Microwave spraying vacuum drying machine

A vacuum dryer and microwave technology, applied in the direction of dryers, drying solid materials, drying chambers/containers, etc., can solve the problems of increased equipment cost, complicated equipment structure, energy waste, etc., to prevent overheating of finished products, avoid Effect of overheating burnout and improvement of energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

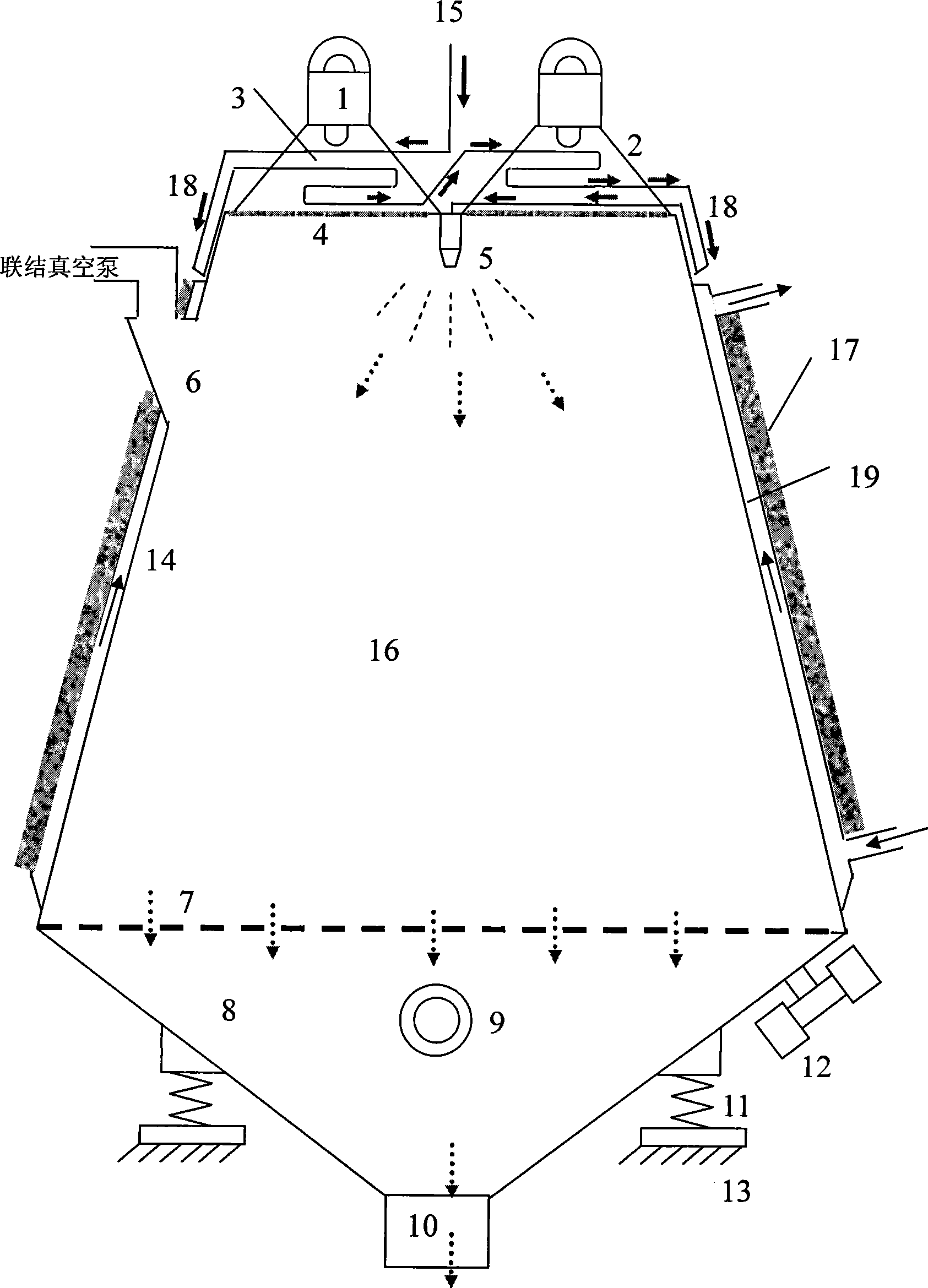

[0022] Embodiment 1: as figure 1 The microwave spray vacuum dryer shown includes a drying chamber 16 and a material inlet 15. The top of the drying chamber 16 is provided with a microwave feeding device and a material atomization device 5. The lower part of the drying chamber 16 is provided with a dry finished product chamber 8. The drying chamber 16 A wire mesh screen 7 is arranged between the dry product warehouse 8, a vacuum pump joint 6 is provided on the side wall of the drying warehouse 16, and a cloth bag filter is provided at the vacuum pump joint 6. The bottom of the microwave spray vacuum dryer is connected to the base 13 through a spring support mechanism 11, and a vibrating mechanism 12 is provided on the outer wall 14 of the finished product bin 8. According to actual operation requirements, the vibrating mechanism 12 can be operated automatically or manually. Intermittent action, the vibration mechanism 12 can effectively prevent the material from depositing and ...

