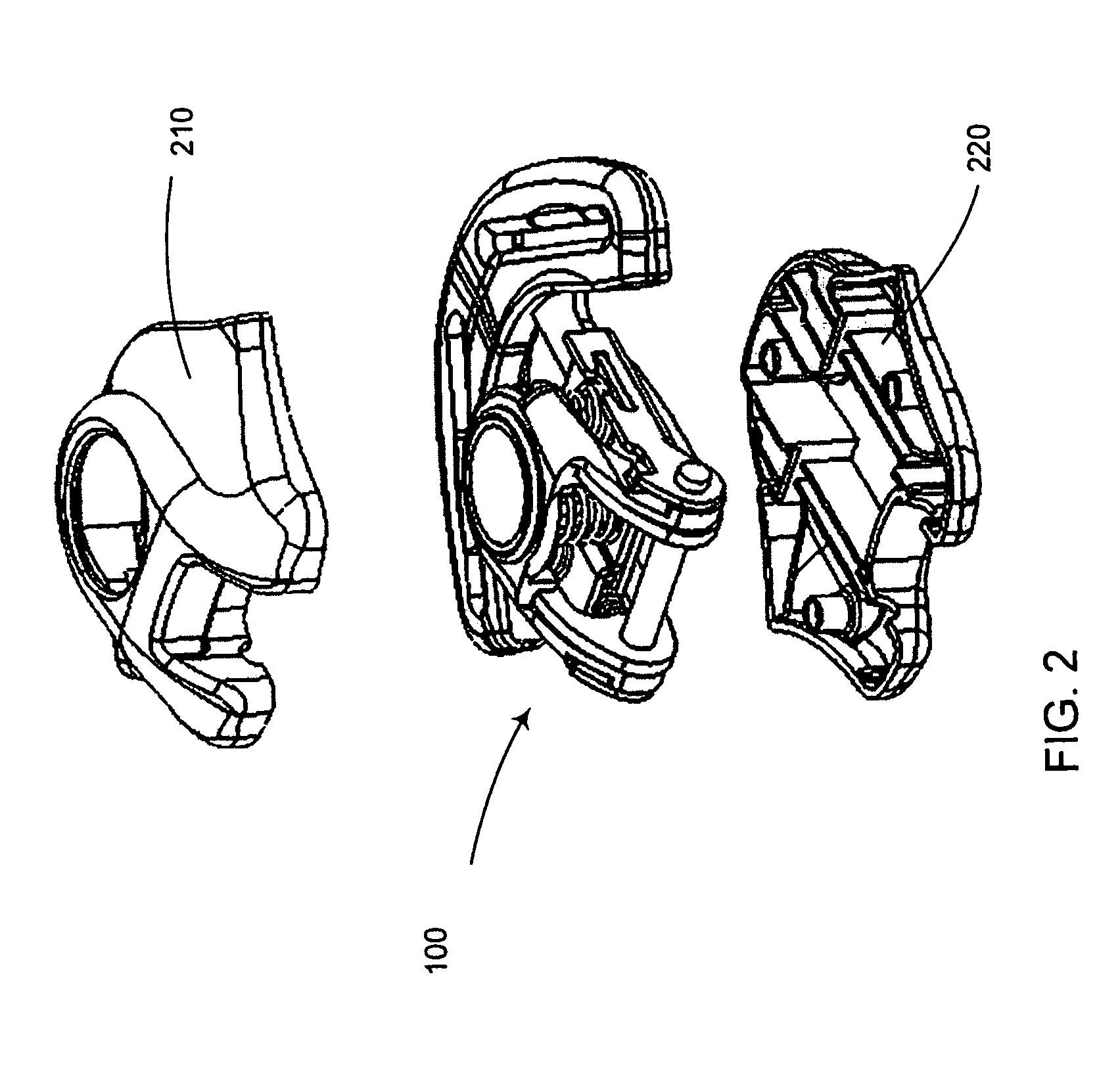

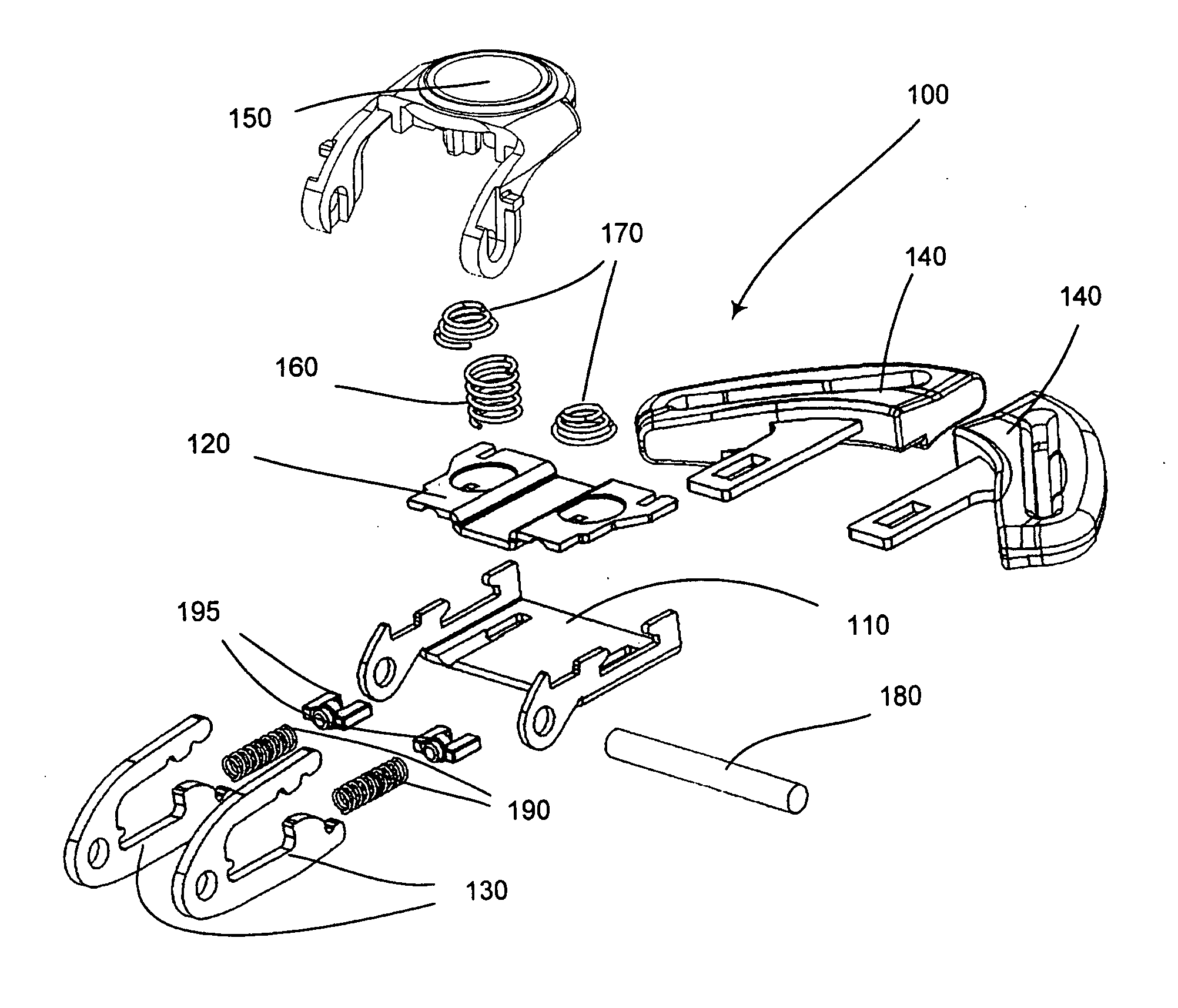

A buckle mechanism for a seat belt arrangement of a child safety seat comprises a guiding member forming at least one internal cavity for guiding and receiving at least one tongue of a tongue member, at least one latch for engaging with and locking the at least one tongue and disengaging means for disengaging the at least one latch from the at least one tongue. The buckle mechanism further has the at least one latch pivotably secured and connected with an anchor pin, to which webbing of a seat belt is attached, the other webbing being attached in a way known per se to the at least one tongue member. The at least one latch engages with the at least one tongue and the force transmission from the webbings through the mechanism only consists of the at least one tongue, the at least one latch and the anchor pin.

Owner:HOLMBERGS CHILDSAFETY HLDG

Preparation method of composite vegetable protein peptide

InactiveCN110037163ARaise the gradeImprove market competitivenessMulti-step food processesVegetable proteins working-upBiotechnologyHeart cells

The invention discloses a preparation method of a composite vegetable protein peptide. Soybean protein, walnut protein, sesame protein, wheat protein and corn protein are mixed according to a certainproportion to prepare a solution, and then enzymolysis is carried out to prepare the composite vegetable protein peptide. After enzymolysis, the vegetable proteins have different biological activities: the soybean peptide provides continuous nutritional power for heart cells and removes blood fat in cardiovascular blood vessels; the corn oligopeptide protects liver cells from being damaged; the wheat oligopeptide has good effect on spleen deficiency; the walnut peptide has the function of clearing lung; and the sesame peptide can nourish the kidney.

Owner:王书敏

Seat belt arrangements for child safety seats

ActiveUS20050115035A1Heat sensitiveAvoid short travelSnap fastenersClothes buttonsSeat beltEngineering

A buckle mechanism for a seat belt arrangement of a child safety seat comprises a guiding member forming at least one internal cavity for guiding and receiving at least one tongue of a tongue member, at least one latch for engaging with and locking the at least one tongue and disengaging means for disengaging the at least one latch from the at least one tongue. The buckle mechanism further has the at least one latch pivotably secured and connected with an anchor pin, to which webbing of a seat belt is attached, the other webbing being attached in a way known per se to the at least one tongue member. The at least one latch engages with the at least one tongue and the force transmission from the webbings through the mechanism only consists of the at least one tongue, the at least one latch and the anchor pin.

Owner:HOLMBERGS CHILDSAFETY HLDG

Production method of biobased solvent-free polyurethane synthetic leather

ActiveCN107012692AWith double foam technologyImprove controllabilityTextiles and paperProduction lineSolvent free

A production method of biobased solvent-free polyurethane synthetic leather comprising the steps of adding a hydroxyl containing component A and an isocyanate group containing component B into a reaction kettle, stirring for reaction to form foaming slurry, applying the foaming slurry to release paper in a scraping manner by using a dry synthetic leather production line to form a coating, laminating the coating with base cloth in a clearance laminating manner by using a laminating machine, putting in an oven for curing, and performing cooling and stripping to form the biobased solvent-free polyurethane synthetic leather. The biobased solvent-free polyurethane synthetic leather is produced by using a double foaming technology, an in-situ polyurethane polymerize technology, a heat-sensitive catalyst asynchronous catalysis technology and a single-knife constant temperature thermal scraping application technology; a production technology is environment-friendly, concise and stable; the product quality is good; biomass that is cheap and easy to obtain serves as a raw material; the use of a fossil raw material can be reduced; and environmental protection is facilitated.

Owner:聊城市鑫润达塑胶制品有限公司

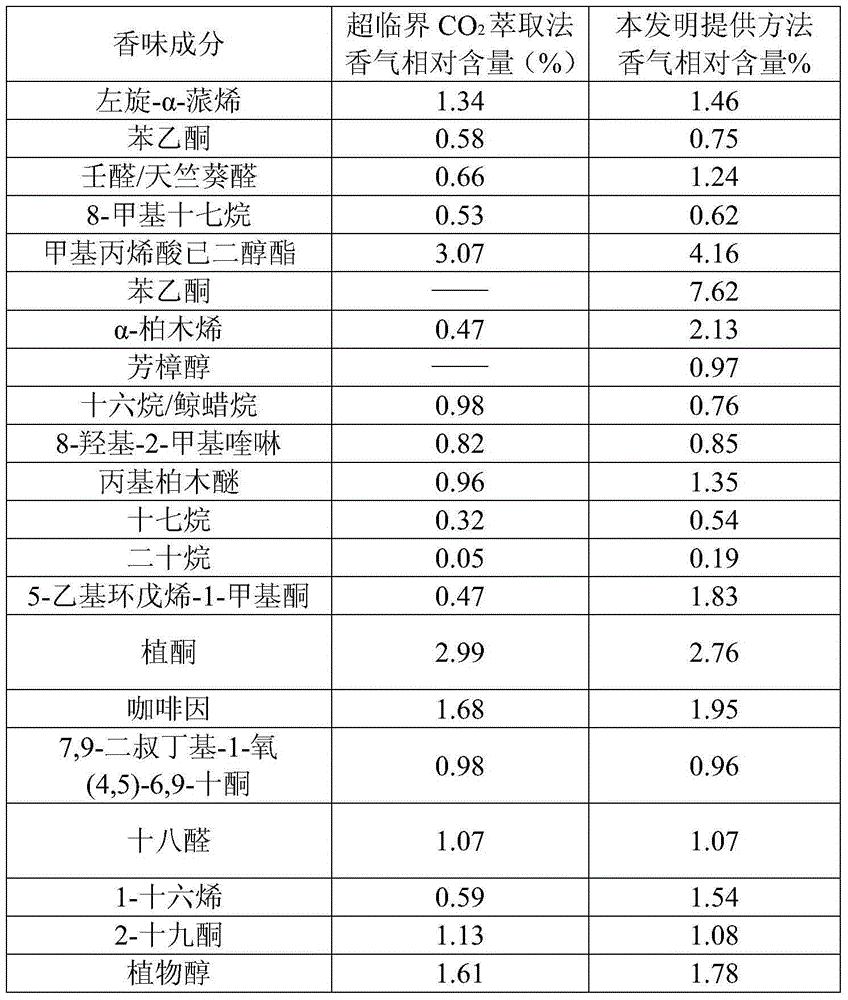

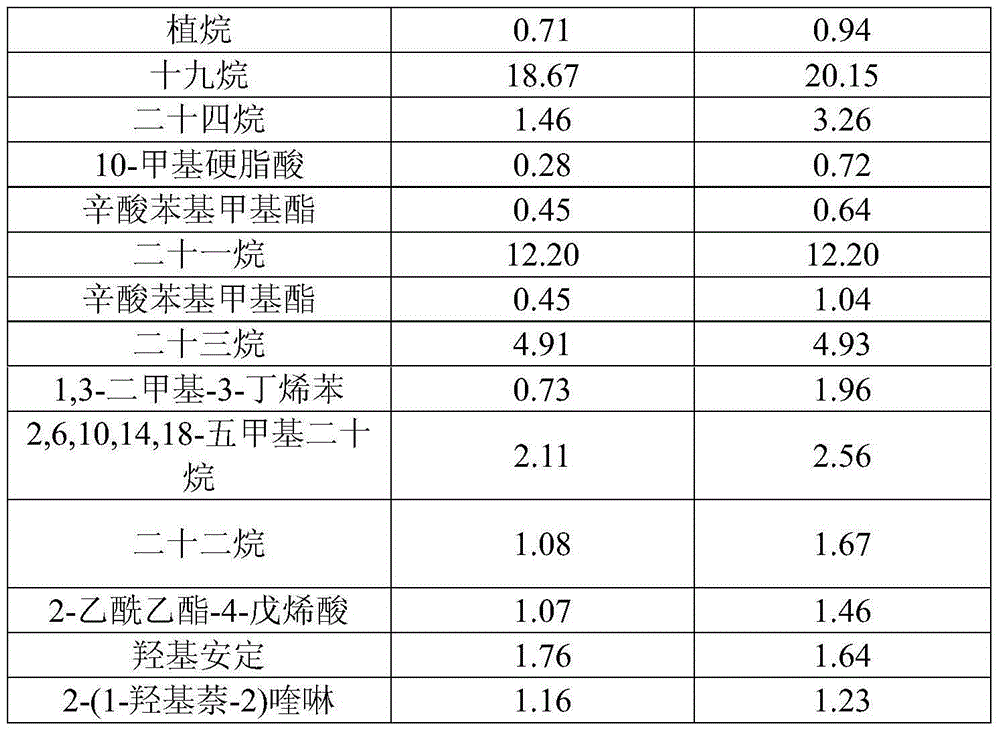

Method for preparing tea tree flower essential oil

The invention discloses a method for preparing tea tree flower essential oil. The method comprises the following steps: firstly, preparing a tea tree flower raw material into an sizing agent, adding a composite enzyme system for enzymolysis on the sizing agent so as to obtain first slurry; secondly, adding a defoaming agent into the first slurry so as to obtain second slurry; finally conveying the second slurry to a rotational conical distillation column for enhancing the fragrance, collecting a tea tree flower fragrance extract, and further separating by using an oil-water separator, thereby obtaining the tea tree flower essential oil. The composite enzyme system is adopted to treat tea tree flowers, so that the content of the effective fragrance component in the tea tree flowers is remarkably increased, release of precursor substances of the tea tree flower fragrance is promoted, the tea tree flower aromatic substances can be efficiently and comprehensively recycled by using SCC equipment, the yield of tea tree flower essential oil is greatly increased, and the natural flavor of the tea tree flower essential oil is effectively maintained.

Owner:ANJI E SWEET CANDY FOOD

Method of preparing chewing gum powder

InactiveUS7351438B2Heat sensitiveReduce the amount requiredChewing gumPharmaceutical non-active ingredientsChewing gumPharmacology

The invention is a chewing gum formulation in powder form, a process for producing it, and a chewing gum in tablet produced by direct compression of a the chewing gum formulation in powder form that is characterized by a chewability that remains unchanged throughout the chewing period.

Owner:GUM BASE

Production method of waterproof organosilicon modified solvent-free polyurethane synthetic leather

InactiveCN107268290AImprove controllabilityImprove waterproof performanceWaterborne vesselsTextiles and paperPolymer scienceIn situ polymerization

The invention discloses a production method of waterproof organosilicon modified solvent-free polyurethane synthetic leather. The production method comprises the following steps: firstly, adding a component A containing hydroxyl and a component B containing an isocyanate group into a reaction still, and reacting by stirring to obtain foaming slurry; secondly, adopting a dry process production line of the synthetic leather, blade coating the foaming slurry on release paper to form a coating, and then laminating the coating with a base fabric by a gap fitting mode through a laminating machine; thirdly, feeding a mixture into a drying oven for cooking to obtain the waterproof organosilicon modified solvent-free polyurethane synthetic leather. According to the production method disclosed by the invention, the waterproof organosilicon modified solvent-free polyurethane synthetic leather is produced by adopting a double foaming technology, a polyurethane in-situ polymerization waterproof technology, a heat-sensitive catalyst asynchronous catalysis technology and a single-pole constant temperature heating scrape coating technology; the production technology is environmentally friendly, simple, and stable; the quality of a product is good; a contact angle of water droplets on the surface of the synthetic leather is as high as 107 degrees, and static water seepage prevention can be kept for 15 days; the waterproof organosilicon modified solvent-free polyurethane synthetic leather can be used as a high-end functional yacht seat covering material.

