Patents

Literature

68results about How to "Accurate polishing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polishing pad, process for producing the same and method of polishing therewith

InactiveUS20060199473A1Reduced polishing speedIncrease the number ofAbrasion apparatusSemiconductor/solid-state device manufacturingFiberDevice material

Provided is a polishing pad comprising a fiber including organic fiber and a matrix resin holding the fiber, wherein at least the organic fiber is exposed on the work material-side surface thereof at least after dressing. The polishing pad suppresses generation of minute polishing scratches on the work material and allows flat polishing at low load. It in also possible to manage the polishing end point of the work material without generation of polishing scratch with its optical detection system monitoring the polishing state of work material. Thus, for example, it is possible to polish substrates under a small load on the interlayer insulating film and give products superior in flatness in semiconductor device manufacturing processes and thus, the polishing pad according to the invention may be used easily in the next-generation dual damascene method.

Owner:HITACHI CHEM CO LTD

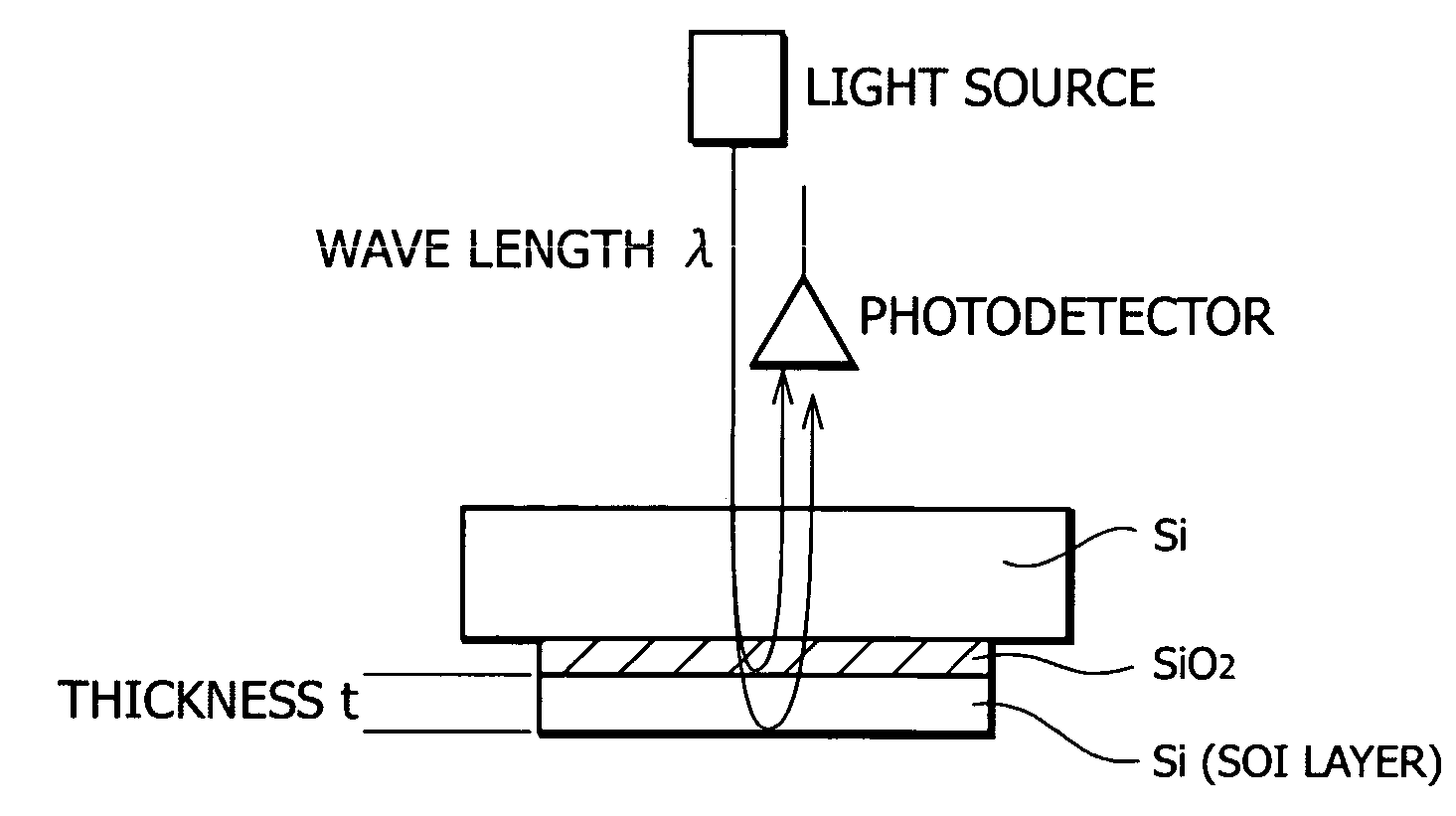

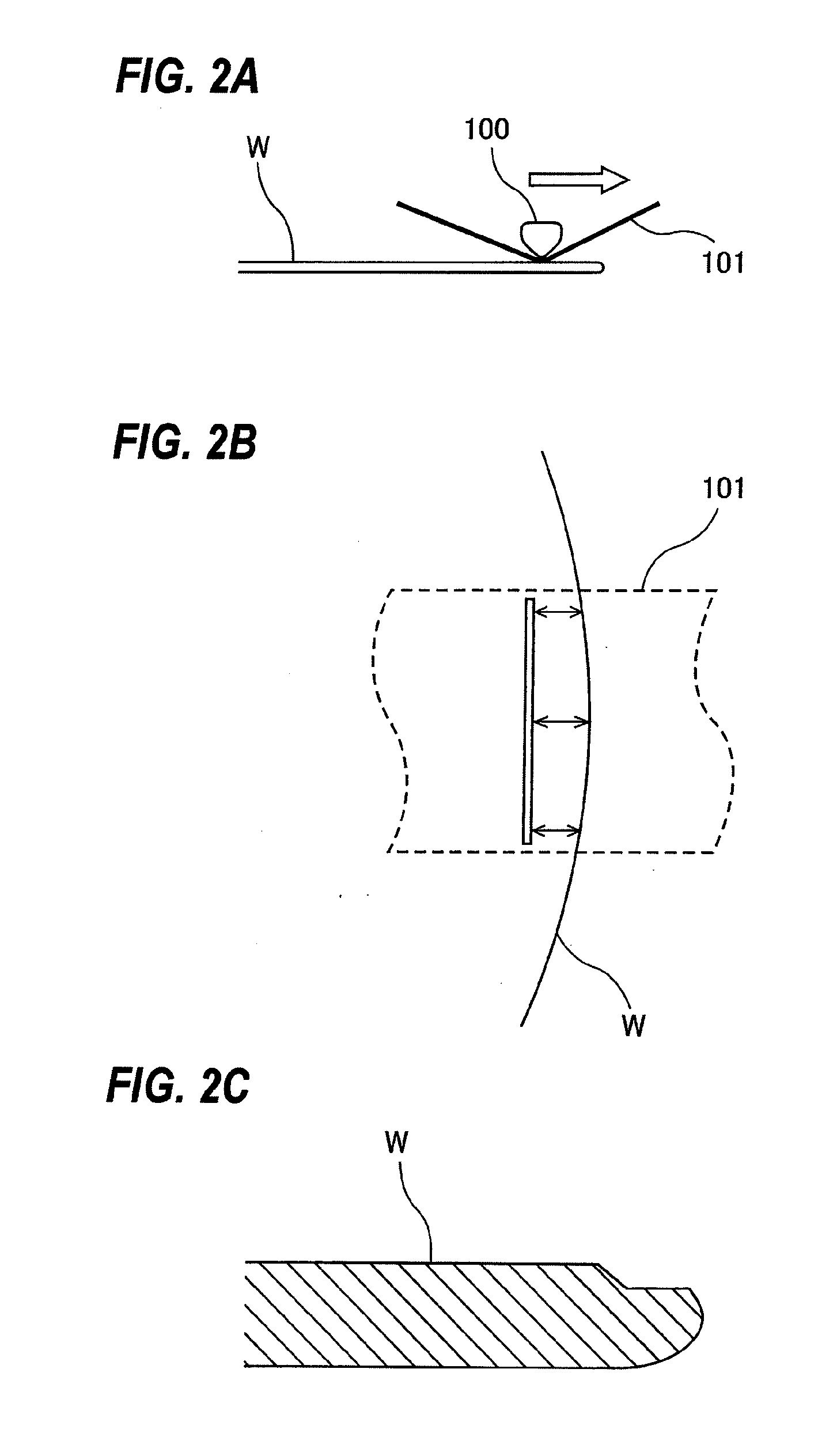

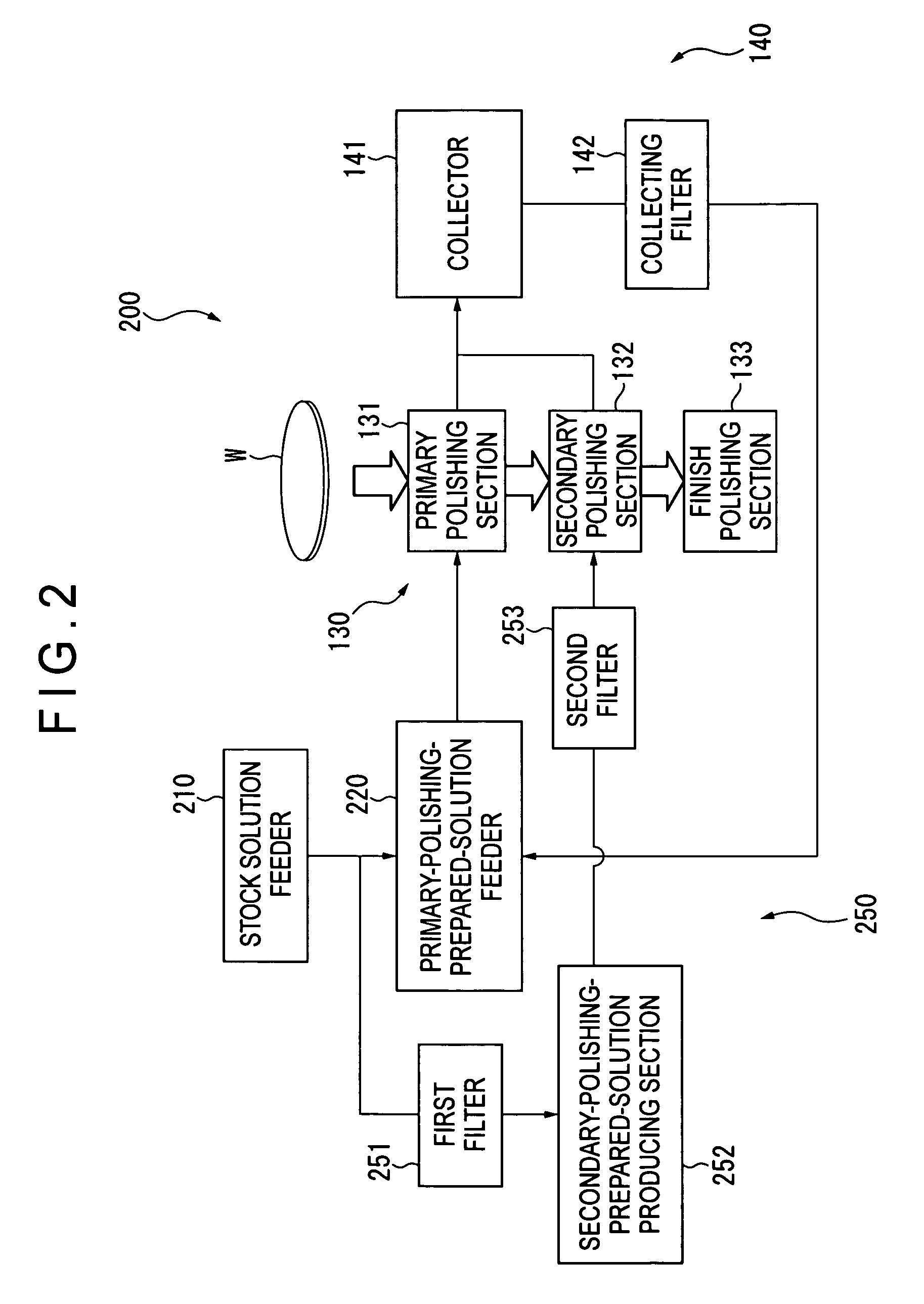

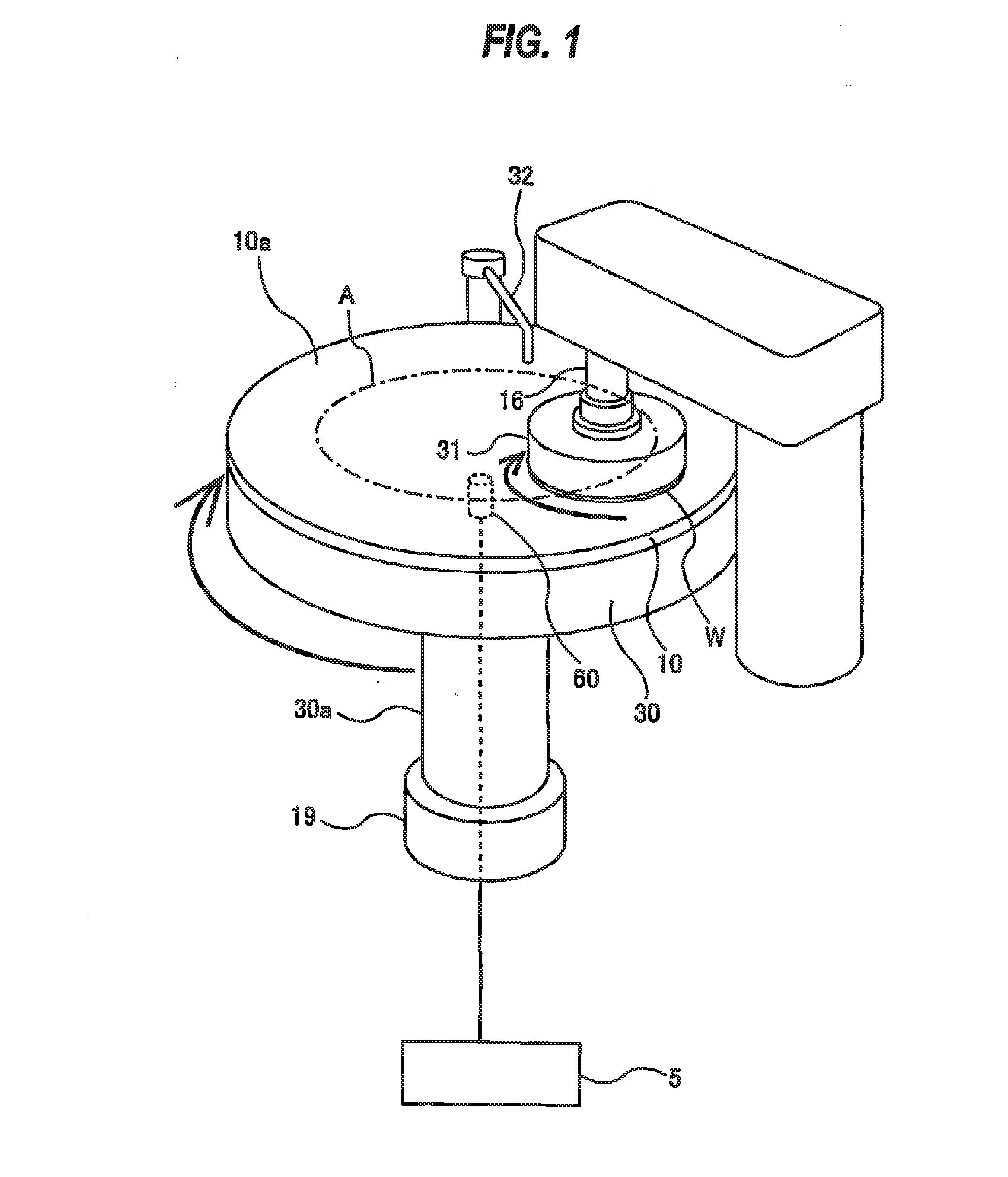

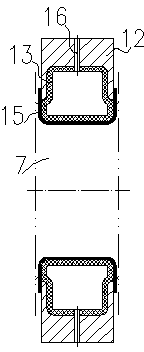

Method for measuring thickness of thin film-like material during surface polishing, and surface polishing method and surface polishing apparatus

ActiveUS7193724B2Easy to insertEasily pulled outSemiconductor/solid-state device manufacturingLapping machinesReflection spectroscopyWave shape

A thickness of a wafer during polishing operation is detected to accurately perform the polishing. A thickness measuring method, which measures the thickness of the wafer of wafer 7 in polishing a surface, comprises the steps of irradiating the thin film-like material during the surface polishing from a backside with probe light, measuring a reflectance spectrum with a dispersion type multi-channel spectroscope using a photodiode array which has particularly high sensitivity to light having a wavelength ranging from 1 to 2.4 μm, and calculating the thickness on the basis of a wave form of the reflectance spectrum. The surface polishing is performed while the thickness of the wafer 7 is measured by the above-described thickness measuring method, and the polishing is finished when the thickness of the wafer 7 reaches a target thickness.

