Method for mounting prestressed T-shaped girder at sea by non-rotating synchronous hoisting of double cranes

A non-rotating, pre-stressed technology, used in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of high crane leasing costs, affecting construction efficiency, and lack of crane resources, so as to reduce construction safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

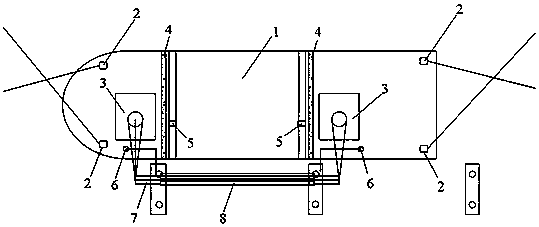

[0027] A method for installing prestressed T-beams at sea with non-rotating synchronous double lifting cranes, taking Shenhua Guohua Indonesia Java No. 7 2×1050MW coal-fired power generation project supporting wharf and approach bridge project for water intake and drainage facilities as an example, including steps:

[0028] (1) Renovation of square barge

[0029] ① Fix two crawler cranes

[0030] The reinforcement positions of the two crawler cranes 3 should meet the requirements of the lifting distance during the loading and installation of the T-beam;

[0031] In order to strengthen the rigidity of the deck, a thick steel plate is laid at the installation position of the crawler crane 3, and the steel plate is welded with the deck around the joints; in order to prevent the crawler crane from shifting during operation and causing safety hazards, the crawler crane 3 is fixed by section steel. In addition, gears are set at the front and back of the two crawlers, and the sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com