Cold-soluble freeze-dried coffee and preparation method thereof

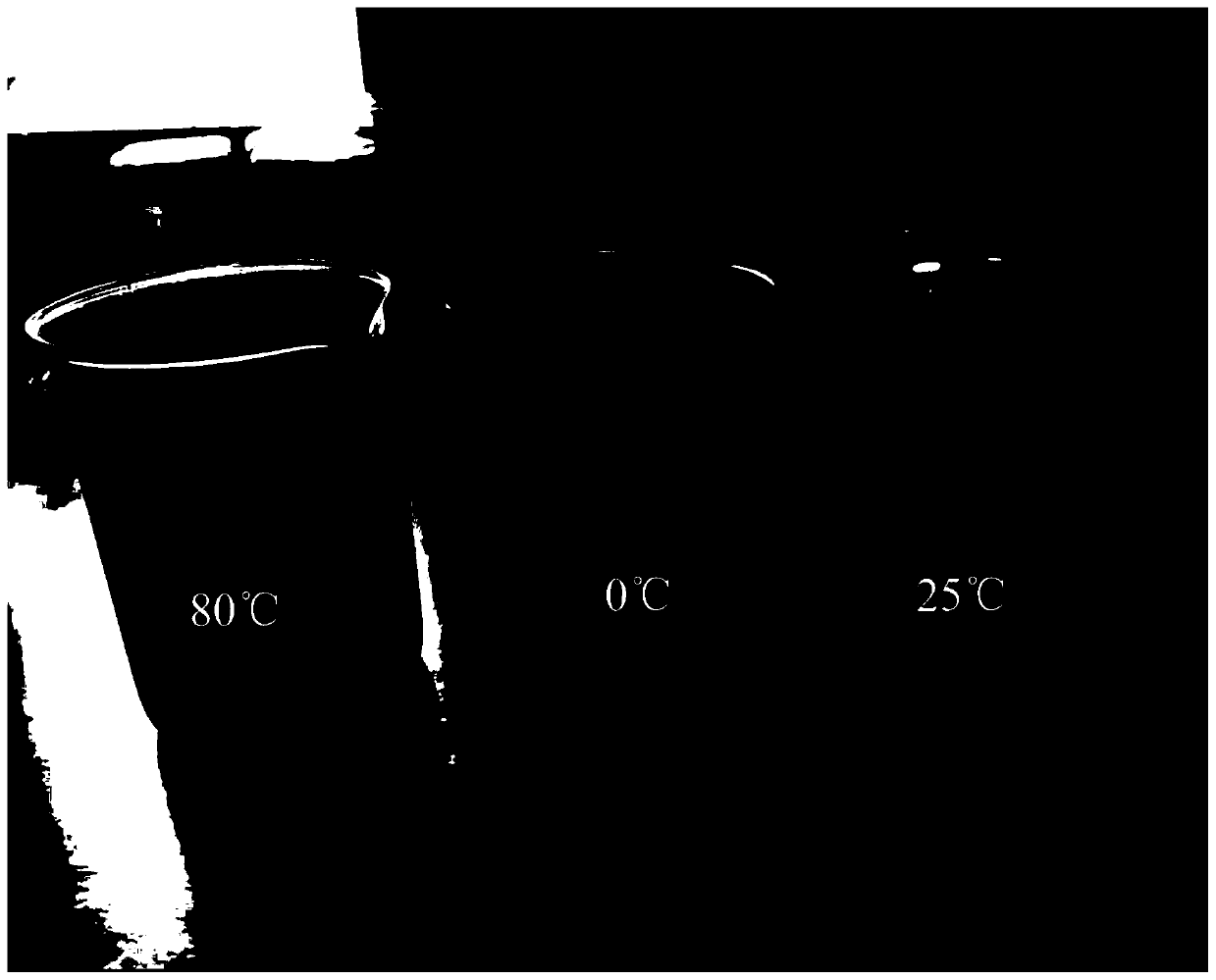

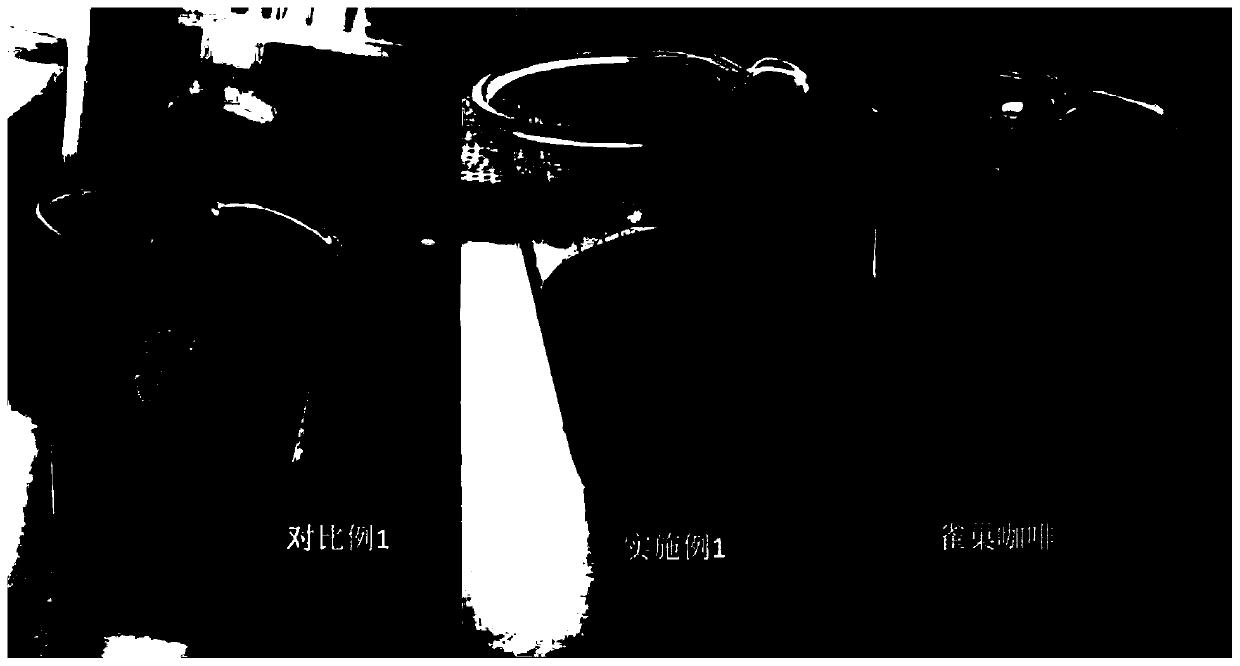

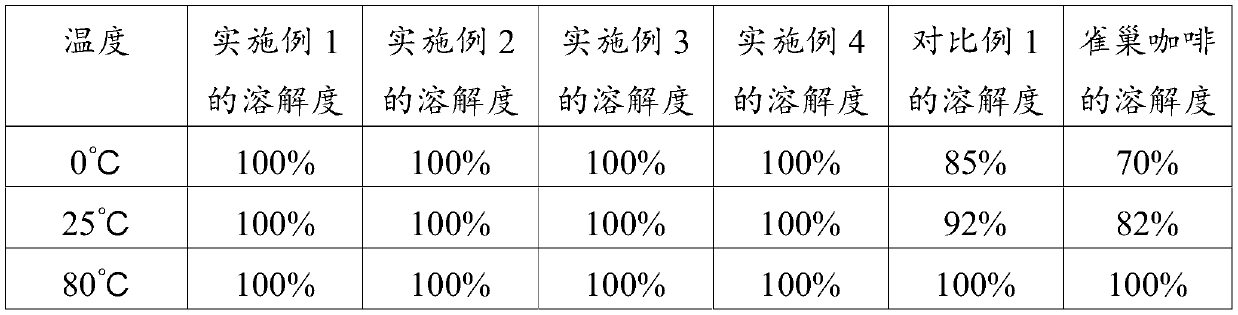

A technology of freeze-dried coffee and cold melting, which is applied in the fields of coffee, food science, and applications. It can solve problems such as difficulty in fully dissolving, and achieve a more pure and soft taste without burnt bitterness, pure and soft taste, and strong aroma.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This embodiment is a kind of cold-melt freeze-dried coffee of the present invention, comprising the following components in weight percentage: 44% of Columbia, 5% of Catisque, 18% of Blue Mountain, 15% of Mocha, 8% of Java, Ethiopia 10%.

[0029] The preparation method of the above-mentioned cold-melt freeze-dried coffee comprises the following steps:

[0030] (1) Roasting: Weigh the coffee beans of each component of the above-mentioned cold-melt freeze-dried coffee in proportion, and carry out five-stage roasting after mixing; The cold-melt and freeze-dried coffee beans were heated to 172°C and roasted for 200 seconds; in the second stage, the coffee beans obtained in the first stage were heated to 160°C under the condition of air temperature of 160°C, and lightly preheated for roasting 234 seconds; the third stage, at an air temperature of 227°C, heat the coffee beans obtained in the second stage to 210°C, and carry out the Menard reaction for 470 seconds; the fourth...

Embodiment 2

[0037] The present embodiment is a kind of cold-melt freeze-dried coffee of the present invention, comprising the following components by weight percentage: Columbia 42%, Katiske 8%, Blue Mountain 10%, Mocha 20%, Java 8%, Ethiopia 12%.