Owner:SUMITOMO MITSUBISHI SILICON CORP

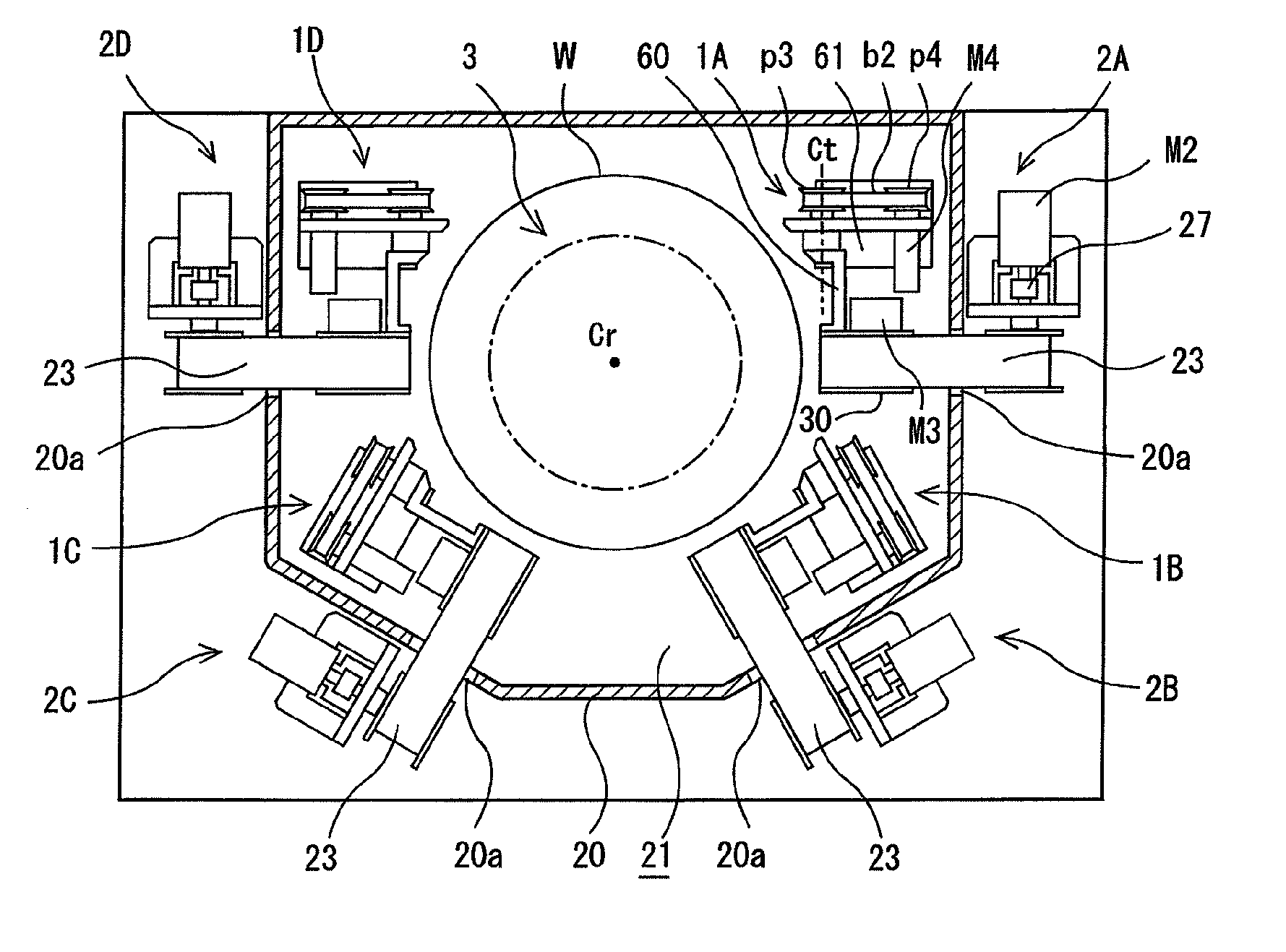

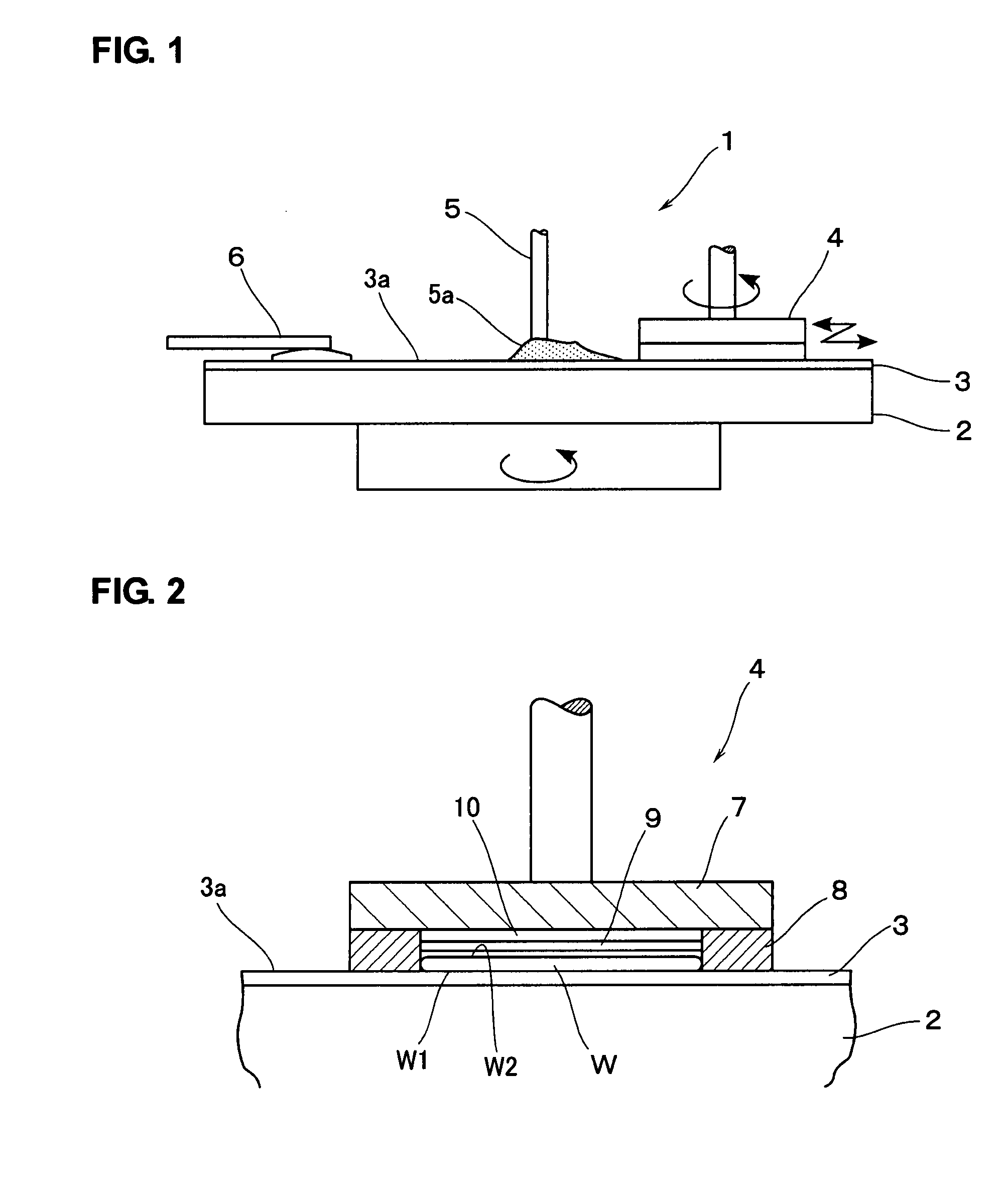

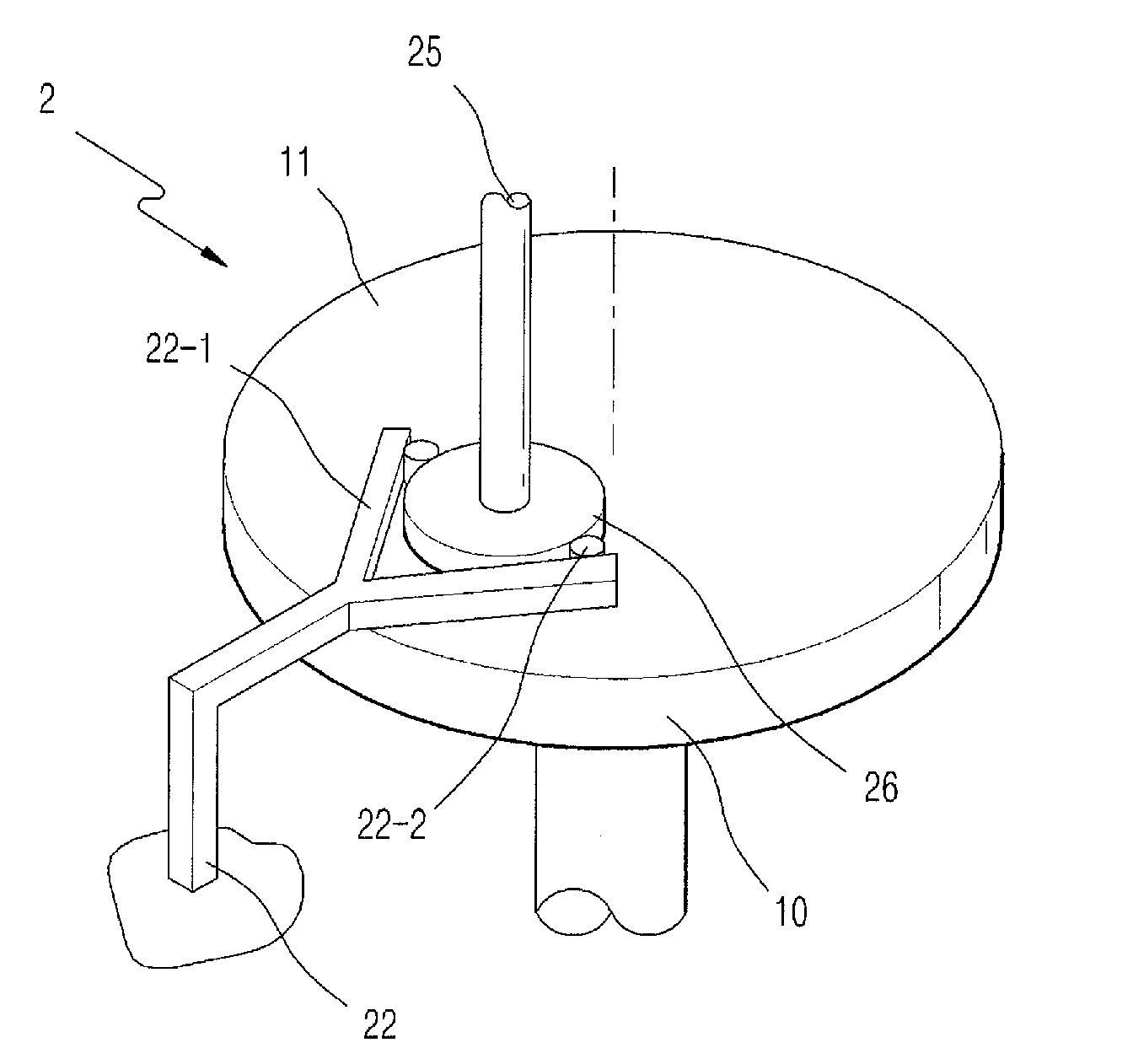

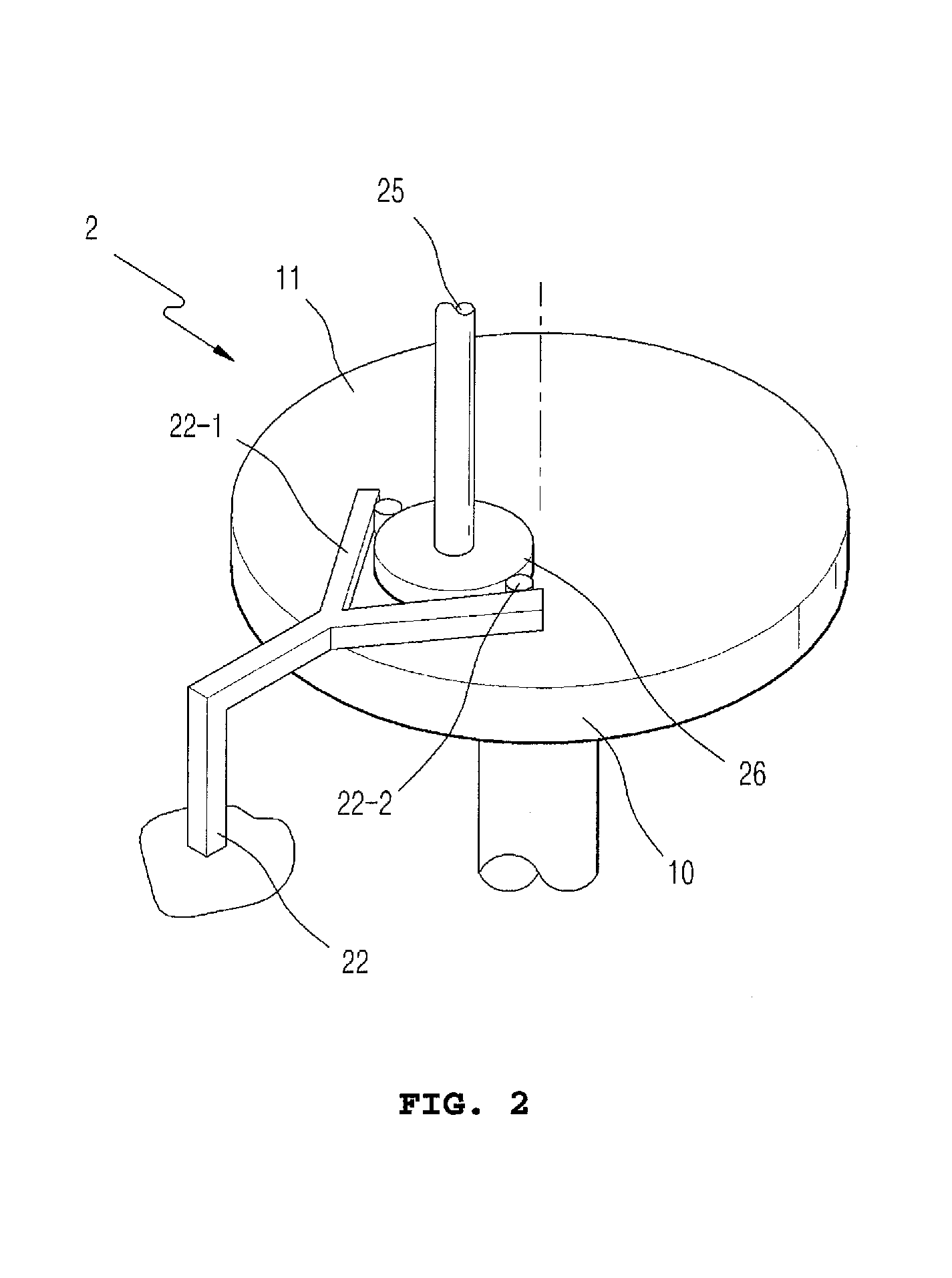

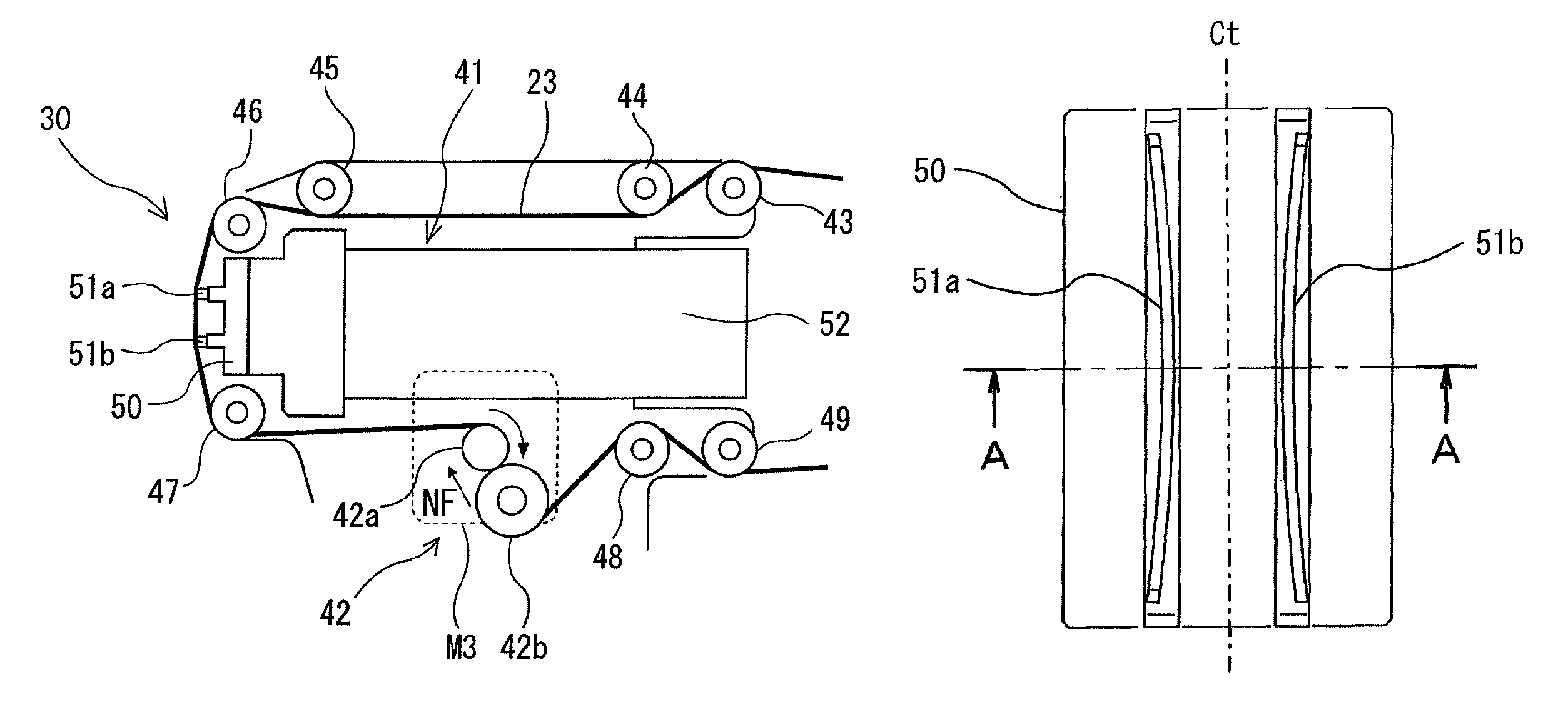

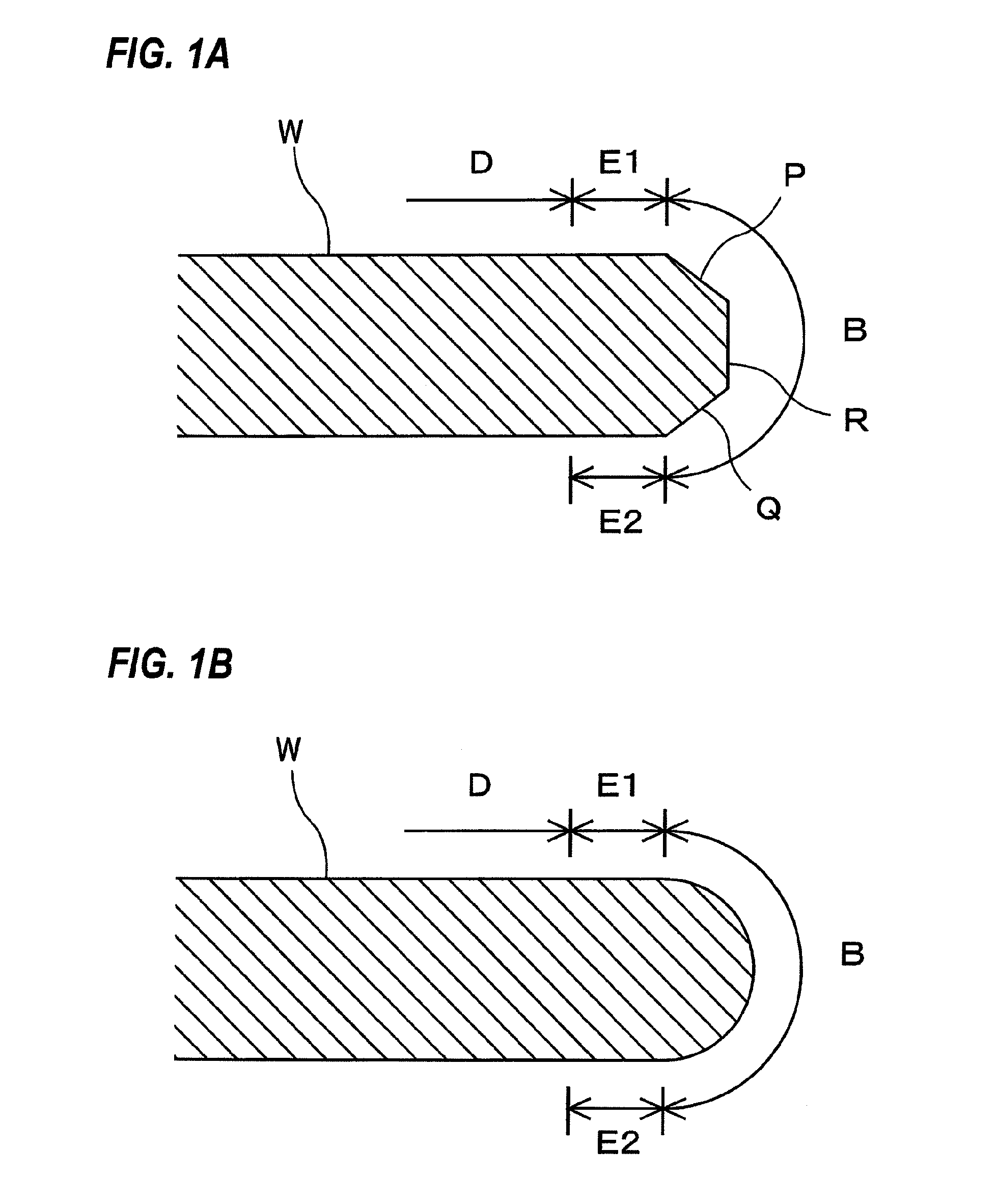

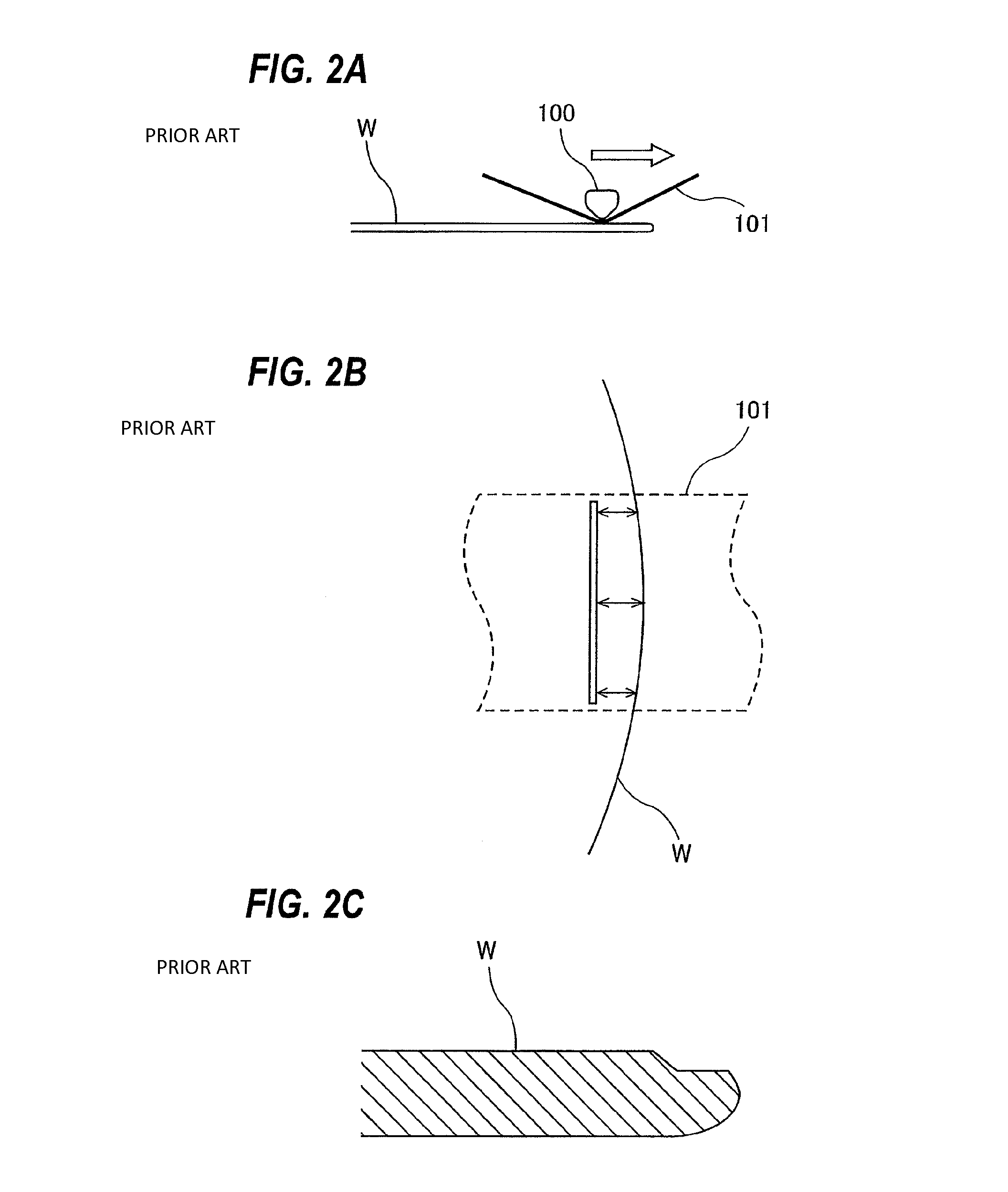

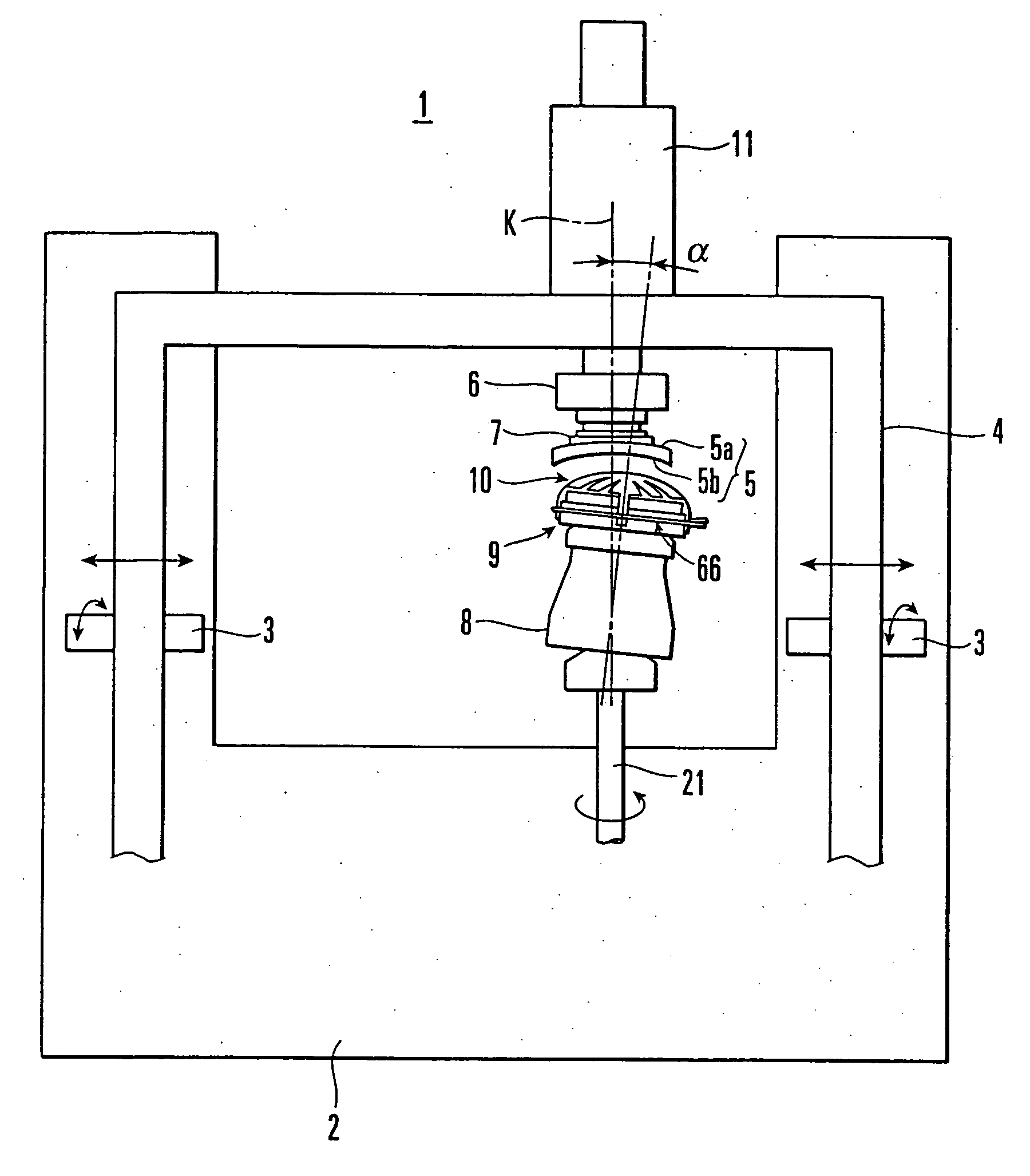

Polishing apparatus, polishing method and pressing member for pressing a polishing tool

ActiveUS20110237164A1Accurate polishingUniform contact timeEdge grinding machinesGrinding drivesMechanical engineering

A polishing apparatus polishes a top edge portion and / or a bottom edge portion of a substrate accurately and uniformly. The polishing apparatus includes a rotary holding mechanism 3 configured to hold the substrate W horizontally and to rotate the substrate W; and at least one polishing head 30 disposed near the peripheral portion of the substrate. The polishing head 30 has at least one protrusion 51a, 51b extending along a circumferential direction of the substrate W, and the polishing head 30 is configured to press a polishing surface of a polishing tape 23 by the protrusion 51a, 51b against the peripheral portion of the substrate W from above or below.

Owner:EBARA CORP

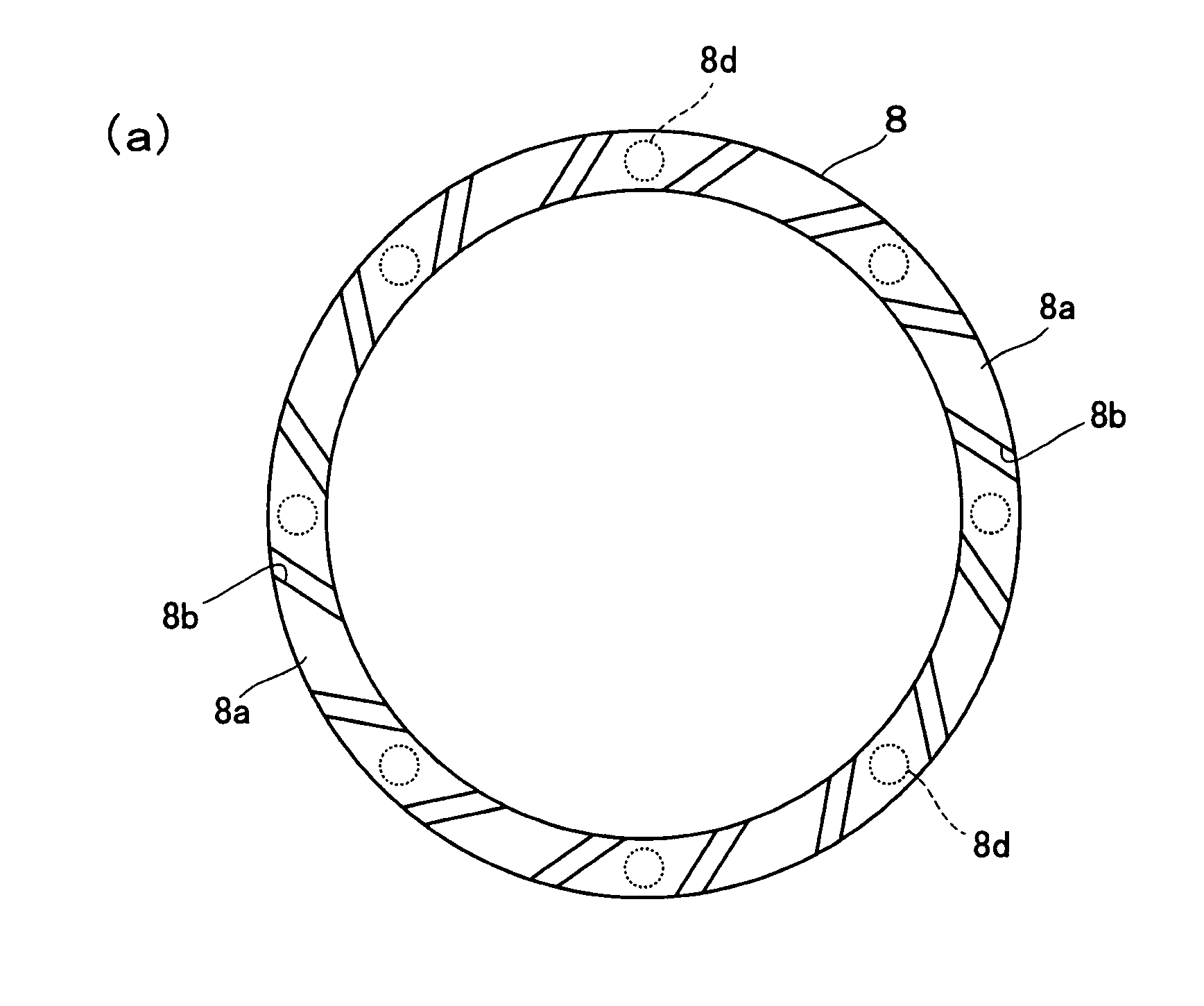

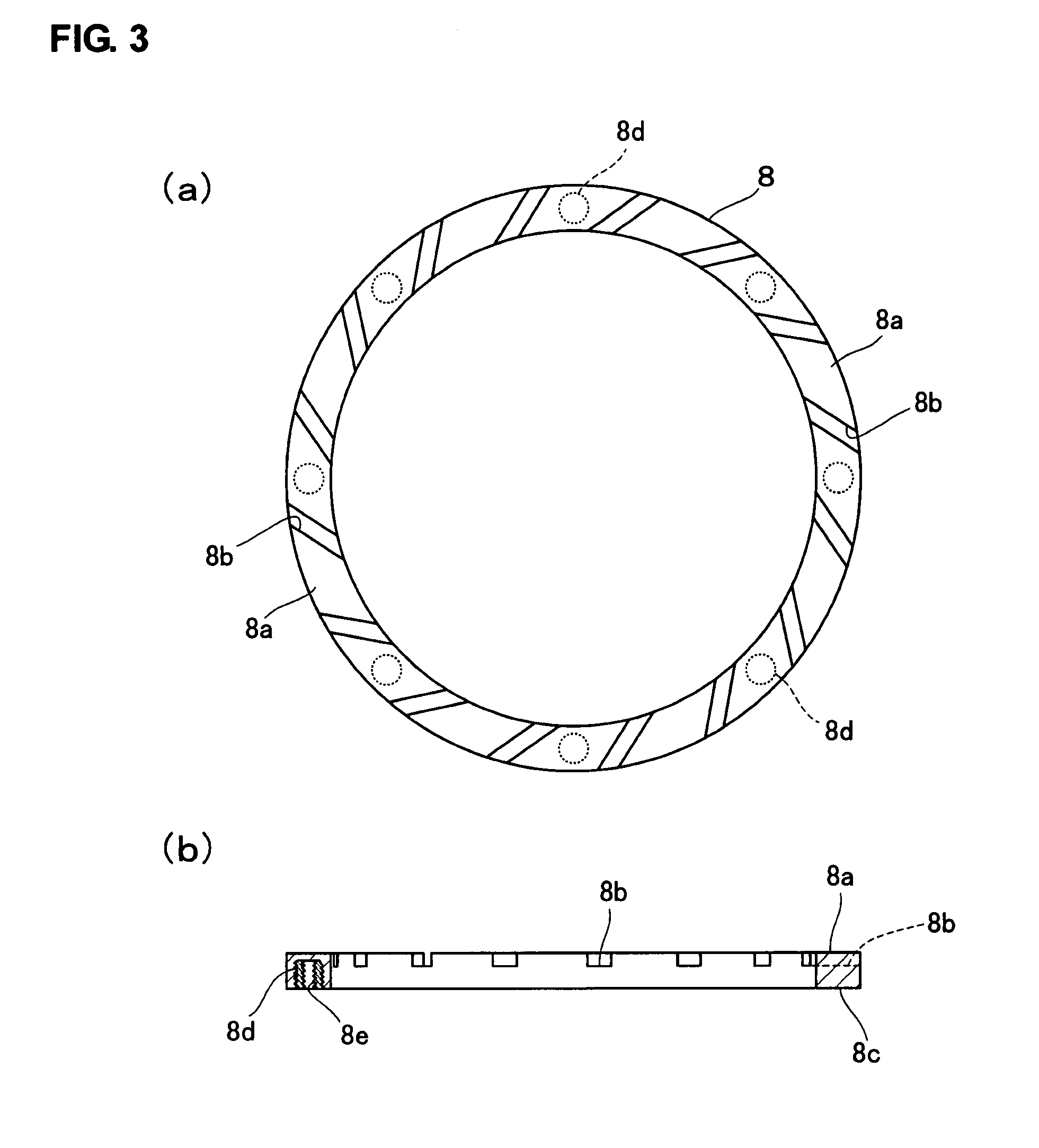

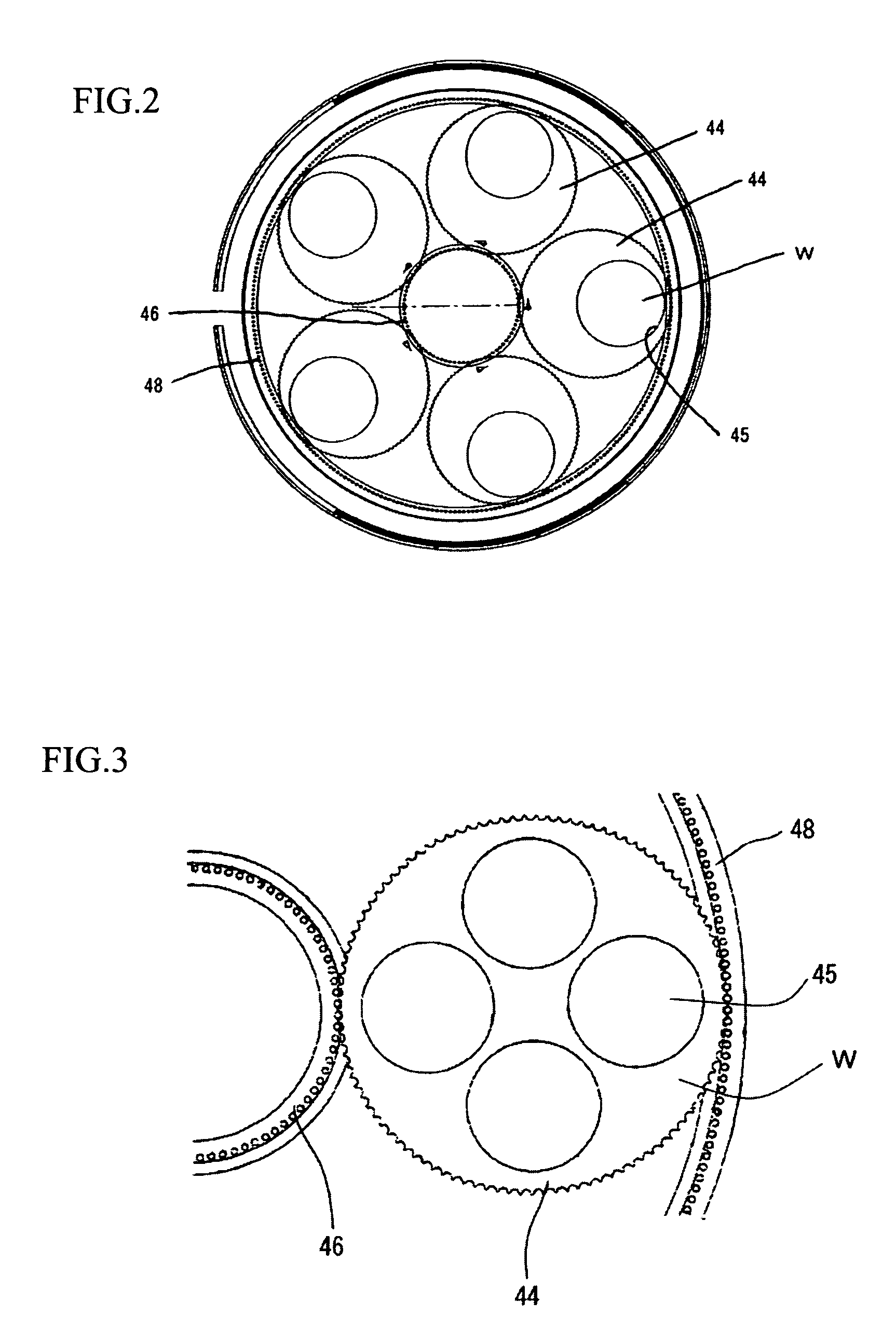

CMP-apparatus retainer ring and manufacturing method thereof, and CMP apparatus

InactiveUS20070298693A1Improve surface roughnessImprove flatnessPolishing machinesRevolution surface grinding machinesEngineering plasticSurface roughness

A retainer ring is provided which is capable of, effectively in practice, restraining the time taken for a break-in polish to the minimum. This retainer ring 8: is disposed inside of a holding head 4 in a CMP apparatus 1 which polishes a wafer W chemically and mechanically; has a ring shape so as to surround the periphery of the wafer W; presses a polish surface 3a of a polish pad 3; is made of an engineering plastic material such as PPS; and has a pressure surface 8a for pressing the polish surface 3a of the polish pad 3 whose surface roughness is a center-line average roughness (Ra) of 0.01 μm or below.

Owner:NIPPON SEIMITSU DENSHI

Moving head for semiconductor wafer polishing apparatus

InactiveUS7294041B1Accurate polishingGrinding drivesSemiconductor/solid-state device manufacturingEngineeringLoad cell

Disclosed herein is a moving head for a semiconductor wafer polishing apparatus. The semiconductor wafer polishing apparatus has a table on which a polishing pad is formed, and the moving head mounted via a support unit to hold a wafer relative to a polishing surface of the table. In this case, the moving head includes a sensing means having a load cell and a piezoelectric sensor to measure pressing force and frictional force acting on the wafer provided in the moving head. The present invention relates to the polishing of a semiconductor wafer material from which an integrated circuit is made. That is, the present invention provides a moving head for semiconductor wafer polishing apparatuses, which detects vibrations transmitted to a wafer and outputs signals indicating frictional force and pressing force acting on the wafer, using a load cell and a piezoelectric sensor installed in the moving head so as to maintain optimum frictional force and pressing force relative to the surface of a polishing pad, thus realizing precise final polishing.

