Manufacturing method for diffusion plate used for high-reliability liquid crystal display

A technology of liquid crystal display and reliability, which is applied in the direction of nonlinear optics, diffusion elements, instruments, etc., can solve the problems affecting the optical characteristics of the diffusion film, easy deformation, etc., and achieve a wide temperature range, strong resistance to heat and humidity, and reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

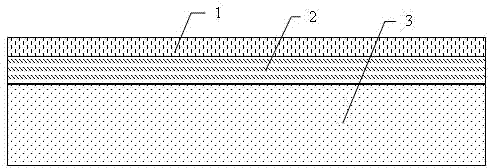

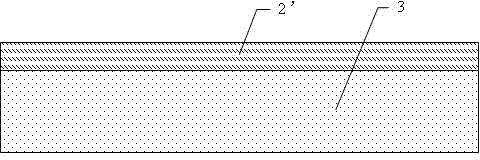

[0020] Such as Figure 1-2 shown.

[0021] A preparation method for a high-reliability liquid crystal display diffuser plate, which comprises the following steps:

[0022] First, use flat glass as the substrate; the flat glass should be glass commonly used in the display industry;

[0023] Secondly, evenly apply glue on the glass substrate according to a certain graphic design ("I" type, double "Y" or fish bone type, etc.); the glue can be one-component silica gel, epoxy glue or UV glue. One, several combinations of multi-component glue can also be used. There is no special requirement for the proportion of each component when there are multiple components. It is best to remove the air bubbles in the glue by vacuum, centrifugation or a combination of the two before use.

[0024] Third, stick the diffusion film on the glue, and apply press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com