Conductive polymer alkali metal salt with heat-sensitive properties and preparation method and application thereof

A technology of conductive polymers and alkali metal salts, applied in circuits, electrical components, battery electrodes, etc., can solve problems such as performance degradation and lack of ion conductivity, achieve easy operation, improve safety performance and electrochemical performance, and solve Effect of Security Questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

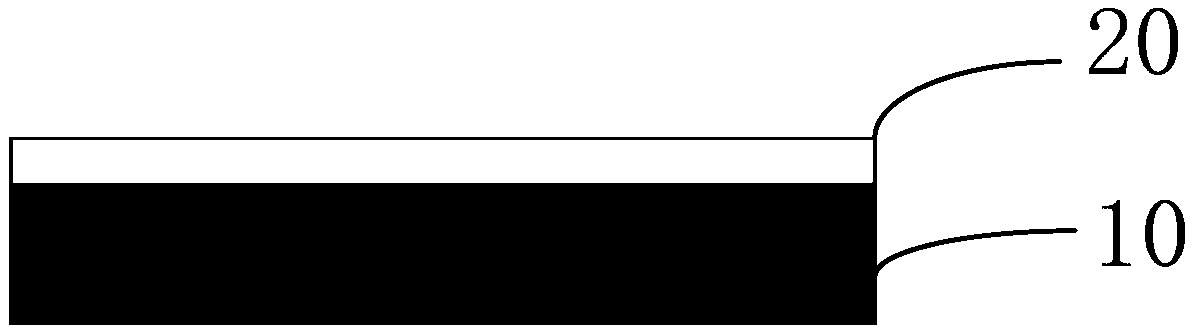

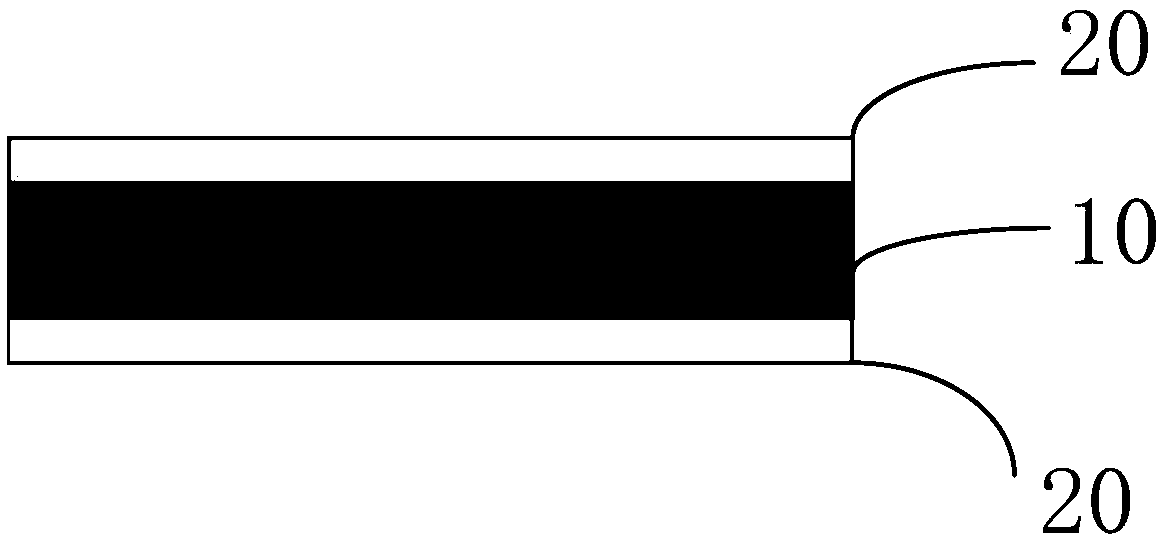

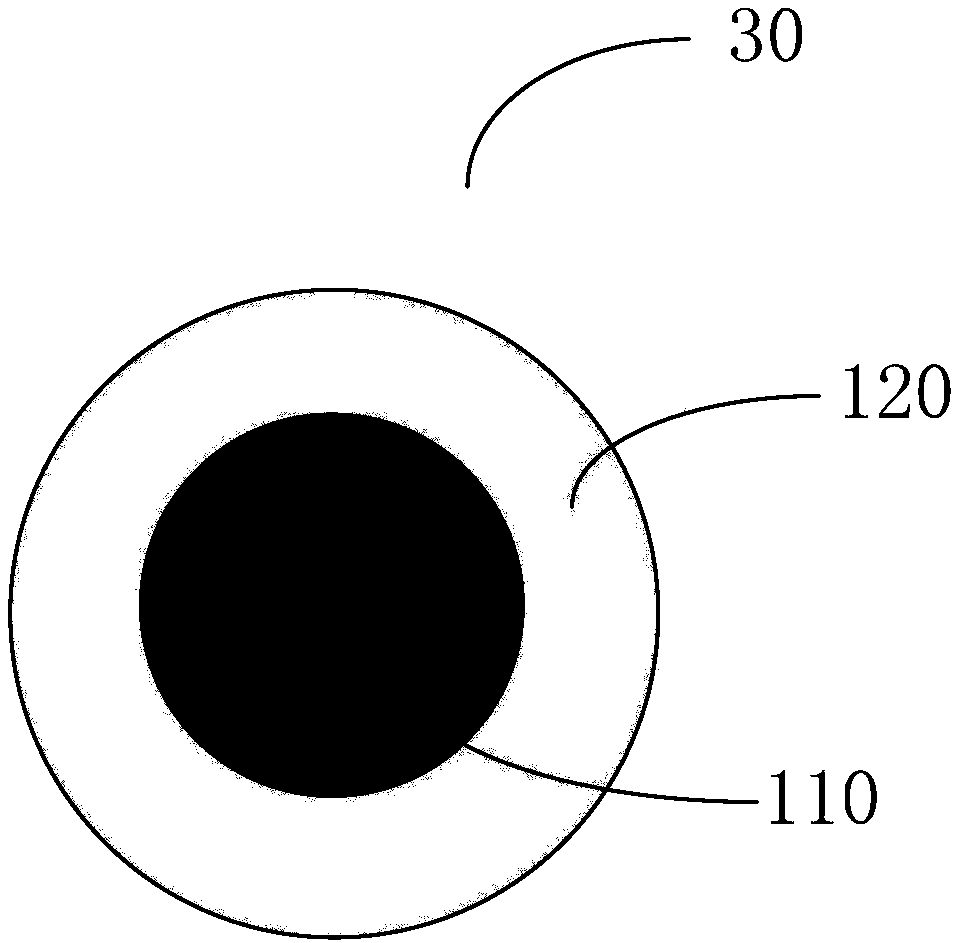

[0074] Correspondingly, an embodiment of the present invention also provides a method for preparing a conductive polymer alkali metal salt with heat-sensitive properties, comprising the following steps:

[0075] The polymer monomer is reacted at -40°C-100°C for 6-48 hours in the presence of anhydrous initiator and solvent, and the polymer monomer is polymerized to obtain a conductive polymer alkali metal with thermosensitive properties Salt, the polymer monomer includes a five-membered unsaturated heterocyclic structure and a substituted imine alkali metal salt on the five-membered unsaturated heterocyclic structure, the conductive polymer alkali metal salt includes a conductive polymer repeating unit and a substituted imine alkali metal salt grafted on the repeating unit of the conductive polymer, the conductive polymer repeating unit includes a five-membered unsaturated heterocyclic structure, and the substituted imine alkali metal salt includes a substituted imide base One ...

Embodiment 1

[0121] Using lithium poly(4-n-octyl substituted thiophene) (trifluoromethylsulfonyl)imide (as shown in formula (D)) to modify the current collector and apply it to lithium secondary batteries, the method is as follows:

[0122] (1) Preparation of poly(4-n-octyl substituted thiophene)(trifluoromethylsulfonyl)imide lithium (D), the synthetic route is shown in formula (6):

[0123] a) Add 0.5mol 3-bromo-4-n-octyl substituted thiophene, 1.1mol triethylamine and 500mL dichloromethane solvent to a 1000mL three-necked flask, slowly add 0.5mol trifluoromethylsulfonamide, stirred for 18 hours, filtered, and dried under reduced pressure to obtain (4-n-octyl substituted thiophene) (trifluoromethylsulfonyl)imide triethylamine salt;

[0124] b) Under the protection of argon, add 0.25mol (4-n-octyl substituted thiophene) (trifluoromethylsulfonyl)imide triethylamine salt and 250mL acetonitrile solvent to a 500mL three-necked flask respectively. Under conditions, add 0.5mol anhydrous lithium...

Embodiment 2

[0132] Using lithium poly(4-n-heptyl substituted furan)(hexafluoropropylsulfonyl)imide (as shown in formula (G)) to modify the current collector and apply it to lithium secondary batteries, the method is as follows:

[0133] (1) Preparation of poly(4-n-heptyl substituted furan)(hexafluoropropylsulfonyl)imide lithium (G), the synthetic route is shown in formula (7):

[0134] a) Add 0.5mol 3-bromo-4-n-heptyl substituted furan, 1.1mol triethylamine and 500mL dichloromethane solvent to a 1000mL three-necked flask, slowly add 0.5mol hexafluoropropylsulfonamide, stirred for 18 hours, filtered, and dried under reduced pressure to obtain (4-n-heptyl substituted furan) (hexafluoropropylsulfonyl)imide triethylamine salt;

[0135] b) Under the protection of argon, add 0.25mol (4-n-heptyl substituted furan) (hexafluoropropylsulfonyl)imide triethylamine salt and 250mL acetonitrile solvent to a 500mL three-necked flask respectively. Under the conditions, 0.5mol anhydrous lithium carbonate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com