Owner:INHA UNIV RES & BUSINESS FOUNDATION

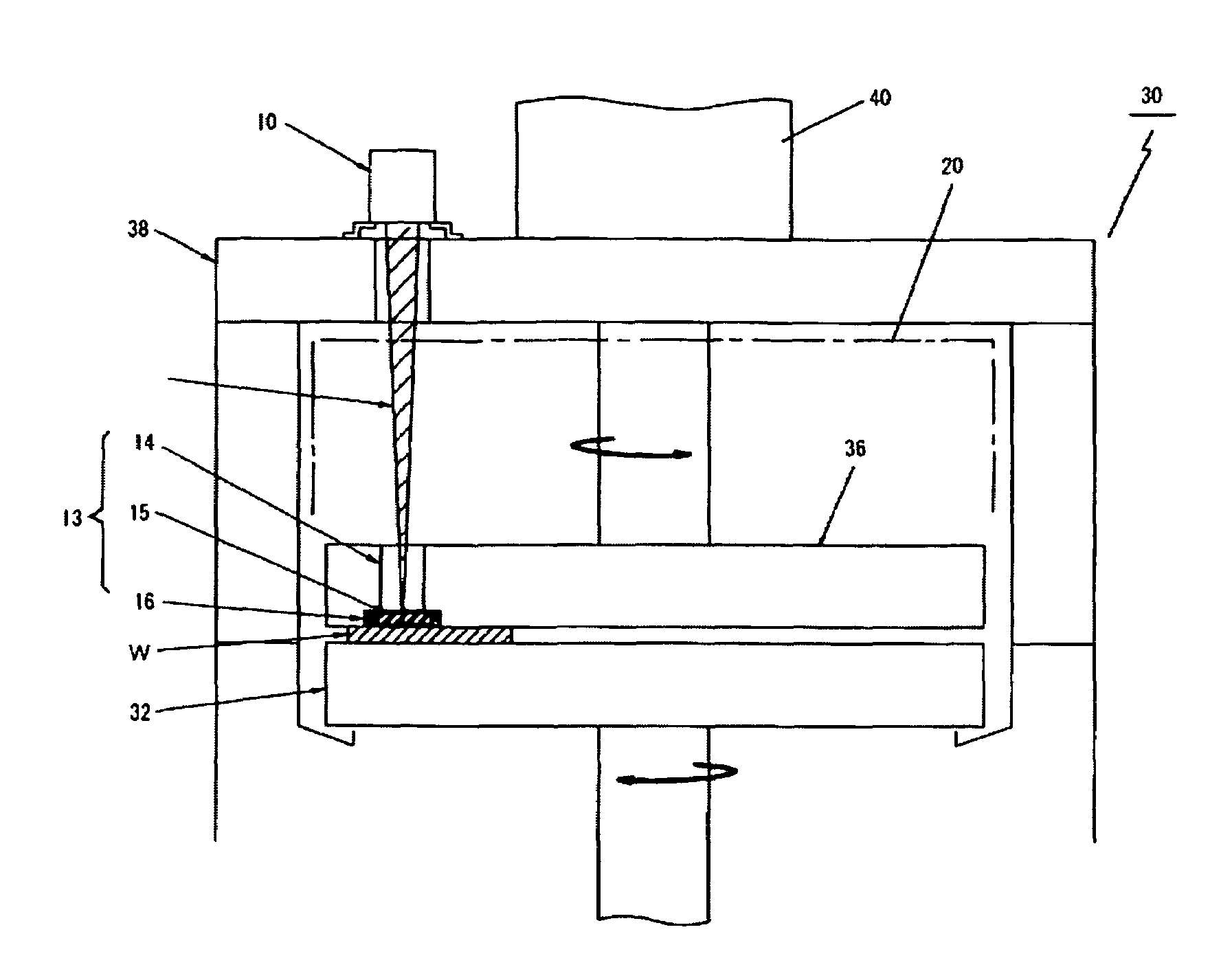

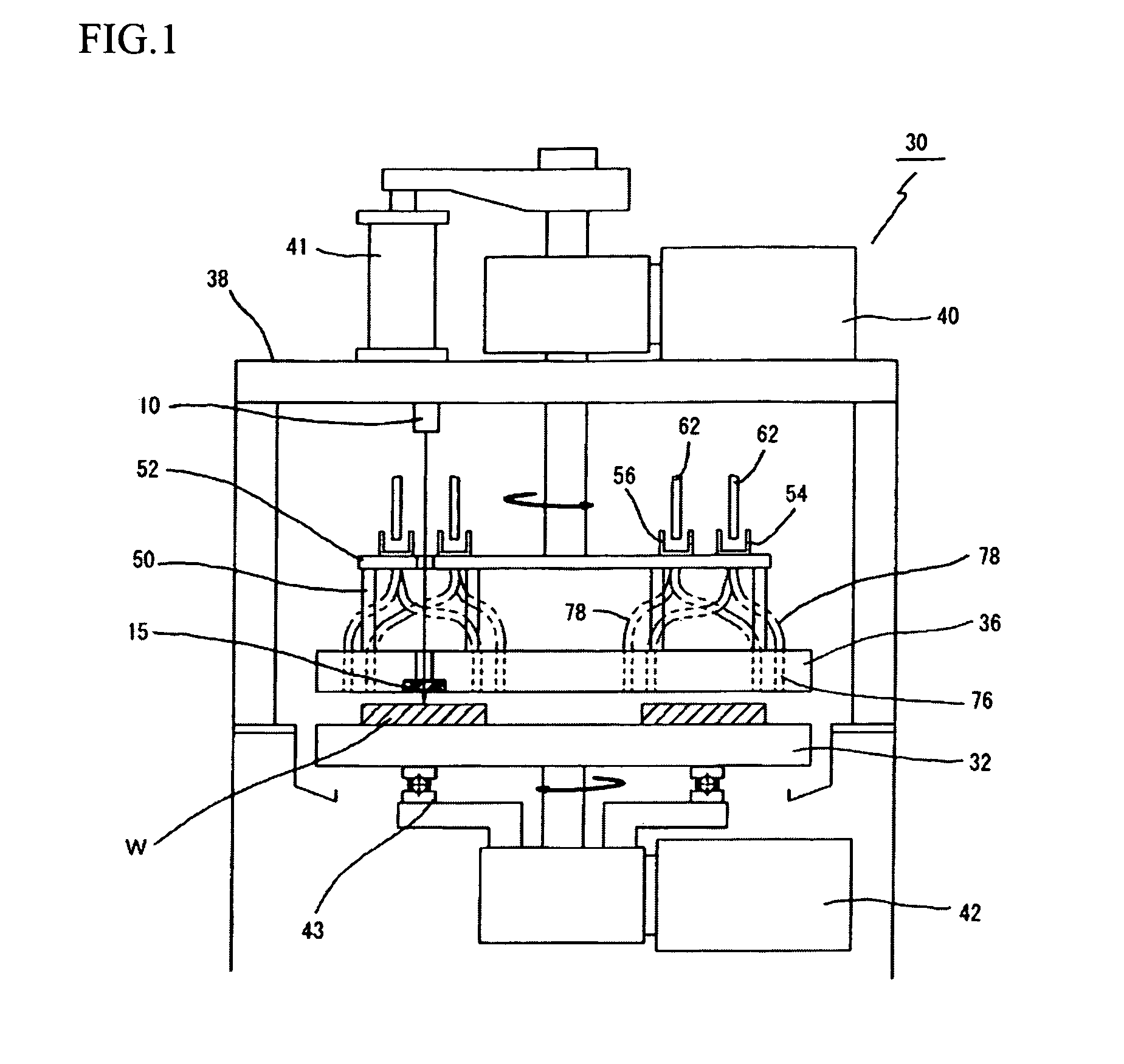

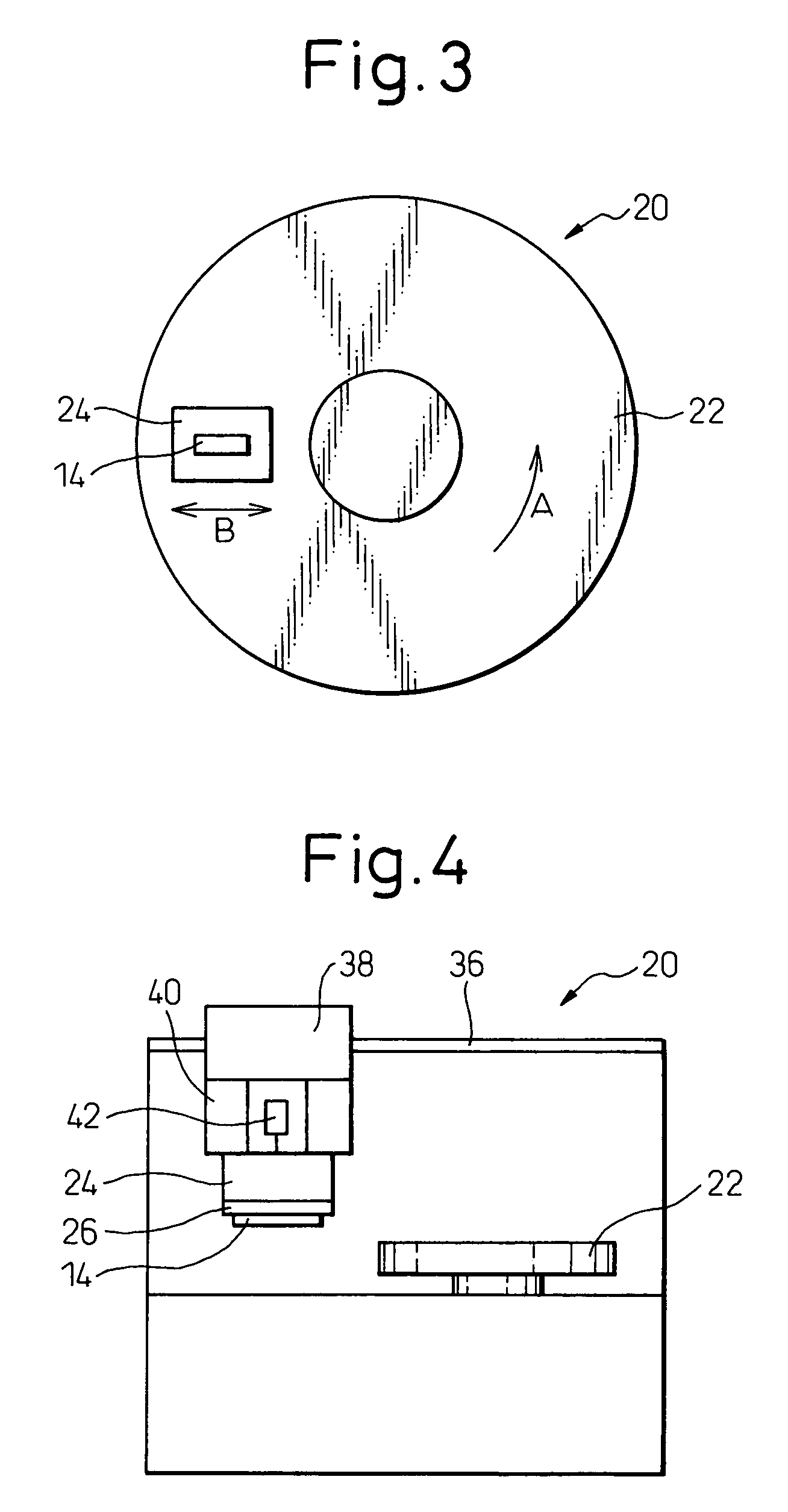

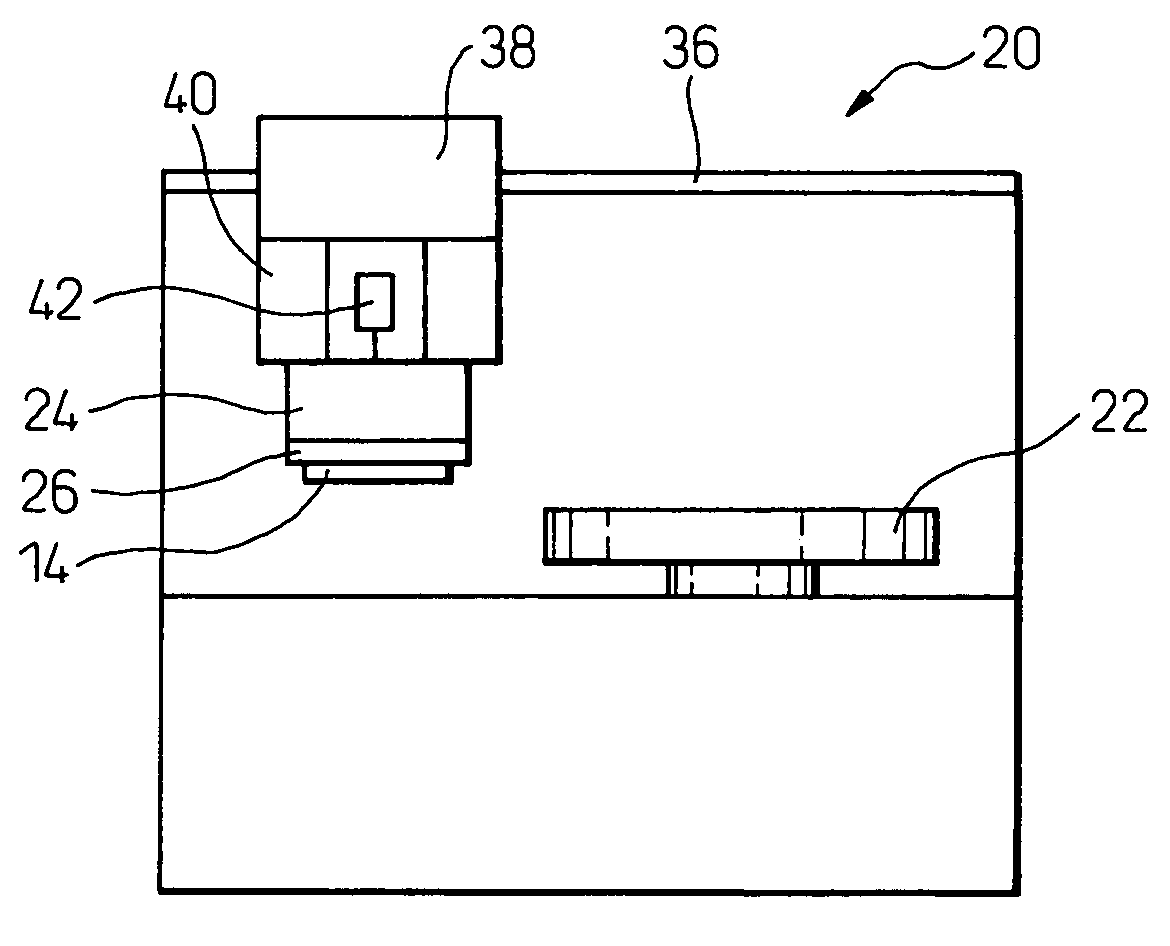

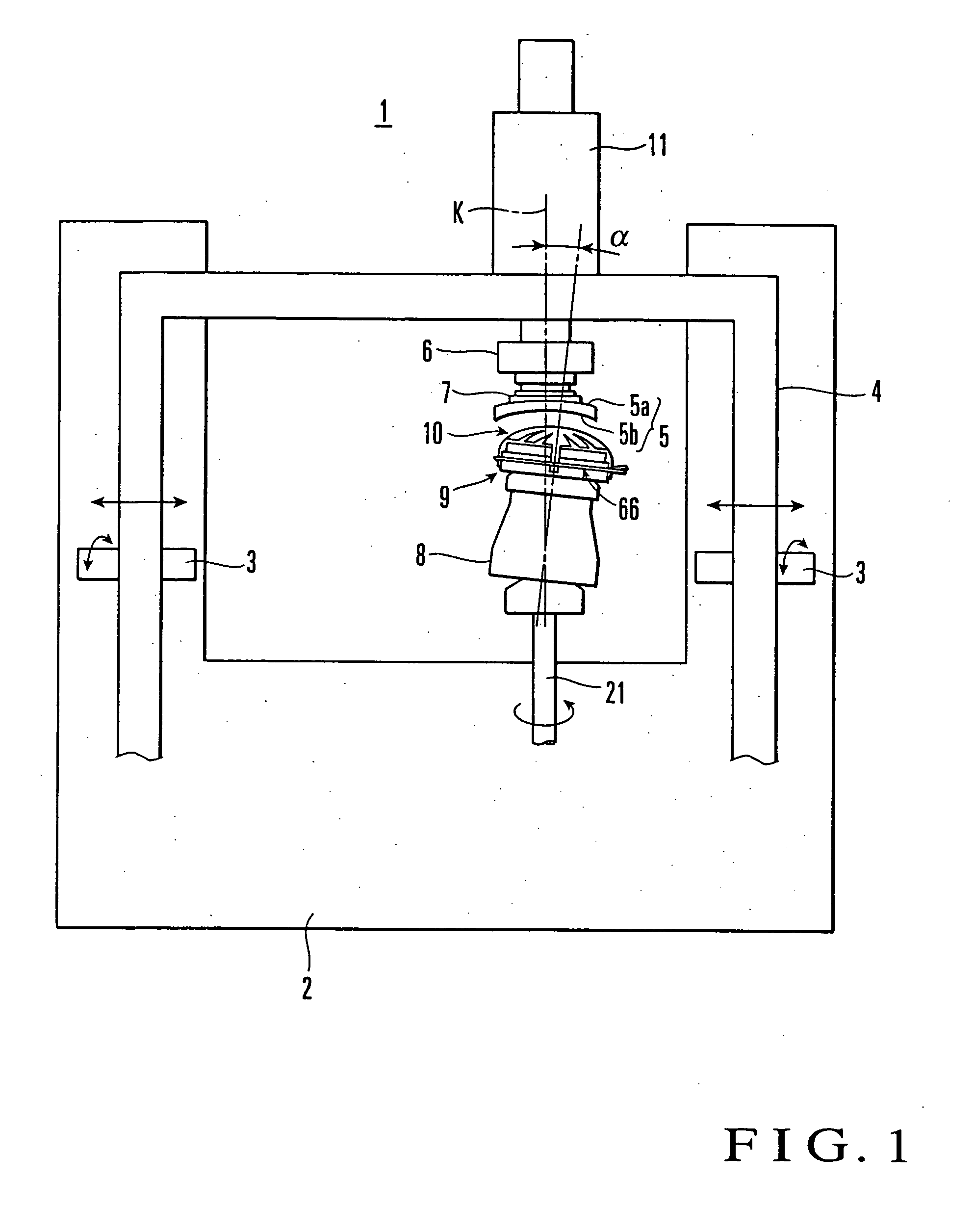

Double-side polishing apparatus

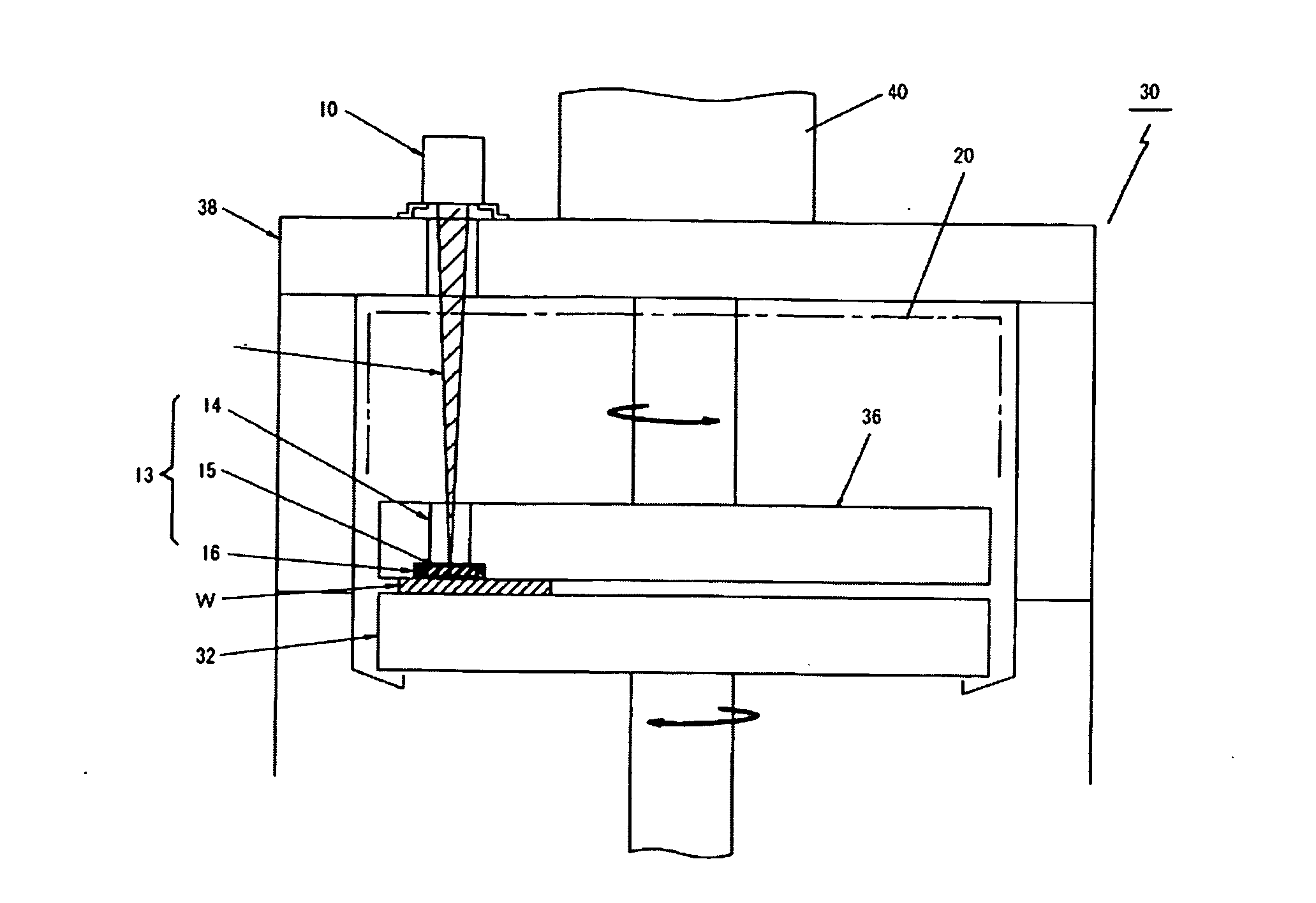

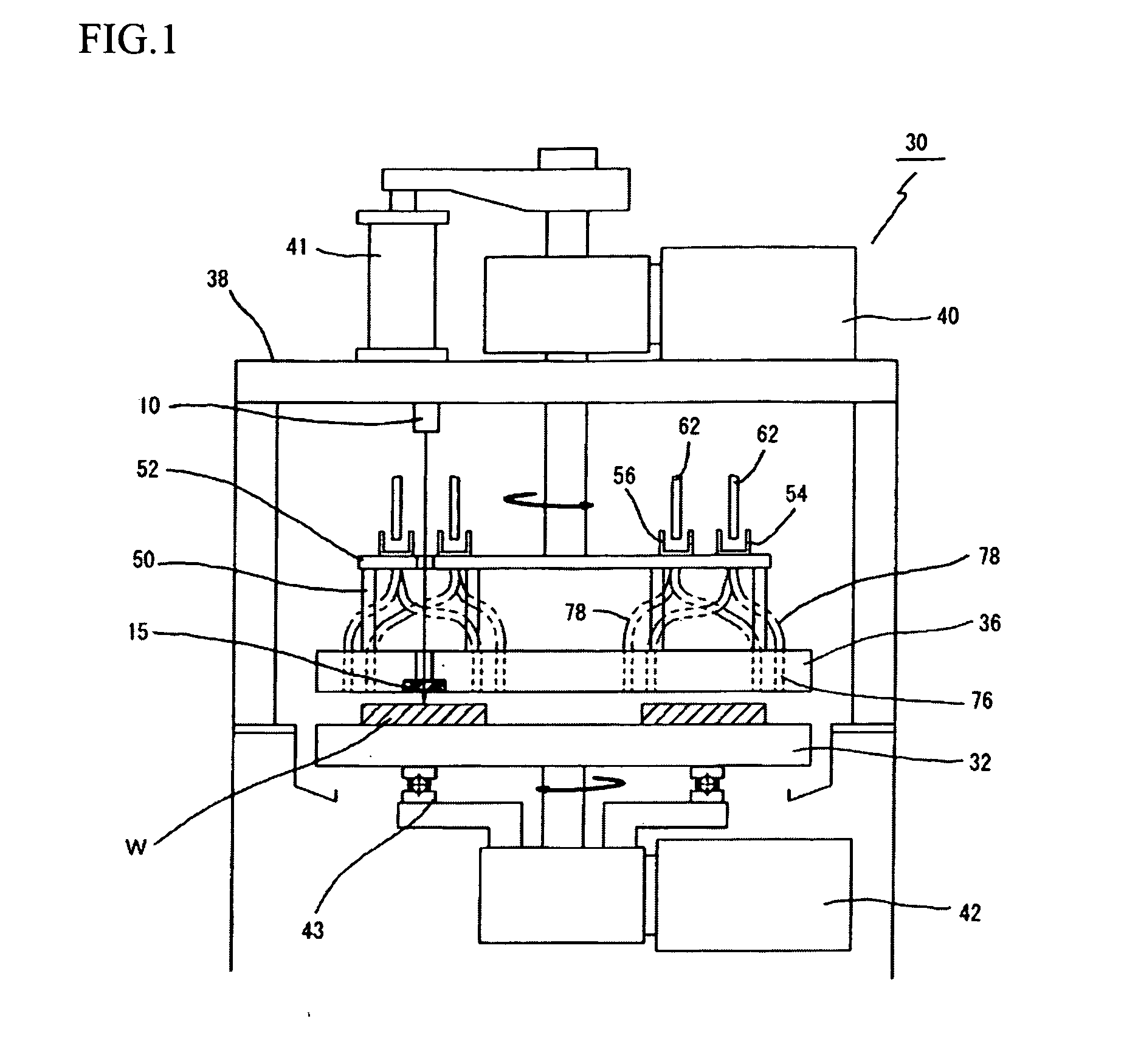

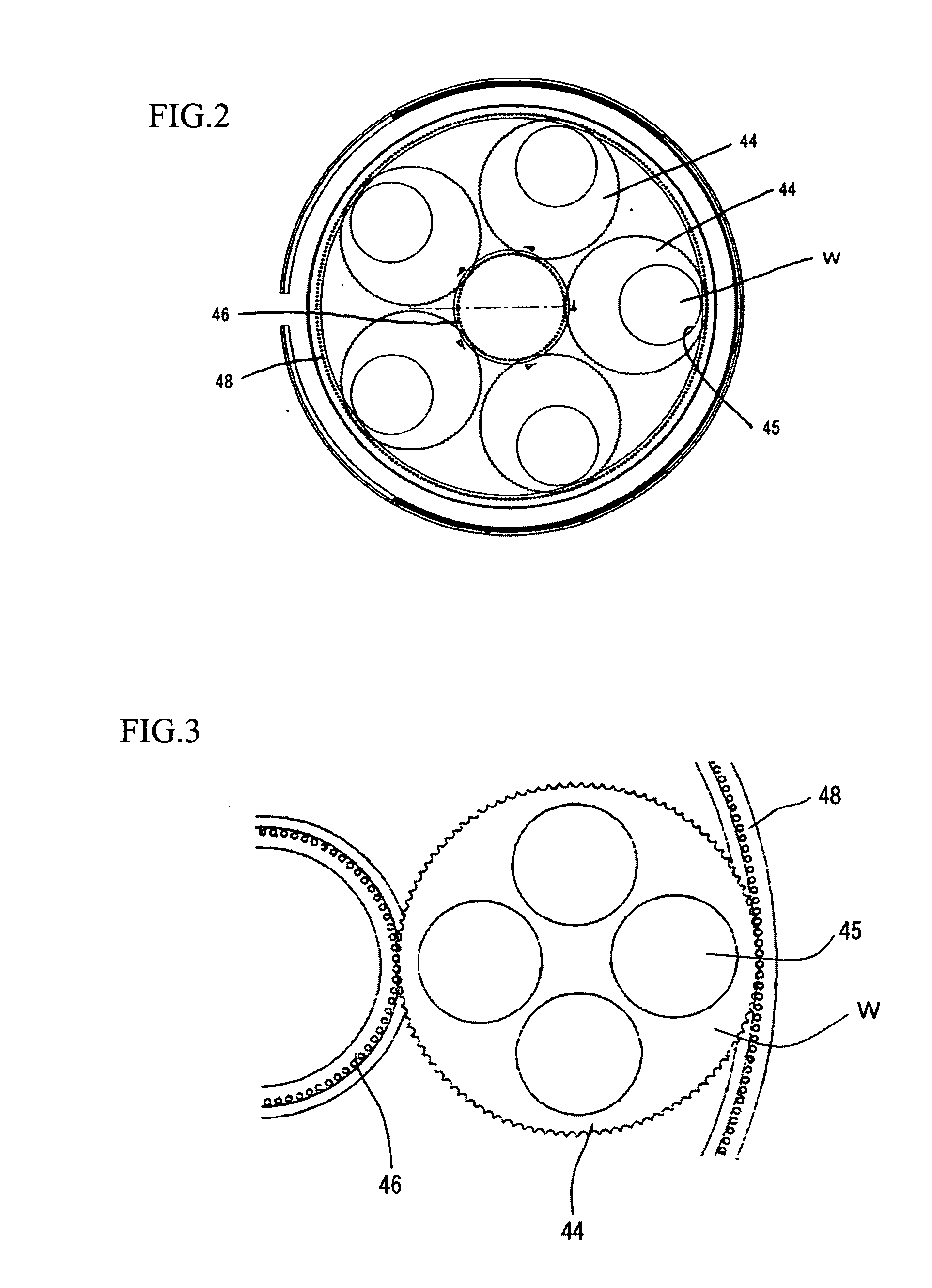

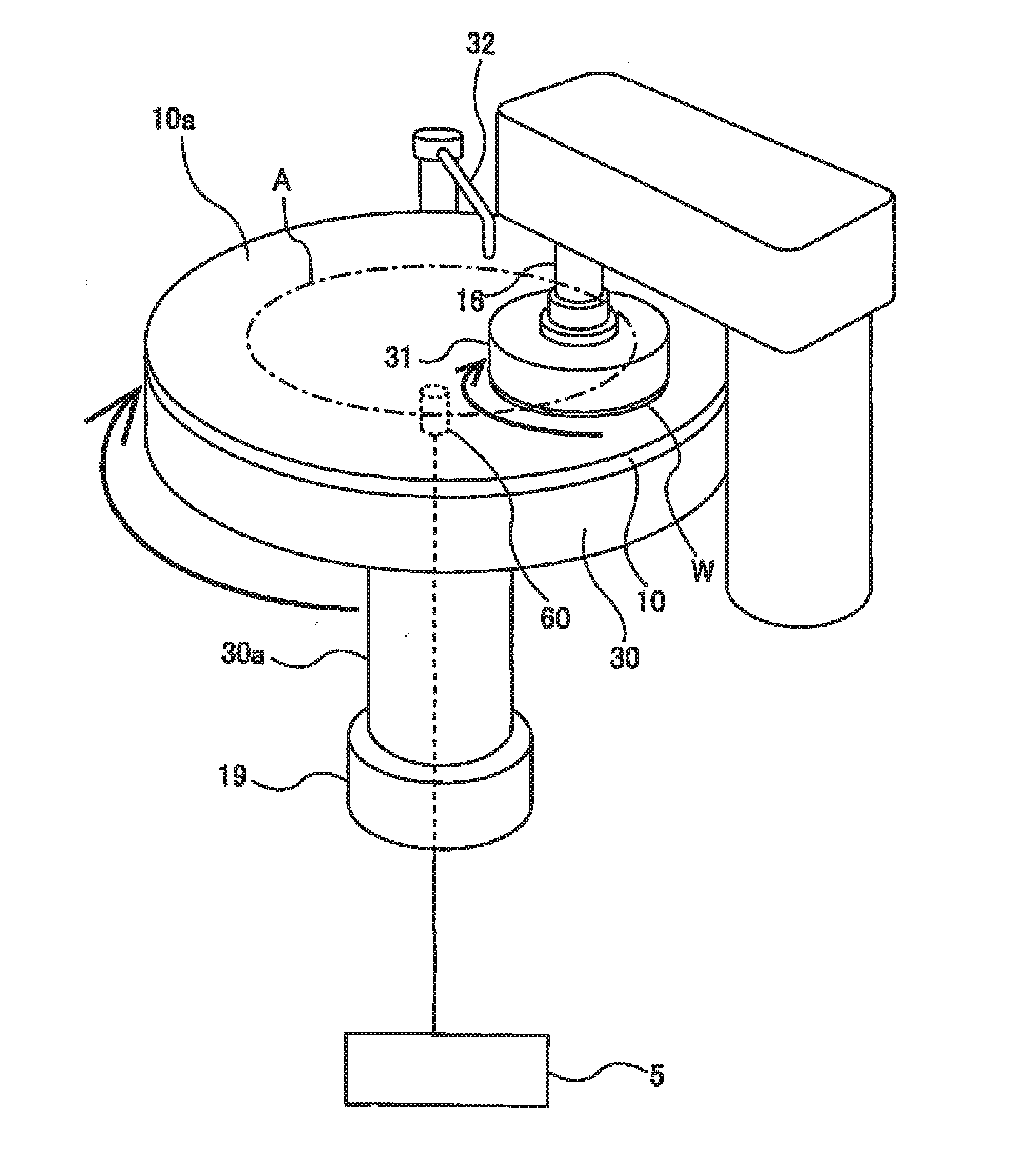

ActiveUS20080227371A1Accurate polishingAccurate thicknessEdge grinding machinesSemiconductor/solid-state device manufacturingPeak valueEngineering

The double-side polishing apparatus for polishing both faces of a wafer is capable of reliably measuring not only a thickness of an outer part of the wafer but also a thickness of a center part thereof. The double-side polishing apparatus comprises: a lower polishing plate; an upper polishing plate held by a frame; and a carrier having a through-hole for holding the wafer. A window section, through which a laser beam passes, is formed in a part of the upper polishing plate, under which the wafer held by the carrier passes. An optical thickness measuring equipment is provided to a part of the frame, under which the window section passes while the upper polishing plate is rotated. The thickness measuring equipment emits the laser beam through the window section, receives reflected beams reflected from an upper face and a lower face of the wafer, and calculates the thickness of the wafer on the basis of peak values of the reflected beams.

