Rod fin-type horizontal double-shaft stirring reboiler with propulsion blades

A propelling blade, horizontal double shaft technology, applied in mixers with rotary stirring devices, chemical instruments and methods, dissolution and other directions, can solve the problem of poor stirring effect of reboiler, poor heat transfer effect of reboiler, and product loss. It can ensure the safe and continuous operation, shorten the residence time, and reduce the thermal loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

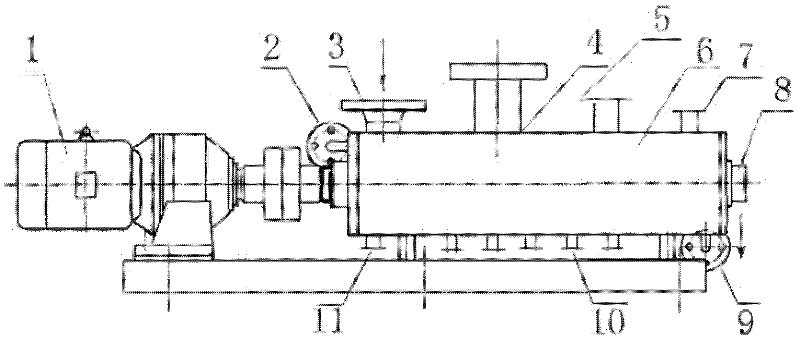

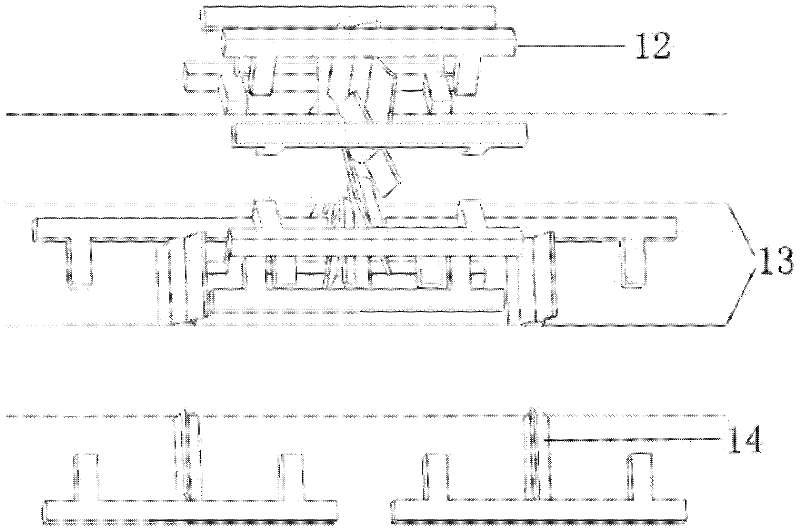

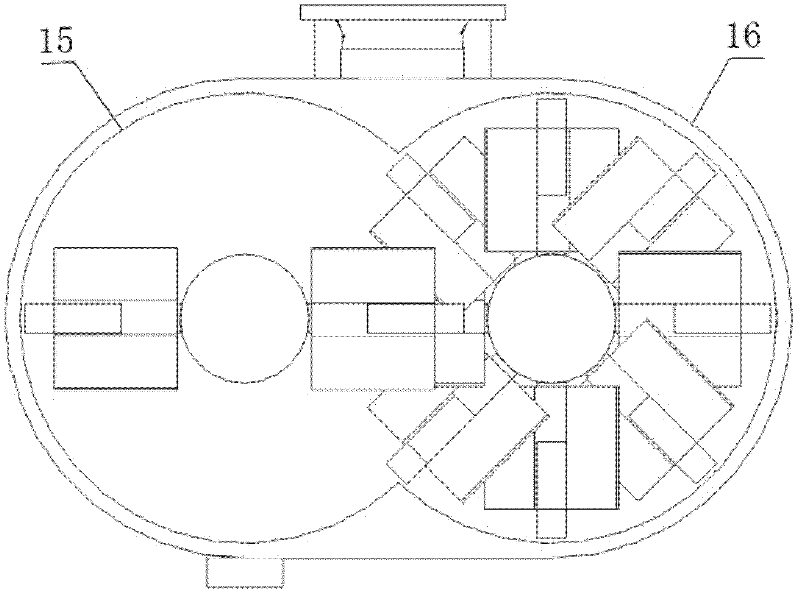

[0012] like figure 1 The shown rod-fin horizontal twin-shaft stirring reboiler with propulsion blades of the present invention includes a kettle body 6, a motor 1 and a speed reducer connected to the motor 1, and at the top of the kettle body A material inlet 3, a gas outlet 4 and a manhole 5 are respectively provided, and a plurality of material outlets 8 and 10 are arranged on the bottom or the side wall of the kettle body 6, and the described speed reducer is arranged in the kettle body 6 The two rotating shafts 13 connected to the output shaft are respectively provided with a plurality of rod-type stirring fins 12 at intervals on the two rotating shafts, and each rod-type stirring fin 12 is provided with a propulsion blade 14 . The rod-type stirring fins and propulsion blades on the two rotating shafts are arranged alternately. The cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com