Thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer and raw material technology, applied in the field of thermoplastic elastomer and its preparation, can solve the problems of thermoplastic elastomer VOC index reduction, liquid entrainer is difficult to mix, high viscosity, etc., to achieve a significant reduction in VOC index and increase the degree of firmness or consistency, efficiency-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A kind of preparation method of thermoplastic elastomer, is characterized in that, comprises the following steps:

[0042] S1: Preparation of stripping agent;

[0043] S2: Weigh 100-120 parts of SEBS, 80-100 parts of white oil, 50-60 parts of PP, 20-32 parts of filler, 26-35 parts of stripping agent according to their mass parts, and add SEBS and white oil to high Mix in the mixer for 30 minutes, then add PP and filler and mix for 20 minutes, then add stripping agent and mix for 5-6 minutes, and obtain the mixed raw material after the materials in the high mixer are mixed evenly;

[0044] S3: Put the mixed raw materials into the screw extruder, the vacuum degree in the screw extruder is 0.004MPa, add and melt and extrude to obtain the thermoplastic elastomer as the product.

[0045] The preparation method of stripping agent:

[0046] With ethanol and calcium acetate as the main raw materials,

[0047] Carry out vacuum heating and drying of calcium acetate, then weigh...

Embodiment 1

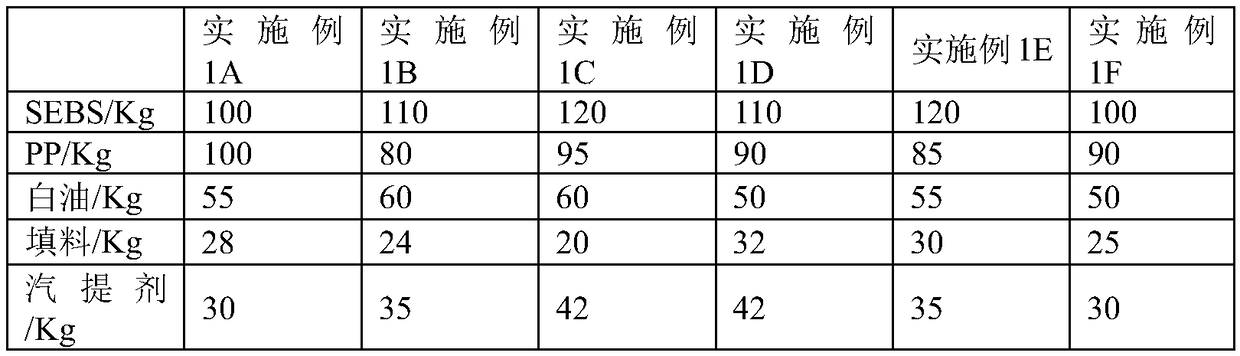

[0053] According to the above-mentioned preparation method, the preparation of thermoplastic elastomer is carried out, and embodiment 1A-1F is obtained, wherein embodiment 1A-1C selects the stripping agent with ethanol and calcium acetate as main raw materials for use, and embodiment 1D-1F selects ethanol and stearin for use Sodium acid is the stripping agent of the main raw material, and the specific raw material dosage parameters are as follows.

[0054]

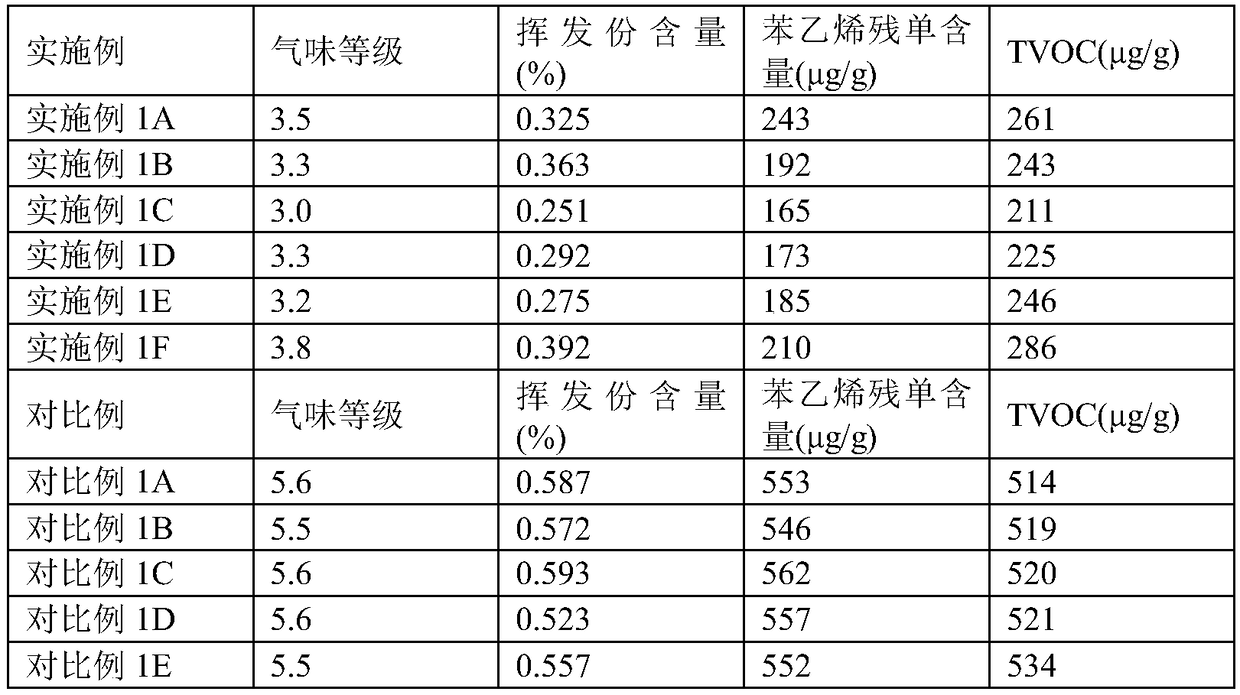

[0055] Simultaneously according to the proportioning of SEBS, white oil, PP and filler of embodiment 1A-1F, adopt the Chinese patent of authorized announcement number CN104530628B a kind of TPE material and preparation method that can be used for automobile interior decoration, disclose to carry vacuum zone by liquid entrainer The method in which the organic volatiles released by the elastomer material in the molten state in the first third zone are discharged together to reduce the volatilized VOC index of the extruded ...

Embodiment 2

[0071]

[0072] And tested, the test results are as follows.

[0073]

[0074] It can be seen from the above that the TVOC and volatile content of Examples 2A-2C added with DOPO are lower than those of Examples 1A-1C.

[0075] Example 1A

[0076] Thus, the flame retardancy of Examples 2A-2C added with DOPO is improved compared with that of Examples 1A-1C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com