Owner:FUJIKOSHI MACHINERY

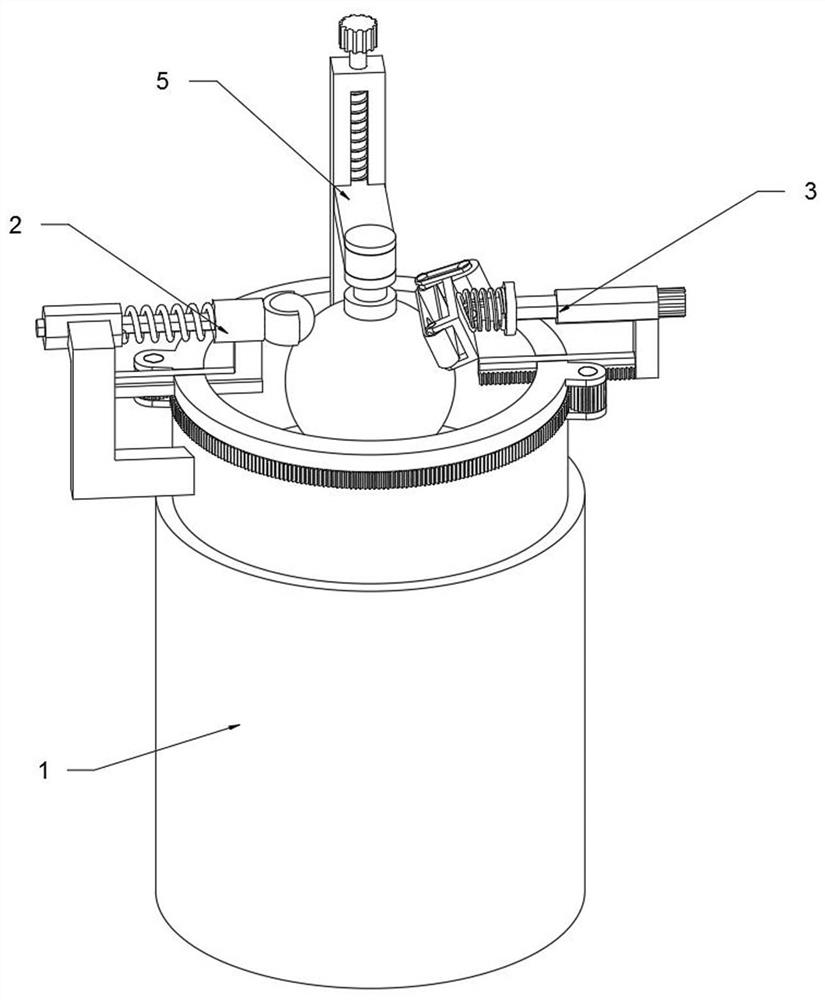

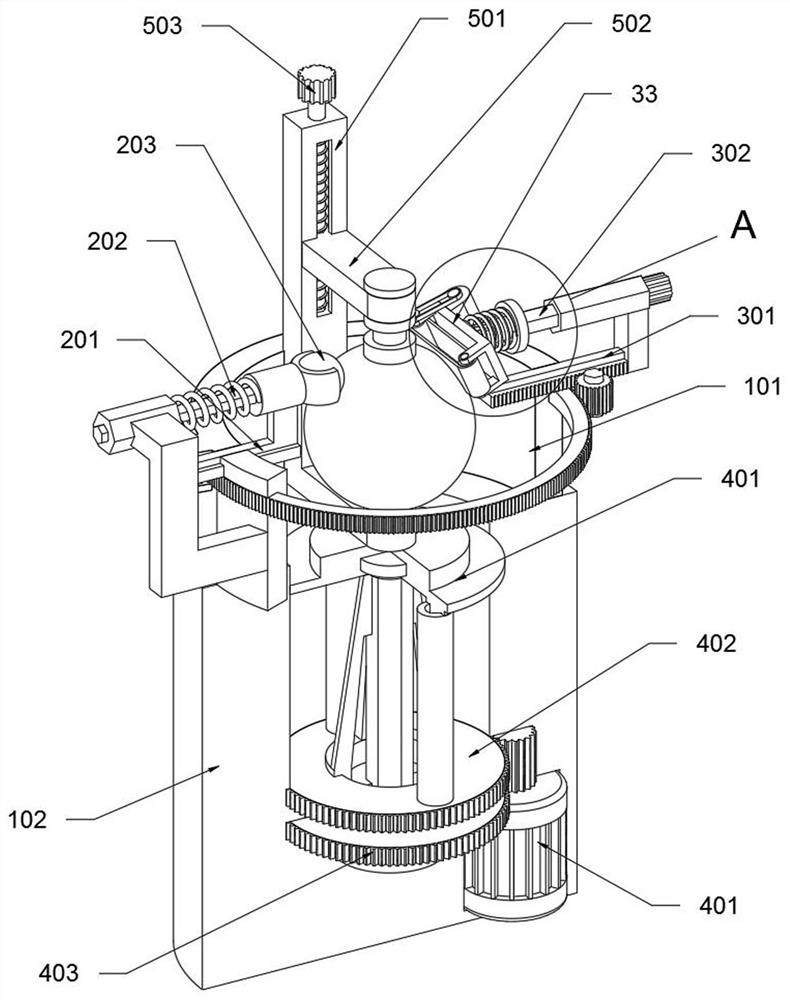

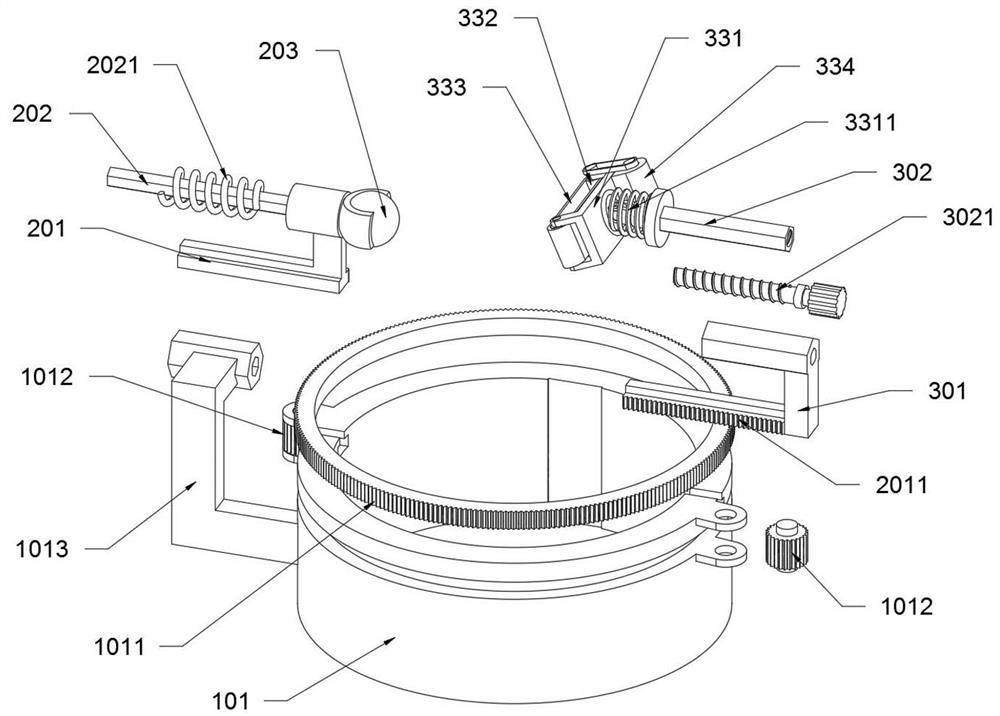

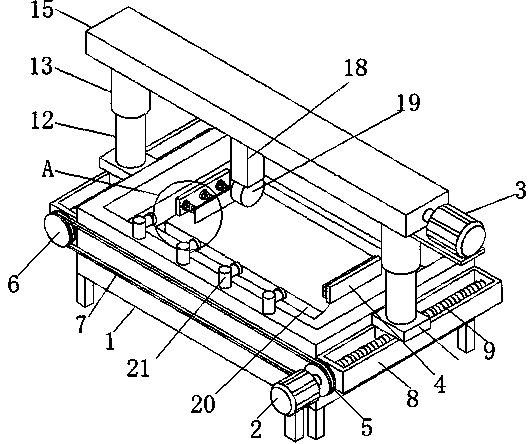

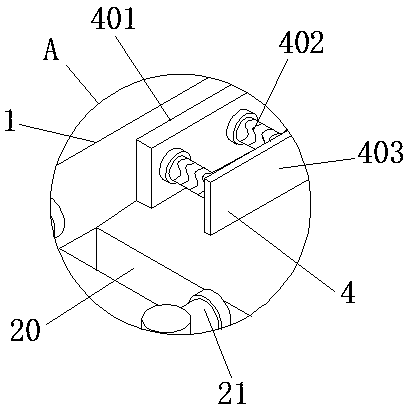

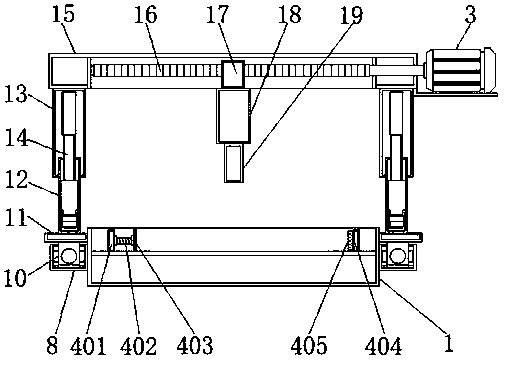

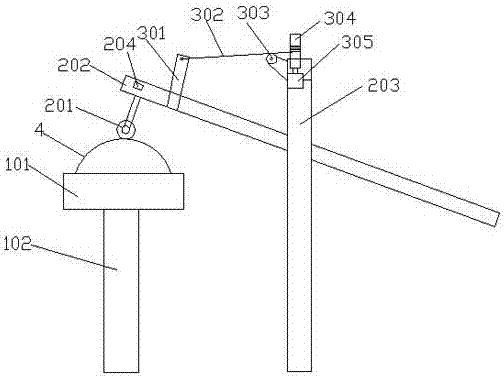

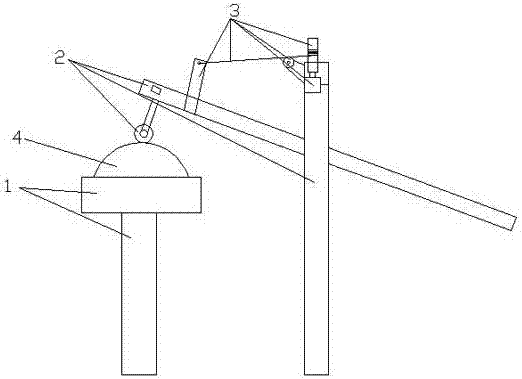

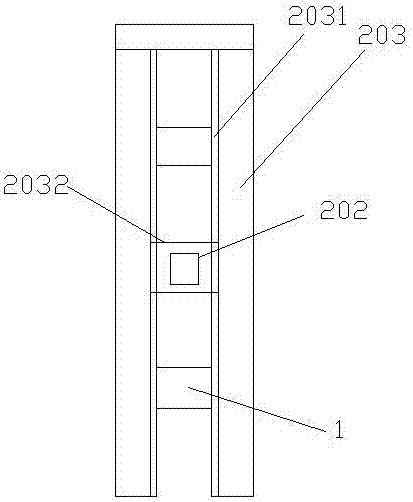

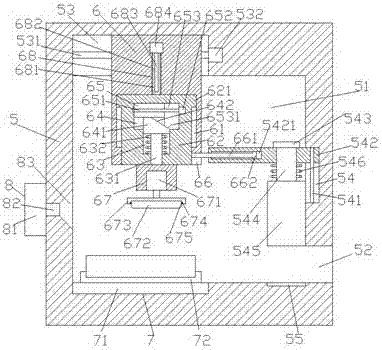

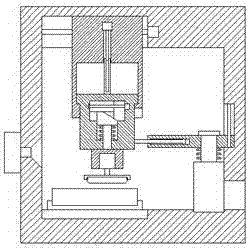

Machining-based spherical workpiece polishing device

ActiveCN113601347AAccurate polishingImprove polishing effectGrinding carriagesBelt grinding machinesContact pressurePolishing

The invention discloses a machining-based spherical workpiece polishing device, relates to the technical field of polishing devices, and solves the problems that when an existing polishing device is used for polishing a spherical workpiece, the contact area and polishing pressure of a polishing belt and the surface of a sphere cannot be ensured to be constant, the polishing effect is poor, and the labor intensity is high due to the fact that workers need to polish the spherical workpiece around the spherical workpiece. The machining-based spherical workpiece polishing device comprises a mounting fixing part, wherein a the mounting top seat is fixedly mounted at the top of a mounting base. When the device is used for polishing the spherical workpiece, a positioning mechanism can control the contact area and the contact pressure of a polishing mechanism on the surface of the spherical workpiece, so that accurate polishing of the surface of the spherical workpiece is guaranteed; and the spherical workpiece can circularly rotate and ascend and descend in a spherical surface polishing assembly through a rotating lifting assembly, so that the surface of the spherical workpiece can be circularly and completely polished, the polishing effect is good, and the labor intensity is low.

Owner:南通铭品机械有限公司

Double-side polishing apparatus

ActiveUS7614934B2Reliably measuring not only a thicknessAccurate polishingEdge grinding machinesSemiconductor/solid-state device manufacturingPeak valueEngineering

The double-side polishing apparatus for polishing both faces of a wafer is capable of reliably measuring not only a thickness of an outer part of the wafer but also a thickness of a center part thereof. The double-side polishing apparatus comprises: a lower polishing plate; an upper polishing plate held by a frame; and a carrier having a through-hole for holding the wafer. A window section, through which a laser beam passes, is formed in a part of the upper polishing plate, under which the wafer held by the carrier passes. An optical thickness measuring equipment is provided to a part of the frame, under which the window section passes while the upper polishing plate is rotated. The thickness measuring equipment emits the laser beam through the window section, receives reflected beams reflected from an upper face and a lower face of the wafer, and calculates the thickness of the wafer on the basis of peak values of the reflected beams.

Owner:FUJIKOSHI MACHINERY

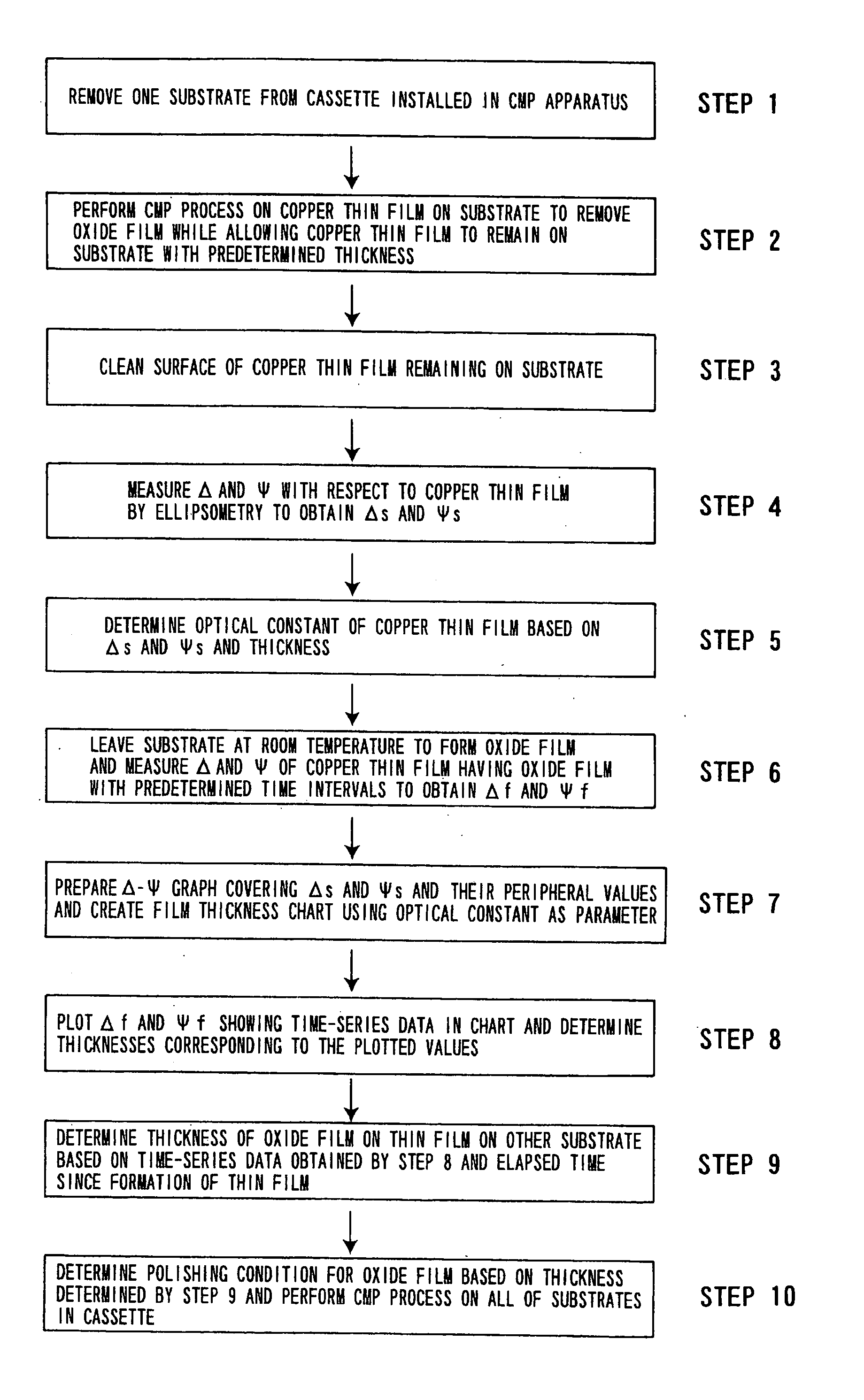

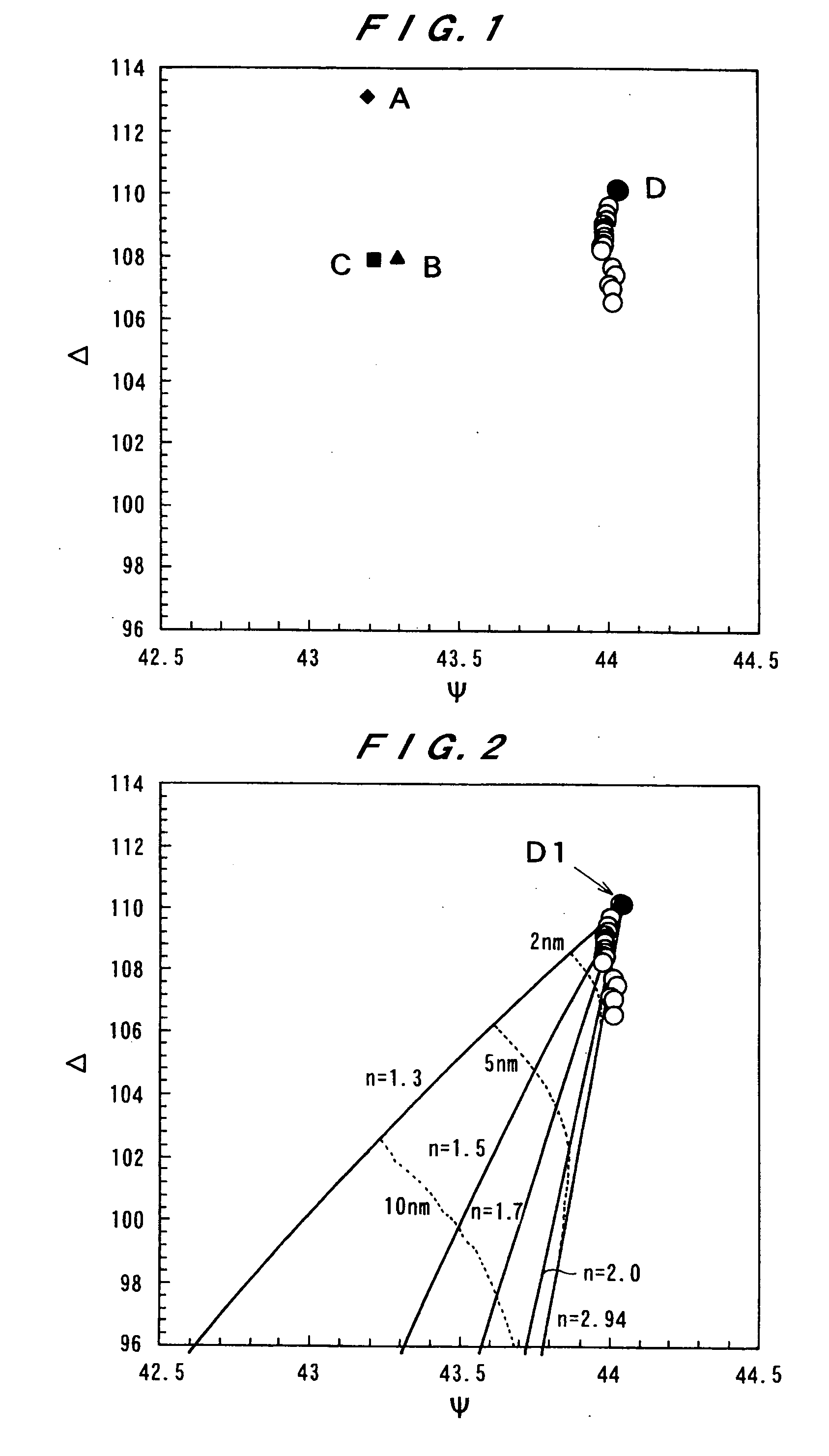

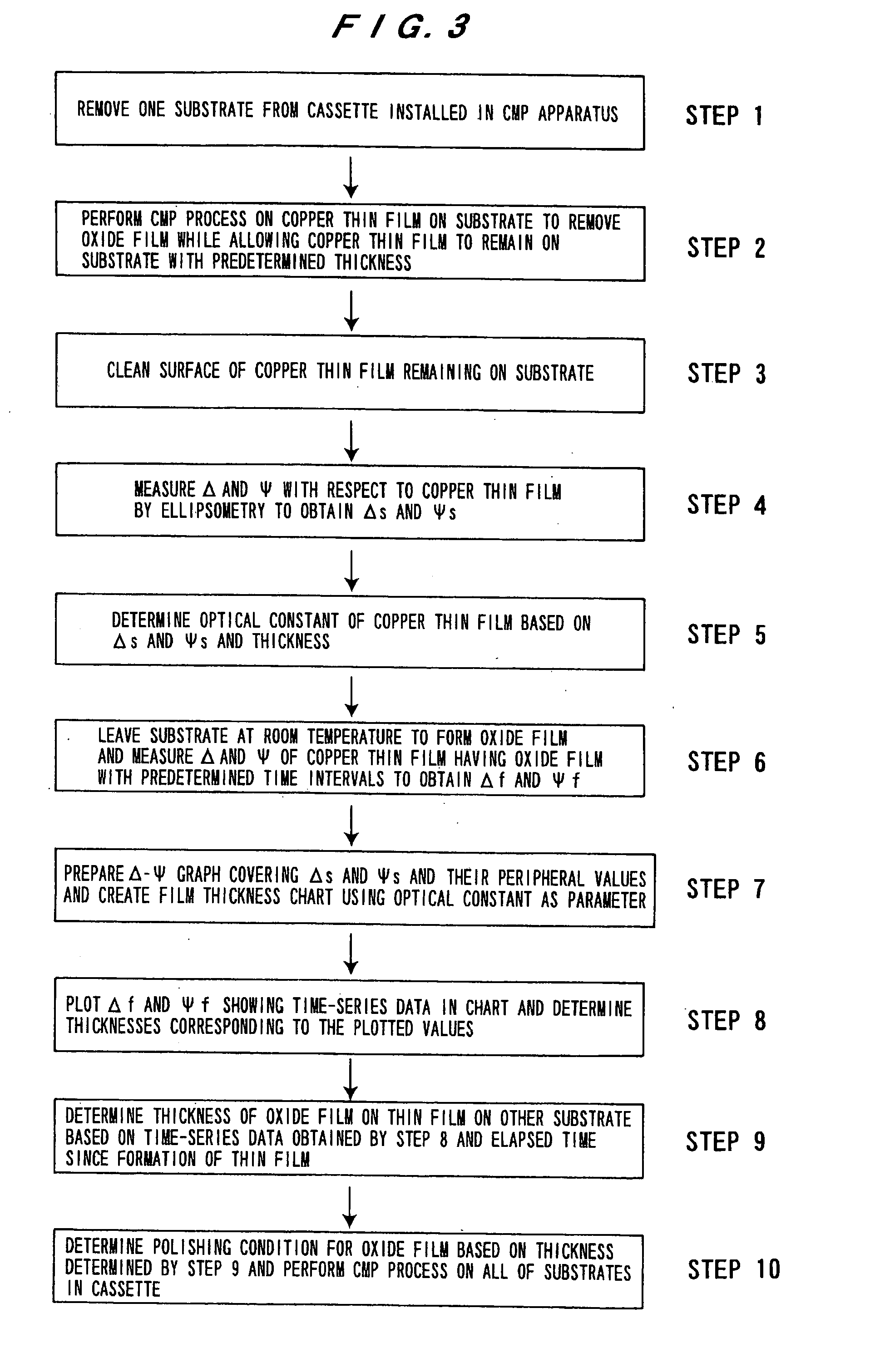

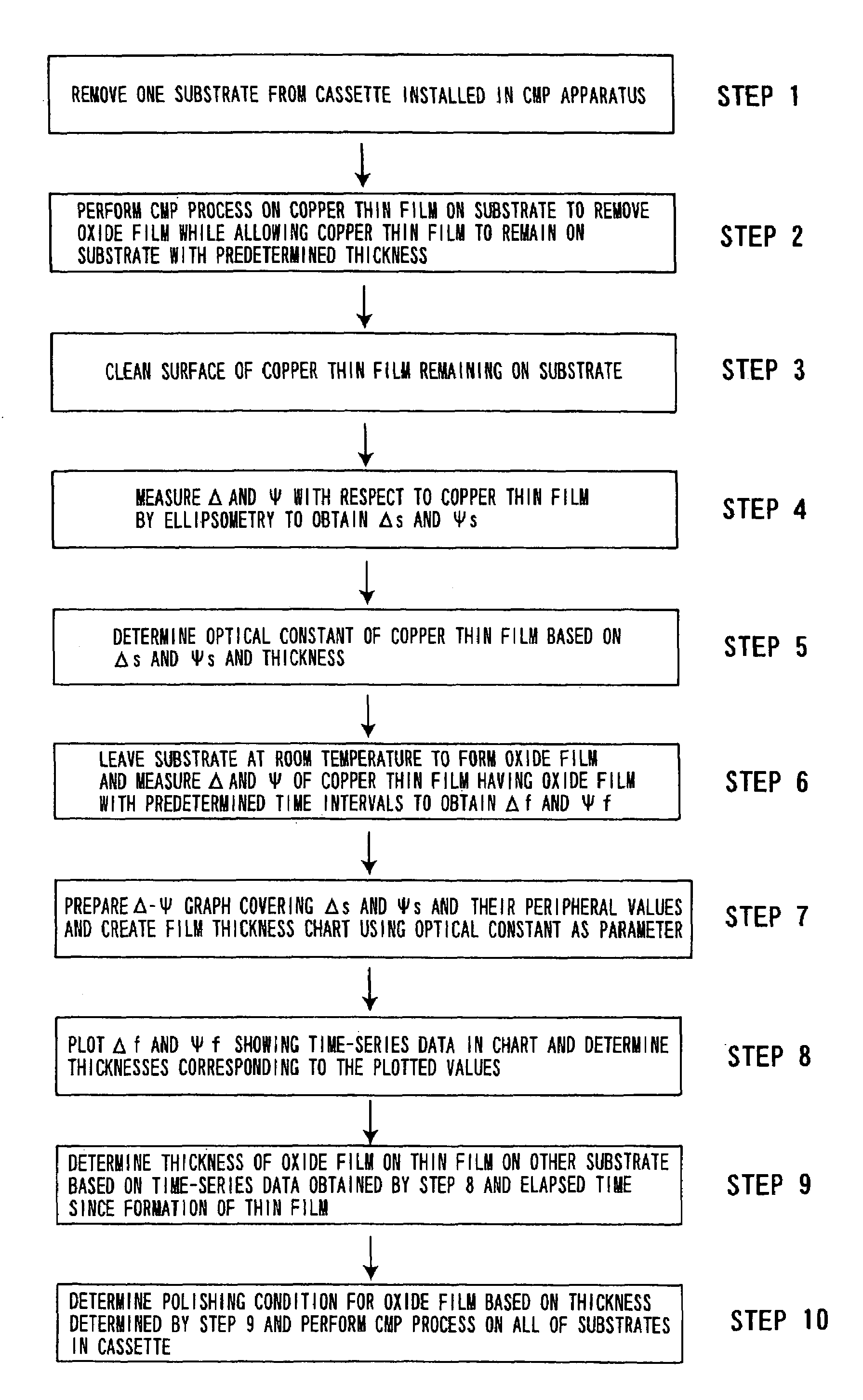

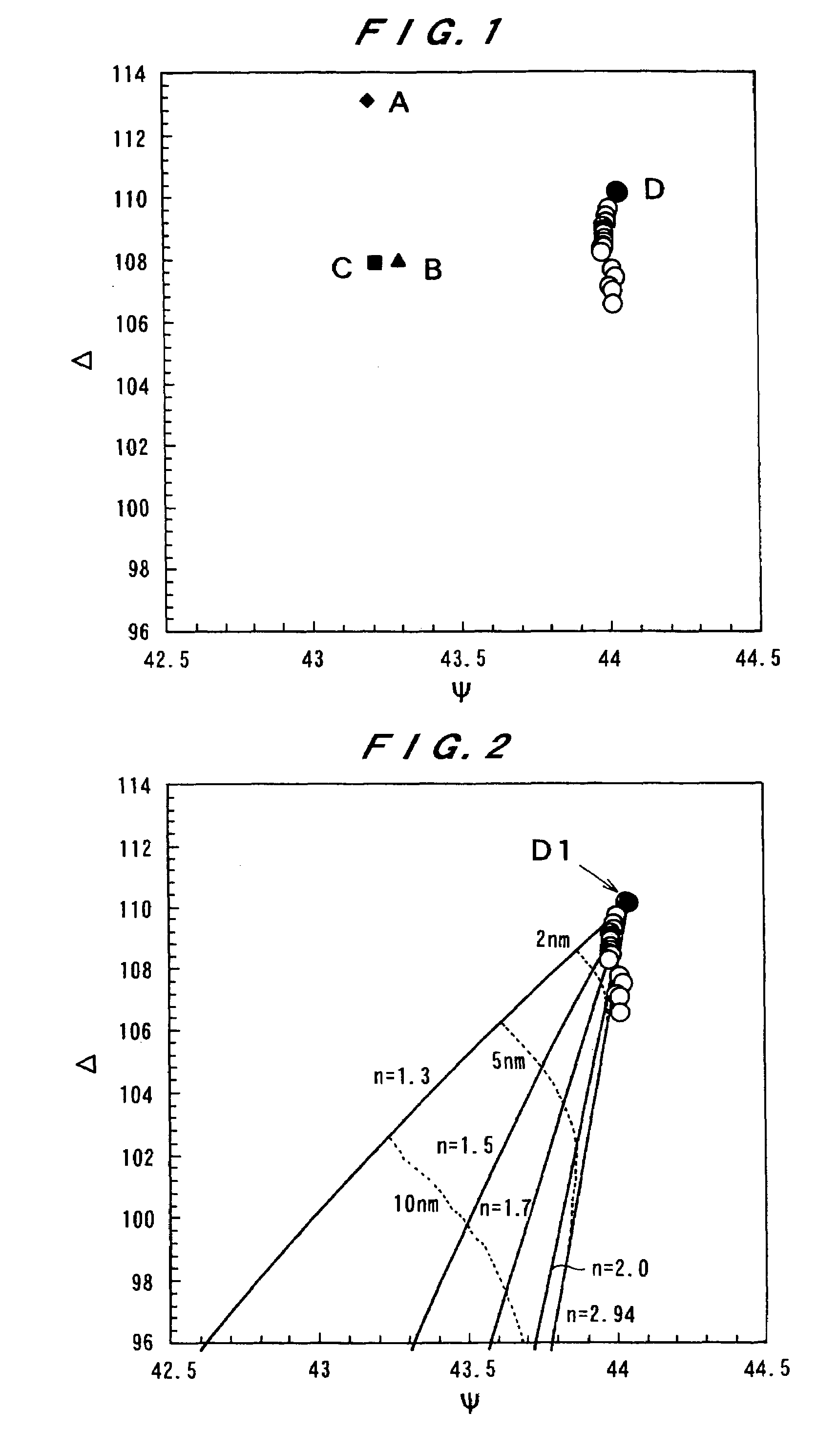

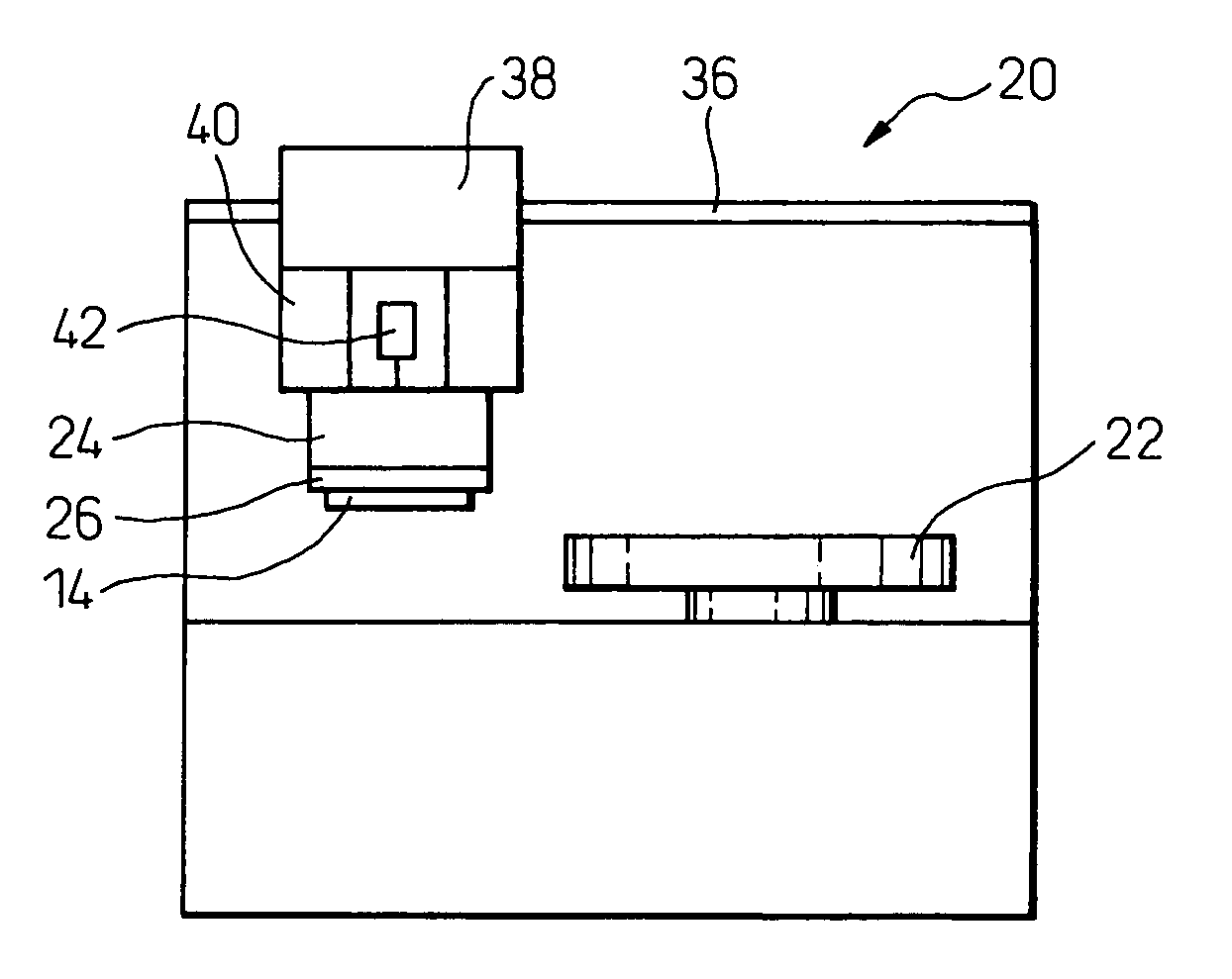

Method of polishing thin film formed on substrate

ActiveUS20050254051A1Accurately measureAccurately determinedPolarisation-affecting propertiesSemiconductor/solid-state device manufacturingOptoelectronicsPhysical property

A method for polishing a thin film formed on a substrate includes planarizing a thin film formed on a reference substrate by a CMP process such that the thin film remains on the reference substrate. After the planarizing, the thin film is cleaned, and then values of Δ and Ψ with respect to the cleaned thin film are measured by ellipsometry. A physical property of the thin film is determined based on the Δ and Ψ which have been measured by ellipsometry, and a polishing condition for an other substrate having a thin film to be polished is set based on physical property data which are obtained by the determining of the physical property.

Owner:EBARA CORP

Abrasive compounds for semiconductor planarization

InactiveUS20060283092A1Improve flatnessIncrease speedPigmenting treatmentOther chemical processesCerium oxideMetallurgy

A polishing slurry for semiconductor planarization containing cerium oxide particles and water, wherein the content of the cerium oxide particles having a diameter of 3 μm or more is 500 ppm or less (weight ratio) in a solid, preferably 100 ppm or less and it is more preferable that D99 (99% by volume of the whole particles in polishing slurry) of the cerium oxide particles is 1 μm or less. The polishing slurry can reduce the generation of scratches, and can polish a surface of the semiconductor substrate in the wiring formation process of semiconductor device precisely at a high speed.