[0038] The preparation method of described cold-melt freeze-dried coffee, comprises the following steps:

[0039] (1) Roasting, weighing the coffee beans of each component of the cold-melt freeze-dried coffee in proportion, and performing five stages of roasting after mixing; in the first stage, under the condition of air temperature of 198°C, weigh the coffee beans after mixing. The cold-melt and freeze-dried coffee beans were heated to 172°C and roasted for 200 seconds; in the second stage, the coffee beans obtained in the first stage were heated to 160°C under the condition of air temperature of 160°C, and lightly preheated for roasting 234 seconds; in the third stage, under the condition of air temperature of 230°C, the coffee beans obtai...

Embodiment 3

[0046] The present embodiment is a cold-melt freeze-dried coffee of the present invention, comprising the following components by weight percentage: Colombia 45%, Katiske 7%, Blue Mountain 15%, Mocha 12%, Java 10%, Ethiopia 11%.

[0047] The preparation method of described cold-melt freeze-dried coffee, comprises the following steps:

[0048] (1) Roasting, weighing the coffee beans of each component of the cold-melt freeze-dried coffee in proportion, and performing five stages of roasting after mixing; in the first stage, under the condition of an air temperature of 190°C, weigh the coffee beans after mixing. The cold-melt and freeze-dried coffee beans were heated to 172°C and roasted for 200 seconds; in the second stage, the coffee beans obtained in the first stage were heated to 160°C under the condition of air temperature of 160°C, and lightly preheated for roasting 234 seconds; the third stage, at an air temperature of 228°C, heat the coffee beans obtained in the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com