Multi-element perovskite material, as well as preparation and application thereof

A perovskite material and perovskite technology, applied in the growth of polycrystalline materials, electrical components, crystal growth, etc., can solve the problems of large environmental pollution, high permeability, and poor regulation, and achieve a large application area, The effect of pollution reduction, large regulation and selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

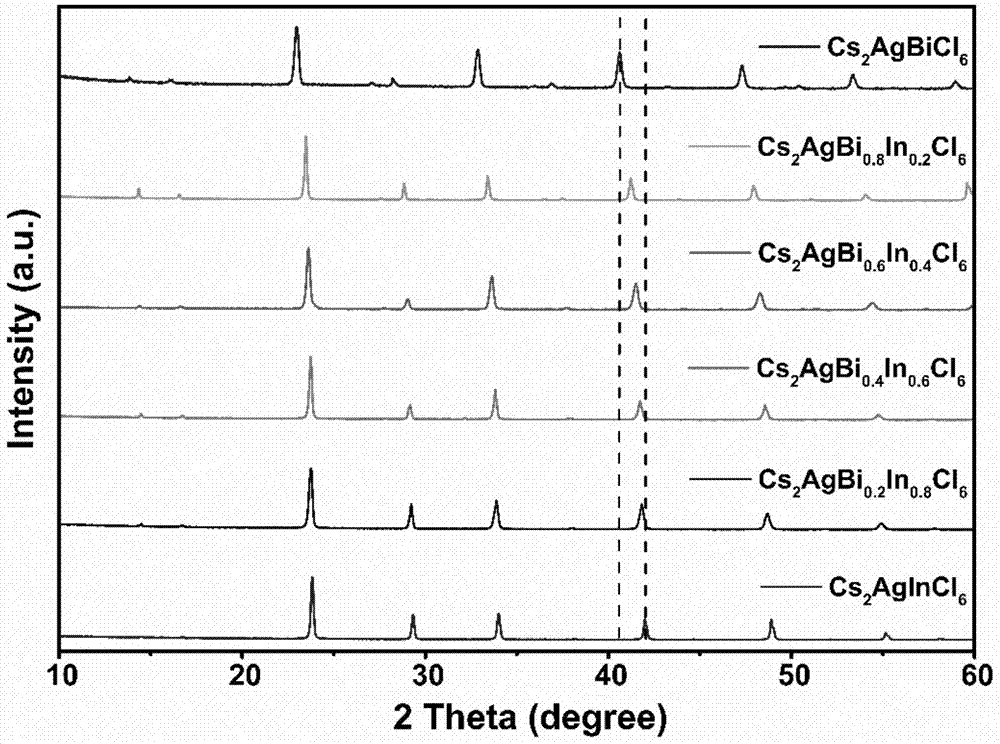

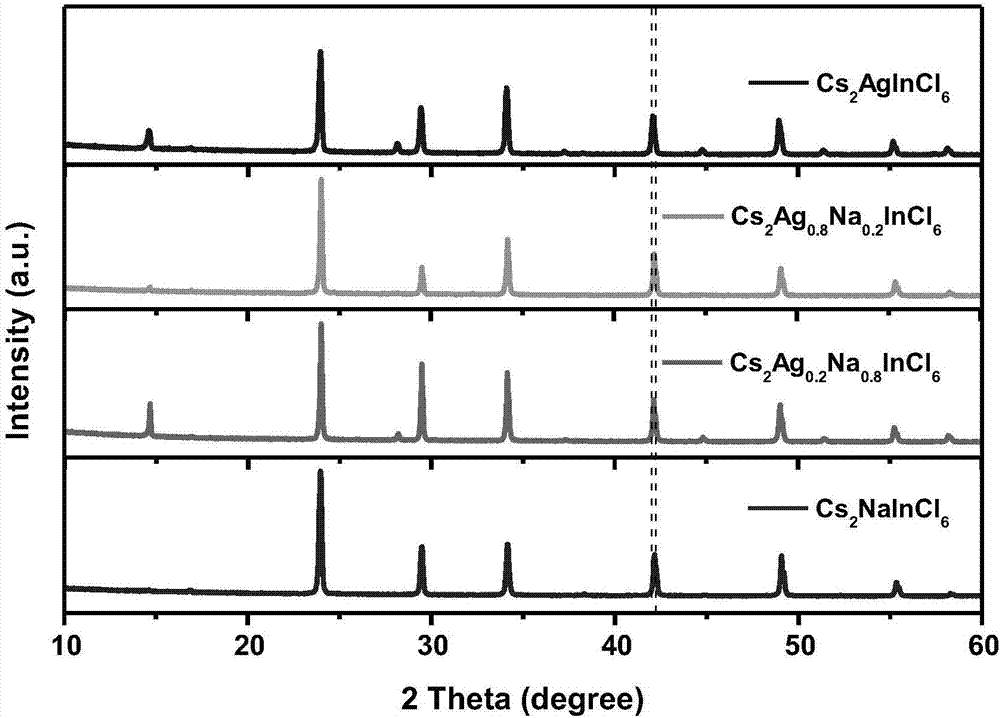

[0028] The above-mentioned multi-inorganic metal non-lead halide perovskite material with continuously adjustable components can be single crystal and can be used in photodetectors. The corresponding preparation method can be inorganic metal halide AX (A: Cs + ;X:Cl - ), B 1 X, B 2 X, B 3 X 3 , B 4 X 3 (B 1 , B 2 :Na + , Ag + ; B 3 , B 4 :In 3+ ,Bi 3+ ;X:Cl - ), and an inorganic solvent hydrochloric acid, for example, it can include the following steps:

[0029] (1) B can be weighed at room temperature (such as 10℃~30℃) according to the ratio of x:(1-x) 1 X and B 2 X, weigh B according to the ratio of the amount of matter in y:(1-y) 3 X 3 And B 4 X 3 And makes the B 1 X and the B 2 The sum of the amount of the two substances in X is equal to the B 3 X 3 And the B 4 X 3 The sum of the amount of the two substances; then weighed with B 1 X,B 2 X,B 3 X 3 , B 4 X 3 The amount of the substance and the same amount of AX, and mix well.

[0030] (2) Put the mixed powder in the polytetrafluoro...

Embodiment 1

[0034] In the preparation method of the perovskite single crystal in this embodiment, the specific preparation steps are as follows:

[0035] a) Clean the PTFE liner with deionized water for 10 minutes, clean the PTFE liner with acetone for 10 minutes, clean the PTFE liner with isopropanol for 10 minutes, and clean the PTFE liner with deionized water 10min, then blow dry with a nitrogen gun.

[0036] b) Weigh 0.3366g CsCl, 0.1433g AgCl, 0.0442g InCl 3 ,0.2523g BiCl 3 , Mix and place in the cleaned polytetrafluoroethylene liner, add 15ml of hydrochloric acid (the mass percentage concentration of hydrochloric acid can be 30%), and assemble the hydrothermal kettle.

[0037] c) Place the hydrothermal kettle in a muffle furnace, set the temperature of the muffle furnace to 30°C, raise it to 180°C for 2h, keep it for 10h, and then slowly decrease to room temperature at a rate of 1°C / h.

[0038] d) Take out the hydrothermal kettle in the muffle furnace, pour out the hydrochloric acid in the ...

Embodiment 2

[0040] In the preparation method of the perovskite single crystal in this embodiment, the specific preparation steps are as follows:

[0041] a) Clean the PTFE liner with deionized water for 10 minutes, clean the PTFE liner with acetone for 10 minutes, clean the PTFE liner with isopropanol for 10 minutes, and clean the PTFE liner with deionized water 10min, then blow dry with a nitrogen gun.

[0042] b) Weigh 0.3366g CsCl, 0.1433g AgCl, 0.0884g InCl 3 ,0.1892g BiCl 3 , Mix and place it in the cleaned polytetrafluoroethylene liner, add 15ml of hydrochloric acid (the concentration of hydrochloric acid can be 38% by mass), and assemble the hydrothermal kettle.

[0043] c) Put the hydrothermal kettle in the muffle furnace, and set the temperature of the muffle furnace to 30°C and raise it to 160°C for 2h, keep it for 10h, and then slowly decrease to room temperature at a rate of 1°C / h.

[0044] d) Take out the hydrothermal kettle in the muffle furnace, pour out the hydrochloric acid in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com