Owner:HITACHI CHEM CO LTD

Hardware accessory polishing device

InactiveCN111015487AAchieve forward and backward movementAchieve left and right movementGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a hardware accessory polishing device and relates to the technical field of hardware accessory processing equipment. The hardware accessory polishing device comprises a worktable, wherein first connecting seats are connected to two side of the worktable, a first motor is mounted on one side of one first connecting seat, the output end of the first motor is connected to a first belt wheel, and one end of the first belt wheel is connected to a first lead screw. By arranging the first motor, a second motor, an electric push rod, the first connecting seats, a second connecting seat, a first slide block and a second slide block, the first motor drives the first slide block to move on the first lead screw in the first connecting seat, so that a polishing wheel moves frontand back; the second motor drives the second slide block to move on the second lead screw in the second connecting seat, so that the polishing wheel moves left and right; the electric push rod stretches , so that the polishing wheel moves up and down to polish a workpiece all around, and therefore, the operating labor force of staff is reduced and the production efficiency of the device is improved.

Owner:徐罗斌

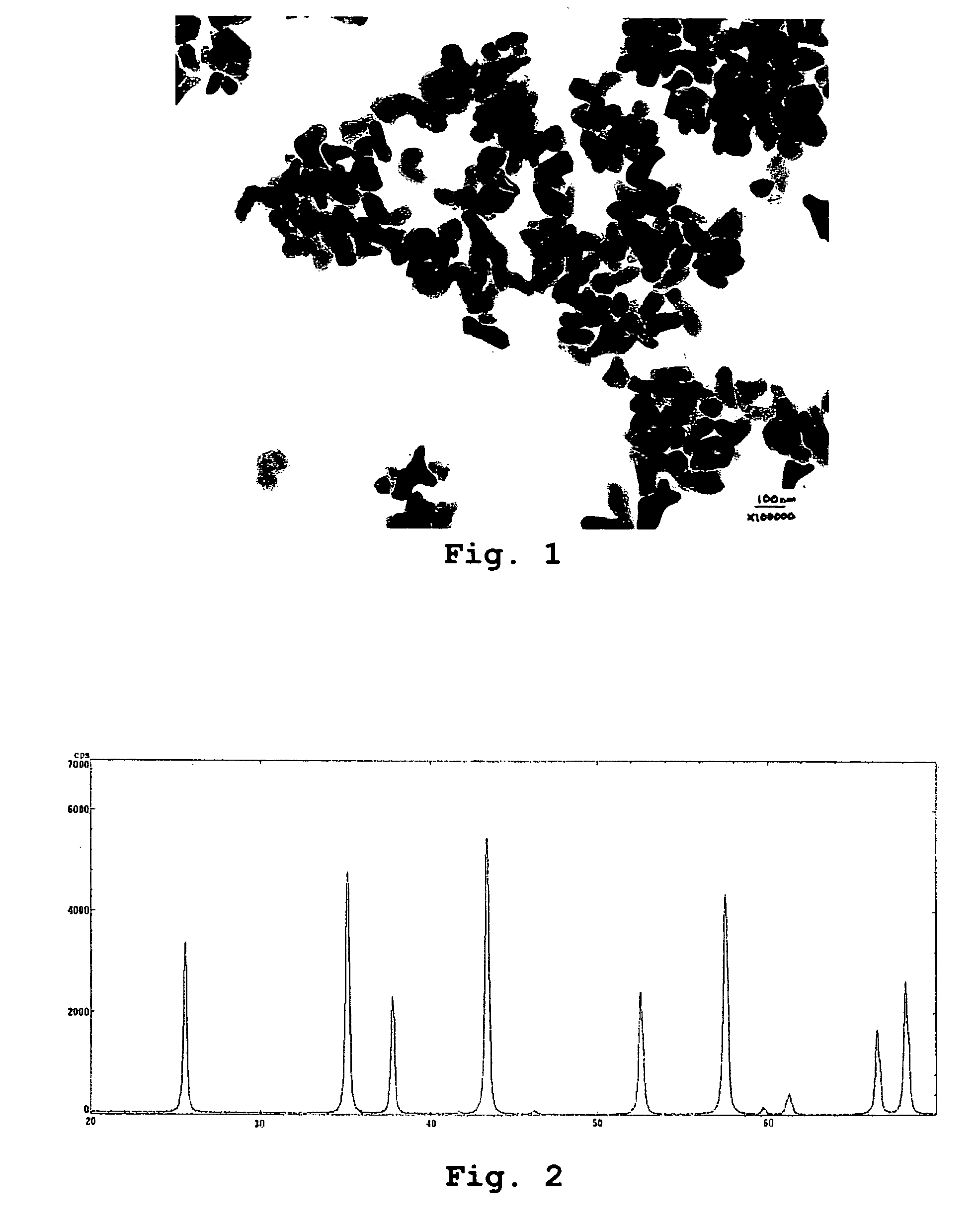

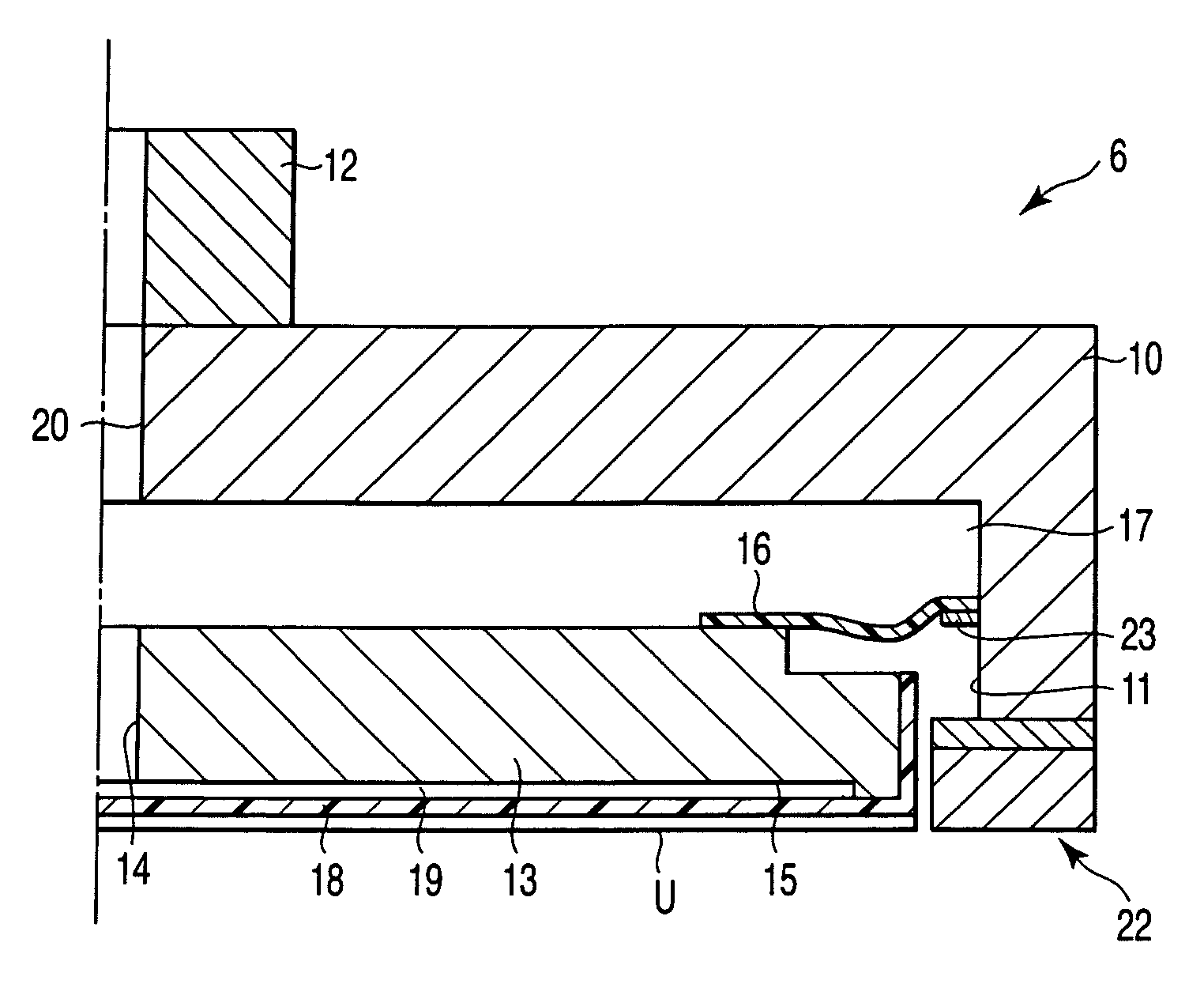

Method for producing alpha-alumina powder

InactiveUS7351394B2Increase frictionImprove propertiesMaterial nanotechnologyPlastic/resin/waxes insulatorsSeed crystalAluminium

A method for producing an α-alumina powder is described. The method for producing an α-alumina powder comprises a step of calcining an aluminum salt in the presence of a seed crystal at 600-890° C.