Owner:SHAANXI UNIV OF SCI & TECH

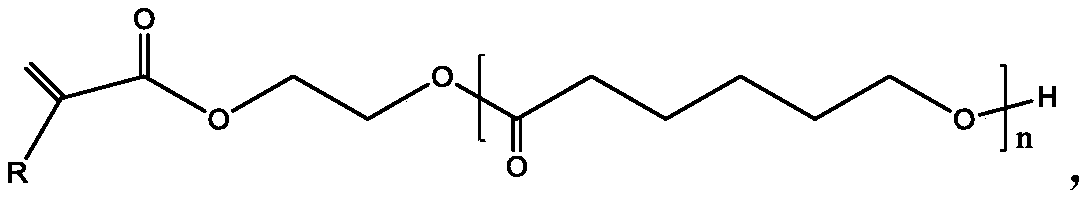

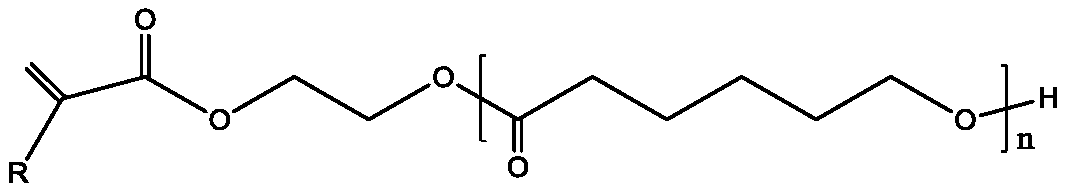

One-component heat curing polyurethane mixed component

The invention discloses a one-component heat curing polyurethane mixed component which is prepared from the components in parts by weight: 100 parts of a modified polyurethane oligomer, 50-200 parts of an active compound, a polymerization inhibitor and a radical initiator, wherein the polymerization inhibitor is 0.3-0.7% of the sum of the mass of the modified polyurethane oligomer and the active compound, and the radical initiator is 0.2-0.8% of the sum of the mass of the modified polyurethane oligomer and the active compound; and the modified polyurethane oligomer is prepared by polymerization reaction of a diisocyanate and a polycaprolactone with single and double bond termination, and the molar ratio of NCO / OH in the raw material is 0.8-1.1. Various additives and fillers can be added according to different purposes of use; and the one-component heat curing polyurethane mixed component can be stably stored at room temperature without hardening, is rapidly solidified when heated to 80DEG C or above, and is suitable for production process with different viscosity and long operation time.

Owner:WANHUA CHEM GRP CO LTD

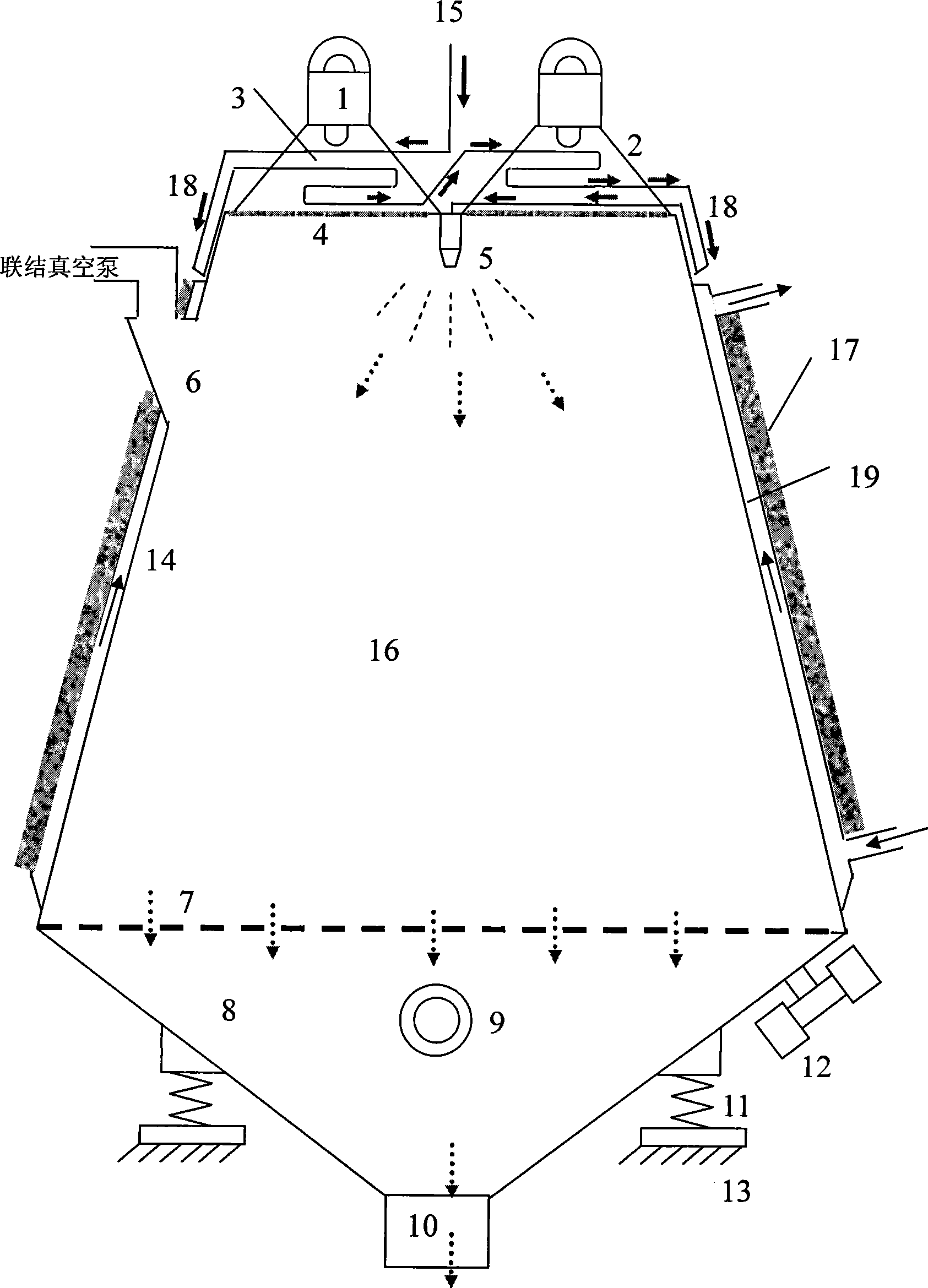

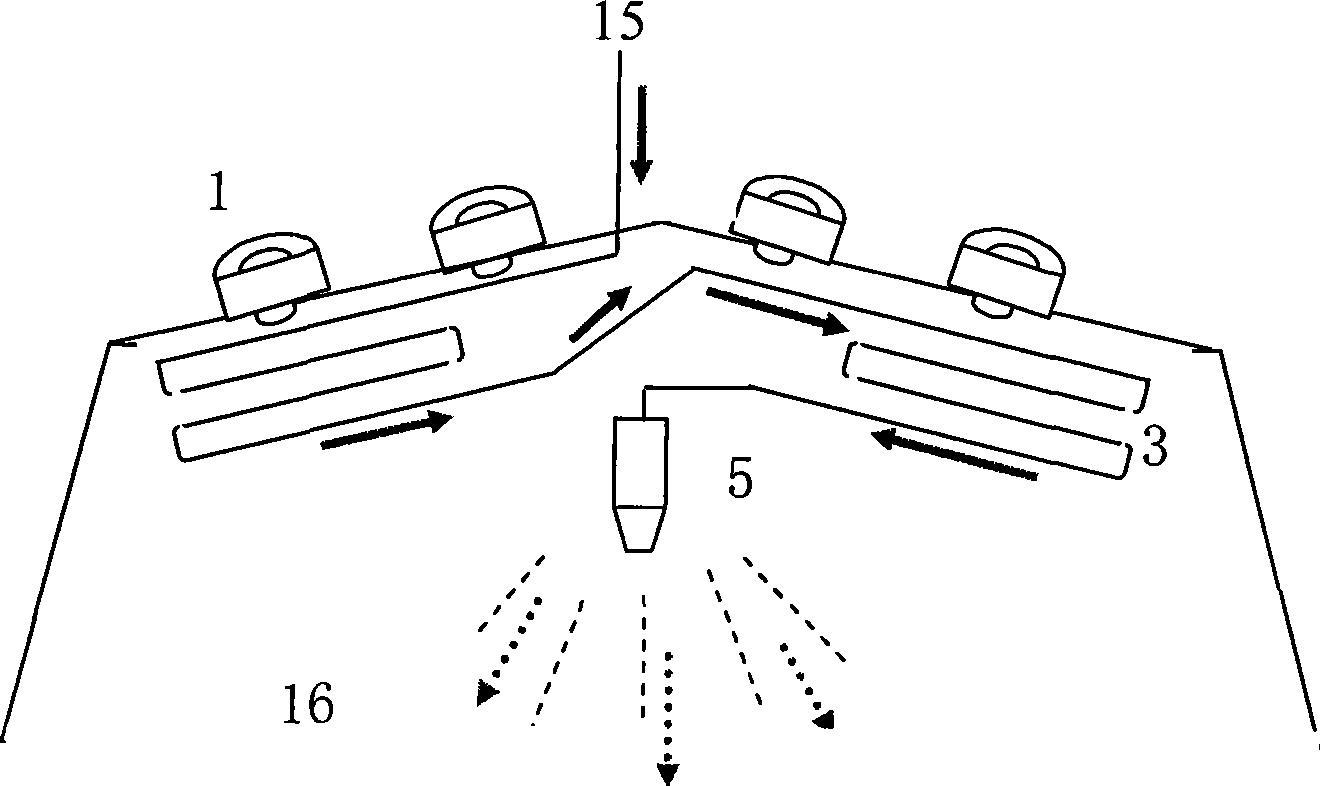

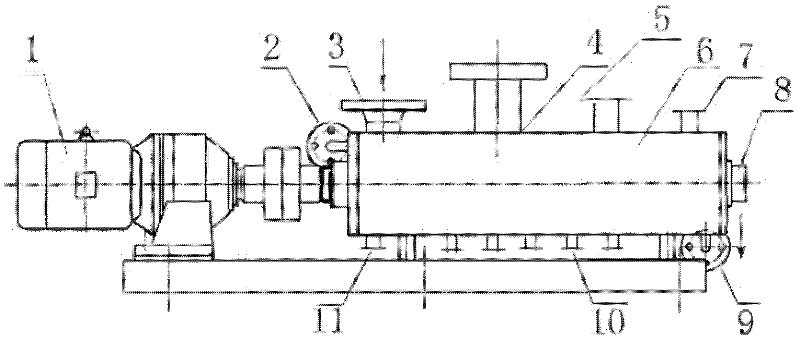

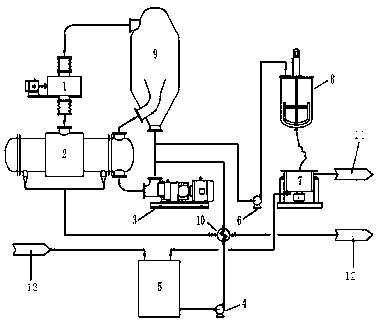

Microwave spraying vacuum drying machine

InactiveCN101458033AAvoid deposition overheating burnt problemAvoid overheating and burningDrying using combination processesDrying solid materials with heatMicrowaveChinese traditional

The invention relates to a microwave spraying vacuum drier for drying sticky materials, in particular for chemicals, Chinese traditional medicines and food, and the like, with strong thermal sensitivity as desiccant. The invention comprises a drying container, a feed inlet, a microwave feed-in device and a material atomization device arranged on the top part of the drying container, a container for drying finished products arranged on the lower part of the drying container, a metal screen arranged between the drying container and the container for drying finished products, a vacuum pump joint arranged on the lateral wall of the drying container, a material preheating components connected between the feed inlet and the material atomization device below the microwave feed-in port of the microwave feed-in device and a vibrating mechanism for delivering materials and preventing materials from being sticky to the wall surface. The vacuum drier of the invention has the advantages of simple production, wide application range, as well as comparatively high drying uniformity and efficiency.

Owner:HENAN UNIV OF SCI & TECH

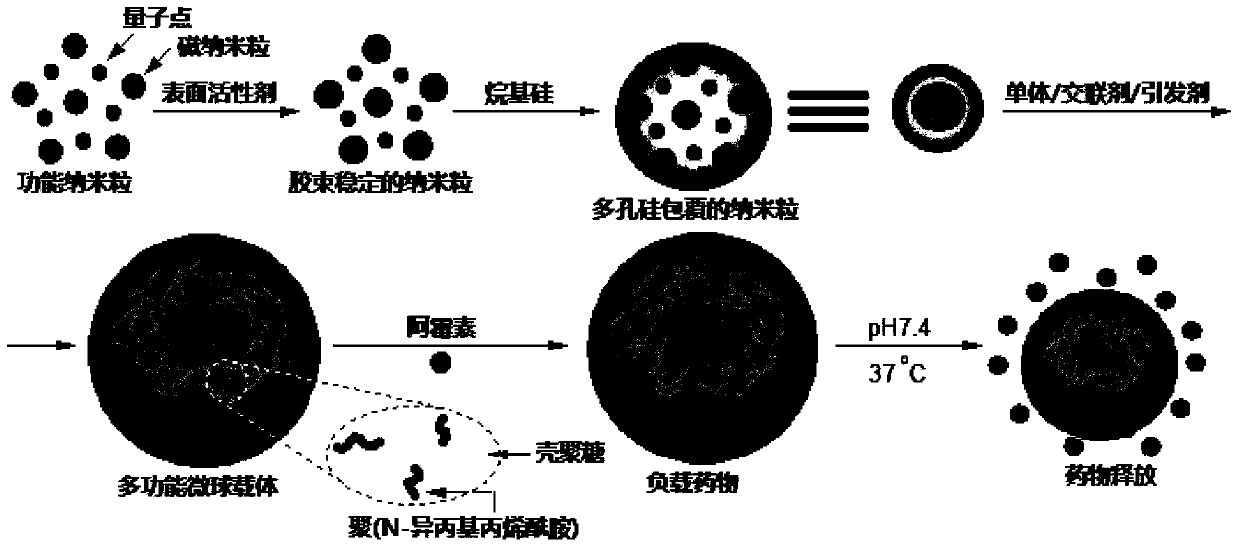

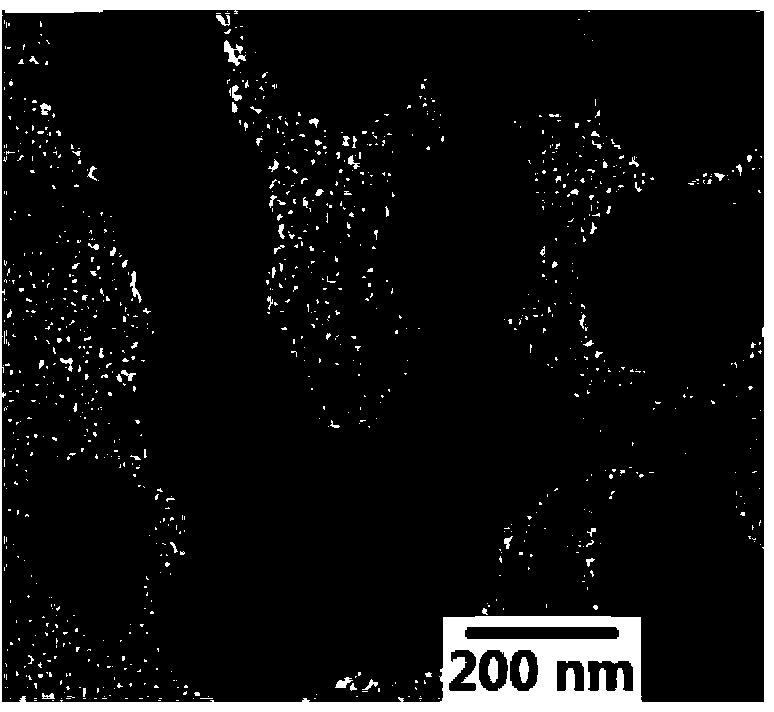

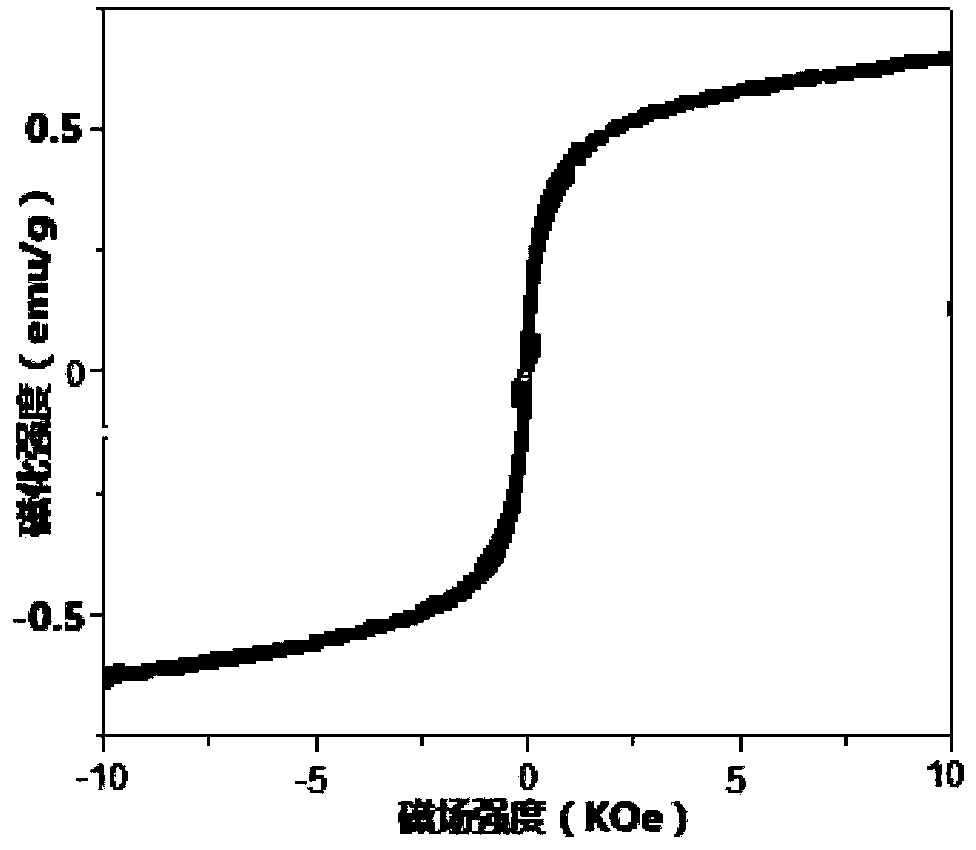

Preparation method of multifunctional medicine carrier integrating magnetism, fluorescence and thermosensitivity

InactiveCN103386135AWith magneticHeat sensitiveOrganic active ingredientsInorganic non-active ingredientsFluorescenceBiocompatibility Testing

The invention relates to a preparation method of a multifunctional medicine carrier integrating magnetism, fluorescence and thermosensitivity. The carrier structure uses chitosan microspheres grafted by poly(N-isopropyl acrylamide) as a main body internally crosslinked with porous silicon nano particles. The nano particles encapsulate superparamagnetic nano particles and inorganic quantum dots, so that a composite microsphere carrier which takes porous silicon nano particles loading magnetic particles and quantum dots as a core and chitosan grafted by poly(N-isopropyl acrylamide) as a shell is formed. The carrier can load the anti-cancer medicine in a shell network of a polymer so as to sequentially release the medicine at special temperatures. Compared with the prior art, the medicine carrier provided by the invention has hydrophilcity and biocompatibility, so that the anti-cancer medicine is controllably encapsulated and released. Meanwhile, the medicine carrier has magnetic targeting fluorescent tracing functions, and has important research and application values in associated fields of biology, medicines and materials such as sustained-release materials, medicine carriers, catalyst carriers and separating media.

