Thermosensitive liposome as well as preparation method and application thereof

A heat-sensitive liposome and liposome preparation technology, applied in the field of liposome embedding, can solve problems that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

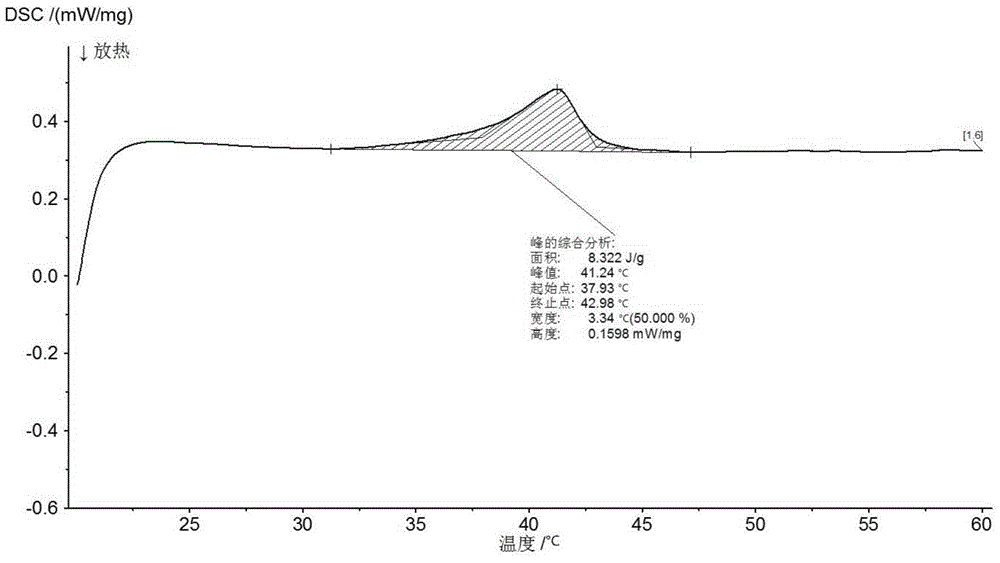

[0033] Thermosensitive liposomes embedded with β-ionone (phosphatidylcholine and hydrogenated lecithin molar ratio 4:1)

[0034] Materials and dosage:

[0035] Composite phospholipid material 200mg; long circulation material 30mg; Tween80 100mg; β-ionone 25mg.

[0036] Preparation:

[0037] Weigh various materials according to the above dosage into a round bottom flask (250ml), add absolute ethanol in a water bath at 50°C until dissolved, remove the ethanol by rotary evaporation under reduced pressure, and form a thin film. PBS buffer solution was added, hydrated by rotary evaporation (50°C), cooled rapidly, and ultrasonically treated in an ice bath at 360W on a probe-type ultrasonic instrument for 4 minutes. After dissolving in water at 50°C for 2 hours, let it stand overnight at 4°C, remove titanium particles by refrigerated centrifugation, and fill with N 2 After sealing, the thermosensitive liposome embedding β-ionone is obtained. After adding the protective agent, the...

