Thin sheet type CPU heat dissipation device and machining method thereof

A heat dissipation device and processing method technology, applied in the direction of instruments, digital data processing parts, electrical digital data processing, etc., can solve the problems that cannot meet the requirements of CPU power density heat transfer space, etc., achieve sensitive thermal response and improve heat exchange level , improve the effect of heat exchange

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

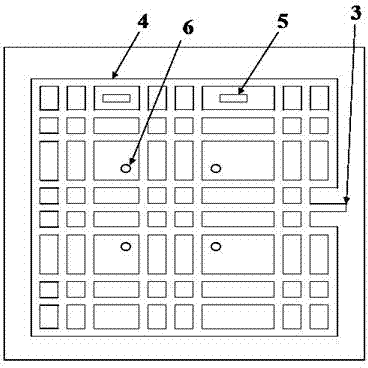

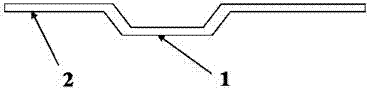

[0018] like figure 1 , 2 As shown, the invention discloses a thin-plate type CPU cooling device. As shown in the figure: it includes a heat transfer and heat dissipation integrated device with a network channel 4 formed by stamping; a certain amount of heat transfer working fluid is filled into the channel from the process filling port 3 and welded; The heat dissipation device includes a heat-conducting substrate 1 and a heat-dissipating part 2, wherein the heat-conducting substrate 1 in contact with the CPU is a convex structure, and the other part of the heat-conducting substrate 1 is a heat-dissipating part 2; the surface of the heat-conducting substrate 1 in contact with the CPU is treated with a mirror surface.

[0019] In the above structure, the surface of the aluminum plate of the thermally conductive substrate 1 that is in contact with the CPU is treated with a mirror finish to reduce the thermal resistance between the CPU and the thermally conductive substrate 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com