Owner:SHANGHAI JIAO TONG UNIV

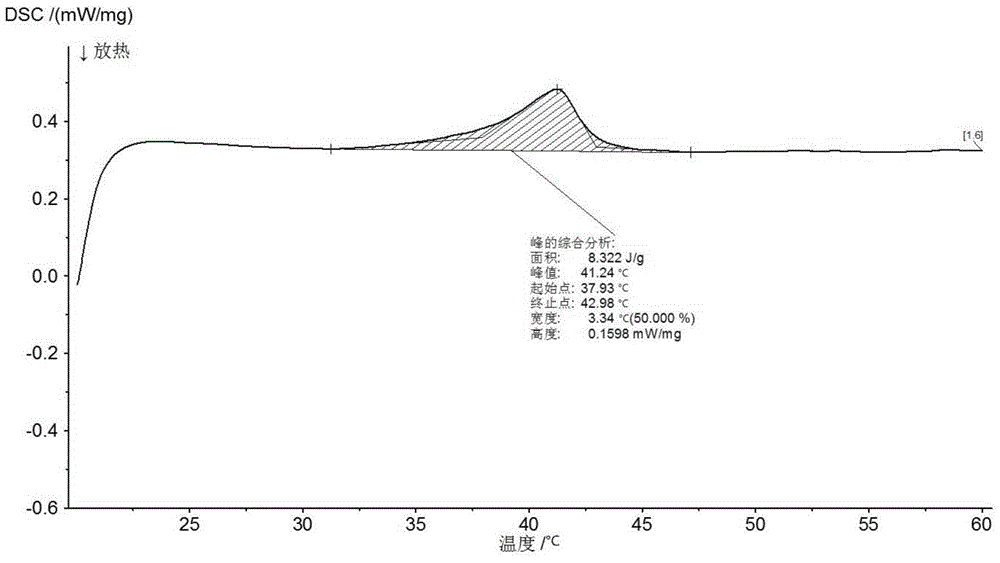

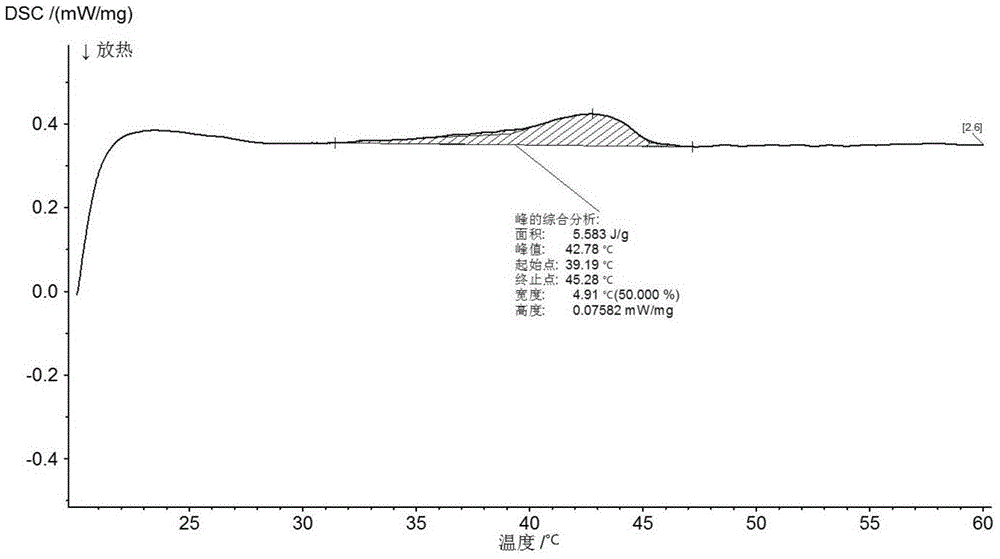

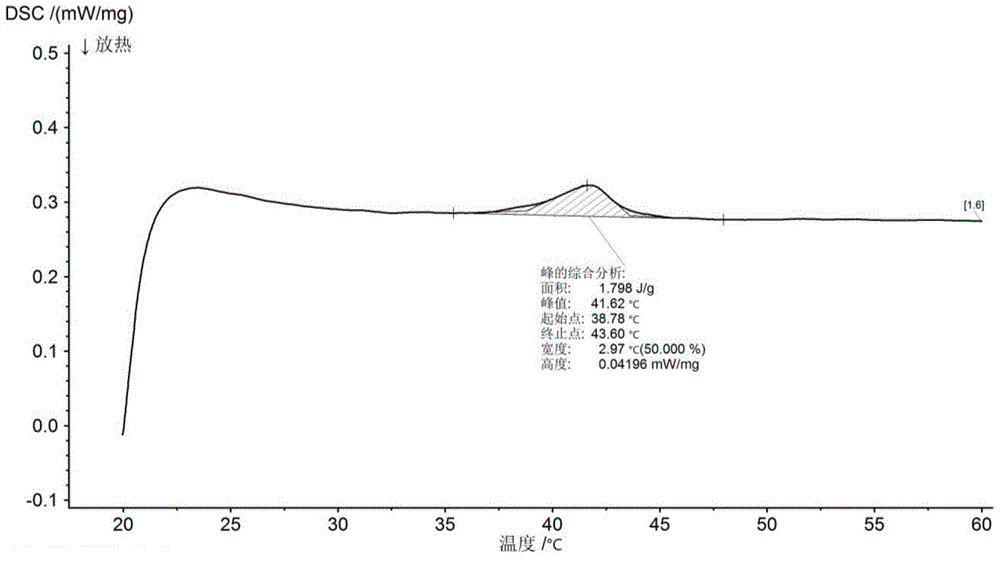

Thermosensitive liposome as well as preparation method and application thereof

InactiveCN104785178AGood embedding effectQuick releaseTobacco smoke filtersEssential-oils/perfumesThermosensitive liposomesRoom temperature

The invention discloses thermosensitive liposome as well as a preparation method and application thereof. The thermosensitive liposome uses phospholipid as a membrane material of the thermosensitive liposome, and is prepared by adding a membrane structure regulating agent and a phase change regulating agent in the preparation process, wherein the phospholipid comprises dipalmitoyl phosphatidyl choline and hydrogenated soybean phospholipid in a mol ratio ranging from 6:4 to 10:0; the phase change regulating temperature range is 35-50 DEG C; the mass ratio of the phospholipid to the membrane structure regulating agent to the phase change regulating agent is 20-40: 0-10: 5-20. The liposome is applied to a cigarette filter, can keep stable at room temperature, and can quickly release embedded substances in the cigarette smoking process.

Owner:JIANGNAN UNIV

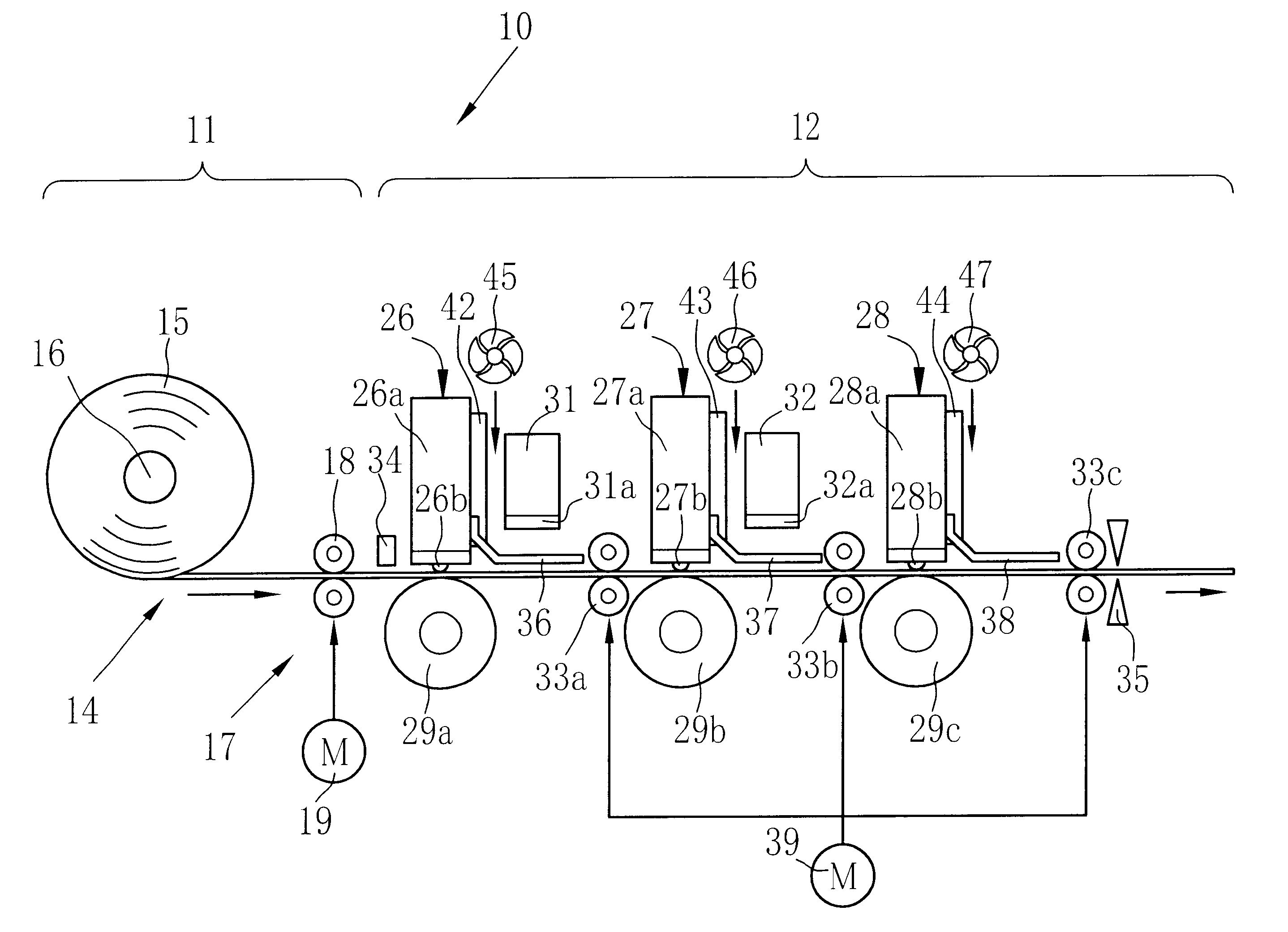

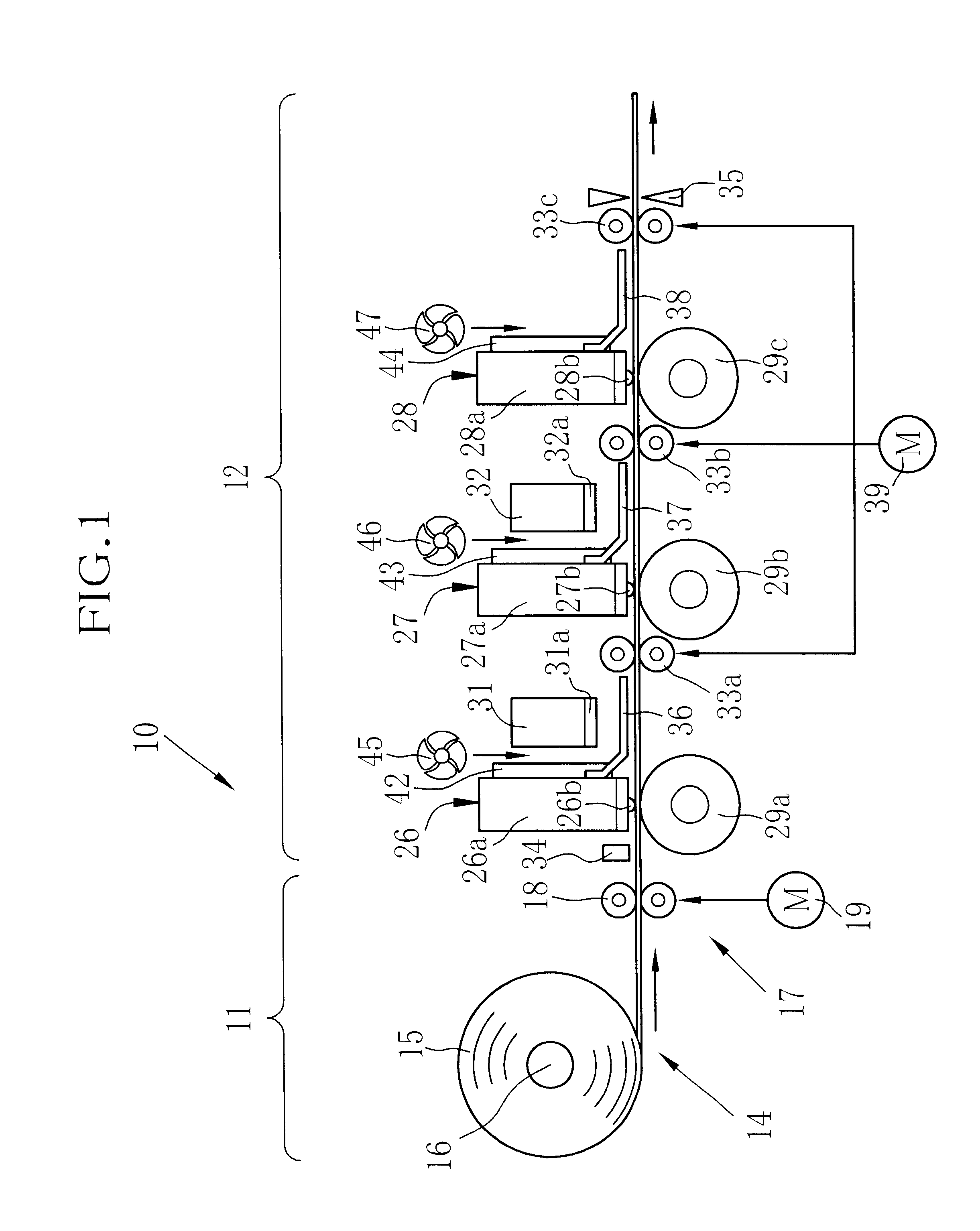

Heat sensitive type printer

InactiveUS6429888B1Improve cooling effectHeat sensitiveRecording apparatusInking apparatusEngineeringHeat sensitive

There is disclosed a heat sensitive type printer wherein glass plates (36, 37, 38) are secured at one ends to thermal heads (26, 27, 28), and extend substantially in parallel to a paper transport path of a heat sensitive color recording paper (14). Surface luminous devices (31, 32) for fixing coloring layers of the recording paper optically are disposed adjacent to heat sinks of the thermal heads with their light emission surfaces facing the paper transport path through the glass plates. Cooling fans send air into between the heat sinks and the surface luminous devices, to cool the heat sinks. Thereafter, the air guide guides the air to flow along a gap between the light emission surface and the glass plate, thereby to cool the light emission surface.