Embodiment 2

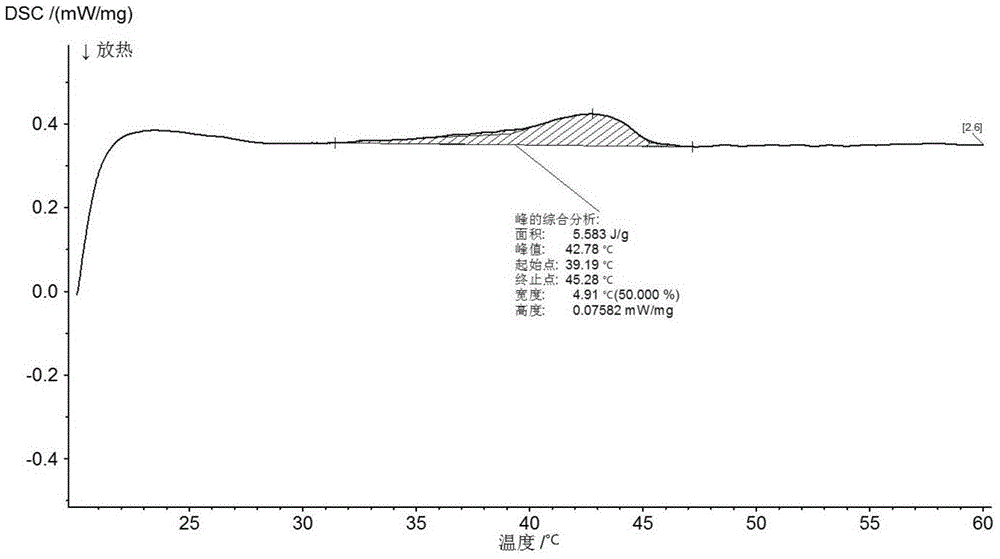

[0040] Thermosensitive liposomes embedded with β-ionone (molar ratio of phosphatidylcholine to hydrogenated lecithin is 3:2)

[0041] Take 200mg of composite phospholipid material; 100mg of Tween80; 30mg of long-circulation material and 50mg of β-ionone. The preparation process of liposome is identical with example 1.

[0042] The obtained liposome has a particle diameter of about 170 nm and an encapsulation efficiency of about 35% as measured by a nanometer particle size distribution analyzer. DSC measurement results show that its phase transition temperature is around 43°C. The liposome can keep stable for at least 1 month at 25°C, and the dried powder liposome can keep stable for at least 3 months at 25°C. Experiments show that at 37°C, β-ionone is released less, and from 42°C, it is released rapidly.

Embodiment 3

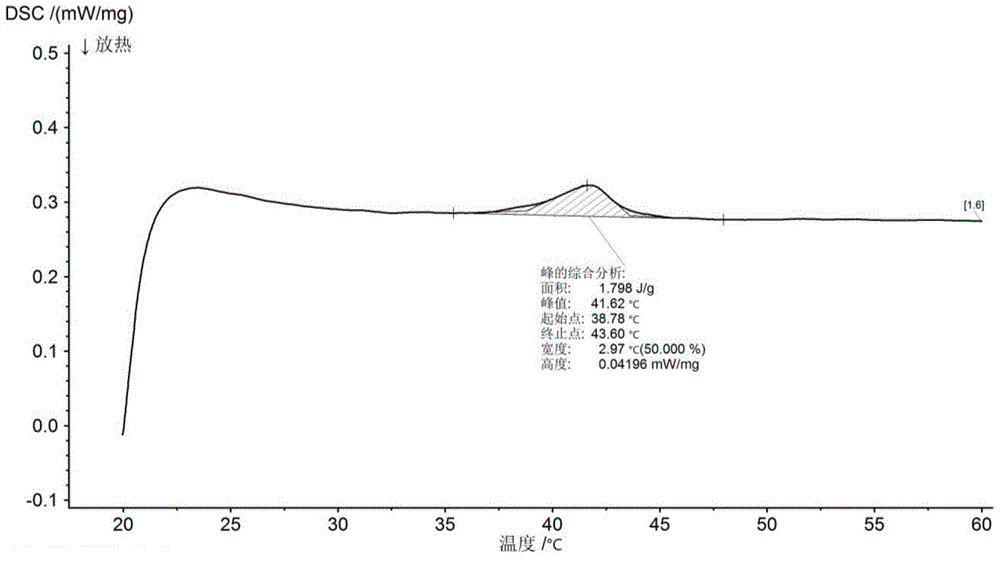

[0044] Thermosensitive Liposomes Encapsulating Rose Essential Oil

[0045] Take 200mg of compound phospholipid material; 100mg of Tween80; 30mg of long circulation material and 25mg of rose essential oil. The preparation process of liposome is identical with example 1.

[0046] The obtained liposome has a particle diameter of about 200 nm and an encapsulation efficiency of about 45% as measured by a nanometer particle size distribution analyzer. The phase transition temperature shown by the DSC spectrum is around 41°C. Stability results showed that the temperature-sensitive liposome remained stable at 25°C for at least 1 month, and remained stable at 25°C for at least 3 months after powdering. Experiments have shown that rose essential oil releases less at 37°C, and it releases rapidly from 42°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com