Self-adaptive control supercritical hydrothermal combustion type multi-element thermal fluid generating system

A multi-element thermal fluid and self-adaptive control technology, applied in water heaters, combustion methods, production fluids, etc., can solve the problems of reducing oil production capacity of oil wells, gas blow-by, etc., to prevent wall surface from overheating and burning, avoid wall surface damage, reduce Effect of small ignition delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

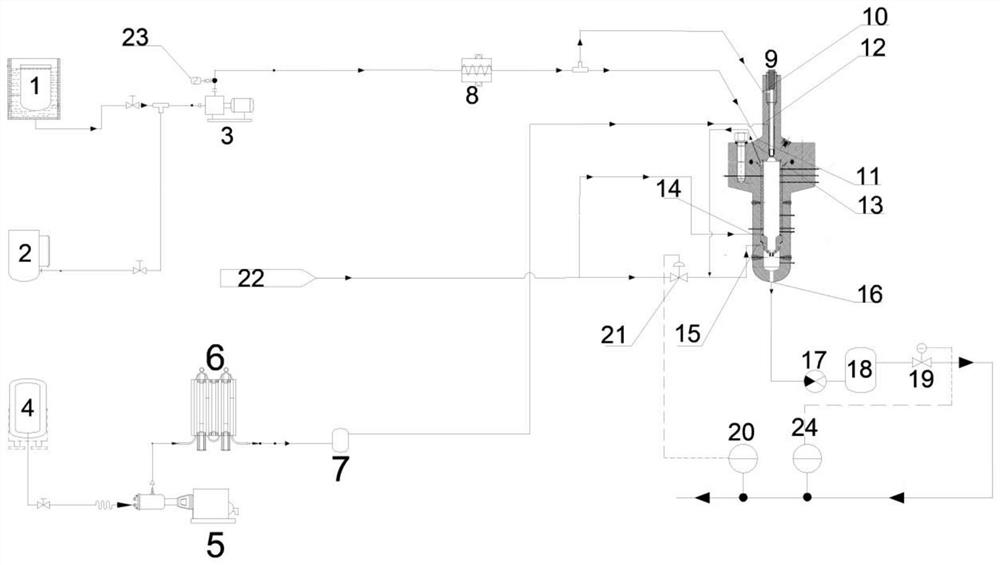

[0028] Such as figure 1 As shown, an adaptively regulated supercritical hydrothermal combustion type multi-element thermal fluid generation system mainly includes a reactor 9, a material pretreatment module, an oxidant supply module, a temperature and pressure regulation module, and a cooling module. The multi-element thermal fluid is generated by supercritical hydrothermal combustion technology, and the temperature-regulating and pressure-regulating module maintains a stable pressure in the supercritical hydrothermal combustion reactor, and obtains the multi-element thermal fluid of the required temperature and pressure, which meets the production process requirements of heavy oil recovery. During the operation of the system, the hydrothermal flame provides the energy required to generate the multivariate thermal fluid, the cooling module prote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com