Owner:FUJIFILM HLDG CORP +1

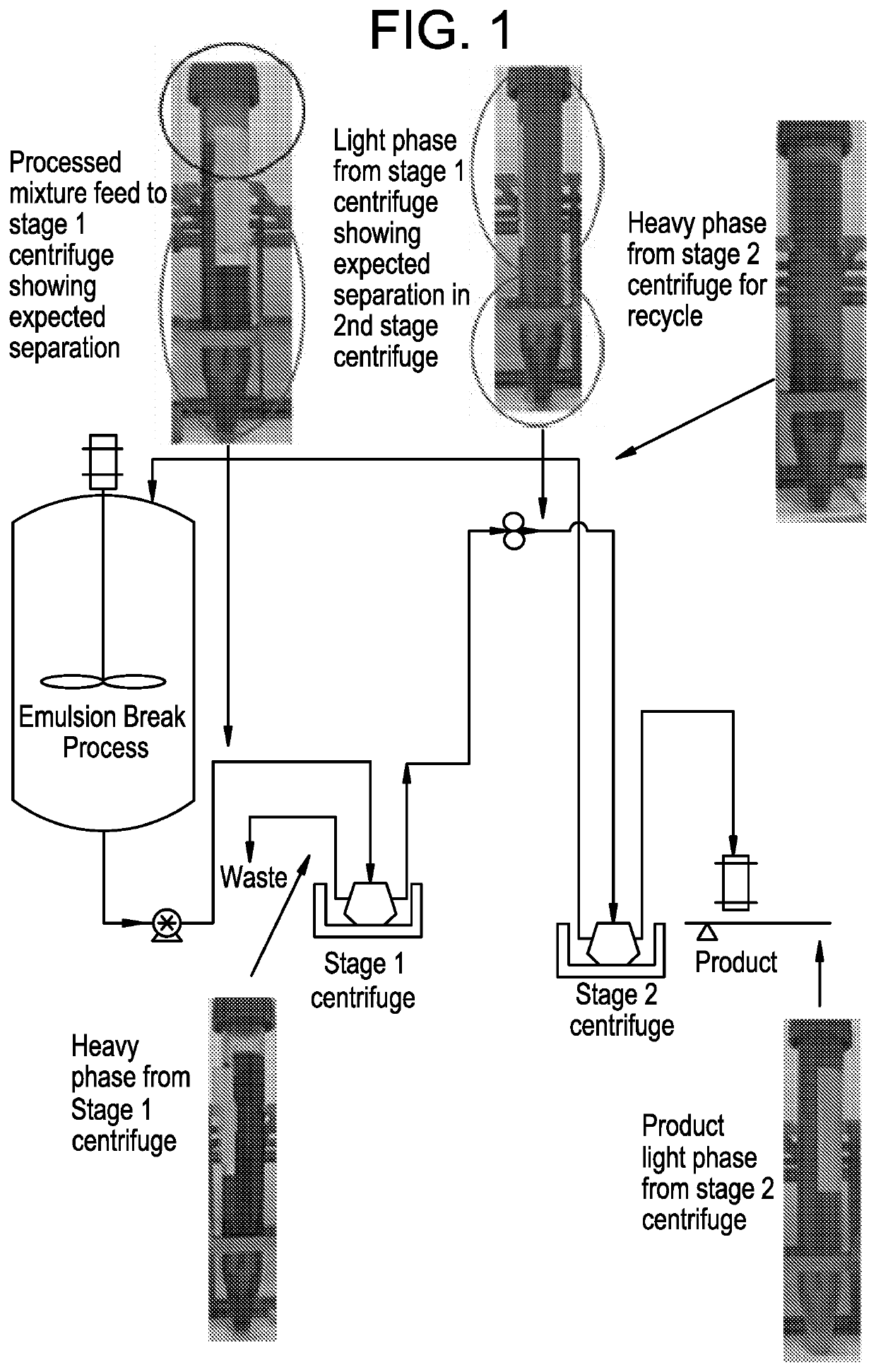

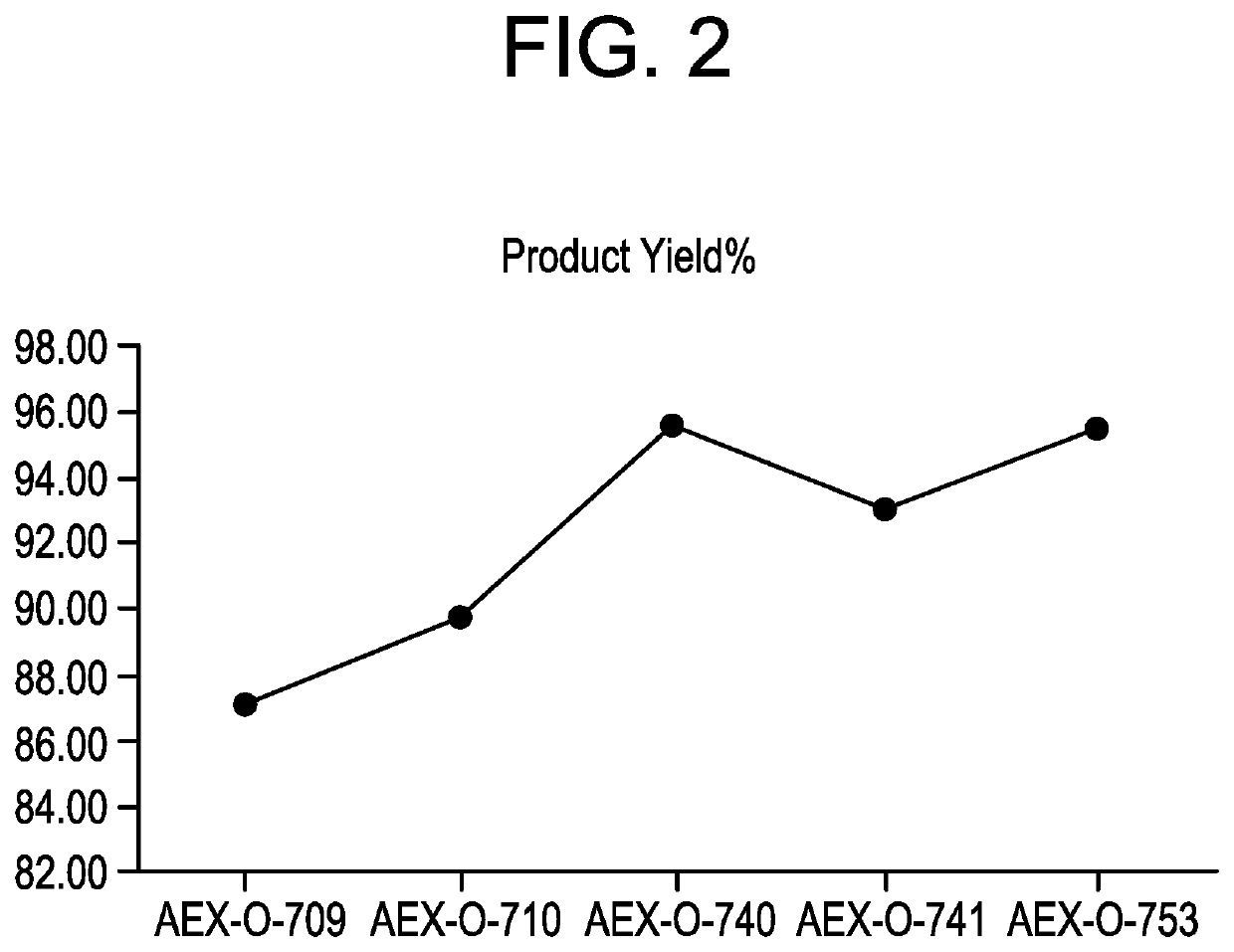

Double centrifugation process for nutritive oil purification

PendingUS20200362373A1Quality improvementLosing on oil yieldCentrifugal force sediment separationFermentationFermentation brothBiotechnology

This invention relates to a method of using a two-step serial centrifugation process in extracting nutritive oil from a fermentation broth, this novel method prevents oil yield losses while preserving product quality.

Owner:EVONIK OPERATIONS GMBH +1

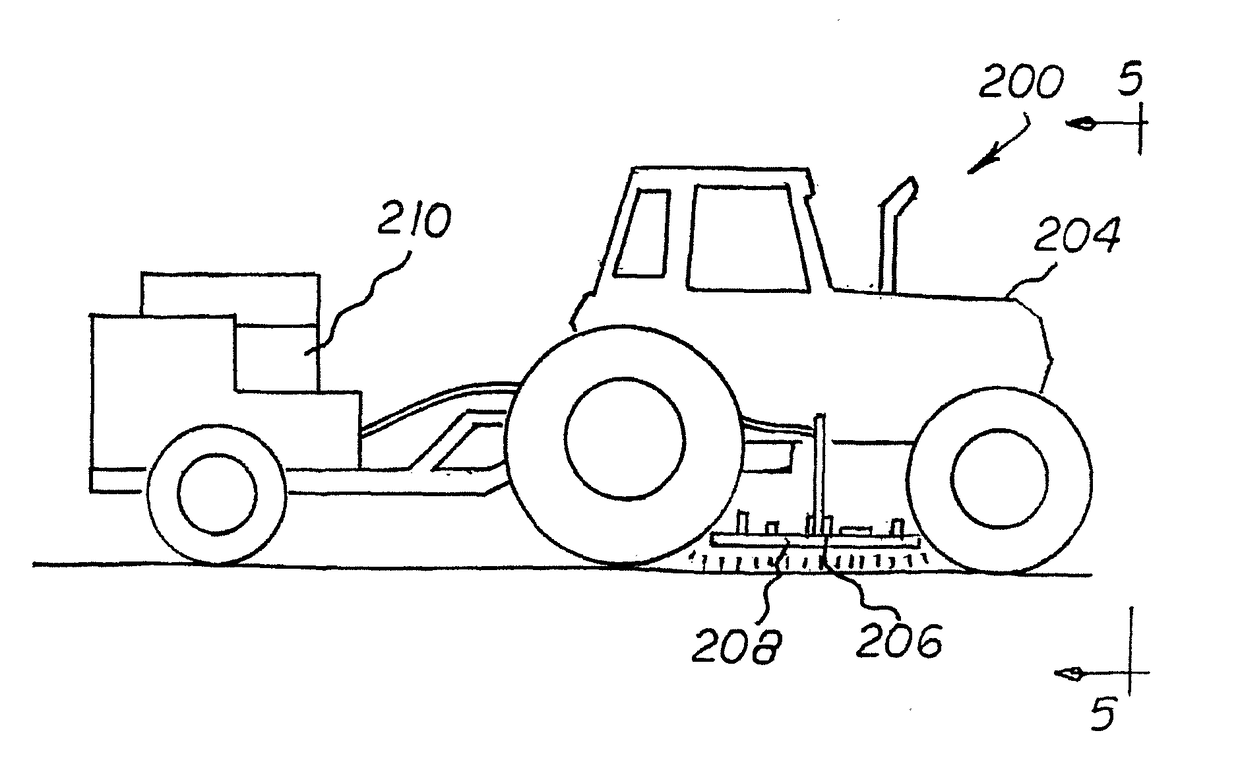

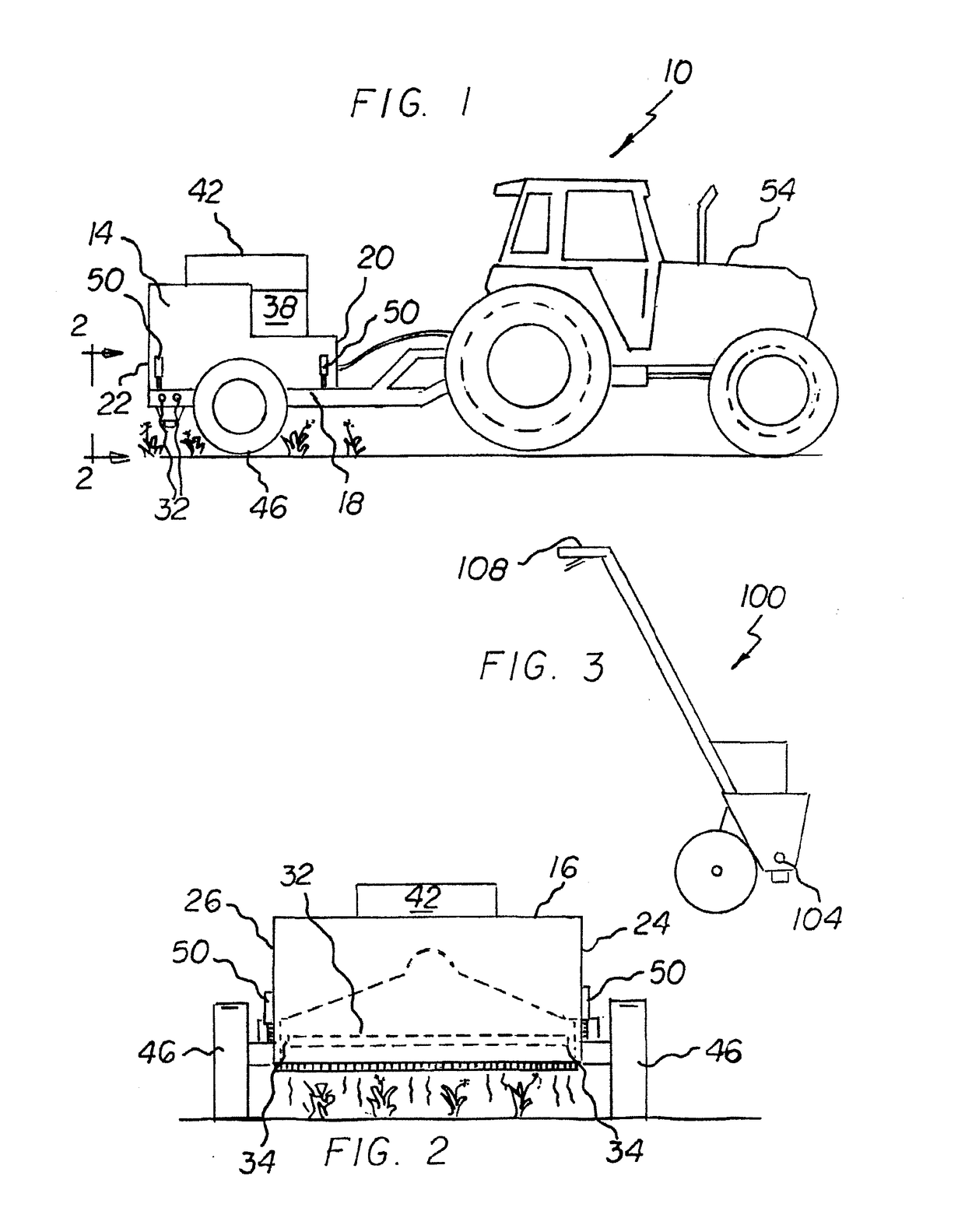

Electrically Powered Infrared Based Thermal Weed Control System

ActiveUS20170215405A1Difficult to focus and controlPrecise focusingWeed killersOhmic-resistance heating devicesInfraredElectricity

An electrically powered infrared based thermal weed control system. A housing has a downwardly facing chamber. At least one electrically powered infrared heating element is mounted within the chamber. A source of electrical power is electrically coupled to the electrically powered infrared heating element. A control assembly varies the electrical power to the electrically powered infrared heating elements and the heat generated for controlling undesired vegetation there adjacent using targeted infrared radiation emitted by the electrically powered infrared heating element.

Owner:STW LLC

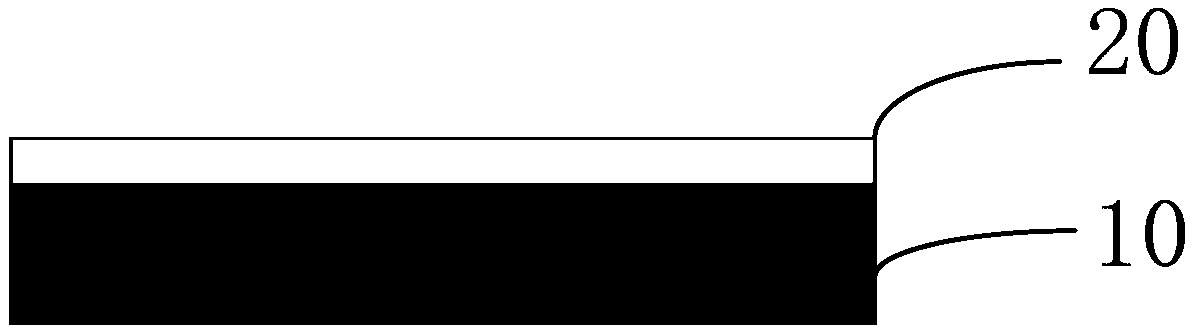

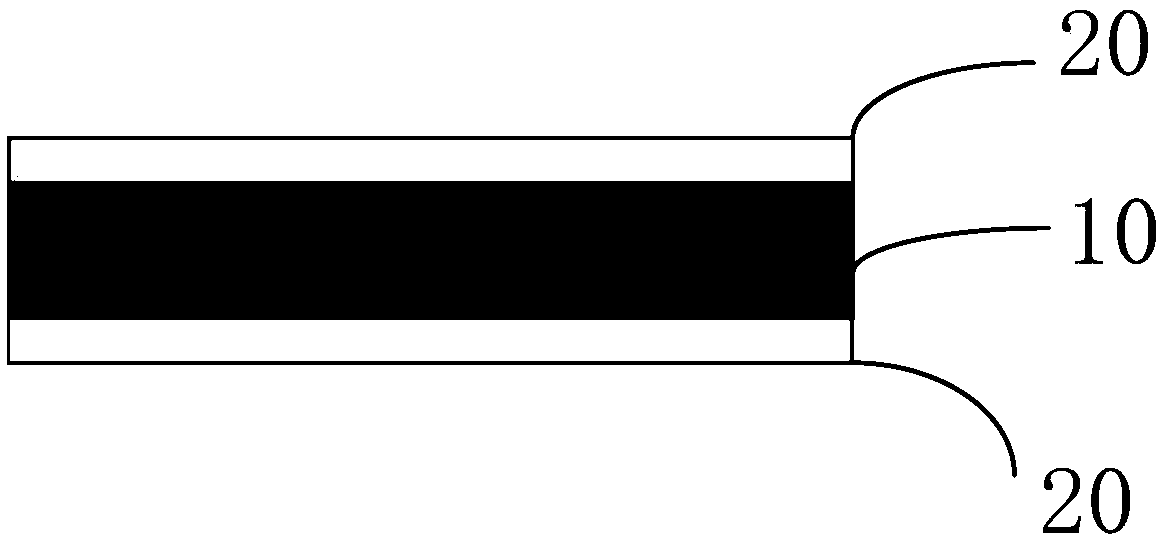

Electrode material with thermosensitive properties, and preparation method thereof

InactiveCN106784778AImprove thermal characteristicsLarge resistanceCell electrodesSecondary cellsLithium metalCurie temperature

The invention belongs to the technical field of lithium ion batteries, and particularly relates to an electrode material with thermosensitive properties, and a preparation method thereof. The electrode material comprises a core formed by a lithium metal oxide, and a shell formed by a thiophene derivative, wherein the weight of the thiophene derivative accounts for 0.1-8% of the total weight of the electrode material, and the Curie temperature of the thiophene derivative is 90-130 DEG C. Compared with the prior art, the electrode material with the core-shell structure, which is formed in a manner that the lithium metal oxide is coated with the thiophene derivative, has the advantages that the thermosensitive properties are excellent, that is, each active particle has the positive temperature coefficient characteristic; and when the internal temperature of a battery adopting the electrode material rises up to the Curie temperature of the material, the resistance of the electrode material can be sharply increased, so that a conductive network among the electrode material particles is blocked, the electron transfer speed is greatly reduced, the battery can be effectively prevented from further temperature rises, and the battery safety is further improved.