Owner:SUMITOMO CHEM CO LTD

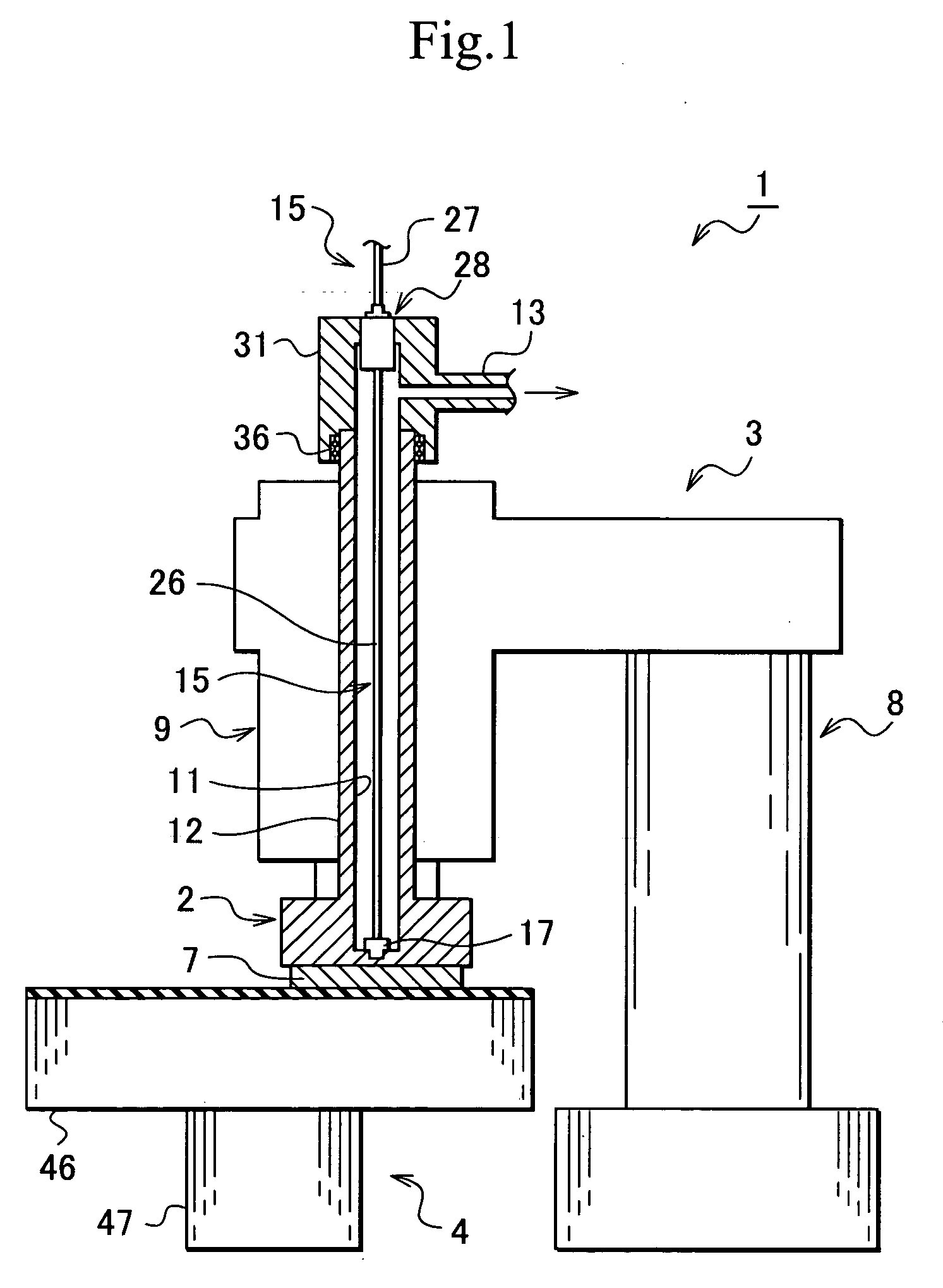

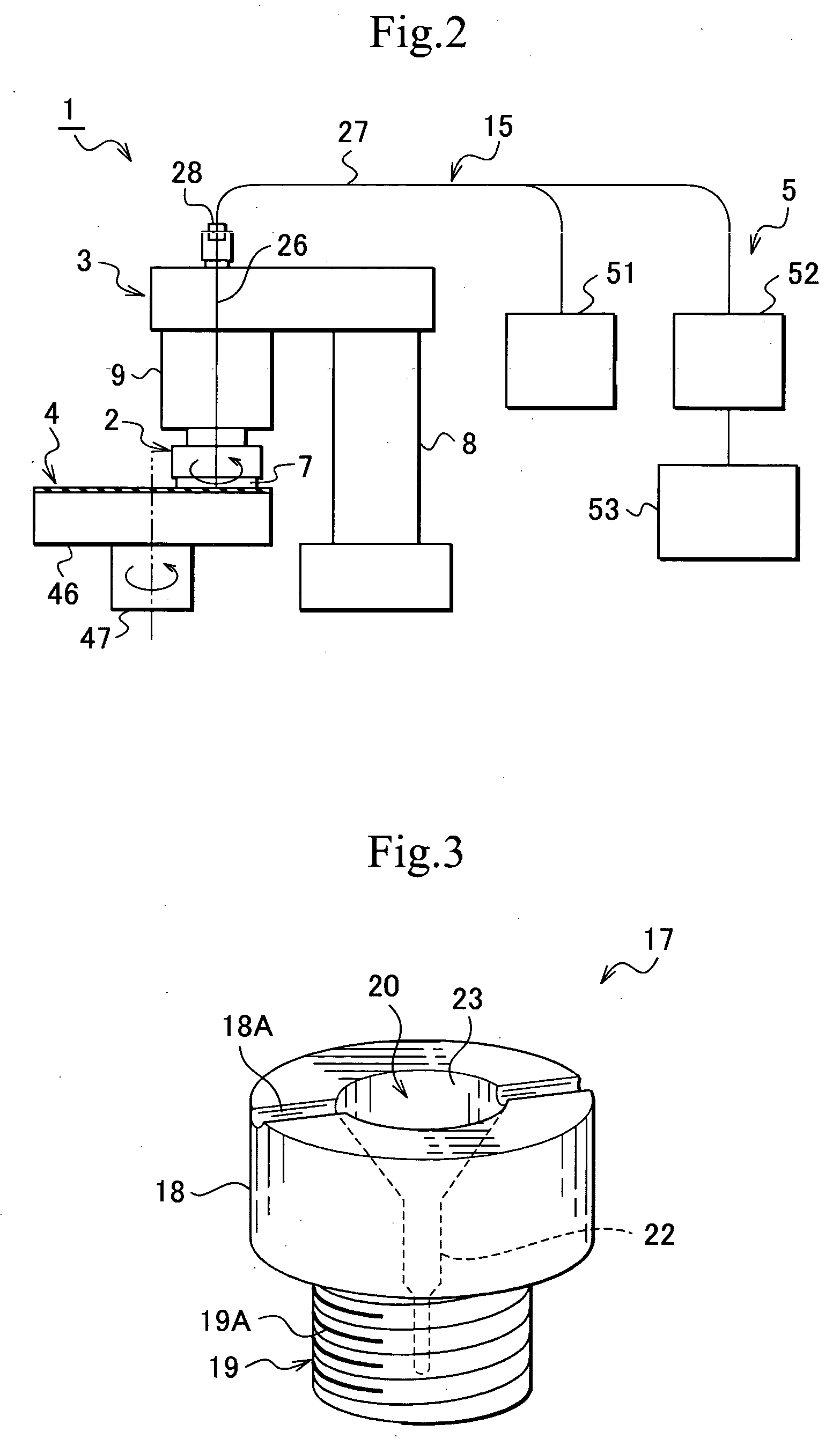

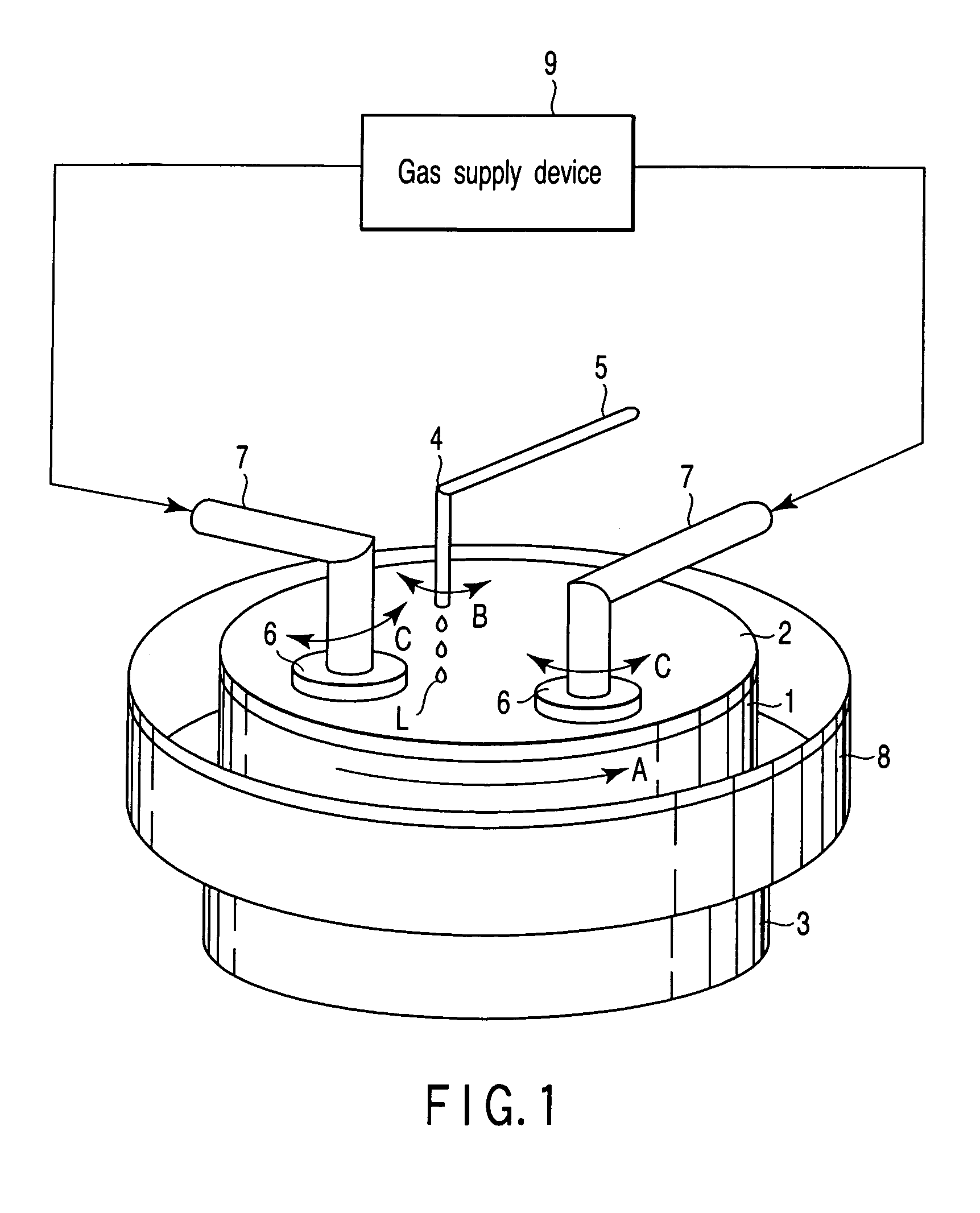

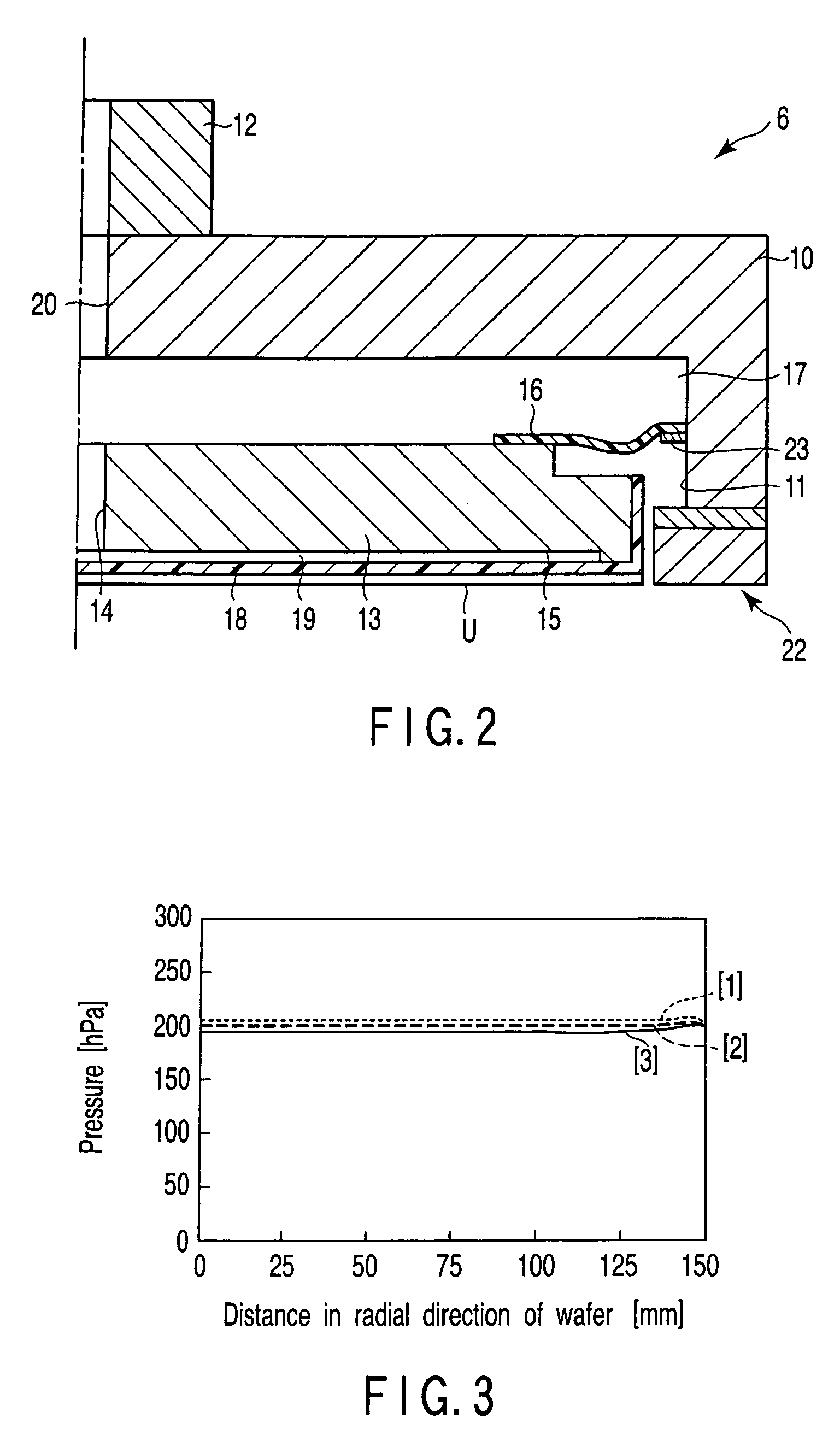

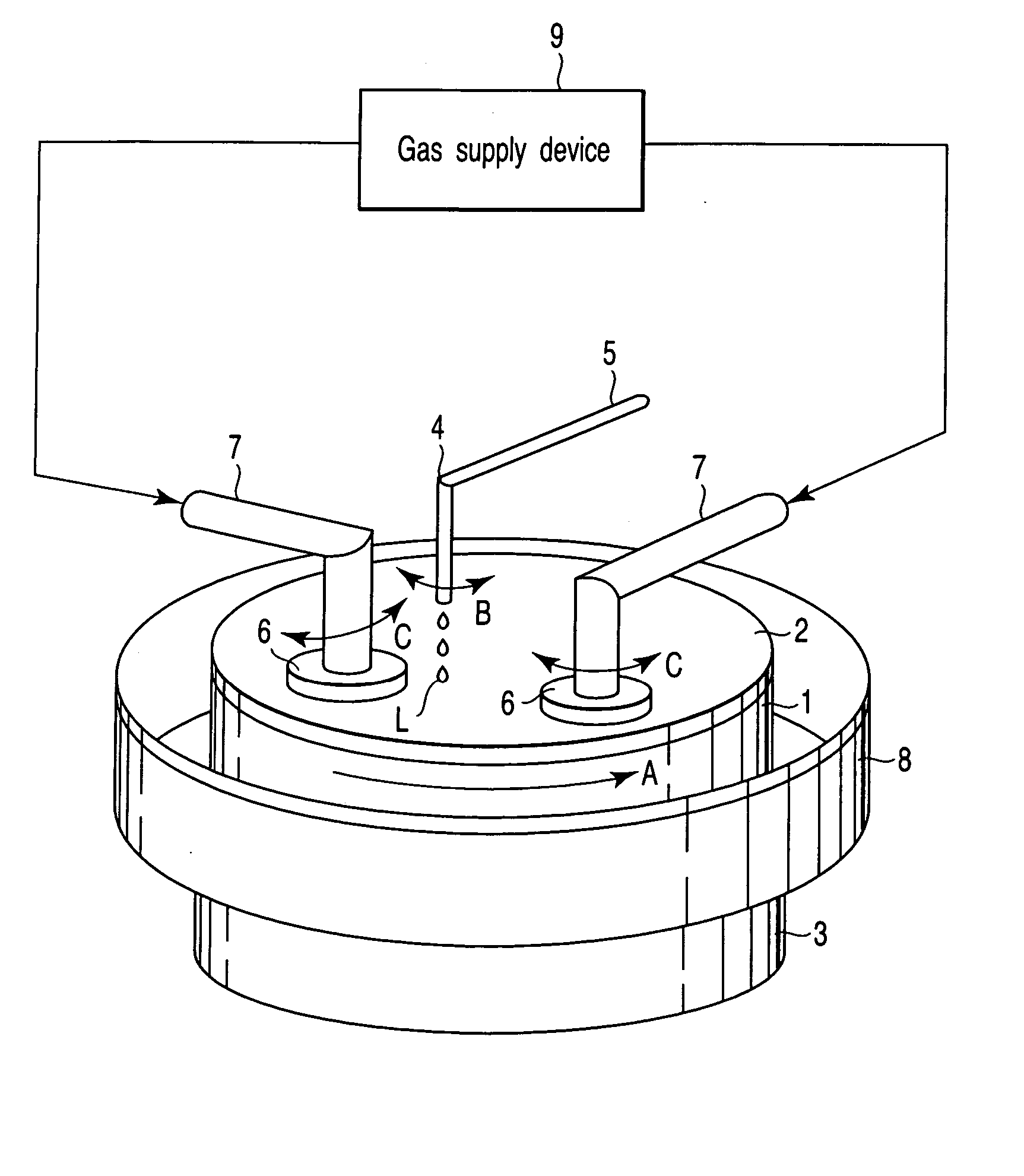

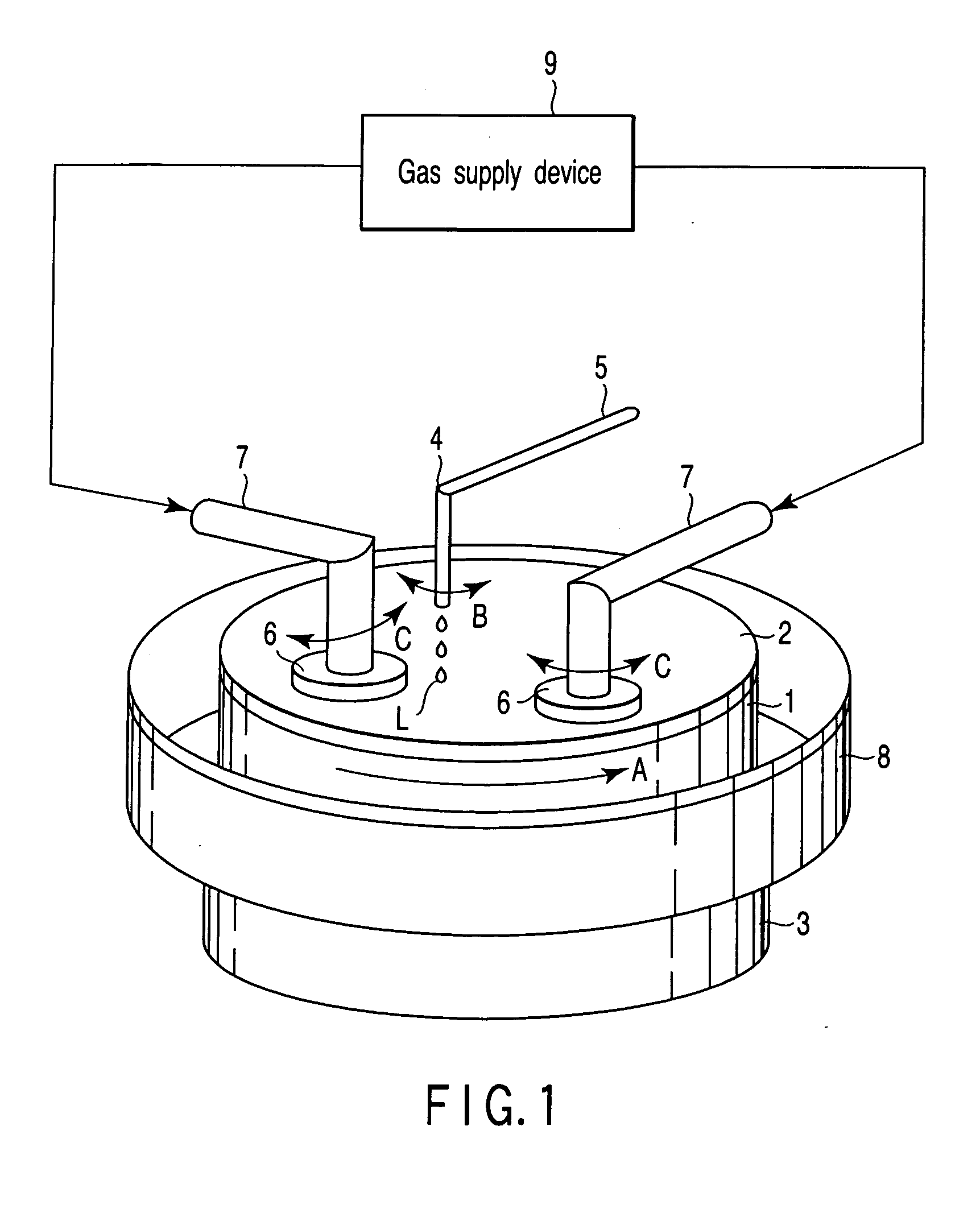

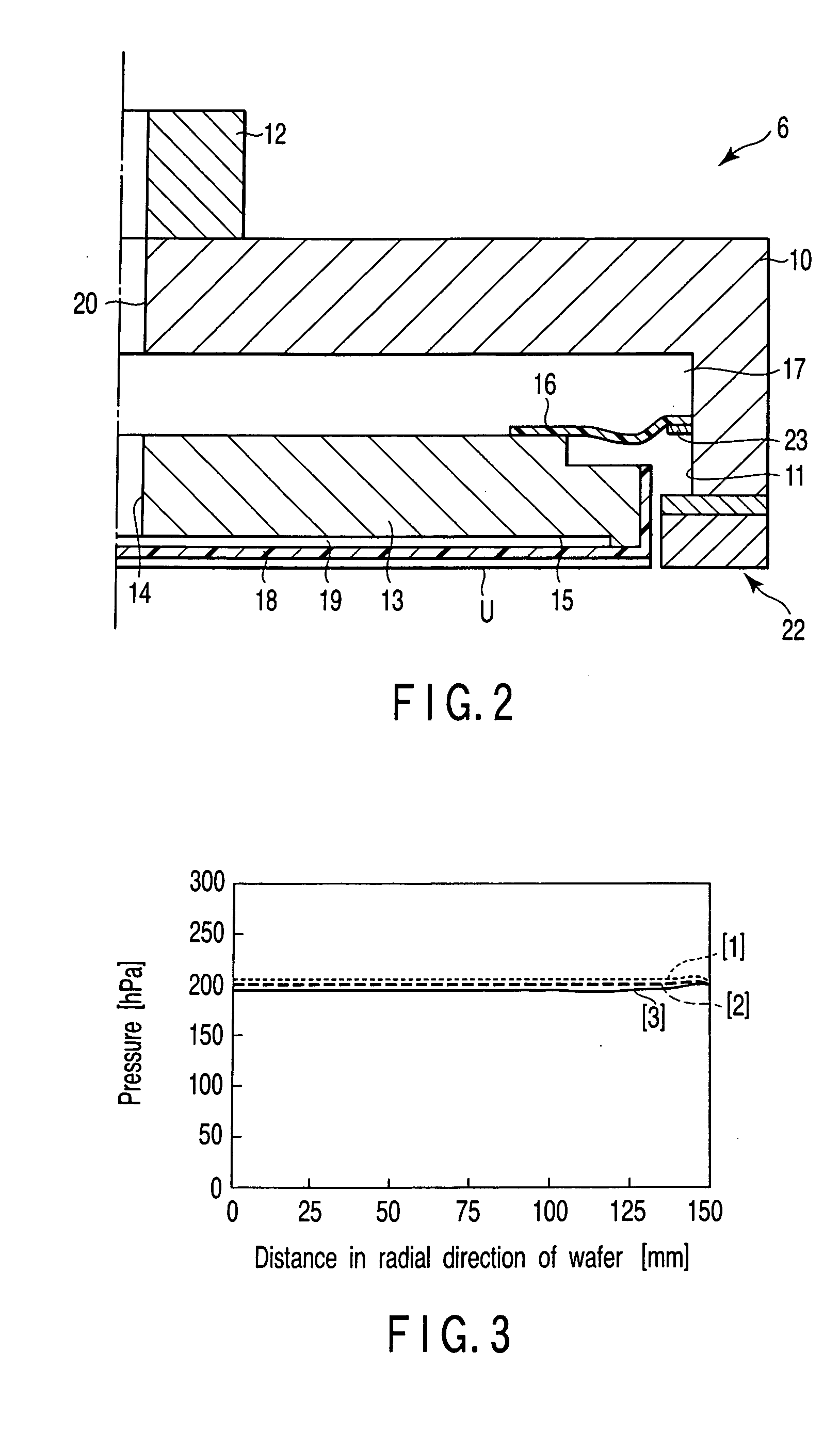

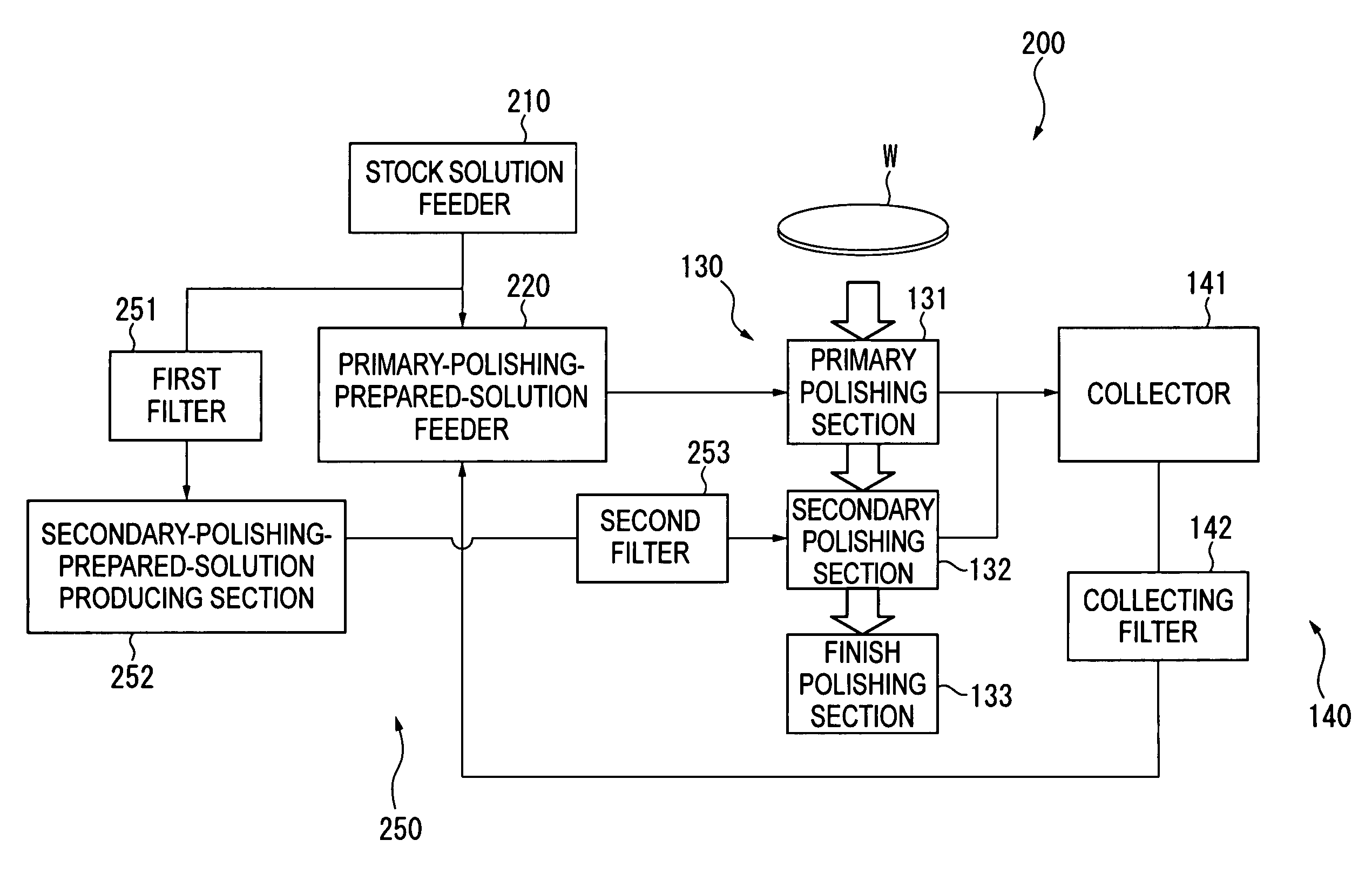

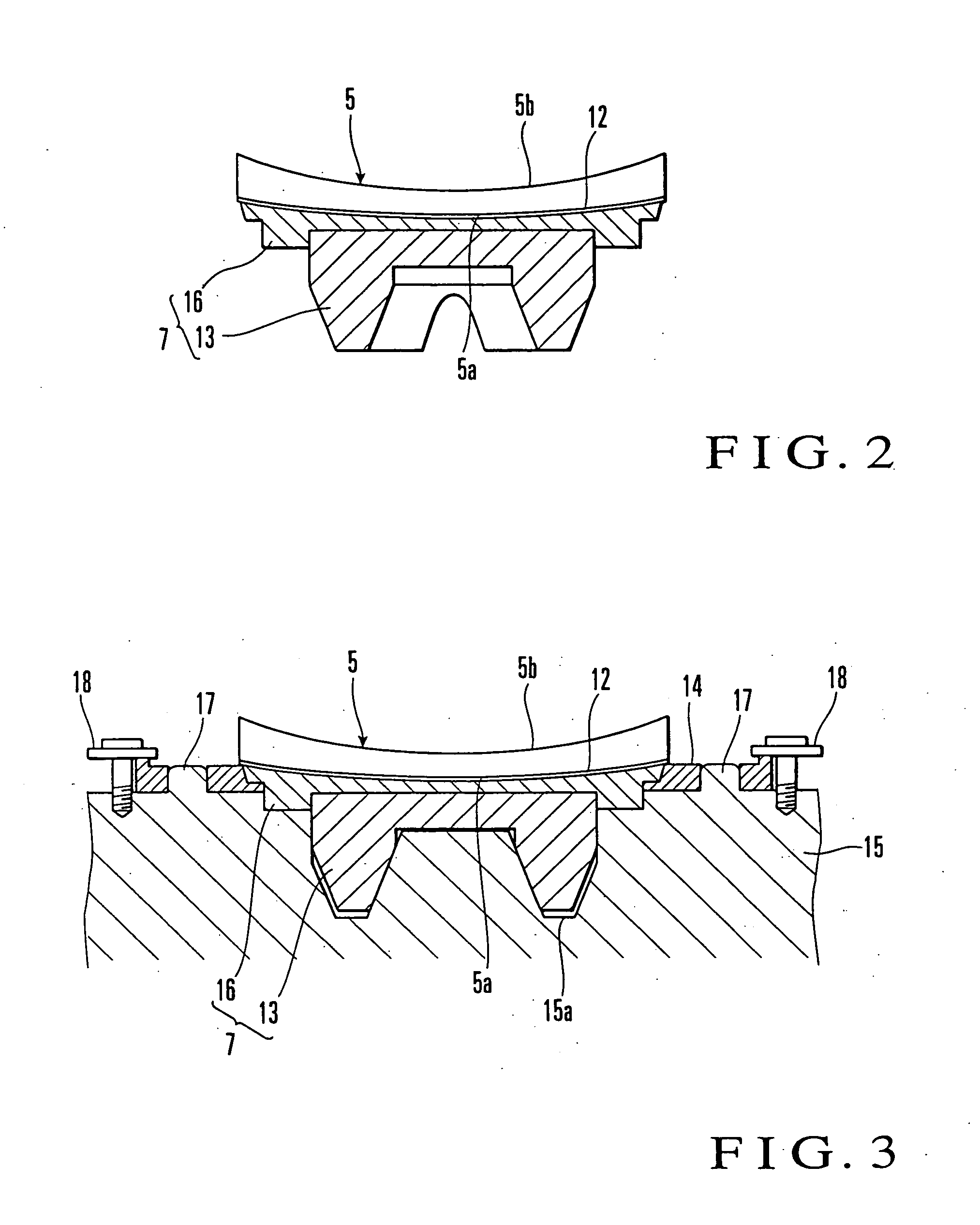

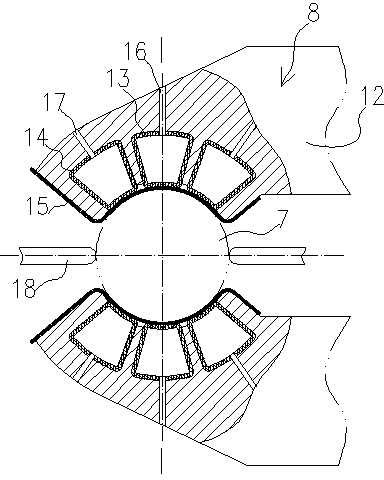

Polishing head and polishing apparatus

ActiveUS6976908B2Accurate polishingReduce impactPolishing machinesRevolution surface grinding machinesGas supplyIncrease pressure

A polishing head includes a head body, a first recessed portion formed in the lower surface of the head body, a support plate which can be moved up and down in the first recessed portion, a first film-like member in which a first space is formed between the upper surface of the support plate and the head body, a second recessed portion formed in a lower surface of the support plate, a second film-like member, in which a second space is formed between the second film-like member and the support plate, and which holds a wafer on the lower, a communicating hole which is formed in the support plate to communicate the first space with the second space, and a gas supply device which increases pressures in the first and second spaces with a fluid to equal pressures to bring the object into press contact with the polishing pad.

Owner:GLOBALWAFERS JAPAN

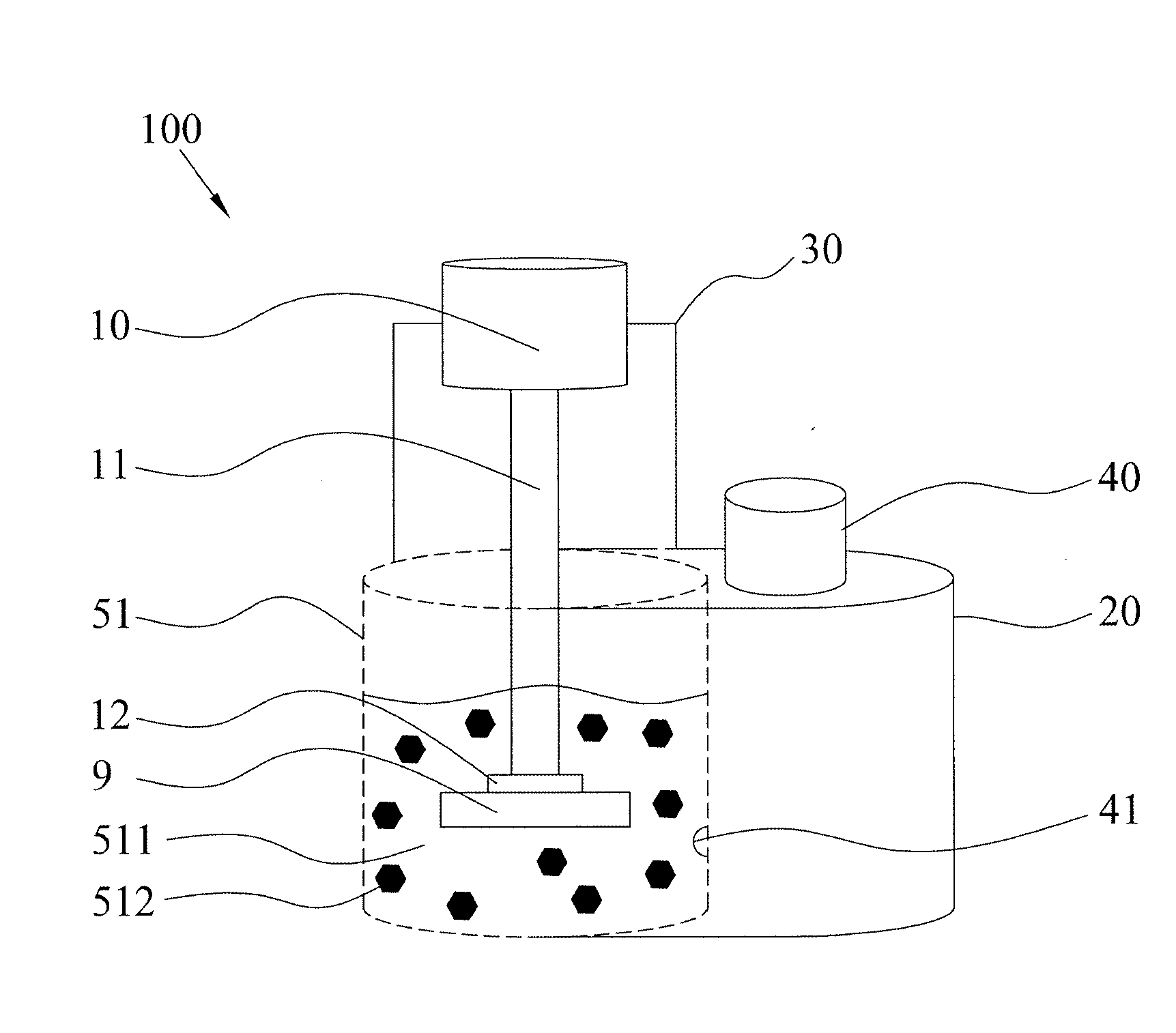

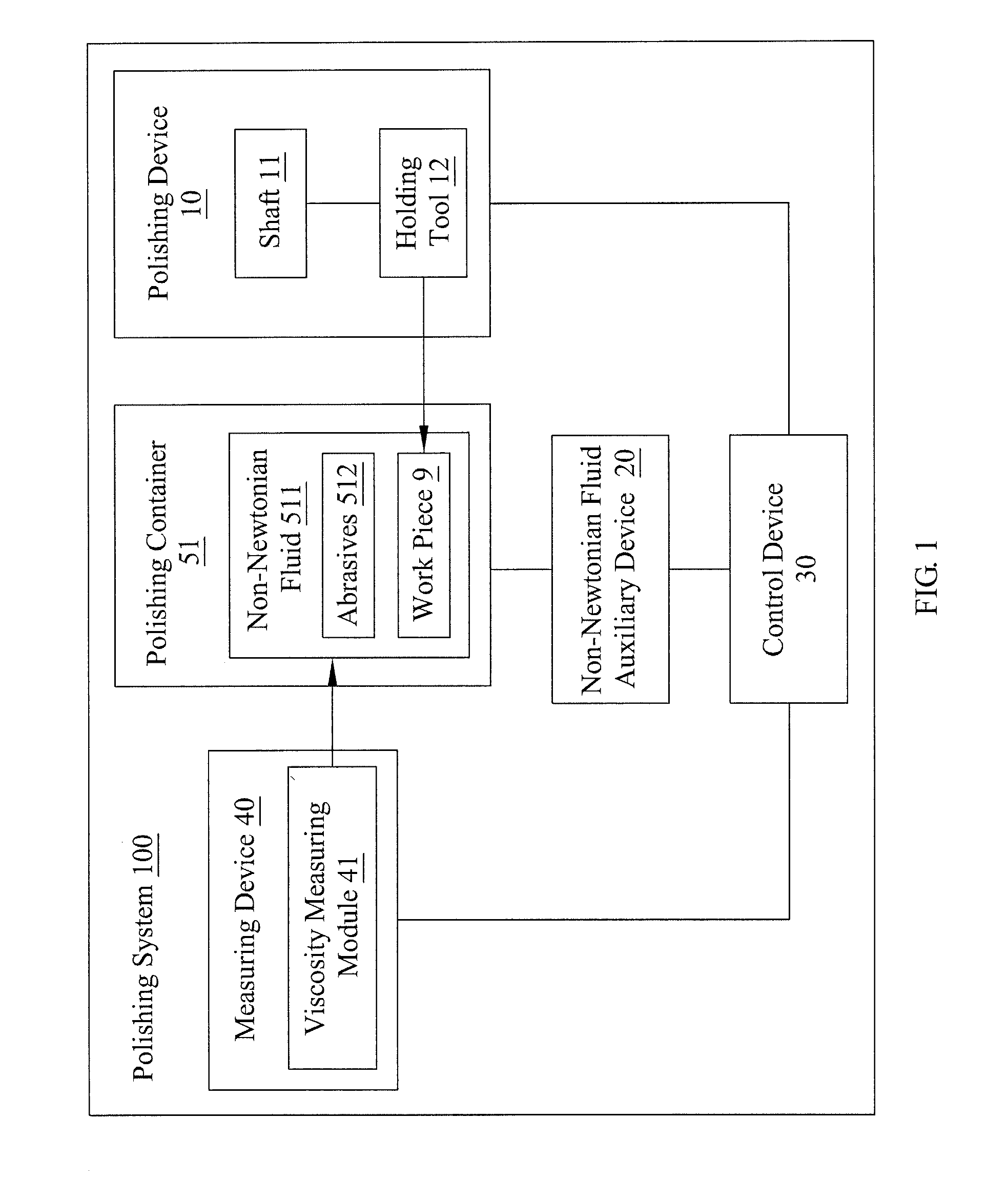

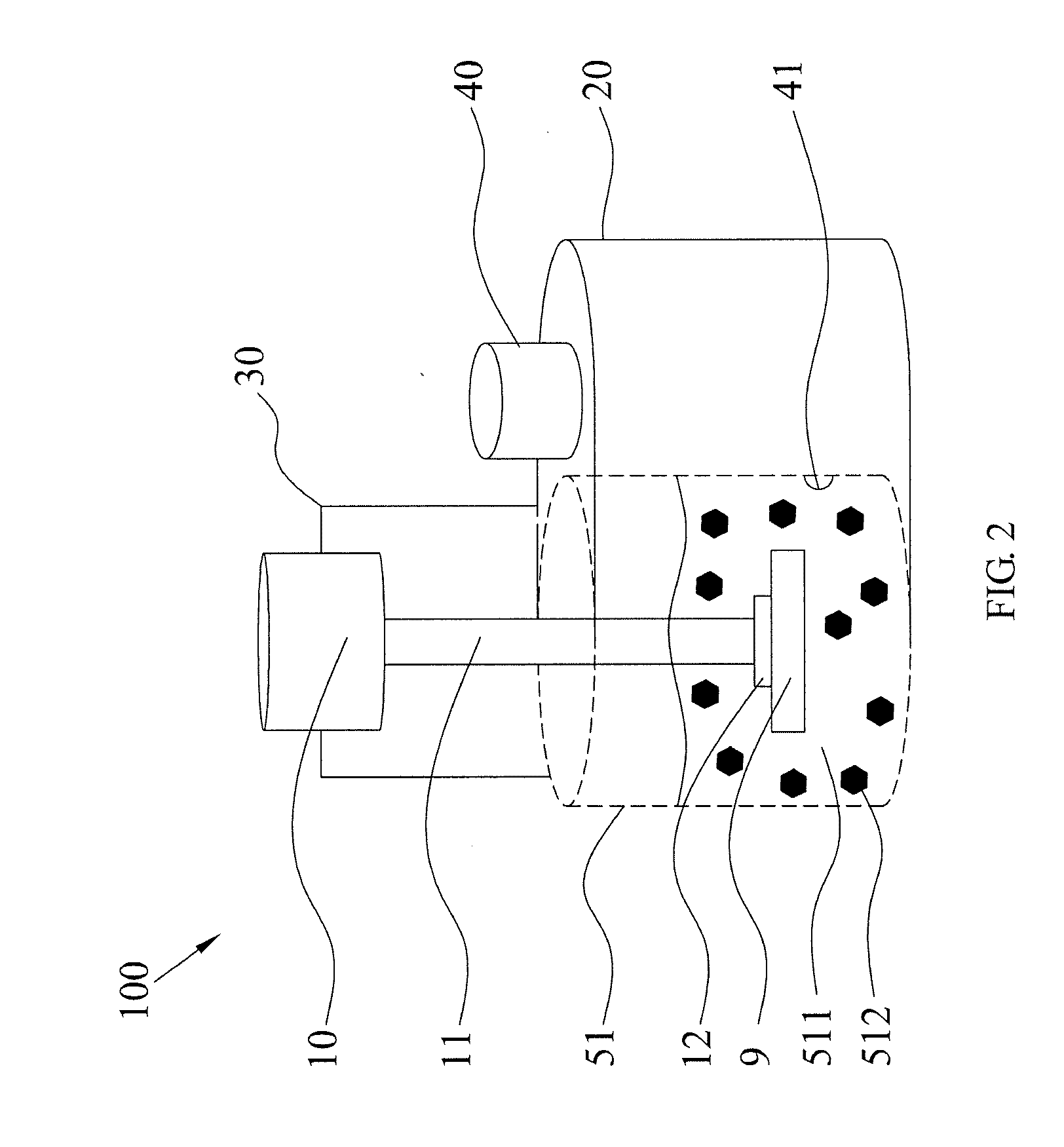

Polishing system based on the non-newton fluid and polishing method thereof

InactiveUS20170050285A1Uniform surface finishPrecise of polishing processEdge grinding machinesPolishing machinesAbrasive agentThree dimensional shape

A polishing system based on a non-Newtonian fluid and a polishing method thereof are provided. The polishing system includes a polishing device, a non-Newtonian fluid auxiliary device and a control device. The polishing device is able to move a work piece in a polishing container containing the non-Newtonian fluid with abrasives that cause the polishing action. The non-Newtonian fluid auxiliary device is able to manipulate the viscosity of the non-Newtonian fluid by varying the pressure, speed, vibration or ultrasonic frequency, which causes the abrasives to polish the work piece. The control device is used to optimize the polishing process by controlling how the polishing device moves the work piece inside the polishing container. In this way, by using the polishing method, the polishing system provided is able to polish a work piece with any three-dimensional shape.

Owner:KUNSHAN NANO NEW MATERIAL TECH

Polishing head and polishing apparatus

ActiveUS20050124269A1Reduce influenceAccurate polishingPolishing machinesRevolution surface grinding machinesEngineeringGas supply

A polishing head includes a head body, a first recessed portion formed in the lower surface of the head body, a support plate which can be moved up and down in the first recessed portion, a first film-like member in which a first space is formed between the upper surface of the support plate and the head body, a second recessed portion formed in a lower surface of the support plate, a second film-like member, in which a second space is formed between the second film-like member and the support plate, and which holds a wafer on the lower, a communicating hole which is formed in the support plate to communicate the first space with the second space, and a gas supply device which increases pressures in the first and second spaces with a fluid to equal pressures to bring the object into press contact with the polishing pad.

Owner:GLOBALWAFERS JAPAN

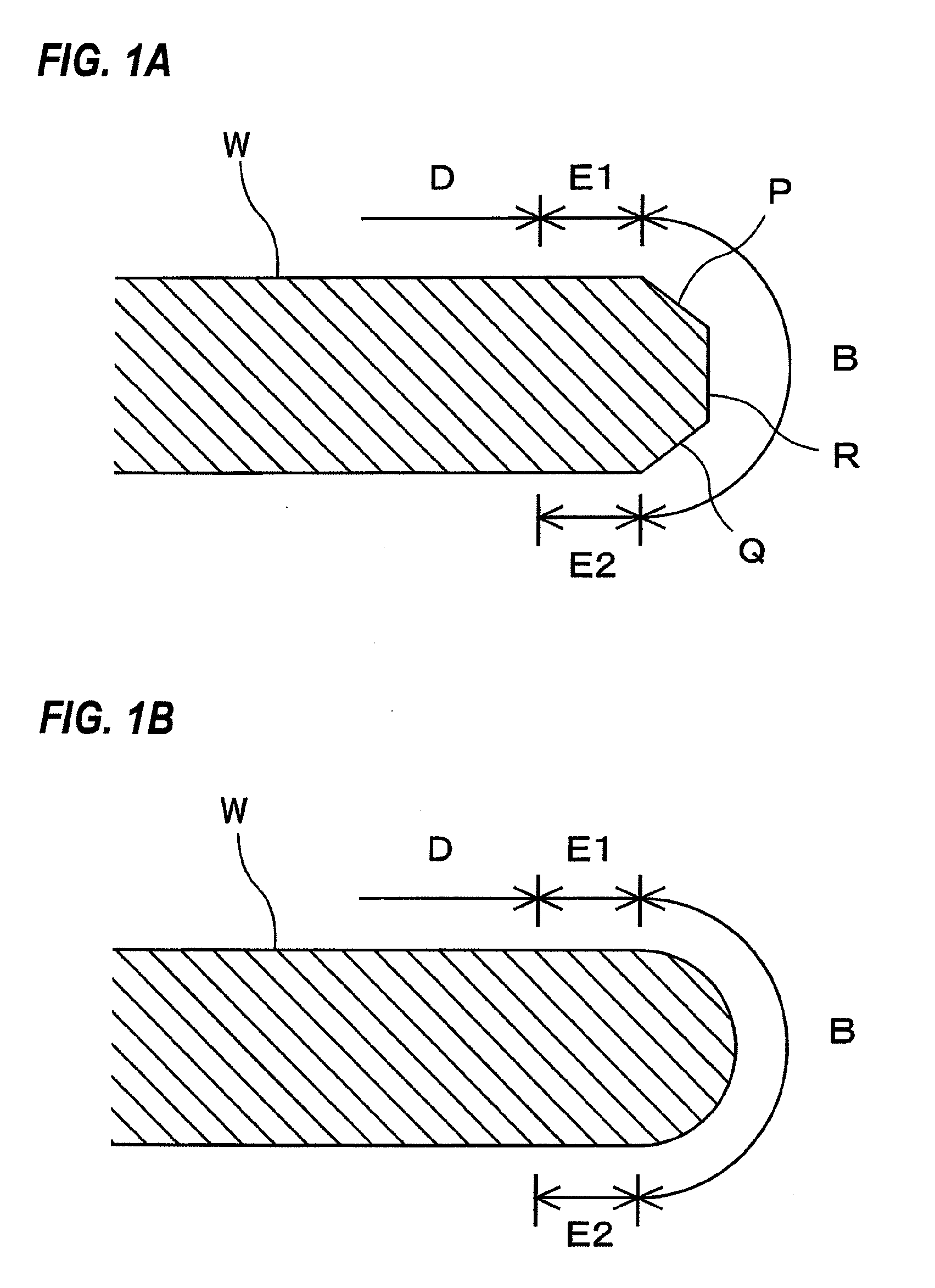

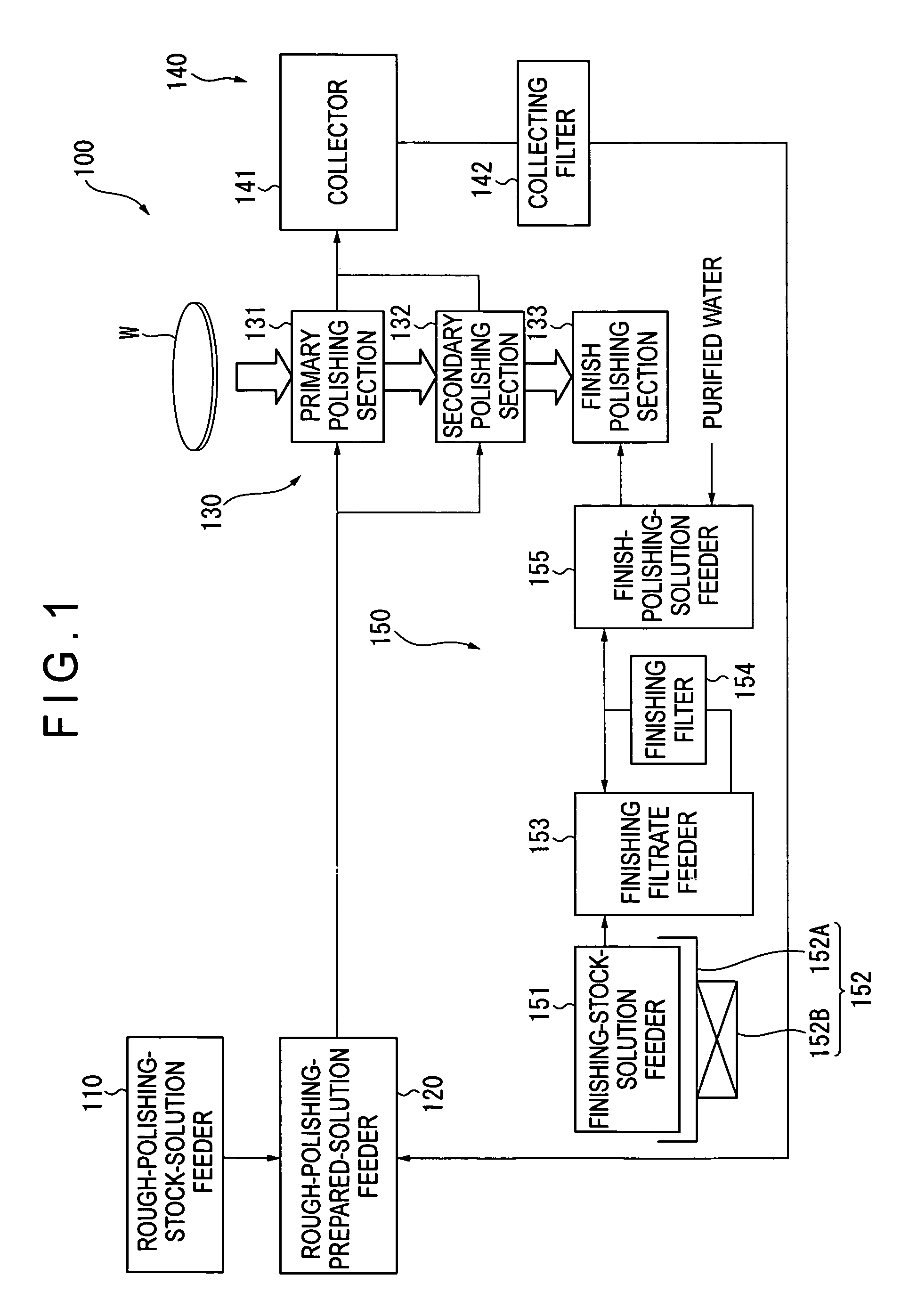

Polishing method for semiconductor wafer

ActiveUS7303691B2Accurate polishingDecorative surface effectsSemiconductor/solid-state device manufacturingSilica particleMetallurgy

Owner:SUMCO TECHXIV

Polishing robot used for external surface of iron pan

ActiveCN106891239APrevent slippageLow costGrinding carriagesPolishing machinesRotary stageControl system

The invention relates to a polishing robot used for the external surface of an iron pan. The polishing robot comprises a rotating mechanism, a polishing mechanism, an adjusting mechanism and a control system. The rotating mechanism comprises a rotating platform and a rotating shaft. The upper end of the rotating shaft extends out of the rotating platform, and fixing rods are arranged on the rotating shaft in a radiation mode. Suction cups are arranged at the ends of the corresponding fixing rods. The rotating shaft and the fixing rods are both hollow. The polishing mechanism is arranged above the rotating mechanism and comprises a polishing wheel, an oscillating rod and a supporting frame. A rail is vertically arranged in the supporting frame. A sliding block is arranged between the two side walls of the rail in a sliding mode. One end of the oscillating rod penetrates into the sliding block, and the other end of the oscillating rod is provided with the polishing wheel. The oscillating rod can adjust the position of the polishing wheel through the adjusting mechanism, so that the polishing wheel is attached to the external surface of a pan blank to be polished and is further matched with the rotating mechanism to achieve polishing. Due to arrangement of the polishing mechanism, the adjusting mechanism and the rotating mechanism, the polishing robot is simple in structure, reasonable in design, convenient to use, and capable of saving manpower and material resources, improving production efficiency and reducing enterprise cost.

Owner:HENAN MOXI MACHINE MFG

Method of polishing thin film formed on substrate

ActiveUS7262849B2Accurately determinedAccurate polishingPolarisation-affecting propertiesSemiconductor/solid-state device manufacturingOptoelectronicsPhysical property

A method for polishing a thin film formed on a substrate includes planarizing a thin film formed on a reference substrate by a CMP process such that the thin film remains on the reference substrate. After the planarizing, the thin film is cleaned, and then values of Δ and Ψ with respect to the cleaned thin film are measured by ellipsometry. A physical property of the thin film is determined based on the Δ and Ψ which have been measured by ellipsometry, and a polishing condition for an other substrate having a thin film to be polished is set based on physical property data which are obtained by the determining of the physical property.

