Reinforced tubular porous body compound film, method of preparing the same and use thereof

A porous body and composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as difficulty in improving membrane water permeability, clogging of internal channels of braids, and membrane defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

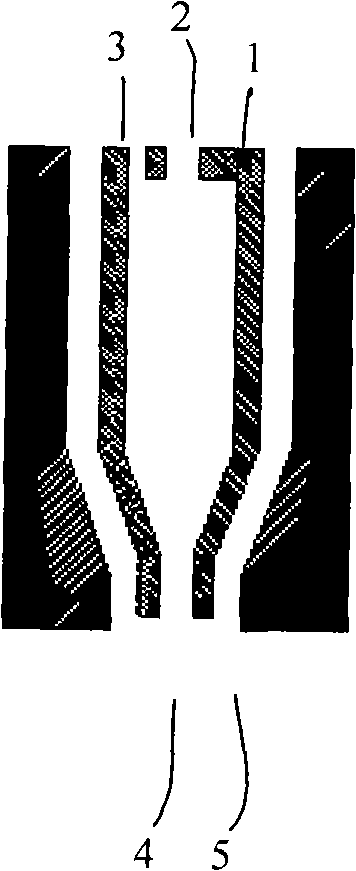

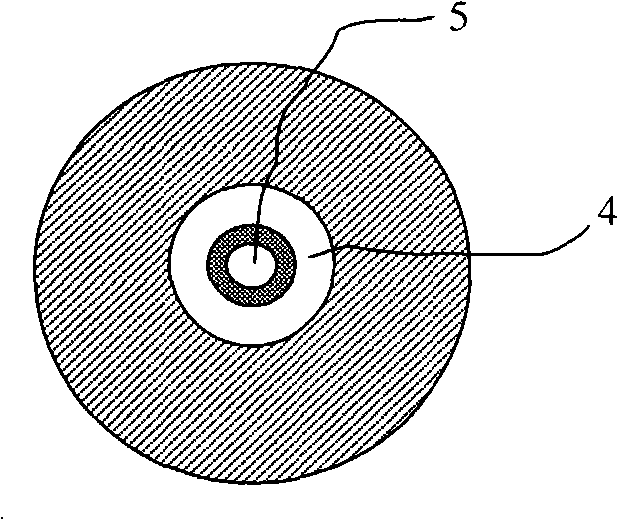

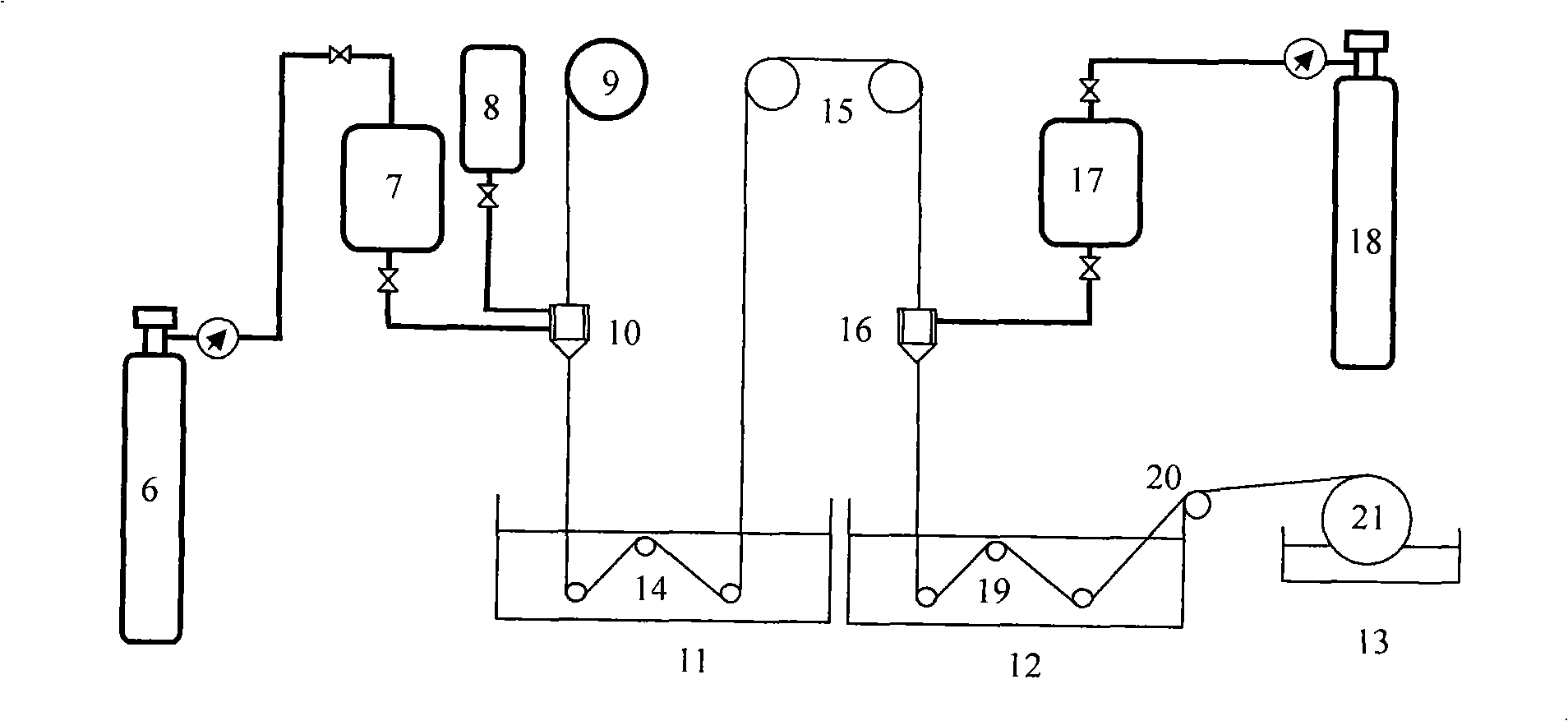

[0061] The hollow braid is woven from 110 polyester monofilaments of 130 decitex, with an inner diameter of 1.0 mm and an outer diameter of 2.2 mm.

[0062] The composition of polymer material membrane liquid I is as follows: 14% by weight of polyvinylidene fluoride, 8% by weight of polyvinylpyrrolidone, 6% by weight of polyethylene glycol, 0.5% by weight of lithium chloride, 1% by weight of Tween, 0.5% by weight of water , 70% by weight of N, N-dimethylacetamide.

[0063] The composition of polymer material film liquid II is as follows: 18% by weight of polyvinylidene fluoride, 9% by weight of polyvinylpyrrolidone, 8% by weight of polyethylene glycol, 1% by weight of lithium chloride, 2% by weight of Tween, 0.5% by weight of water , 61.5% by weight of N,N-dimethylacetamide.

[0064] The composition of the core liquid is: 10% by weight of polyvinylpyrrolidone, and 90% by weight of N,N-dimethylacetamide.

[0065] The composition of the coagulation bath was: 20% by weight of d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com