Organic/inorganic composite microspheres with core-shell structures and preparation method and application thereof

A technology of inorganic composite microspheres and core-shell structure, which is applied in the preparation of microspheres, the treatment of dyed organosilicon compounds, and the treatment of dyed low-molecular-weight organic compounds, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

[0059] The organic / inorganic composite microspheres with core-shell structure with silica gel as the inner core were prepared, and the amount of polymer added was changed.

Embodiment 1

[0061] Take 2 g of the dehydrated membrane material, add 50 ml of toluene at ambient temperature, stir until completely dissolved, and prepare a polystyrene-acrylic acid (PSA) solution with a concentration of 0.04 g / ml, which is stored under a sealed nitrogen atmosphere for use.

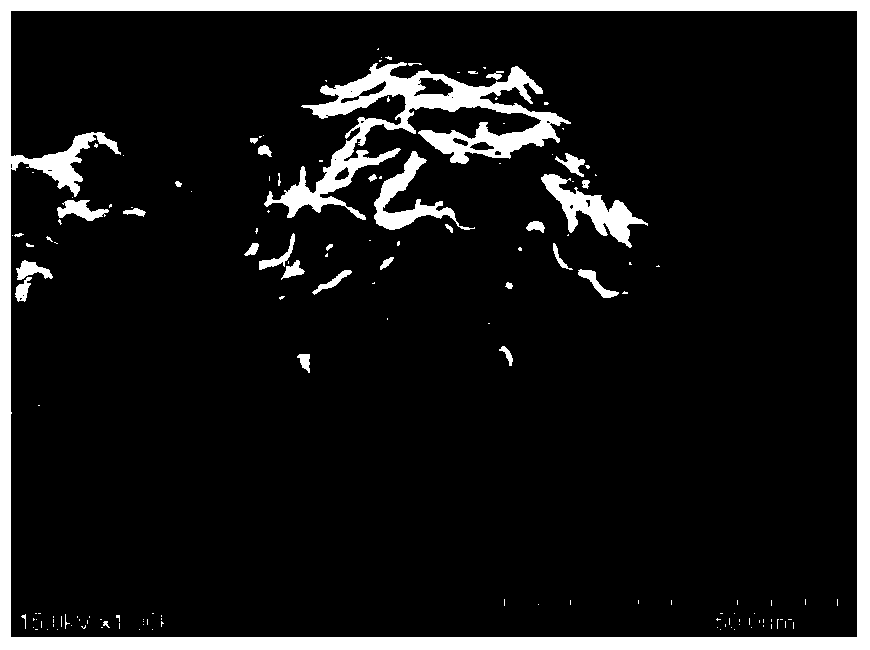

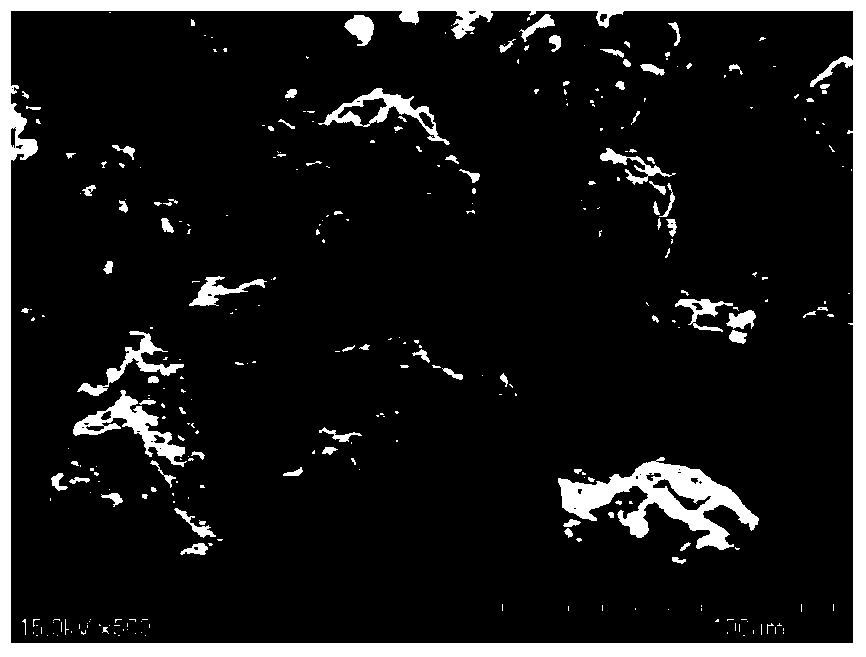

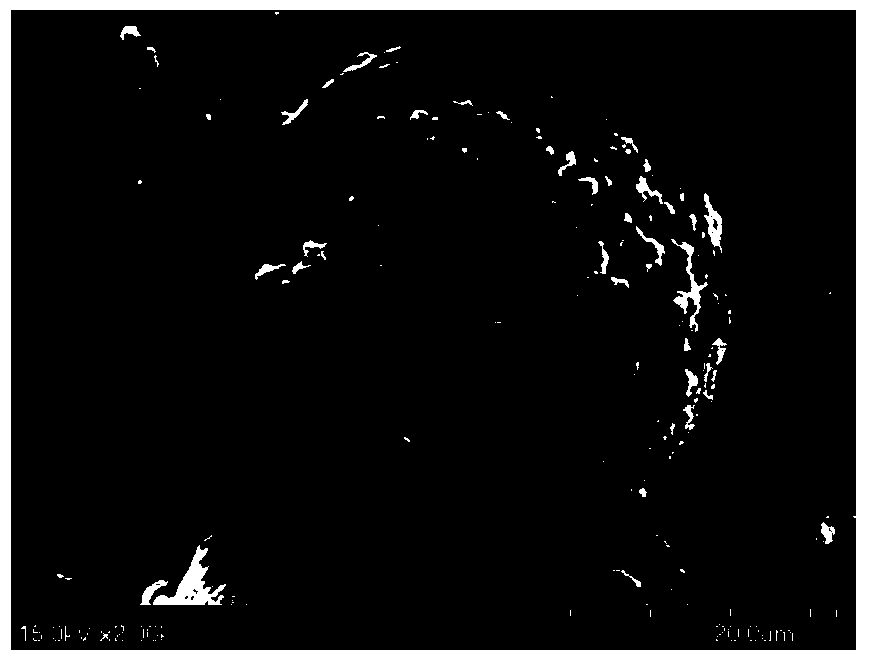

[0062] Set the temperature of the water bath at 60°C, put 2g of silica gel into a three-necked flask, add 10ml of PSA toluene solution, and 0.1ml of n-dodecyltrimethoxysilane (N3112), and stir for 1 hour. Then, 100 ml of non-solvent (n-hexane) was slowly added dropwise (at a speed of 1 ml / min) into the three-necked flask using a dropping funnel, and the polymer was slowly coated on the surface of the silica gel. Until the n-hexane was completely titrated, the stirring was stopped, then washed with n-hexane for 3 times, vacuum-dried to obtain organic shell / inorganic core composite particles, and 2.35 g of composite particles were obtained by weighing. The SEM images of the prepared composite particles...

Embodiment 2

[0064] Composite particles were prepared using the same method as in Example 1, except that the amount of the PSA toluene solution was changed to 5 ml. The properties of the composite particles tested according to the above test methods are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com