Owner:SHENZHEN HAIYING TECH

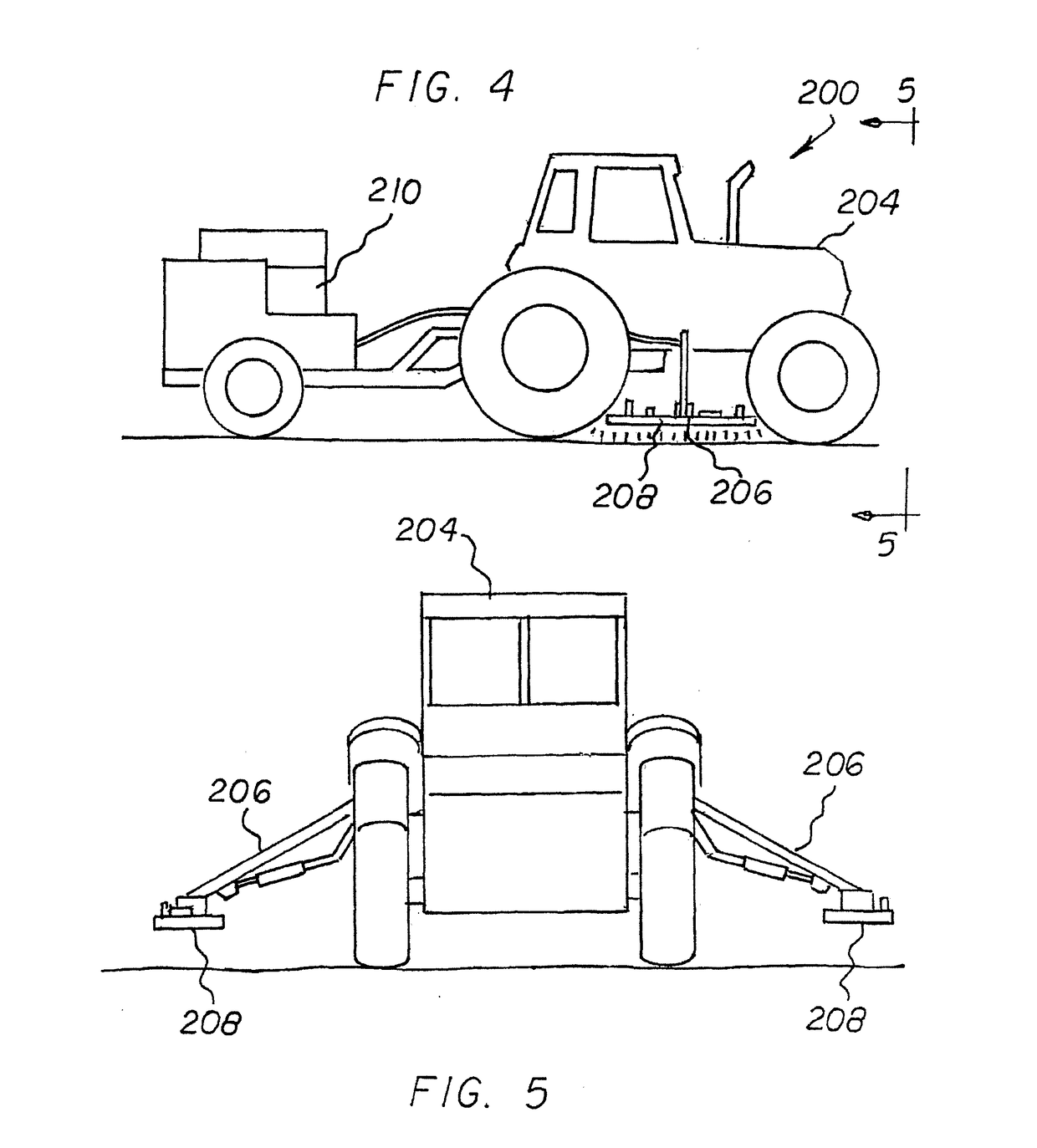

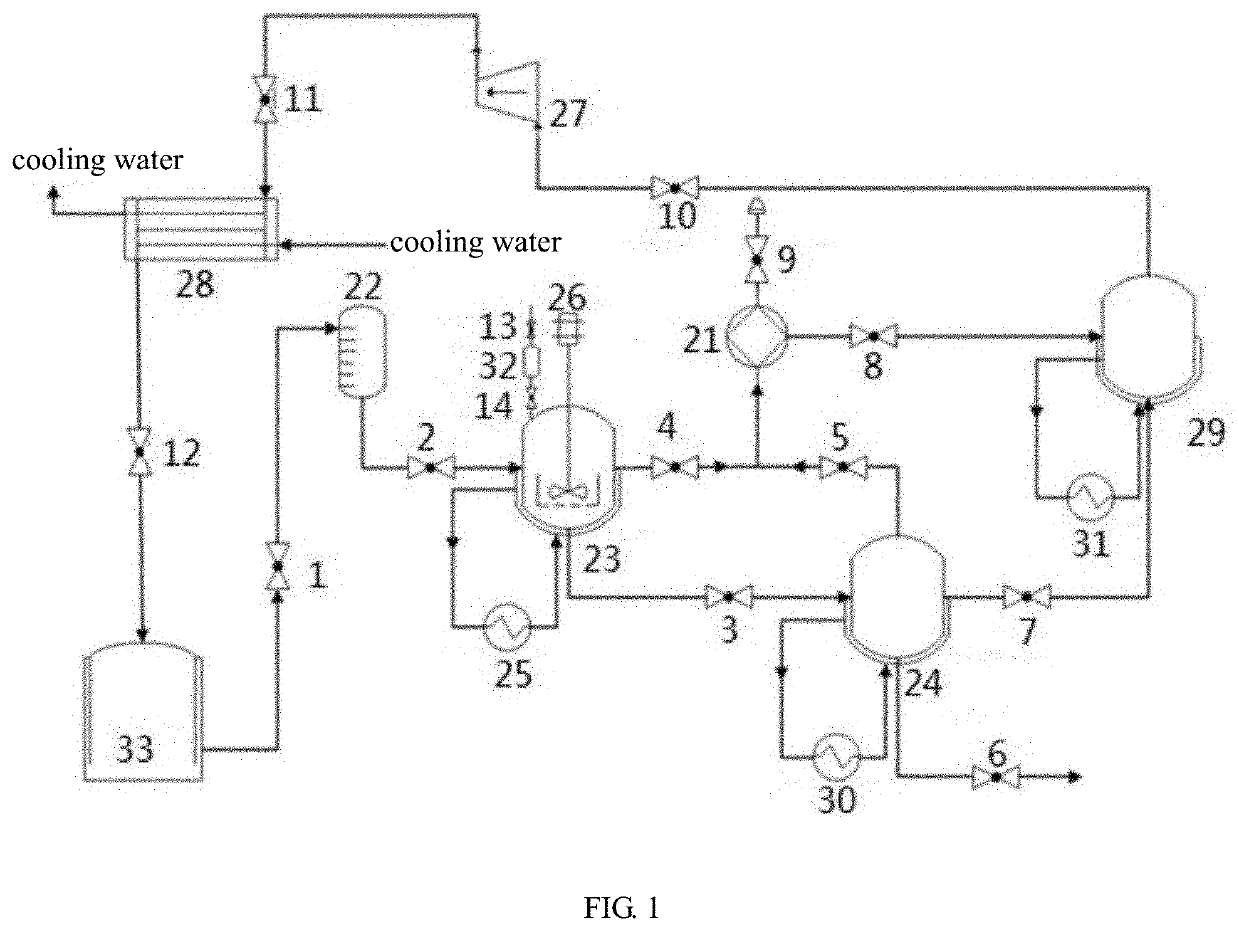

Method for extracting heat-sensitive antarctic krill oil

PendingUS20200063060A1Simple and convenient to operateHigh safetyFatty-oils/fats refiningFatty-oils/fats productionSolventActive agent

The present invention provides a method for extracting heat-sensitive Antarctic krill oil comprising the following steps. Firstly, frozen Antarctic krill is thawed and minced; a surfactant is added to the minced Antarctic krill to form a supercritical micelle system; extract the Antarctic krill multiple times after pressurizing and liquefying mixed gases; at the same time, a low-carbon alcohol solvent is added to strip the material in the critical micelle; after the extraction is completed, the extractant is removed; the extraction product and the residue after the extraction are subsequently collected; the heat-sensitive Antarctic krill oil can be obtained by high-speed centrifugal separation of the oil-water mixed extraction product. The present method has the advantages of simple operation, low extraction pressure and high safety. The extraction method of gas pressure liquefaction is completed under low temperature sealing conditions.

Owner:ZHEJIANG UNIV OF TECH

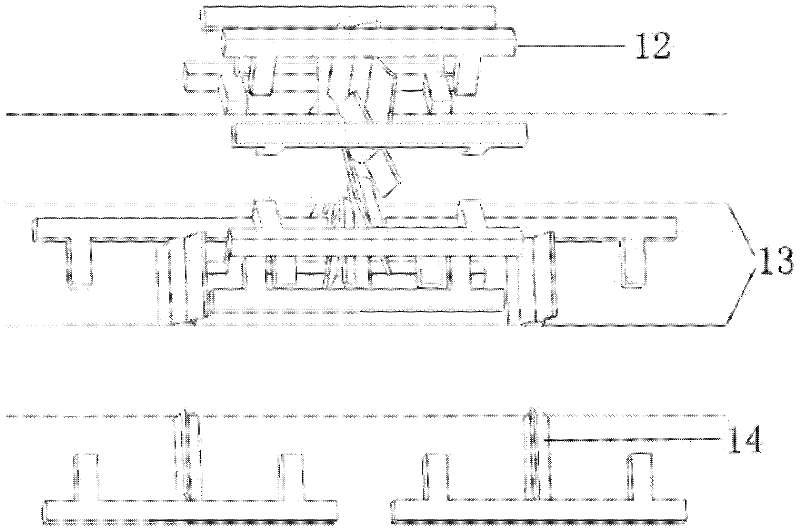

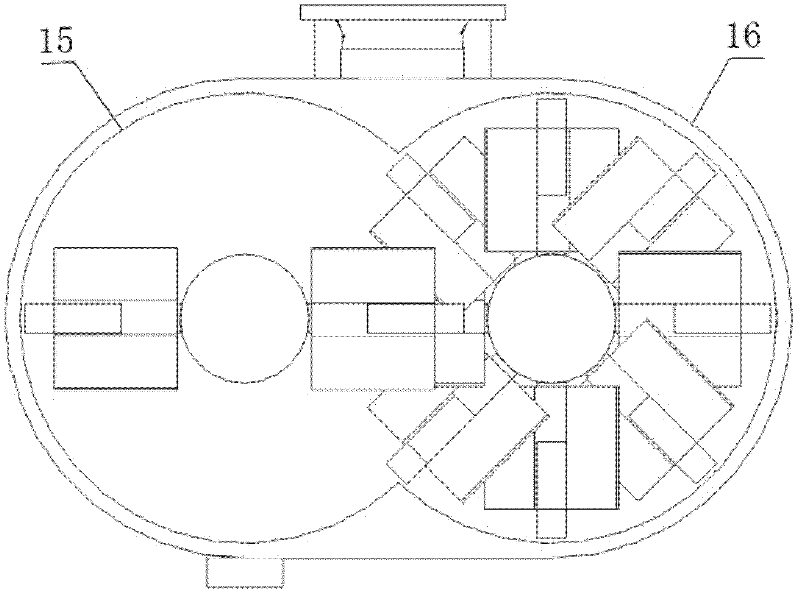

Rod fin-type horizontal double-shaft stirring reboiler with propulsion blades

The invention discloses a rod fin-type horizontal double-shaft stirring reboiler with propulsion blades. The rod fin-type horizontal double-shaft stirring reboiler with propulsion blades comprises a kettle body, a motor and a speed reducer connected to the motor. The top of the kettle body is provided respectively with a material inlet, a gas outlet and a manhole. Multiple material outlets are arranged at the bottom or a side wall of the kettle body. Two rotating shafts connected to an output shaft of the speed reducer are arranged in the kettle body. The two rotating shafts are respectively provided with multiple rod-type stirring fins at intervals. Each one of the rod-type stirring fins is provided with a propulsion blade. The rod-type stirring fins and the propulsion blades of the two rotating shafts are arranged crisscross. The rod fin-type horizontal double-shaft stirring reboiler with propulsion blades eliminates stirring blind angles and enhances stirring effects. Through the action between the rod-type stirring fins and the action between the rod-type stirring fins and the inner wall of the kettle body, materials bonded to the rod-type stirring fins and the inner wall of the kettle body can be scraped. Therefore, the rod fin-type horizontal double-shaft stirring reboiler with propulsion blades has strong self-cleaning effects and can avoid that materials are bonded to the interior of the kettle body.

Owner:TIANJIN UNIV

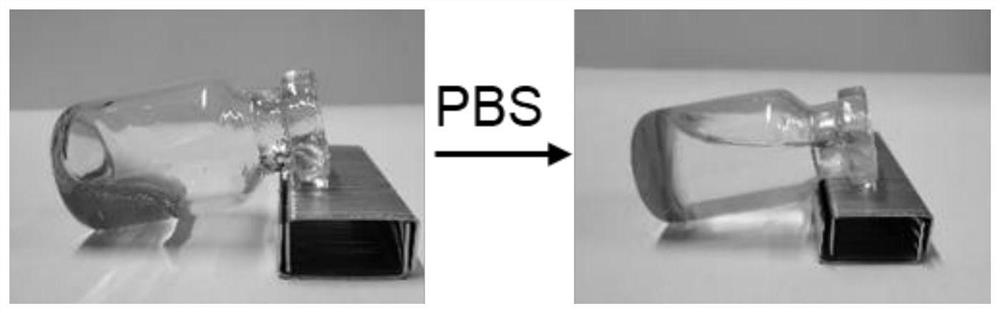

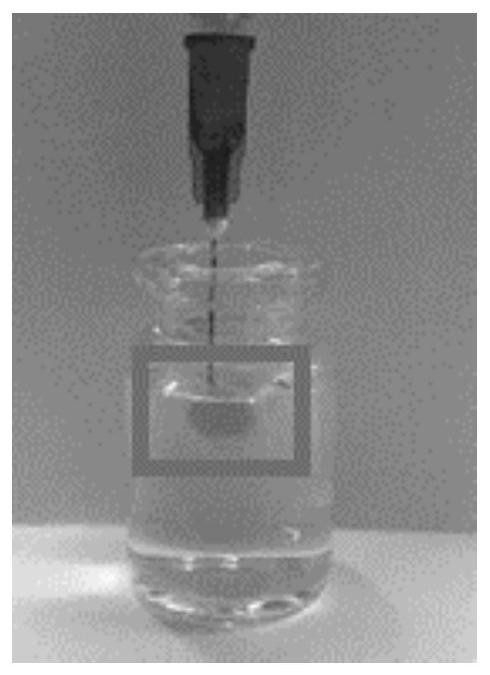

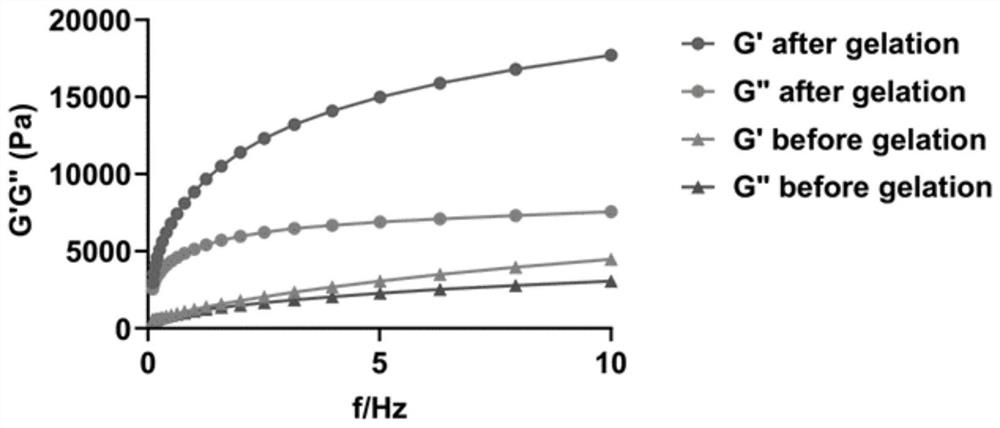

Sustained-release preparation, preparation method and application thereof in preparation of in-situ tumor combined immunotherapeutic medicines

ActiveCN111888475AEffective regulationGrowth inhibitionOrganic active ingredientsDrug photocleavageImmunomodulating AgentPharmaceutical drug

The invention discloses a sustained-release preparation, a preparation method and application thereof in preparation of in-situ tumor combined immunotherapeutic medicines and relates to the technicalfield of biological medical nano-materials. The sustained-release preparation adopts liquid crystal gel as a vector, and an immunogenic inducing agent and an immunomodulator are loaded in the liquid crystal gel. The sustained-release preparation is prepared by the steps of preparing a liquid crystal precursor by adopting a simple agitation mixing method and loading the immunogenic inducing agent and immunomodulator. According to the sustained-release preparation, the immunogenic inducing agent and immunomodulator are co-loaded in the in-situ sustained-release liquid crystal gel, and semi-solidgel is in-situ formed after intratumor, peritumoral or postoperative intraluminal administration to release drugs in a sustained way, so that the tumor microenvironment can be effectively adjusted, the effect of inhibiting tumor growth, relapse and metastasis can be achieved, and whole-body toxic or side effect caused by traditional administration means can be reduced. The sustained-release preparation and the preparation method thereof have a potential application prospect in in-situ local treatment of tumors.

Owner:HUAZHONG UNIV OF SCI & TECH

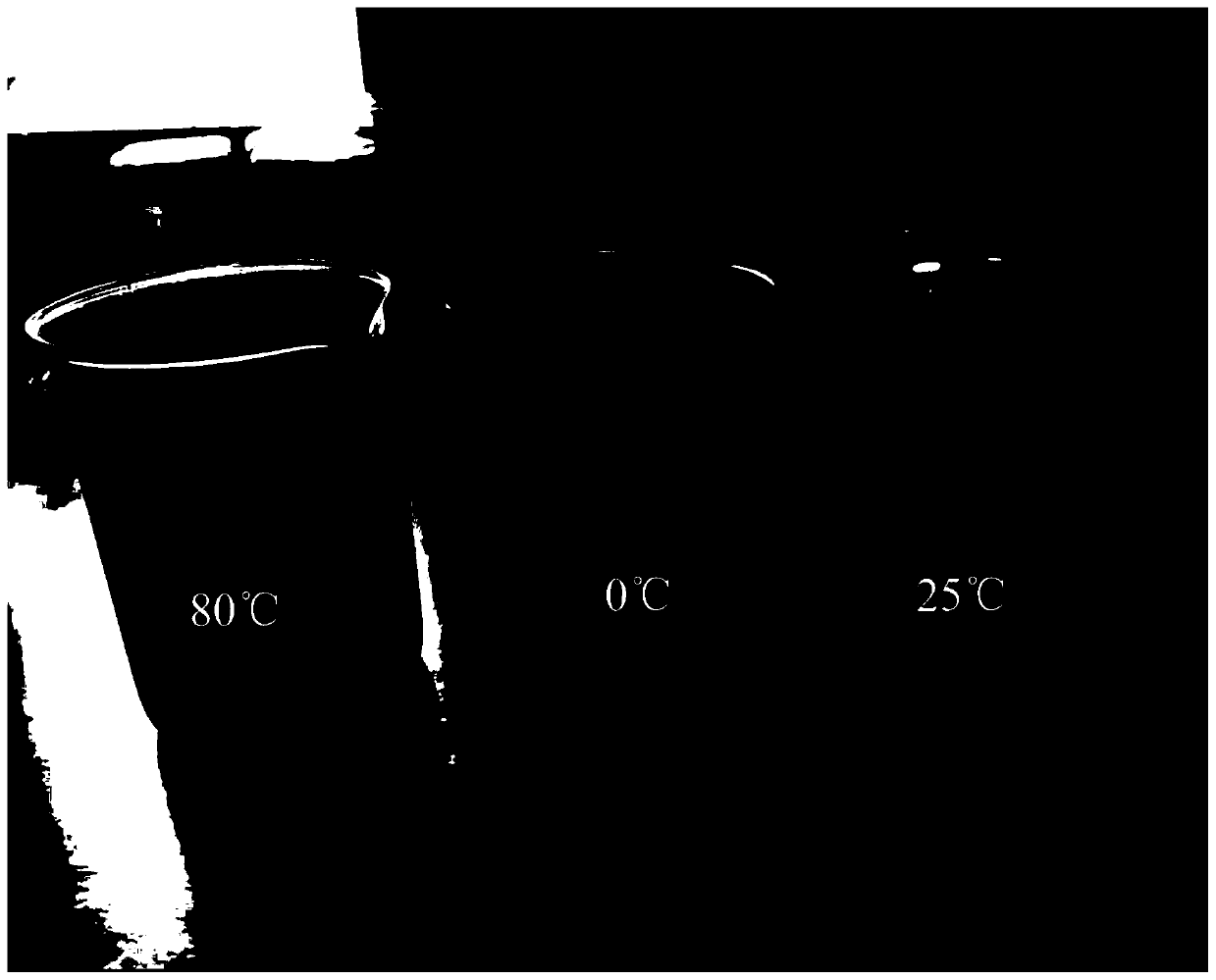

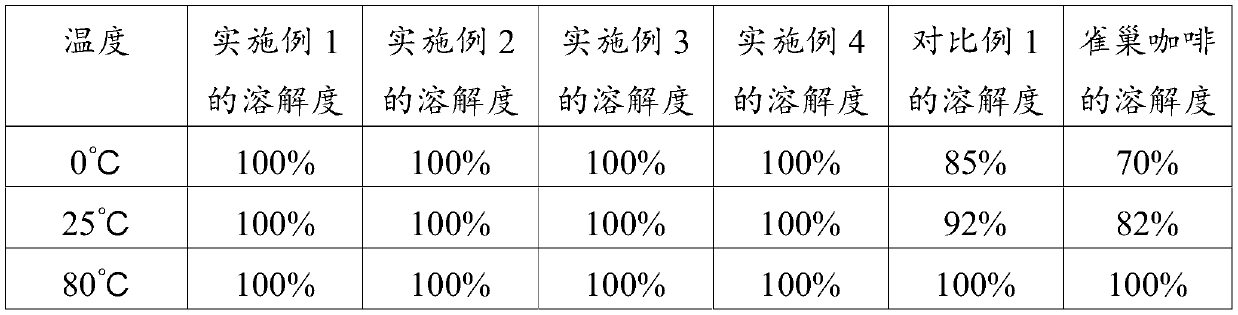

Cold-soluble freeze-dried coffee and preparation method thereof

The invention relates to cold-soluble freeze-dried coffee and a preparation method thereof, and belongs to the technical field of food processing. The cold-soluble freeze-dried coffee is prepared from, by weight, 42-50% of Colombia coffee, 5-8% of Khatisk coffee, 10-20% of Blue Mountain coffee, 12-20% of Mocha coffee, 8-15% of Java coffee and 5-12% of Ethiopian coffee. The preparation method of the cold-soluble freeze-dried coffee sequentially includes the operation steps of baking, grinding, extraction, centrifugation, evaporation and freeze drying. According to the cold-soluble freeze-driedcoffee and the preparation method thereof, by adopting a freeze-drying technology, the cold-soluble freeze-dried coffee is prepared, aromatic substances with high heat sensitivity in coffee beans arereserved, the cold-soluble freeze-dried coffee is rich in fragrance and pure and mild in taste, and the solubility in drinking water at 0 DEG C, 25 DEG C and 80 DEG C is 100%, so that brewing withouthot water or boiled water is convenient.