Owner:EBARA CORP

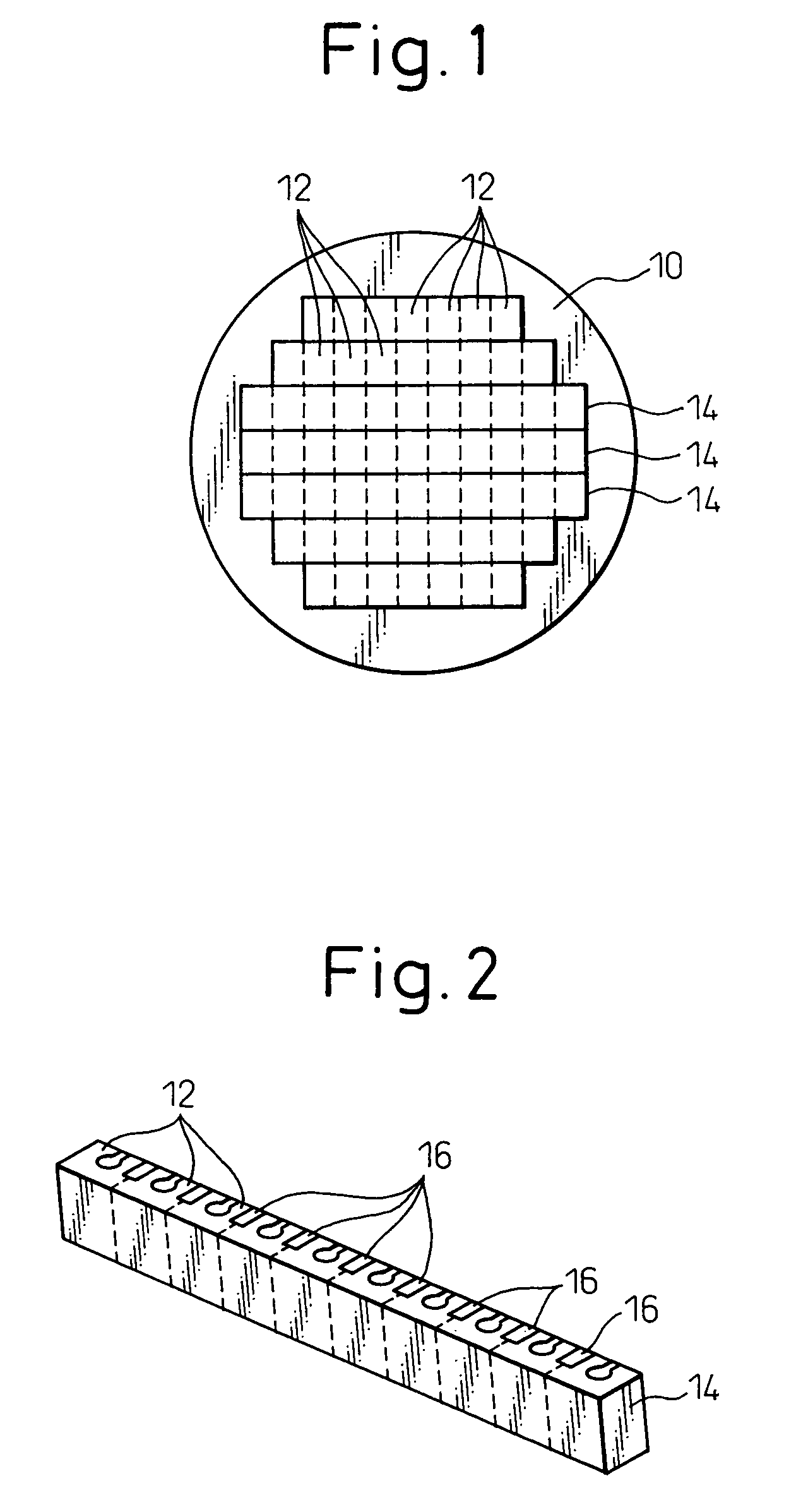

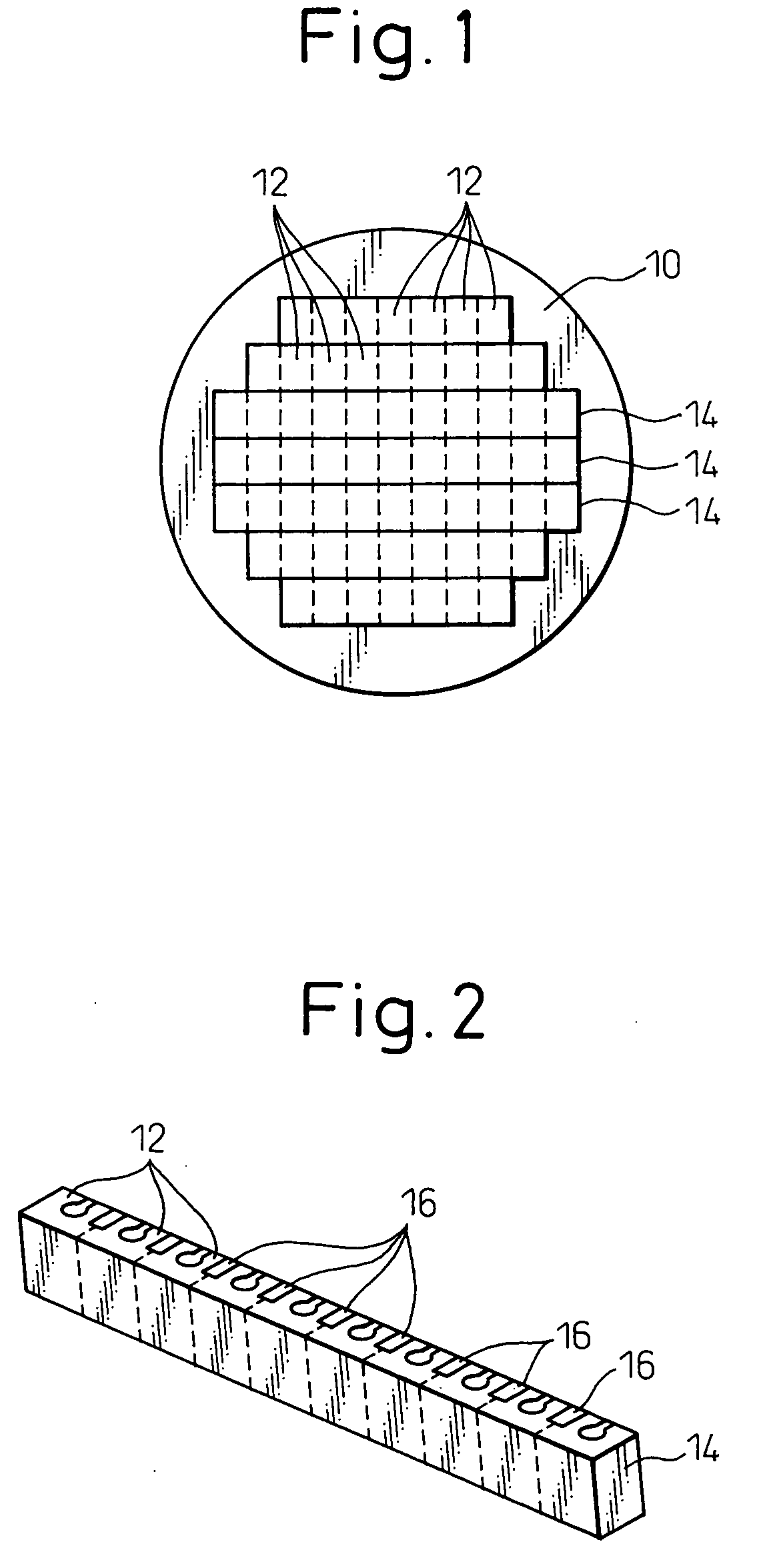

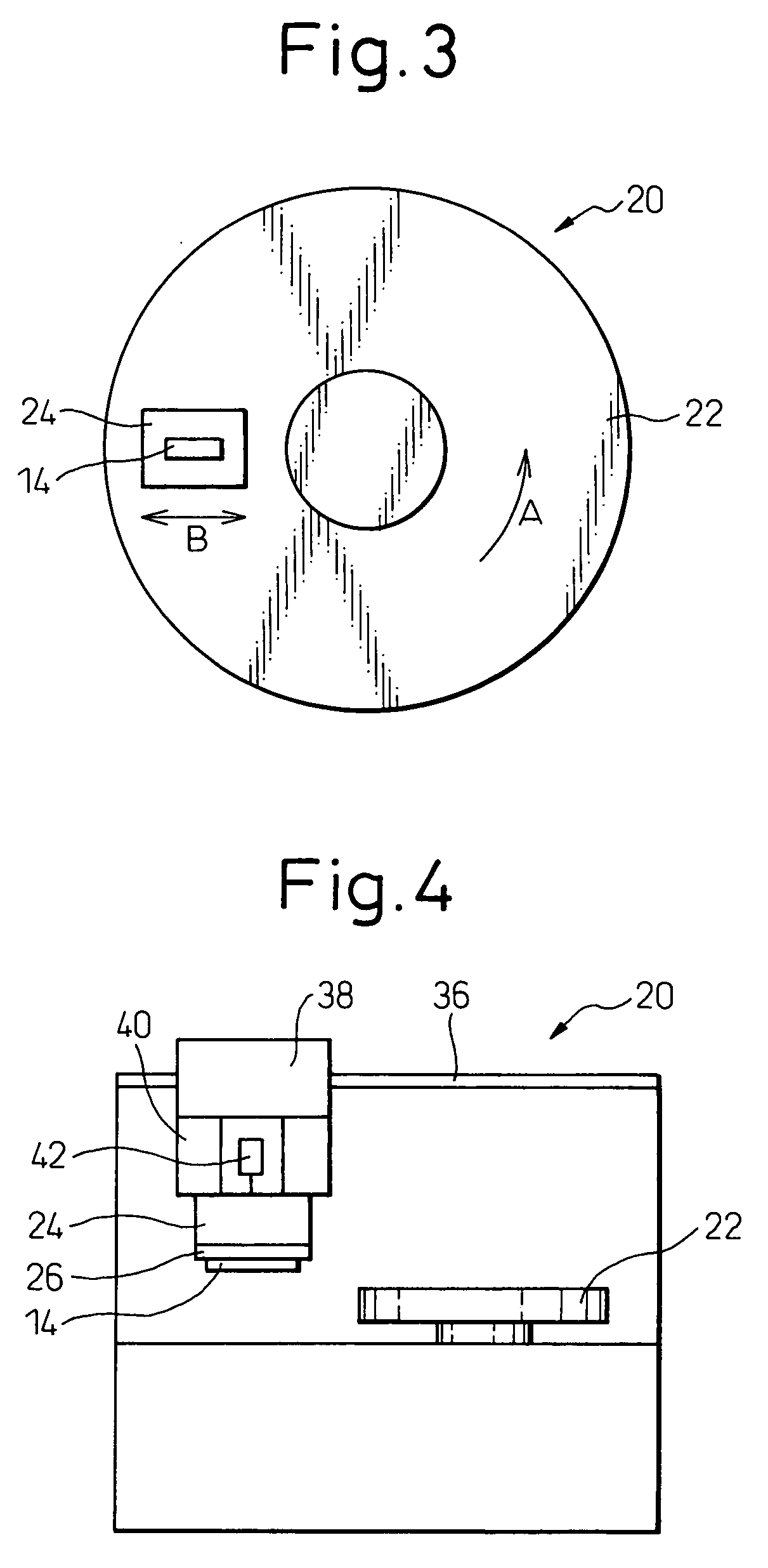

Apparatus and method for polishing row bars

InactiveUS6905394B2Accurate polishingEasily and reliably securedLapping machinesGrinding feed controlAir cylinder PressSurface plate

An apparatus and a method for polishing a row bar including magnetic head sliders. A lapping surface plate is rotatable, and a housing is movable above the lapping surface plate. A jig is secured to the housing for holding the row bar. The jig is formed by an elongated rigid member having a plurality of holes and an elongated elastic member fixed to the rigid member. An air cylinder presses the whole row bar, and a pressing devices individually presses portions of the elastic member corresponding to magnetic head sliders of the row bar through the holes of the rigid member. A portion of the elastic member is deformed to press a portion of the row bar in response to a change in the measured resistance of ELG resistance elements in the row bar.

Owner:FUJITSU LTD

Apparatus and method for polishing row bars

InactiveUS20050064793A1Accurate polishingEasily and reliably securedLapping machinesGrinding feed controlAir cylinder PressResistive element

An apparatus and a method for polishing a row bar including magnetic head sliders. A lapping surface plate is rotatable, and a housing is movable above the lapping surface plate. A jig is secured to the housing for holding the row bar. The jig is formed by an elongated rigid member having a plurality of holes and an elongated elastic member fixed to the rigid member. An air cylinder presses the whole row bar, and a pressing devices individually presses portions of the elastic member corresponding to magnetic head sliders of the row bar through the holes of the rigid member. A portion of the elastic member is deformed to press a portion of the row bar in response to a change in the measured resistance of ELG resistance elements in the row bar.

Owner:FUJITSU LTD

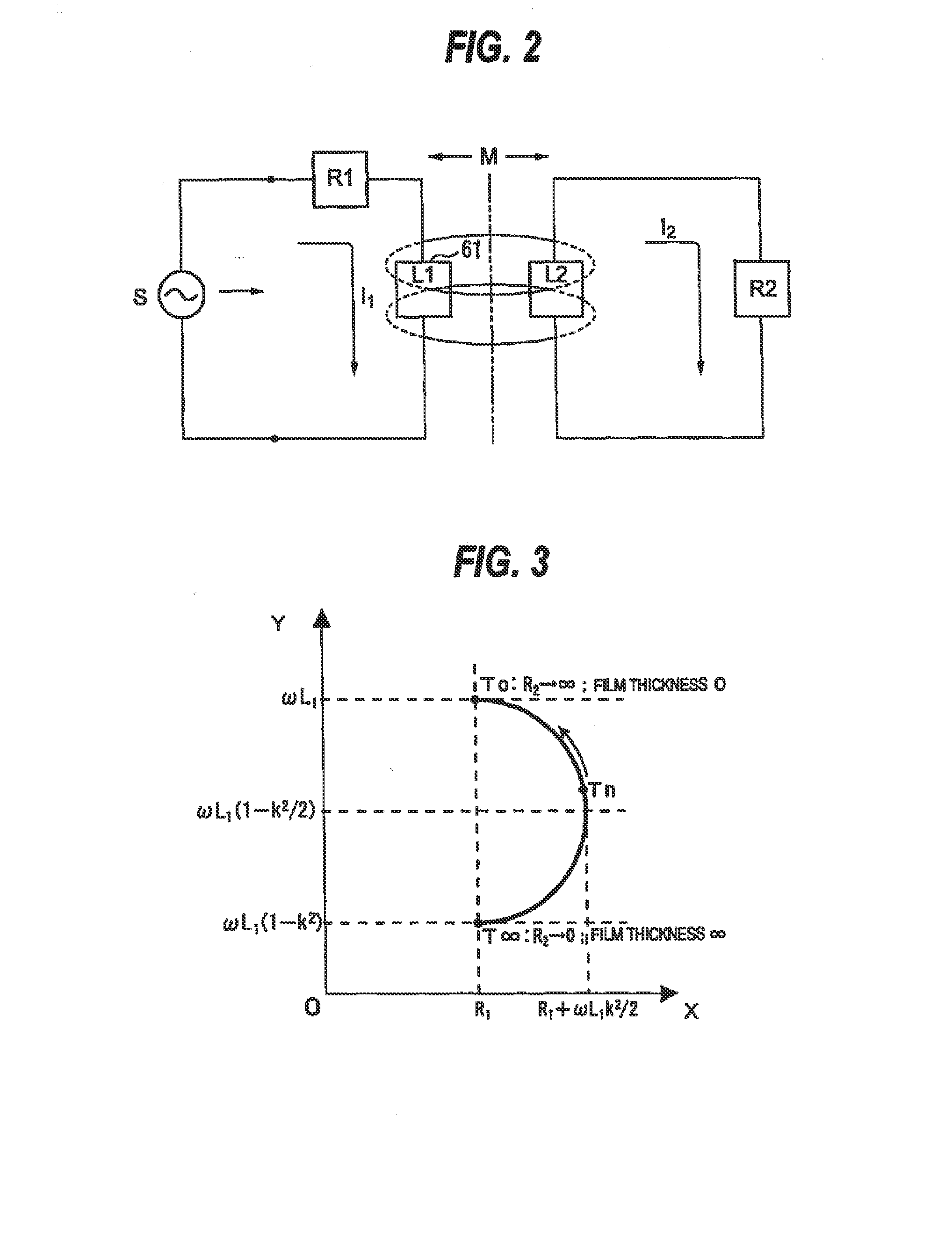

Polishing method

ActiveUS20150099424A1Accurate polishingSemiconductor/solid-state device manufacturingLapping machinesElectrically conductiveConductive membrane

A polishing method includes: rotating a polishing table that supports a polishing pad; polishing a conductive film by pressing a substrate having the conductive film against the polishing pad; obtaining a film thickness signal with use of an eddy current film-thickness sensor disposed in the polishing table; determining a thickness of the polishing pad based on the film thickness signal; determining a polishing rate of the conductive film corresponding to the determined thickness of the polishing pad; calculating an expected amount of polishing of the conductive film to be polished at the determined polishing rate for a predetermined polishing time; calculating a temporary end-point film thickness by adding the expected amount of polishing to a target thickness; and terminating polishing of the conductive film when the predetermined polishing time has elapsed from a point of time when the thickness of the conductive film has reached the temporary end-point film thickness.

Owner:EBARA CORP

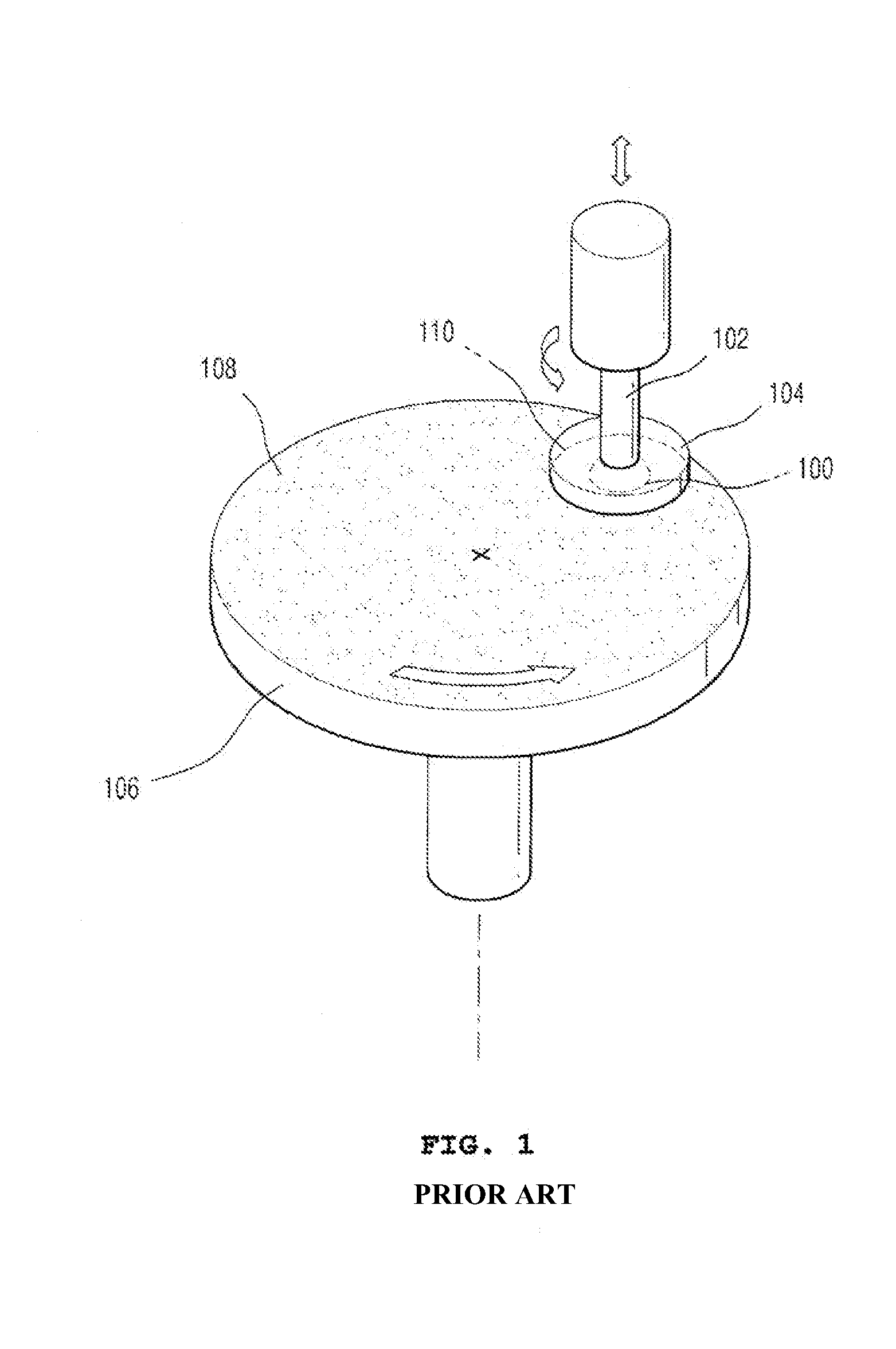

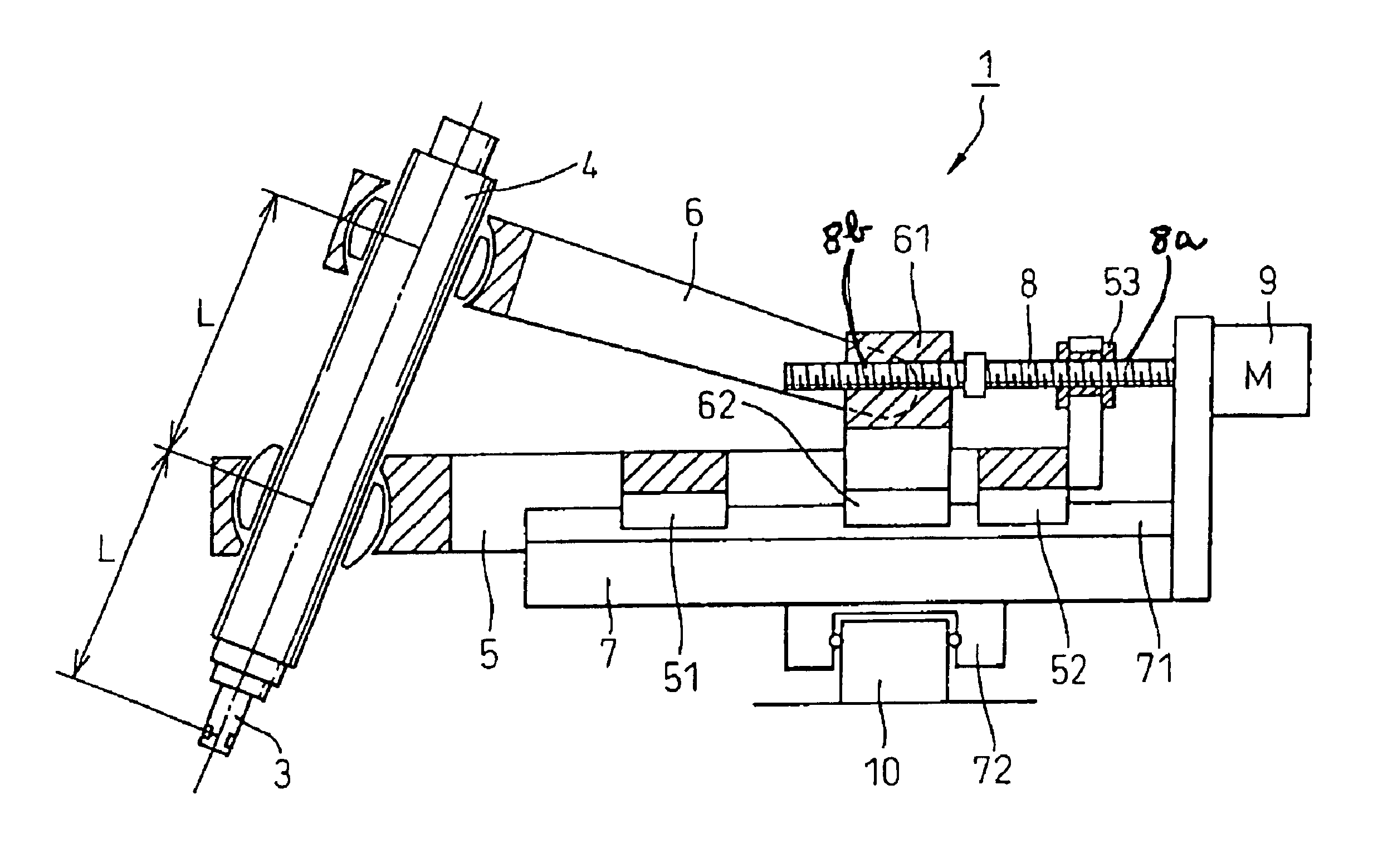

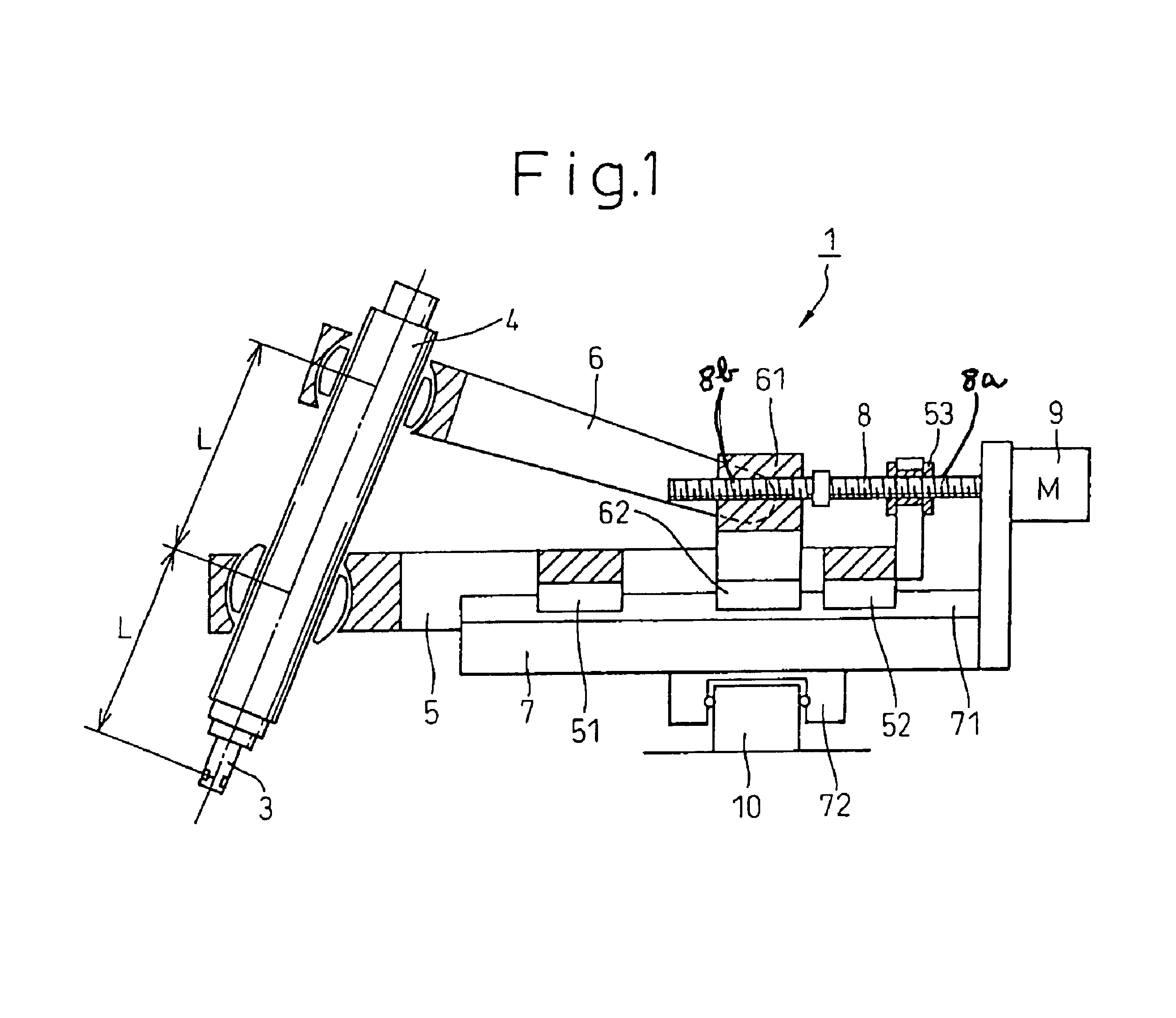

Polishing machine for polishing periphery of sheet

InactiveUS6913526B2Accurate polishingImprove accuracyEdge grinding machinesGrinding drivesRotational axisSheet material

A polishing machine for polishing a periphery of a sheet of the present invention comprises a grinding shaft tilting mechanism (1) capable of changing a tilting angle of a rotary shaft of a grinding stone (3) with respect to a rotary shaft of the sheet (2) and also capable of changing its tilting direction. Accordingly, in a recess portion or a protrusion portion in the periphery, when the tilting direction is changed while the tilting angle is being maintained, chamfering (polishing) can be executed with high accuracy in the same manner as that of the outer circumferential portion of the sheet.