Embodiment 2

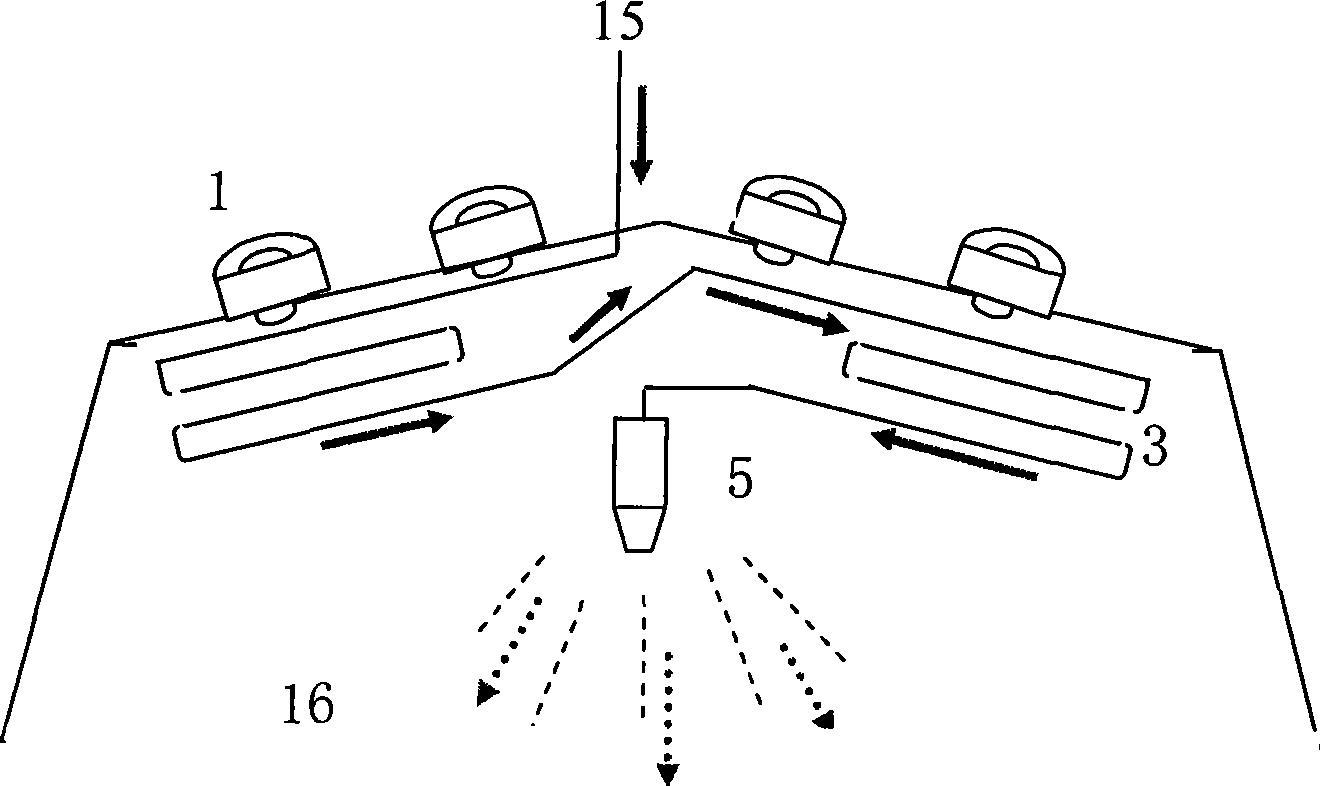

[0030] Embodiment 2: as figure 2 The shown microwave spray vacuum dryer includes a drying bin 16 and a material inlet 15. The top of the drying bin 16 is provided with a microwave feeding device and a material atomization device 5. The microwave feeding device is directly and evenly arranged on the top of the drying bin 16. There are a plurality of magnetrons 1, and a material preheating coil 3 connected between the material inlet 15 and the material atomization device 5 is provided on the lower side of the magnetron 1. The airtight radiation window is directly integrated with the microwave feeding port of the magnetron, and can be made of materials such as polytetrafluoroethylene and other materials with low microwave absorption rate.

[0031] Others are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com