Owner:李镇南

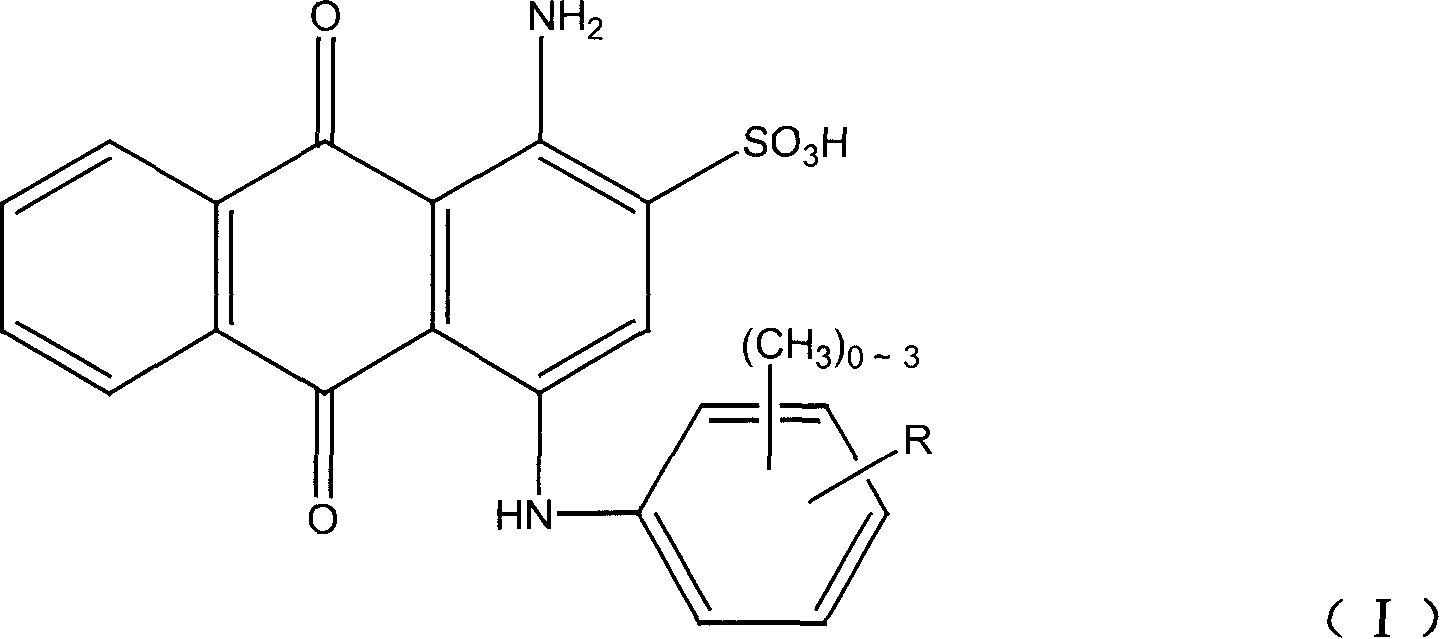

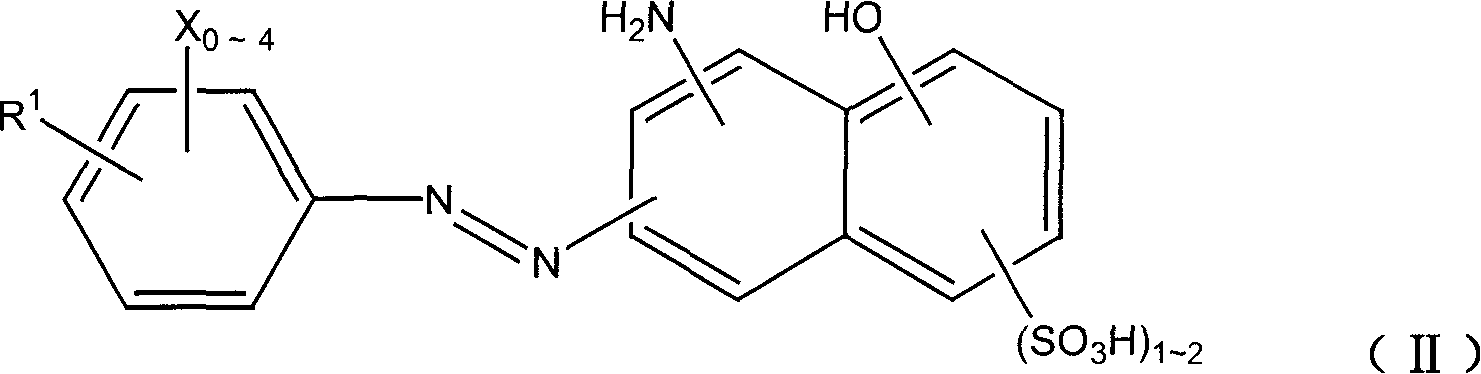

Acid dye mixture

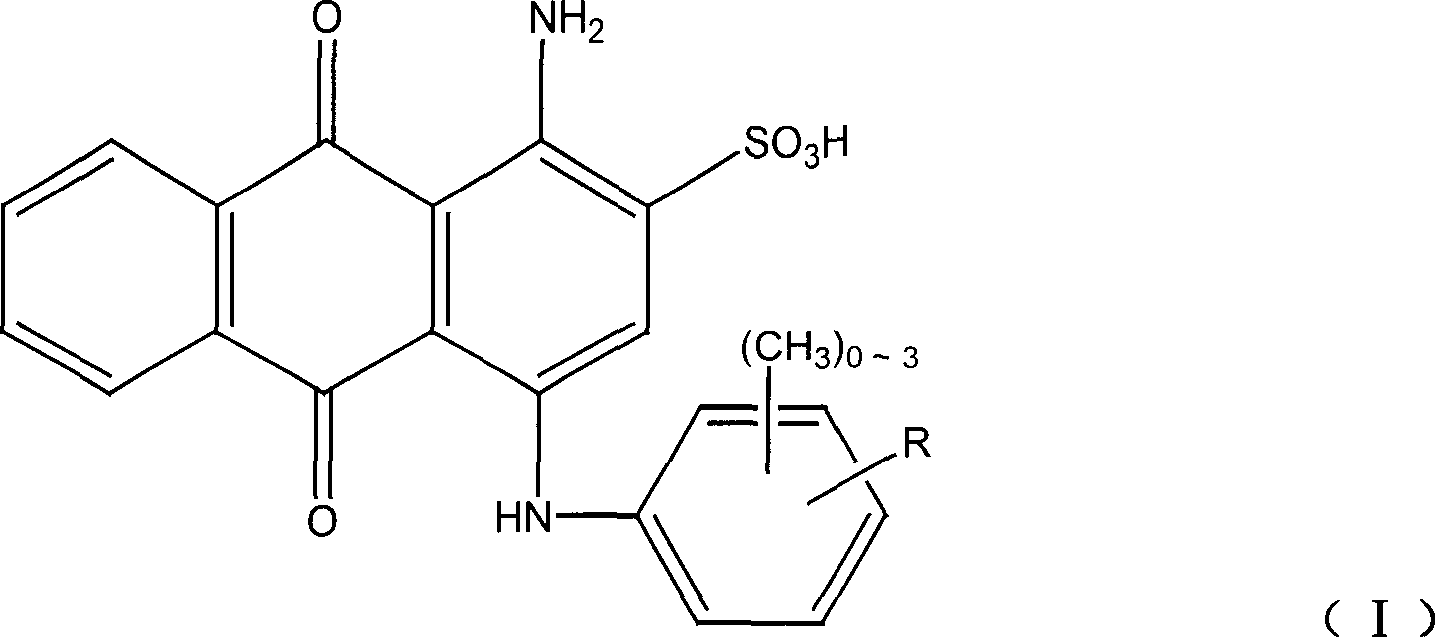

ActiveCN1869130AImprove qualityImprove performanceOrganic dyesDyeing processAcid dyeNuclear chemistry

The invention relates to an acidity dye mixture that includes three structures of dyes: one, the dye according with the general expression (I), or the metal salt, ammonium salt or organic ammonium salt according with the expression; two: the dye according with the general expression (II), or the metal salt, ammonium salt or organic ammonium salt according with the expression; three, C.I acid orange 67 or C.I acid yellow 242 in international dye index, or the metal salt, ammonium salt or organic ammonium salt of the two dyes. The invention could be used in the weak color coloration in polyamide fiber outside material and could satisfy general clothes outside material product quality index demand.

Owner:WUJIANG LVZHOU DYESTUFF CHEM

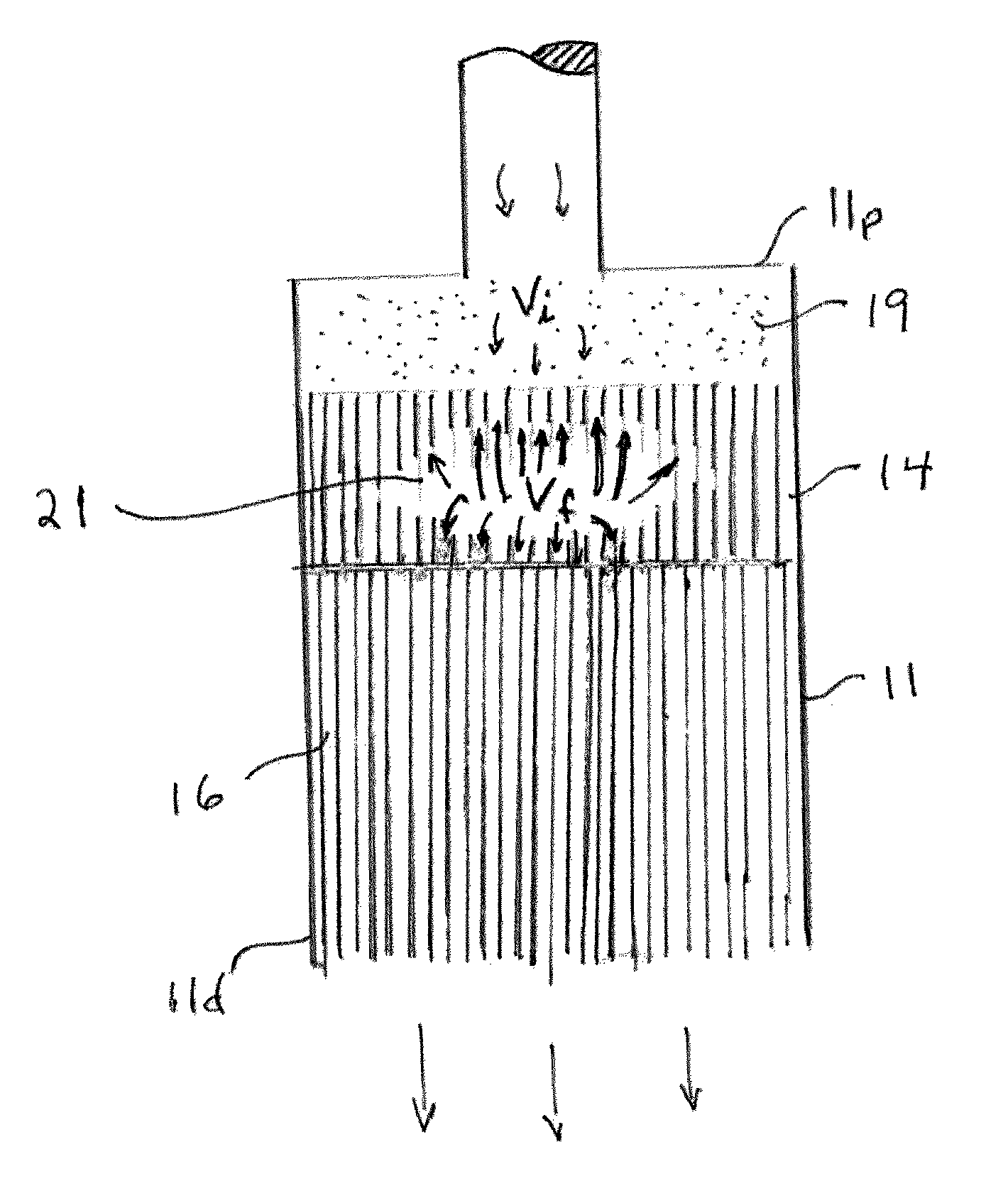

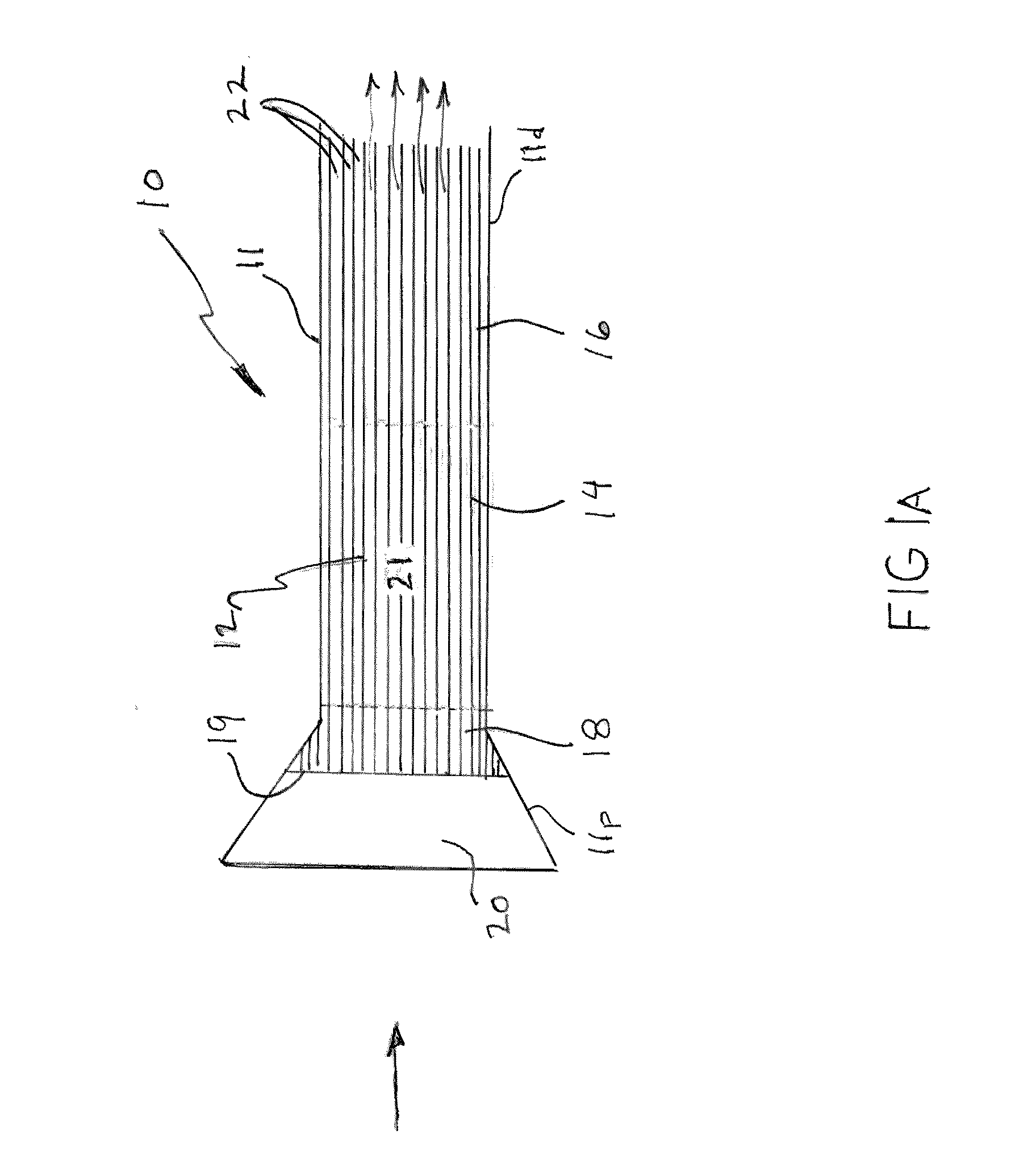

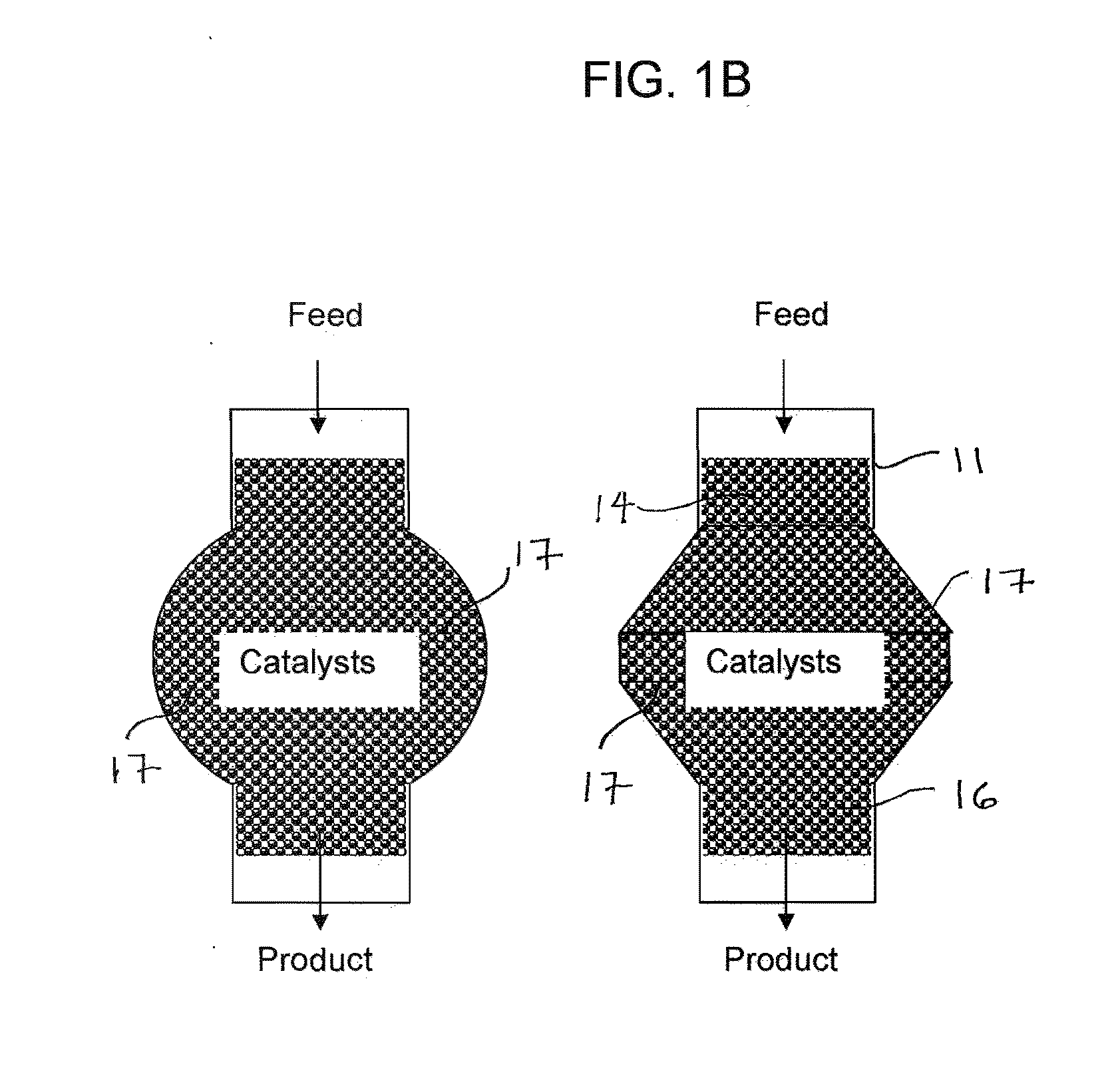

Autothermal and partial oxidation reformer-based fuel processor, method for improving catalyst function in autothermal and partial oxidation reformer-based processors

