Fully-automatic truck loading method

A fully automatic, car loader technology, applied in transportation and packaging, loading/unloading, etc., can solve the problems of heavy management burden, increased sample barrel breakage rate, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

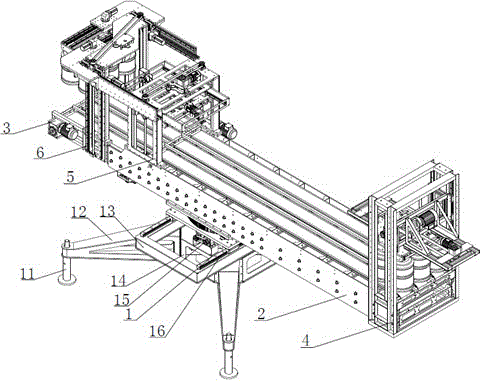

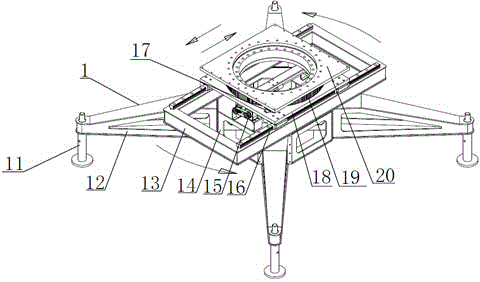

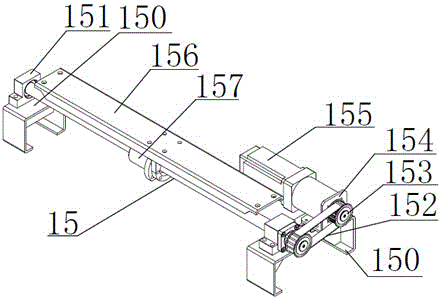

[0052] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

[0053] A fully automatic loading method, comprising the steps of:

[0054] (1) Start fully automatic loading;

[0055](2) After starting the automatic loading, when the photoelectric detection informs that the finished product (bottled water) is in place, the robotic arm descends to grab the bottled water, and after lifting to a safe height, it performs left-right translation and dislocation positioning, and then moves forward at the same time to reach Preset the position, then descend to a safe height and place the bottled water in the first row of the first floor inside the compartment;

[0056] (3) The robotic arm returns to the origin again and waits to grab the next finished product (bottled water) that will be delivered to the designated position. Using similar working steps, the bottled water is placed in the second row on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com