Concentrating crystallization process for tryptophan or glyphosate by using mechanical vapor recompression technology

A mechanical steam, concentration and crystallization technology, applied in the chemical industry, organic chemistry, sustainable manufacturing/processing, etc., can solve the problems of increasing equipment investment, waste of secondary steam latent heat, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

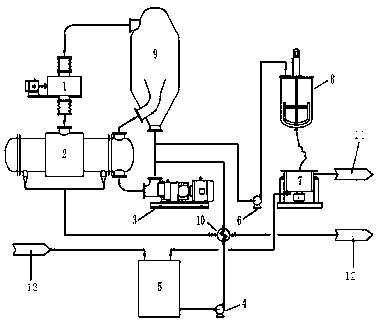

[0007] The tryptophan or glyphosate concentration and crystallization process of mechanical vapor recompression technology is characterized in that: the secondary steam separated in the crystallizer 9 is compressed by the steam compressor 1 to increase the temperature and pressure, and then it is introduced into the heater 2 as heating steam Latent heat is released to heat and concentrate tryptophan or glyphosate 13, and the secondary steam is condensed into condensed water and then discharged; after tryptophan or glyphosate 13 is mixed with the centrifuged mother liquor in the tank 5 and centrifuged by the centrifuge 7, it passes through the pump 4 The circulating fluid with the same chemical elements and different proportions is input into the heater 2 by the circulating pump 3 after being mixed. After absorbing heat in the heater 2, it enters the crystallizer 9 for boiling and evaporation, and the secondary steam enters the vapor compression after being separated. machine 1;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com