InactiveUS20100095590A1Dissipating thermal energy generatedHeat sensitiveHydrogen productionHydrogen/synthetic gas productionPartial oxidationProcess engineering

Owner:UCHICAGO ARGONNE LLC

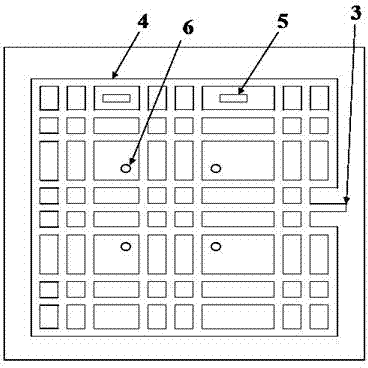

Thin sheet type CPU heat dissipation device and machining method thereof

InactiveCN103488266AReduce precipitationFast heat conductionDigital data processing detailsHeat transmissionAmbient air

The invention relates to heat dissipation devices, in particular to a thin sheet type CPU heat dissipation device and a machining method thereof. The thin sheet type CPU heat dissipation device comprises a heat transmission and heat dissipation integrated device, wherein the heat transmission and heat dissipation integrated device is formed by stamping, and network channels are formed inside the heat transmission and heat dissipation integrated device. The network channels are filled with certain amount of heat transmission working media from technological filling ports and are sealed through welding. The heat dissipation device comprises a heat transmission substrate and a heat dissipation part, wherein the heat transmission substrate in contact with a CPU is of a protruding structure, and the portion outside the heat transmission substrate is the heat dissipation part. Mirror surface machining is carried out on the surface, in contact with the CUP, of the heat dissipation substrate. An efficient heat transmission technology is adopted in the thin sheet type CPU heat dissipation device and the manufacturing method thereof, heat generated by the CPU is made to be transmitted to a heat dissipation end fast, and the heat dissipation end carries out heat exchange with ambient air to ensure the normal work of the CPU.

Owner:ZHEJIANG JIAXI TECH CO LTD

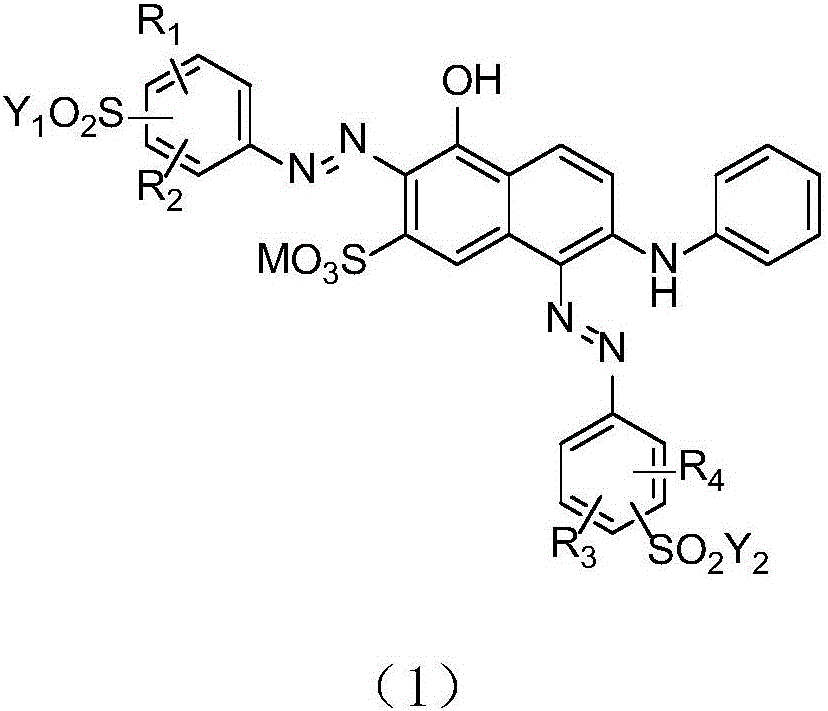

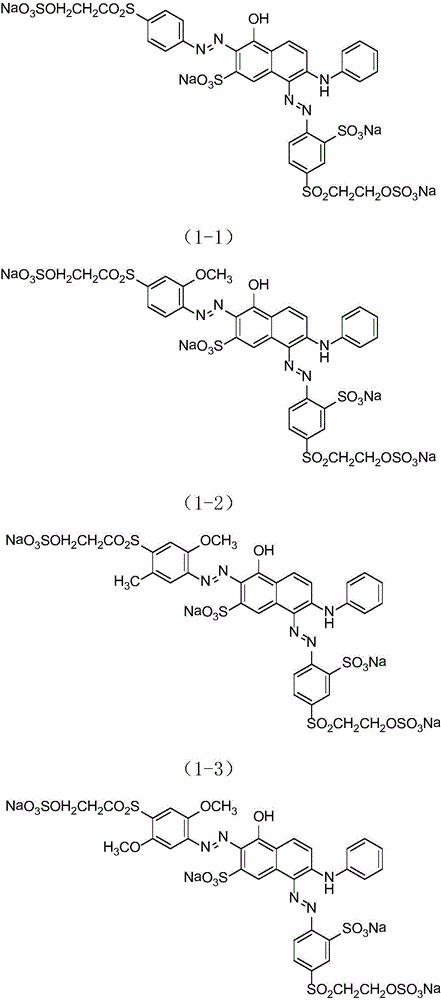

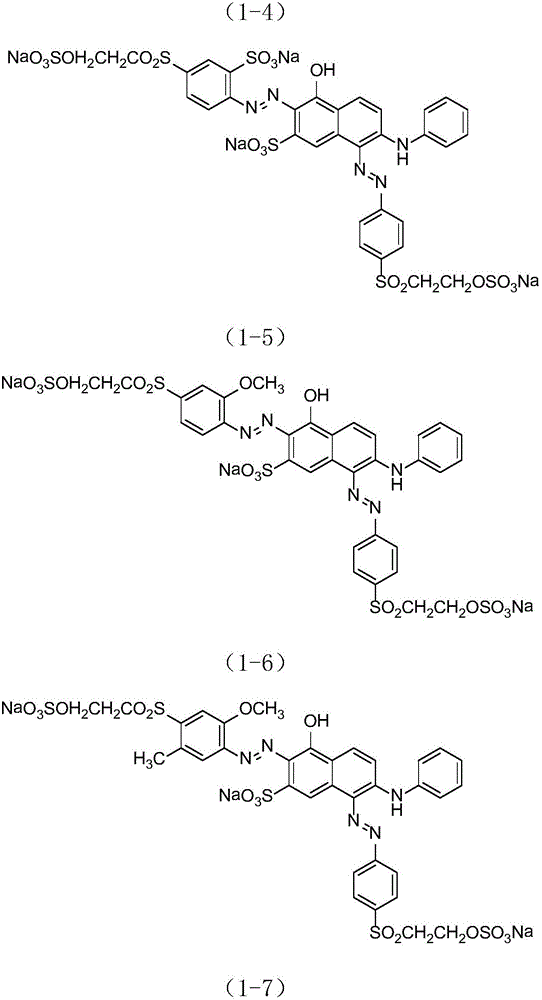

Dark red reactive dye and preparation method thereof

InactiveCN106634045AHigh liftHigh color fixing rateReactive dyesDyeing processHydrogenHeat stability

The invention discloses dark red reactive dye and a preparation method thereof. The dark red reactive dye is one material selected from general formulas of the formula (I) or is a mixture obtained through compounding two or more structures selected from the general formulas of the formula (I) according to any proportion. One material shown by the formula (I) is selected from any one of materials of the following structure general formulas or is a mixture of two or more materials of the structural general formulas, wherein R1, R2, R3 and R4 in the formula (I) respectively and independently represent -H, -CH3, -OCH3 or -SO3M; Y1 and Y2 respectively and independently represent -CH=CH2 or -C2H4OSO3M; M represents hydrogen or alkali metal. The dark red reactive dye has the advantages that the lifting performance is good; the friction firmness, the water washing firmness, the light fastness and the heat stability are high. The formula (I) is shown as the accompanying drawing.

Owner:ZHEJIANG YIDE CHEM

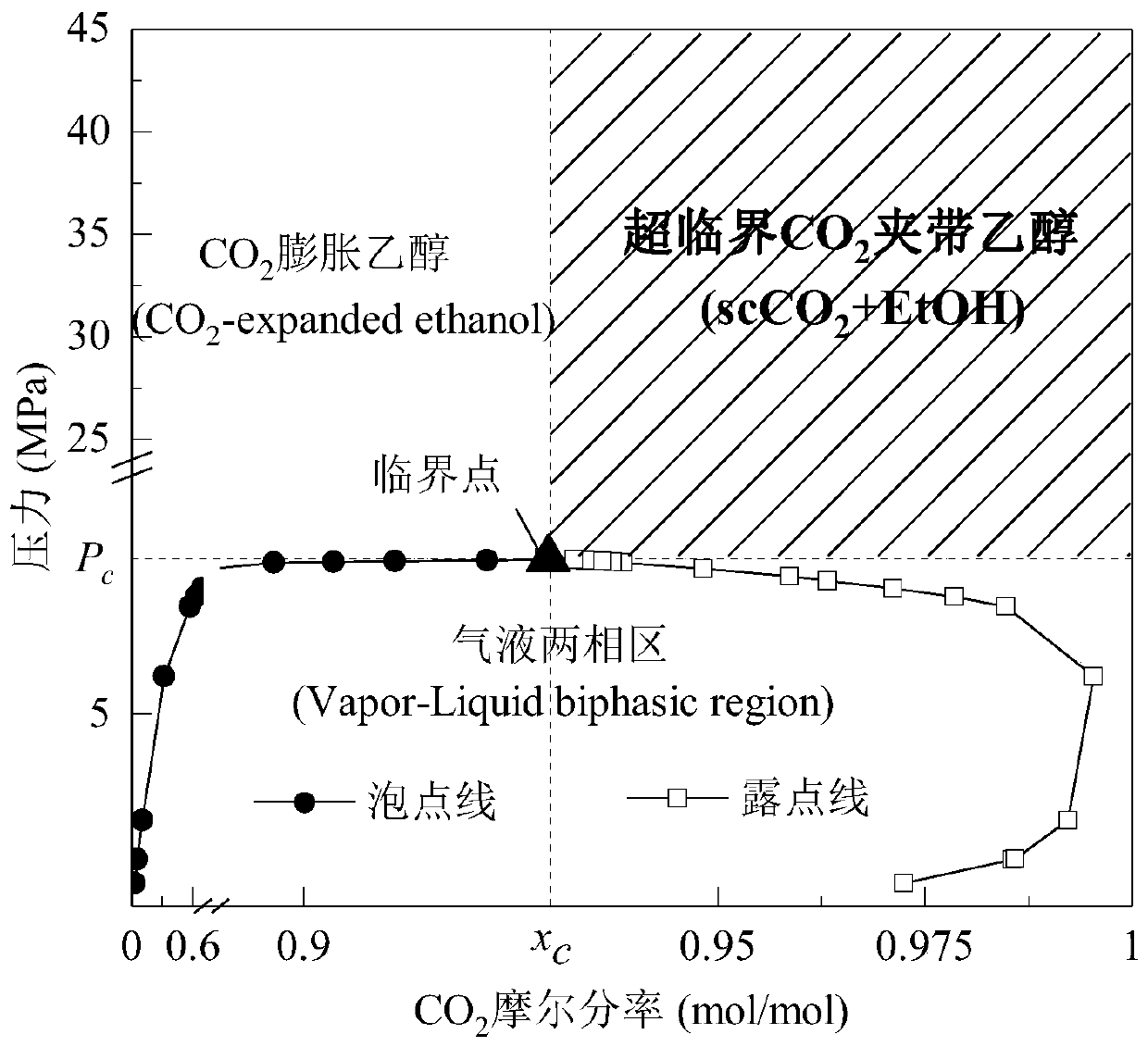

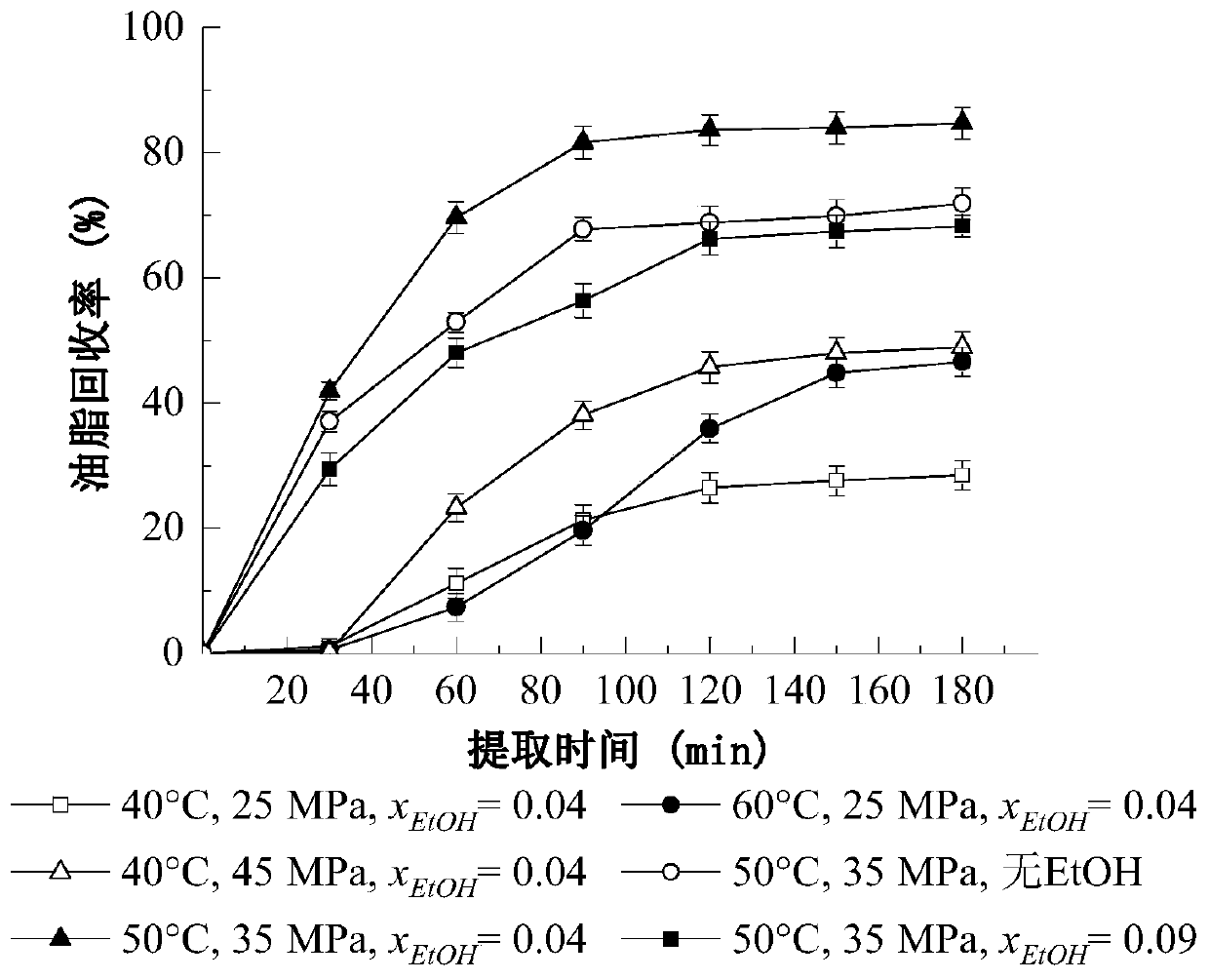

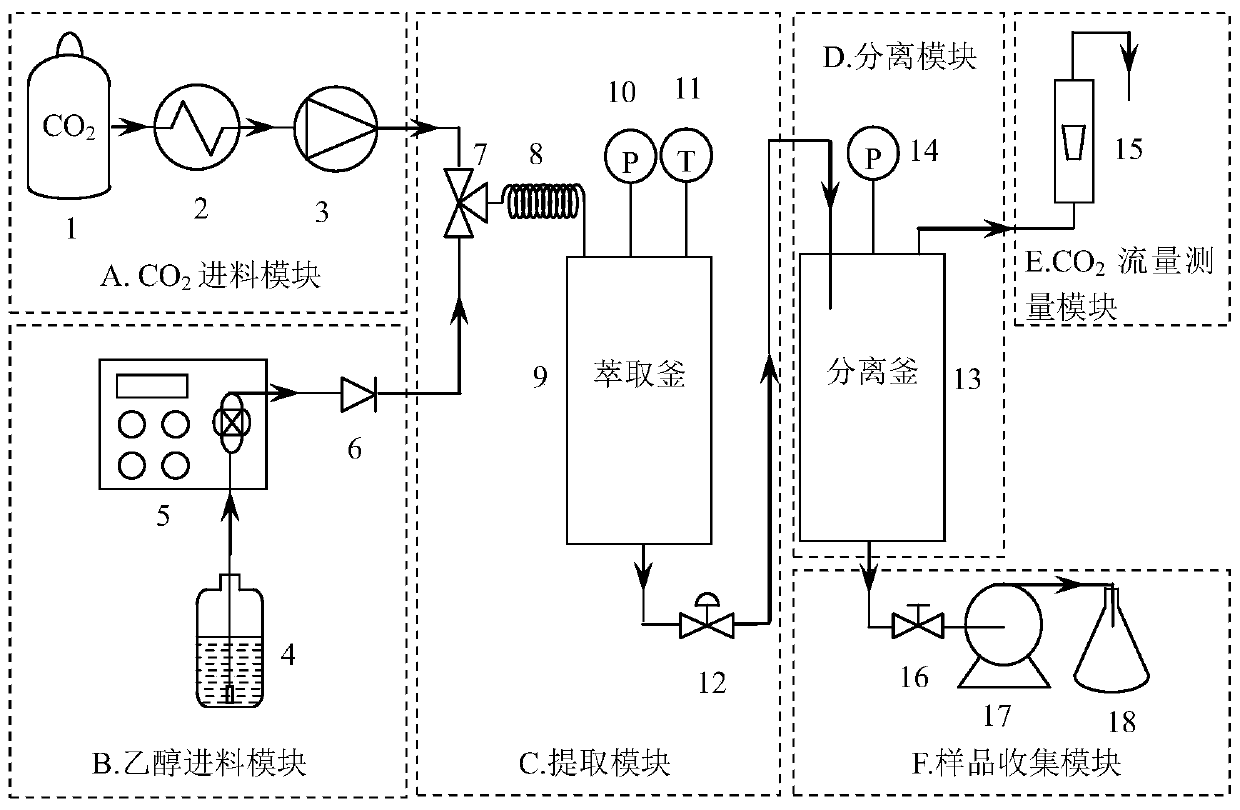

Method for extracting microalgae grease by using supercritical carbon dioxide entraining ethanol

PendingCN110029019AStable compositionThe extraction process is green and environmentally friendlyFatty-oils/fats productionChemistryFreeze dry

The invention discloses a method for extracting microalgae grease by using supercritical carbon dioxide entraining ethanol. The method comprises the following steps: preparing a microalgae fermentation liquid into microalgae freeze-dry powder; uniformly mixing the microalgae freeze-dry powder with glass beads of which the diameter is 2-5mm, and putting into an extraction kettle as a material; extracting the material in the extraction kettle by using a supercritical CO2 entrained ethanol fluid prepared from an entrainment agent ethanol and CO2, wherein the extraction time is 2.5-3 hours; discharging and collecting ethanol-containing microalgae grease from the outlet in the bottom of a separation kettle. Due to the adoption of the ethanol supercritical carbon dioxide entrained ethanol fluid,the method disclosed by the invention has the advantages of being non-toxic, good in selectivity, green and environmental-friendly, adjustable in polarity, possible to recycle and reuse, and the like, and compared with a conventional organic solvent extraction method, the method has the advantages of being safe and non-toxic.

Owner:ZHEJIANG NORMAL UNIVERSITY

Concentrating crystallization process for tryptophan or glyphosate by using mechanical vapor recompression technology

ActiveCN102807521AHeat sensitiveReduce solubilityGroup 5/15 element organic compoundsChemical industryCentrifugationProcess engineering

The invention relates to a concentrating crystallization process for tryptophan or glyphosate by using a mechanical vapor recompression technology. According to the process, secondary vapor separated by a crystallizer is compressed by a vapor compressor, is introduced into a heater to heat and concentrate tryptophan or glyphosate, and then is sequentially subjected to heat emission, condensation and discharging; the tryptophan or the glyphosate is mixed with a mother liquor, and the resulting mixed material is output through a pump and then is mixed with a circulating liquid; the resulting mixture is output to the heater through an circulation pump; after heat absorption is performed, the resulting material enters the crystallizer to carry out boiling evaporation, secondary vapor is separated, and the material liquid is continuously circulated; when the material liquid reaches a preset concentration, one part of the material liquid is output to a magma tank through a material discharge pump, and the other part of the material liquid is adopted as the circulating liquid to continuously participate in the circulation; the concentrated solution entering the magma tank enters a centrifuge, centrifugation is performed to obtain a crystal and the mother liquor, wherein the mother liquor enters a tank. According to the present invention, continuous feeding and continuous discharging are achieved in the whole process; advantages of energy saving, investment saving, and operation cost reducing are provided; tryptophan or glyphosate and other heat-sensitive materials can be subjected to concentrating crystallization at a low temperature so as to ensure product quality and save energy.

Owner:JIANGSU LEKE ENERGY SAVING TECH CO LTD

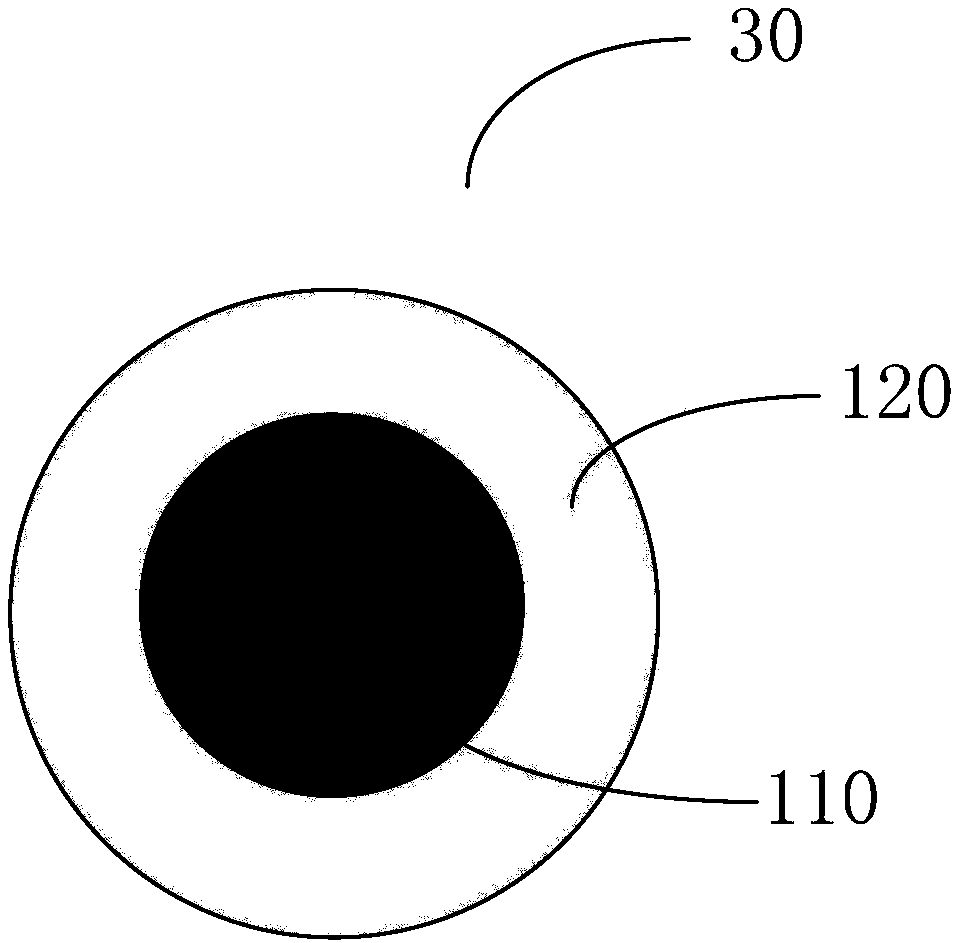

Conductive polymer alkali metal salt with heat-sensitive properties and preparation method and application thereof

ActiveCN110739458AImprove thermal characteristicsGood electrical conductivityCell electrodesSecondary cellsThermal runawayElectrical battery

The embodiment of the invention provides conductive polymer alkali metal salt with heat-sensitive properties. The metal salt comprises a conductive polymer repeating unit and substituted imine alkalimetal salt grafted on the conductive polymer repeating unit. The conductive polymer repeating unit includes a five-membered unsaturated heterocyclic structure. The substituted imine alkali metal saltincludes one or more of substituted imide alkali metal salt and substituted sulfimide alkali metal salt. The substituted imine alkali metal salt forms an N-C bond with C atoms in the five-membered unsaturated heterocyclic structure through N atoms. The conductive polymer alkali metal salt has excellent heat-sensitive properties, electron-conducting ability and ion-conducting ability. When used ina secondary battery, the conductive polymer alkali metal salt can effectively improve the safety and electrochemical performance of a battery and avoid the occurrence of thermal runaway. The embodiment of the invention further provides a preparation method and application of the conductive polymer alkali metal salt.

Owner:HUAWEI TECH CO LTD

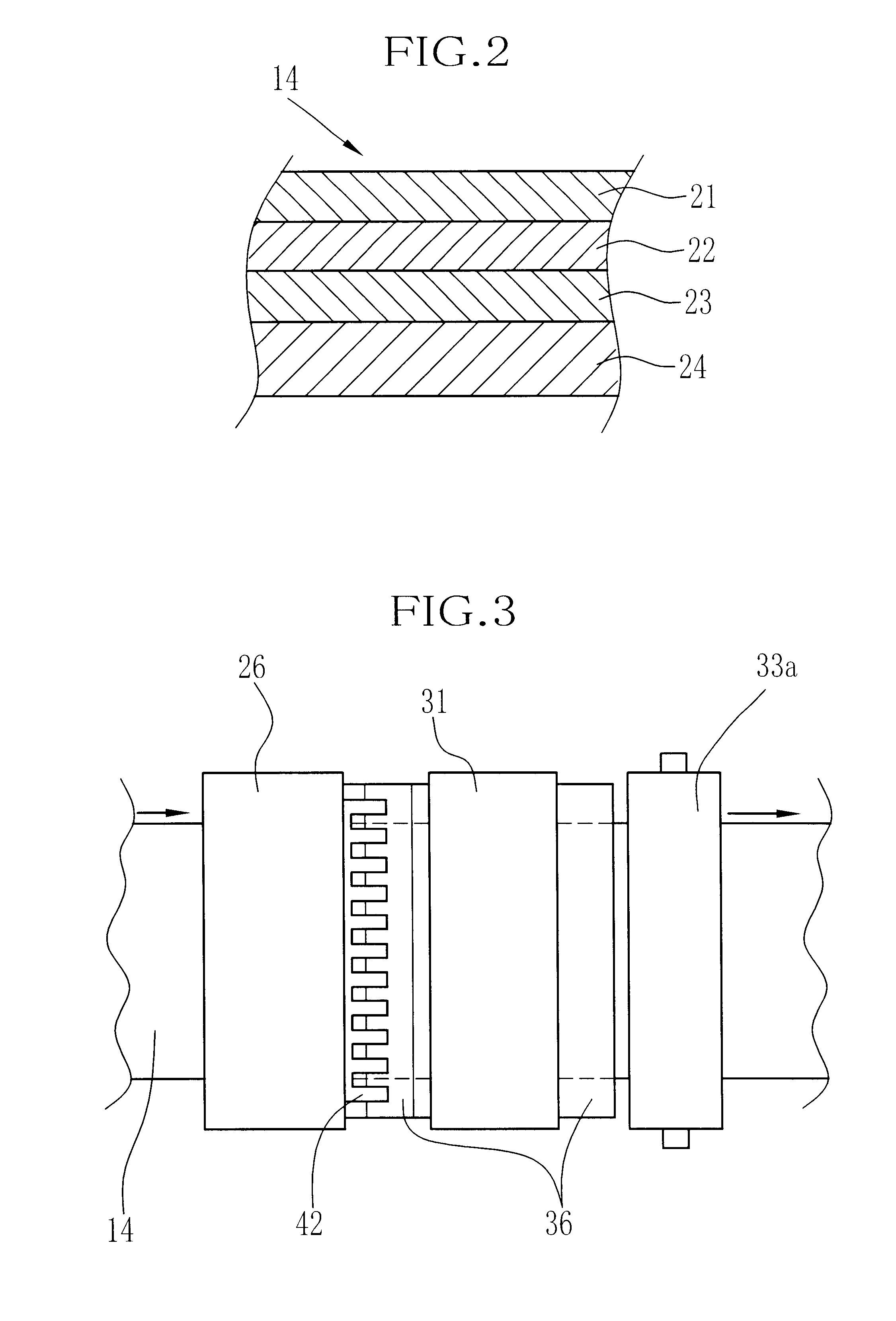

Brake pad in multi-layer composite structure

Provided is a brake pad in a multi-layer composite structure, comprising a steel backing and a brake pad body. The brake pad body is formed by an adhesion thermal insulation layer and a frictional layer. The brake pad is characterized in that the adhesion thermal insulation layer is made of components in the following parts by weight: PROMAXON (R) D calcium silicate, boron containing phenolic resin, magnesium oxide, nano-zinc oxide, nano- alumina, isopropanol, zircon powders, lauryl sodium sulfate, polyacrylonitrile preoxidized fibers, and acrylonitrile butadiene rubber. The frictional layer is made of components in the following parts by weight: Lapinus-Roxul (R) 1000 engineering fibers, aramid fibers, polyacrylonitrile preoxidized fibers, alkali-free bulk glass fibers, calcium sulfate whiskers, potassium titanate whiskers, brass fibers, cashew nut oil frictional powders, flake aluminite powders, tantalum carbide, zirconium silicate, nano-zinc oxide, molybdenum trioxide, and boron containing phenolic resin. The brake pad is characterized by green and environmentally-friendly, good high-temperature resistance and heat fading resistance, good wear-resisting property, stable friction coefficient, long service life, and low cost.

Owner:摩擦一号制动科技(仙桃)有限公司

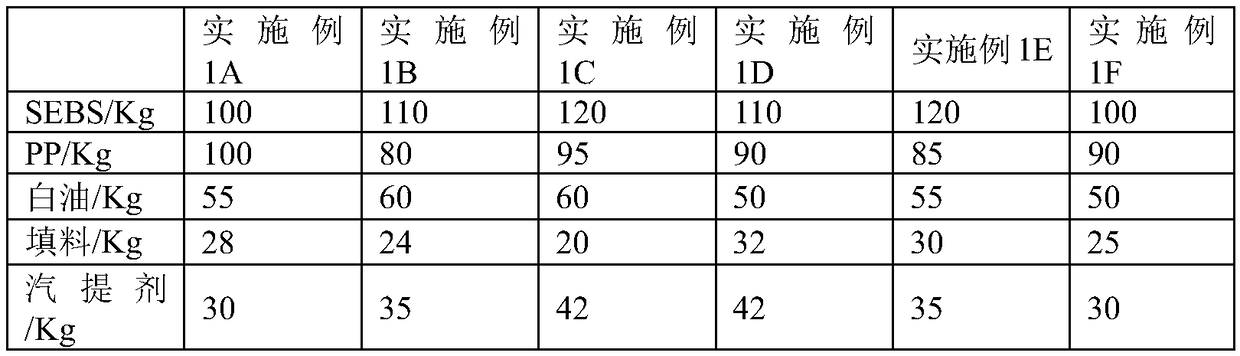

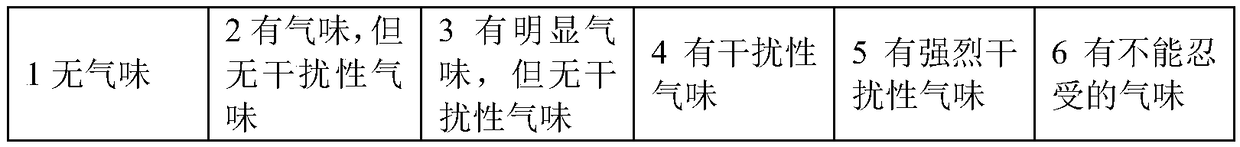

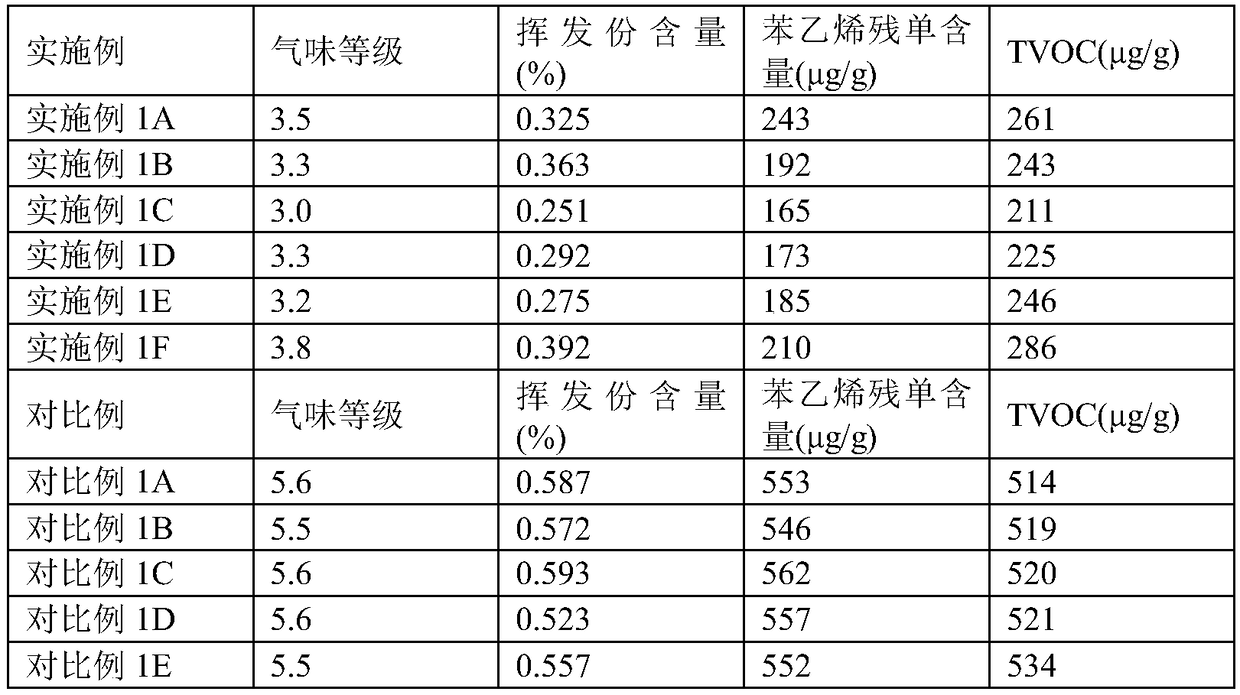

Thermoplastic elastomer and preparation method thereof

The invention relates to automobile interior rubber fittings, and discloses a thermoplastic elastomer and a preparation method thereof. The problem that the effect of reducing the volatile organic compounds (VOC) index is poor due to the fact that a liquid entrainer used in the prior art cannot be easily mixed with a paste in a molten state is solved. The technical scheme is that the thermoplasticelastomer comprises the following raw materials in parts by mass: 100-120 parts of styrene ethylene butylene styrene (SEBS), 80-100 parts of white oil, 50-60 parts of polypropylene (PP), 20-32 partsof filler, 30-42 parts of a stripping agent, wherein the stripping agent is composed of 17-26 parts by mass of ethanol, 8 parts by mass of water and the balance of a coagulator. Organic volatile gas contained in a molten paste is removed in a production process, and the VOC index of the product thermoplastic elastomer is effectively reduced.

Owner:山东朗净新材料科技有限公司 +1

Composition, preparation method of composition, preparation and use

ActiveCN106387904AThe effect of calcium supplementation is remarkableImprove immunityFood ingredient as antioxidantMetabolism disorderCannabisToxin

The invention discloses a composition and a preparation method thereof, a preparation and a use. The composition comprises, by weight, 29.5% to 30.5% of horseradish tree leaf ultrafine powder, 29.5% to 30.5% of cassia seed extract, 14.5% to 15.5% of fructus cannabis powder, 12.5% to 13.5% of refined fructus phyllanthi powder, 6.5% to 7.5% of lotus leaf powder and 4.5% to 5.5% of aloe ultrafine powder. The composition has obvious effects of removing toxins, relaxing bowels, supplying calcium, clearing away heat, lubricating intestines, improving liver, improving eyesight, treating constipation, improving immunity, strengthening and protecting liver and accelerating metabolism.

Owner:CHUXIONG BAICAOLING PHARMA DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com