Owner:TOKYO SEIMITSU

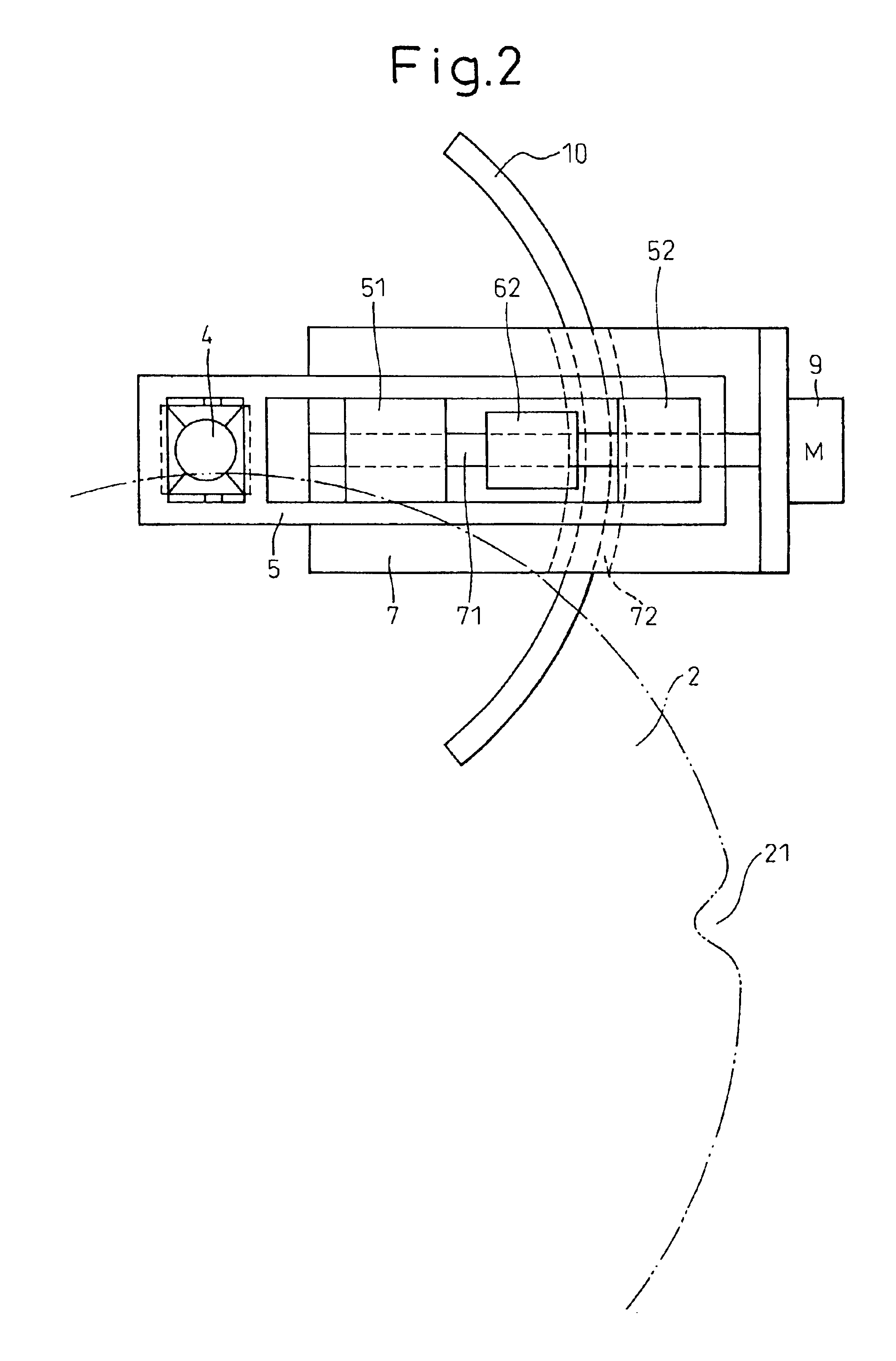

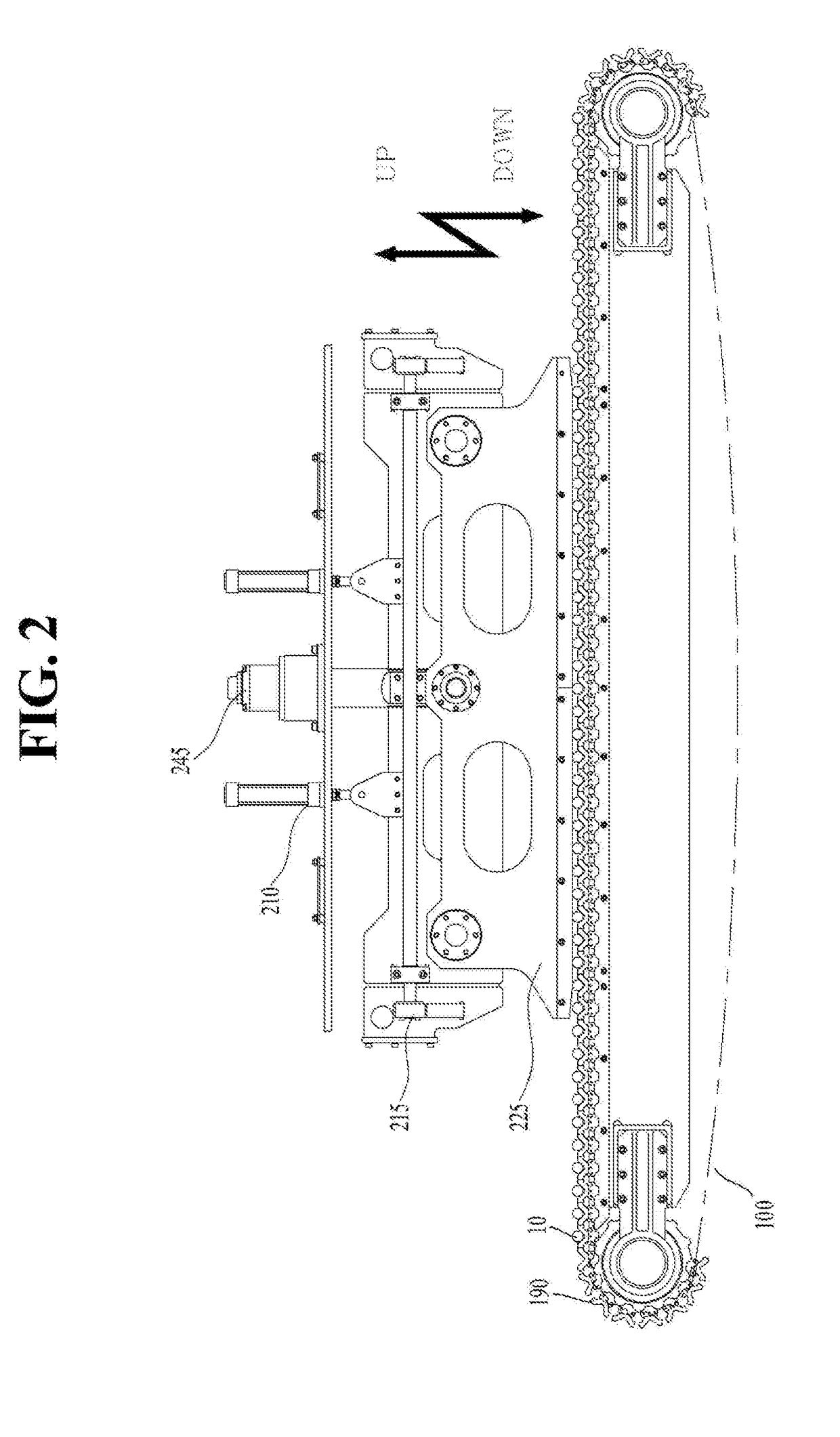

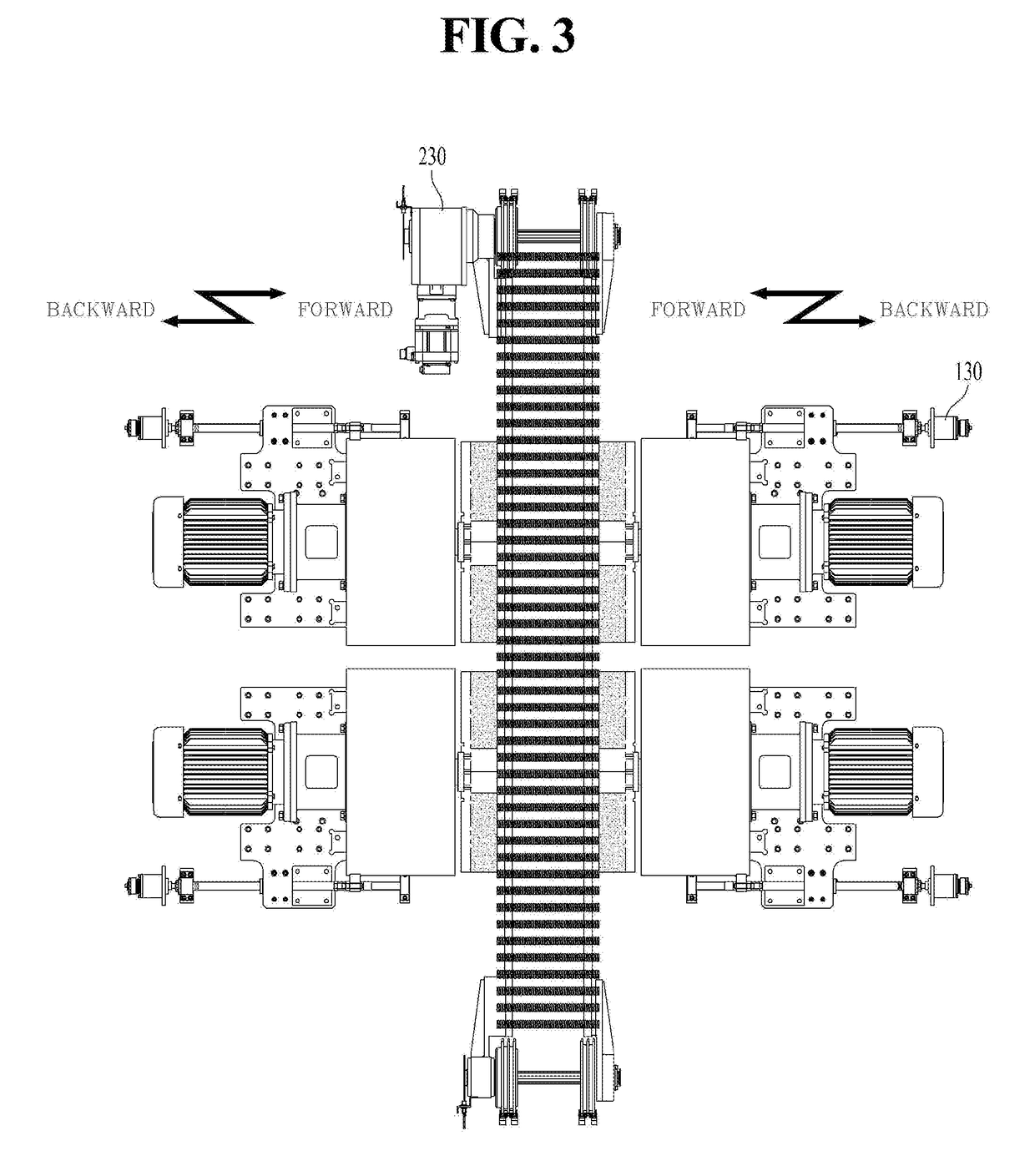

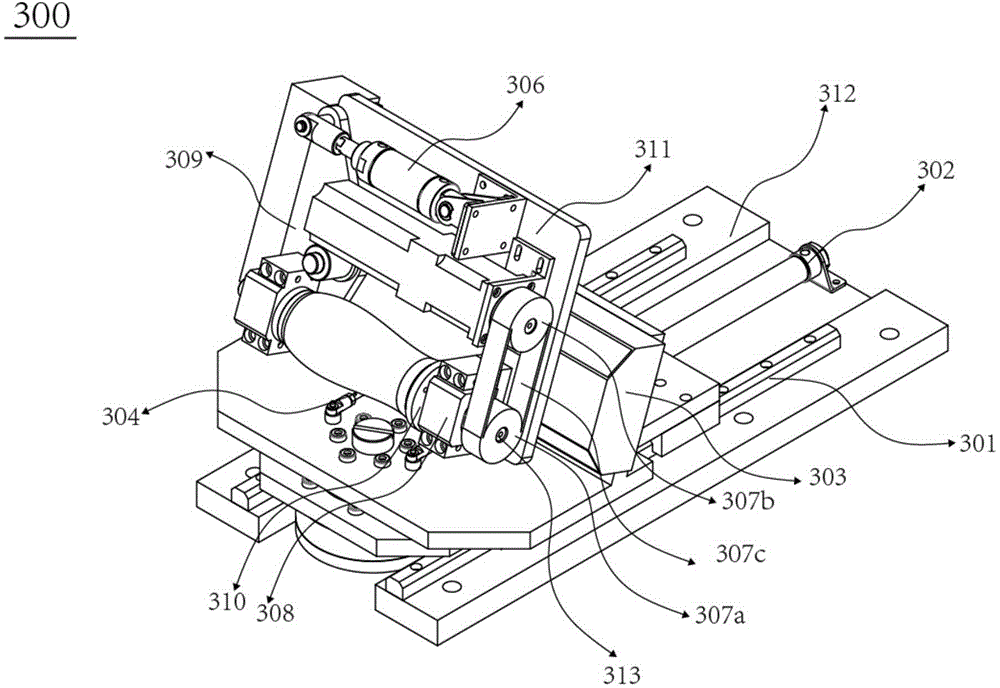

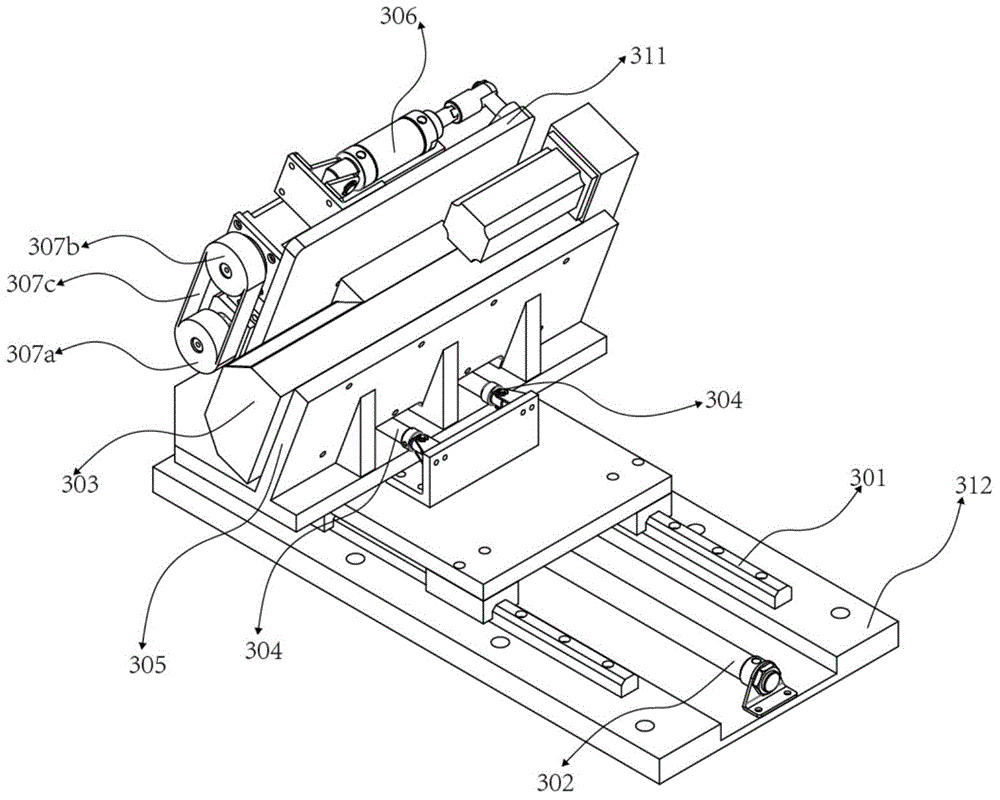

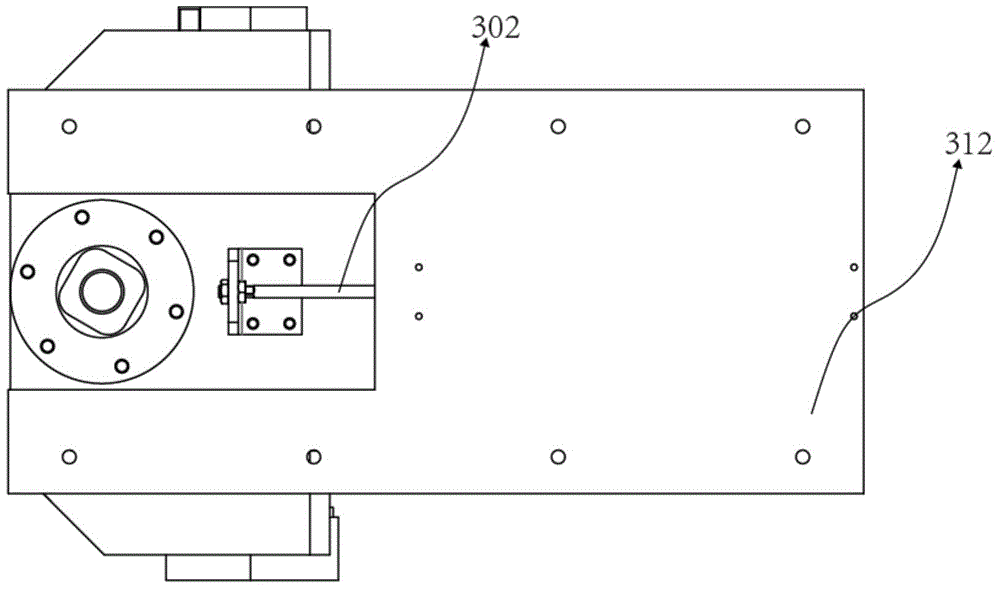

Continuous Compression Wire Spring Polishing Apparatus Configured to Easily Replace Two Parallel and Opposite Grindstones

ActiveUS20180339389A1Reduce replacement timeEasily replaceGrinding wheel securing apparatusGrinding drivesPneumatic cylinderGrindstone

The present disclosure relates to a contiguous compression wire sprang polishing apparatus that continuously polishes end surfaces of compression wise springs (10) by upper and lower chain conveyers 100 and 200 and grinding units 300. The apparatus includes: two gaming units (300) each having a grindstone (350) to which rotational force of a motor (240) is transmitted through a gear box (260), the motor (240) having a rotary shaft being located above a central axis of the grindstone (350), and the two grinding units (300) being installed to be parallel and opposite to each other at opposite sides of a compression wire spring (10) fixed to the continuous compression wire spring polishing apparatus so as to polish opposite end surfaces of the compression wire spring (10); two hinge shafts (140), which are fixed at positions, which are spaced apart from grindstones in the lowest surface of the grinding units (300) by a predetermined distance, and which are inserted into and coupled to bearings, which are fixed to a body of the polishing apparatus; an upper guide (225) configured to prevent the compression wire spring (10) from springing out and a rod end fixing shaft (150) fixed to an end of the cylinder rod (170) of the pneumatic cylinder (180) inserted into and coupled to a bearing fixed at a position between the grindstone rotation shaft and the hinge shaft (140) in each of the grinding units (300). The grindstone rotation shaft of each of the grinding units (300) is turned into the vertical state or the horizontal state according to the forward and backward movements of the pneumatic cylinder (180), so that the two grindstones (350) of the grinding units (300), which are mounted to be parallel and opposite to each other, can be easily replaced.

Owner:DAEWON APPLIED ENG CO

Bridge construction equipment

ActiveCN107142848AHigh polishing precisionSimple structureBridge structural detailsBridge erection/assemblyAutomatic controlBody right side

The invention discloses a piece of bridge construction equipment. The equipment comprises a frame body, wherein a polishing chamber is disposed in the frame body; a first slide connection groove is formed in the left side of the top part inside the polishing chamber; a second slide connection groove is formed in the right side of the polishing chamber; an opened end of which the left end is connected to the polishing chamber is disposed on the frame body right side under the second slide connection groove; a connection and fixation device and a sunken groove are disposed on the left side and the right side of the bottom inside the polishing chamber respectively; a first screwed rod which is disposed in a horizontally stretching manner is disposed in the first slide connection groove; a slide connection block of which the bottom penetrates the polishing chamber is in threaded fitting connection to the first screwed rod; a first slide connection chamber is disposed in the slide connection block; an up-down slide connection block is connected in the first slide connection chamber by slide fitting; and raised slide connection blocks which are in slide fitting connection with interiors of two sides of the first slide connection chamber are disposed on tops of two sides of the up-down slide connection block. According to the invention, the structure is simple; operations are convenient; safety is high; opening and closing of a partition plate can be controlled automatically; dust prevention effects are good; polishing is accurate; and stability is high.

Owner:宿州市徽腾知识产权咨询有限公司

Polishing apparatus, polishing method and pressing member for pressing a polishing tool

ActiveUS9199352B2Accurate polishingUniform contact timeEdge grinding machinesGrinding drivesHead partsEngineering

A polishing apparatus polishes a top edge portion and / or a bottom edge portion of a substrate accurately and uniformly. The polishing apparatus includes a rotary holding mechanism configured to hold the substrate horizontally and to rotate the substrate and at least one polishing head disposed near the peripheral portion of the substrate. The polishing head has at least one protrusion extending along a circumferential direction of the substrate, and the polishing head is configured to press a polishing surface of a polishing tape by the protrusion against the peripheral portion of the substrate from above or below.

Owner:EBARA CORP

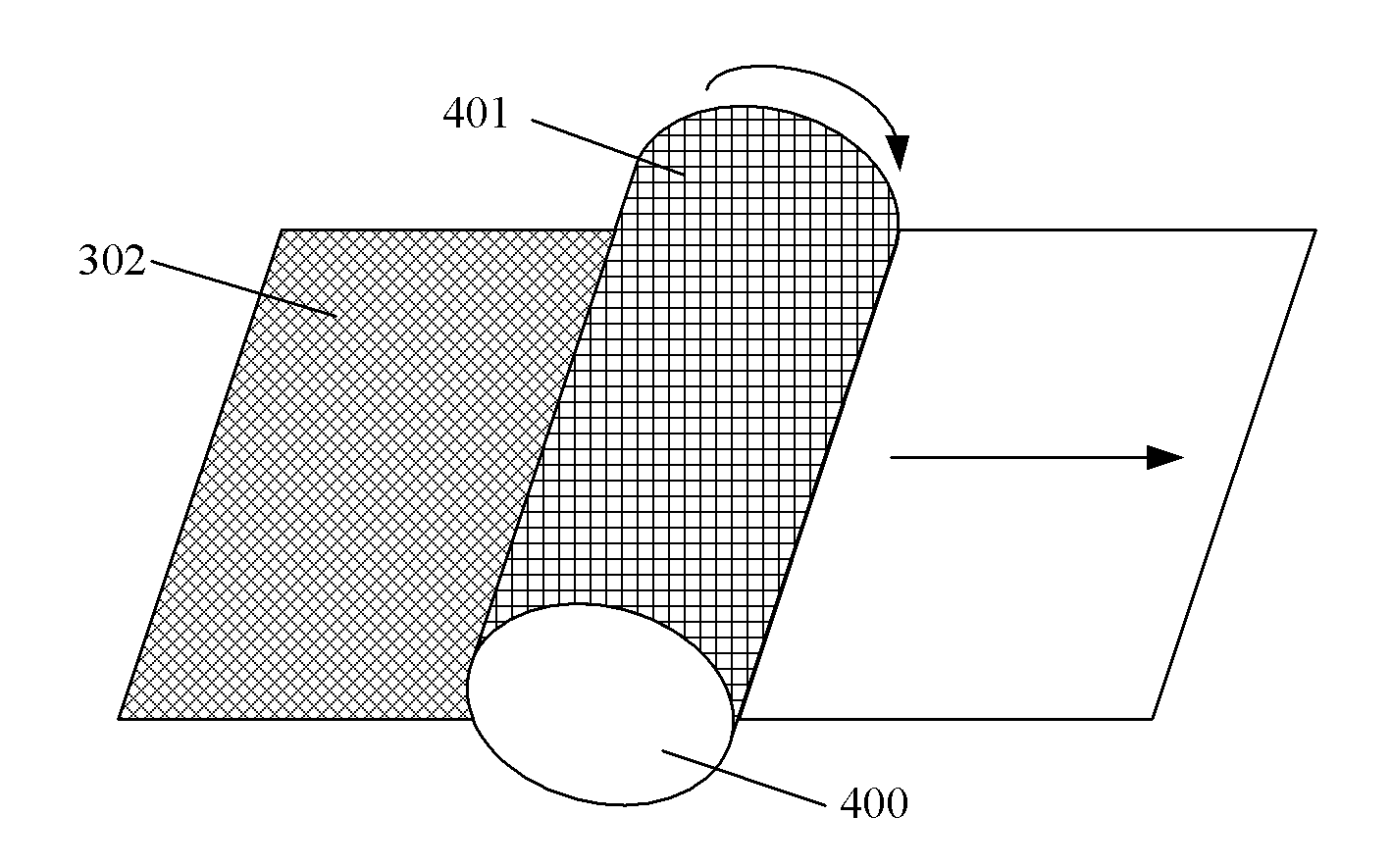

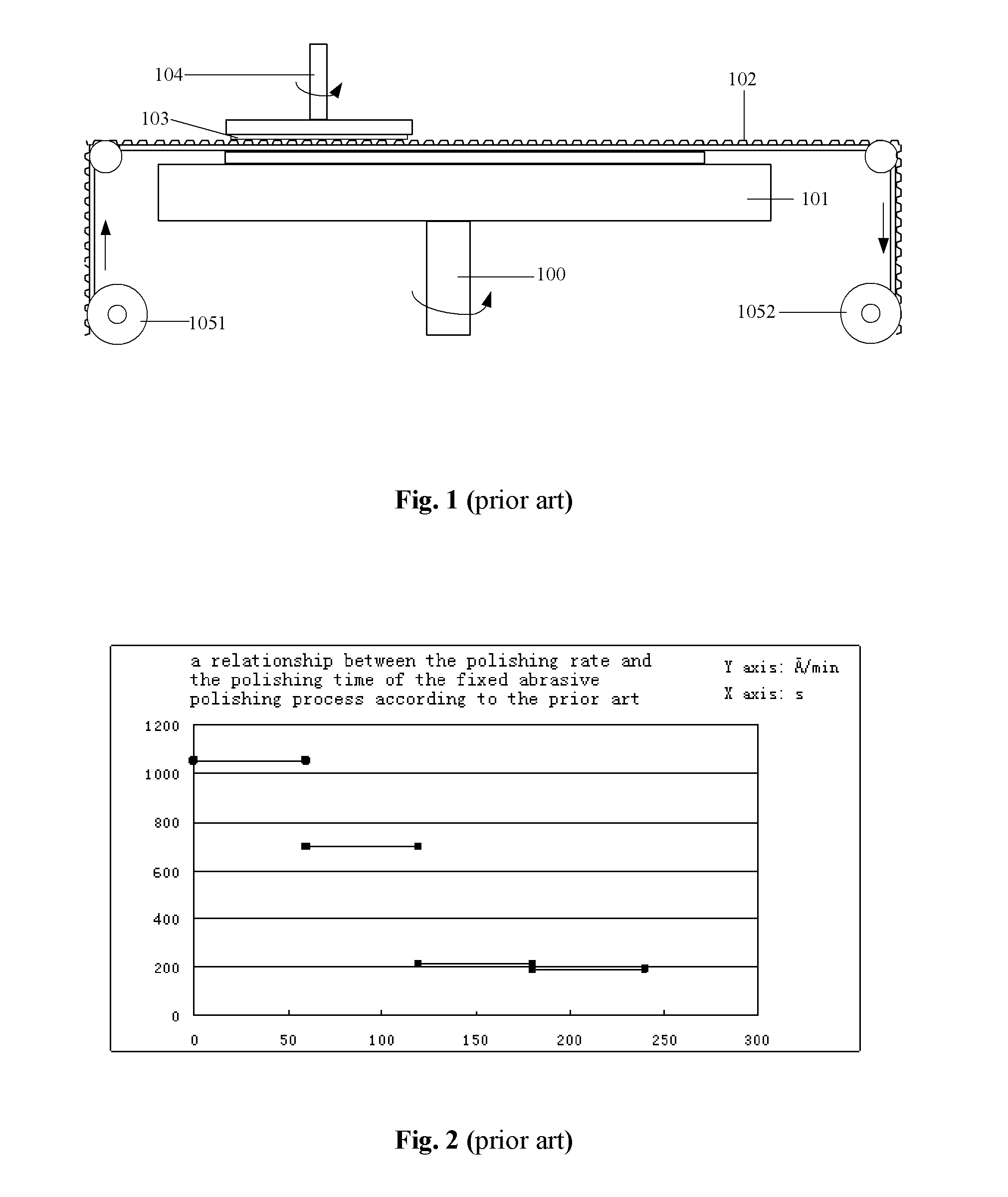

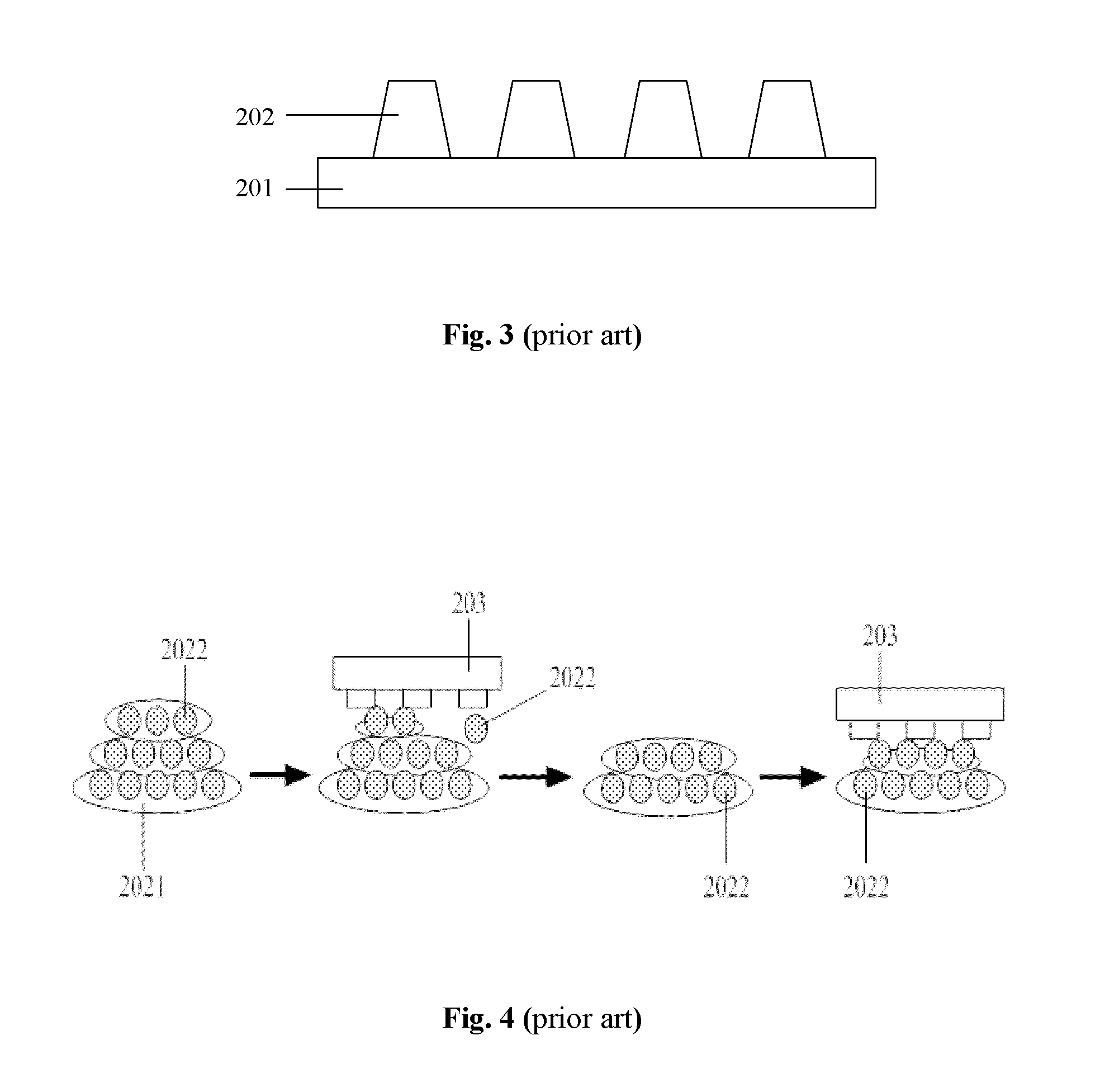

Polishing pad and methods for manufacturing and using the same

InactiveUS20120190276A1Reduce polishing rateComplement polishing efficacyOther chemical processesAbrasion apparatusEngineeringWafering

This invention provides a polishing pad, which includes a substrate and a plurality of discrete abrasive blocks fixed on the substrate, wherein the abrasive blocks are of at least two kinds of heights. This invention would not reduce the polishing rate dramatically during the process for polishing a wafer by using the polishing pad in the long run. Therefore a thickness of the wafer to be polished is able to be controlled accurately, thereby improving the effect and yield of polishing the wafer. The present invention further provides a method for manufacturing the polishing pad. The polishing pad according to this invention is manufactured conveniently by using this method. Correspondingly, a method for using the polishing pad is also provided in this invention.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Polishing apparatus

InactiveUS20050227592A1Easy to replaceThe curvature of a lens more accuratelyOptical surface grinding machinesGrinding feed controlEngineeringFluid supply

A polishing apparatus includes a polishing jig. The polishing jig includes an elastic balloon member, a fixture, and a fluid supply portion. The fixture airtightly closes the rear opening portion of the balloon member. The fluid supply portion supplies a fluid into a space formed by the fixture and balloon member. The balloon member has a cup shape constructed by a dome portion and a cylinder portion extending backward from the outer periphery of the dome portion. The fixture fixes the opening portion of the cylinder portion of the balloon member.

Owner:HOYA CORP

Variable-parameter crank shaft corrective polishing method and device

InactiveCN103158046AShorten the timeOut-of-round correction is accurateBelt grinding machinesAutomatic controlControl valves

The invention discloses a variable-parameter crank shaft corrective polishing method and a device. The variable-parameter crank shaft corrective polishing device comprises a machine tool which drives a crank shaft to rotate, a servo holding device and two polishing pressure heads, wherein each polishing pressure head comprises a base seat, at least two polishing air bags which are fixedly connected in the base seat and a pressurization air bag. The pressurization air bag is located between the polishing air bags, outer ends of the air bags are all located outside the self base seat and are arranged in an arc shape, the outer end faces of the outer ends are all in arc shapes, the base seats are both fixedly connected with abrasive belts, the polishing air bags are connected with a polishing air source, and the pressurization air bags are connected with the polishing air source and a corrective air source through an automatic control valve on external pipelines. A roundness detection sensor is further arranged on the servo holding device or the two polishing pressure heads, the machine tool is provided with a rotation speed sensor, and the auto control valve, the roundness detection sensor and the rotation speed sensor are all connected with an industrial control machine. According to the variable-parameter crank shaft corrective polishing method and the device, not only can the roundness error of a shaft neck of the crank shaft be accurately corrected and polished, but also a crank shaft neck round angle and two side faces of a thrust shaft neck can be polished, and the machining efficiency is high.

Owner:NEIJIANG FUSHENG MACHINERY

Rotary multi-angle automatic polishing system and polishing method thereof

ActiveCN104308710ARealize fixed tighteningRealize multi-angle and multi-face rotationPolishing machinesAutomatic grinding controlMechanical engineering

The invention discloses a rotary multi-angle automatic polishing system and a polishing method thereof. The rotary multi-angle automatic polishing system comprises a working stand, a polishing device, a clamping device and a control device, wherein the polishing device is provided with a hinge plate, a polishing component and a polishing driving device for driving the polishing component to operate; the clamping device is provided with a clamping component, a push driving device and a translation driving device; the clamping component is hinged to the working stand; the push driving device is used for driving the clamping component to rotate towards the polishing component along a plane perpendicular to a rotating shaft; the translation driving device is used for driving the clamping component to move reciprocally along the axial direction of the rotating shaft; the clamping component is also provided with a rotating device and a rotation driving device; the rotation driving device is used for driving the rotation device to rotate; the clamping component is hinged to the hinge plate; the clamping device is also provided with a rotation driving device for driving the clamping component to rotate reciprocally towards the polishing component relative to the hinge plate. According to the rotary multi-angle automatic polishing system, multi-angle continuous polishing can be realized, the polishing is accurate, the health of workers is protected, and the cost is low.

Owner:INST OF INTELLIGENT MFG GUANGDONG ACAD OF SCI

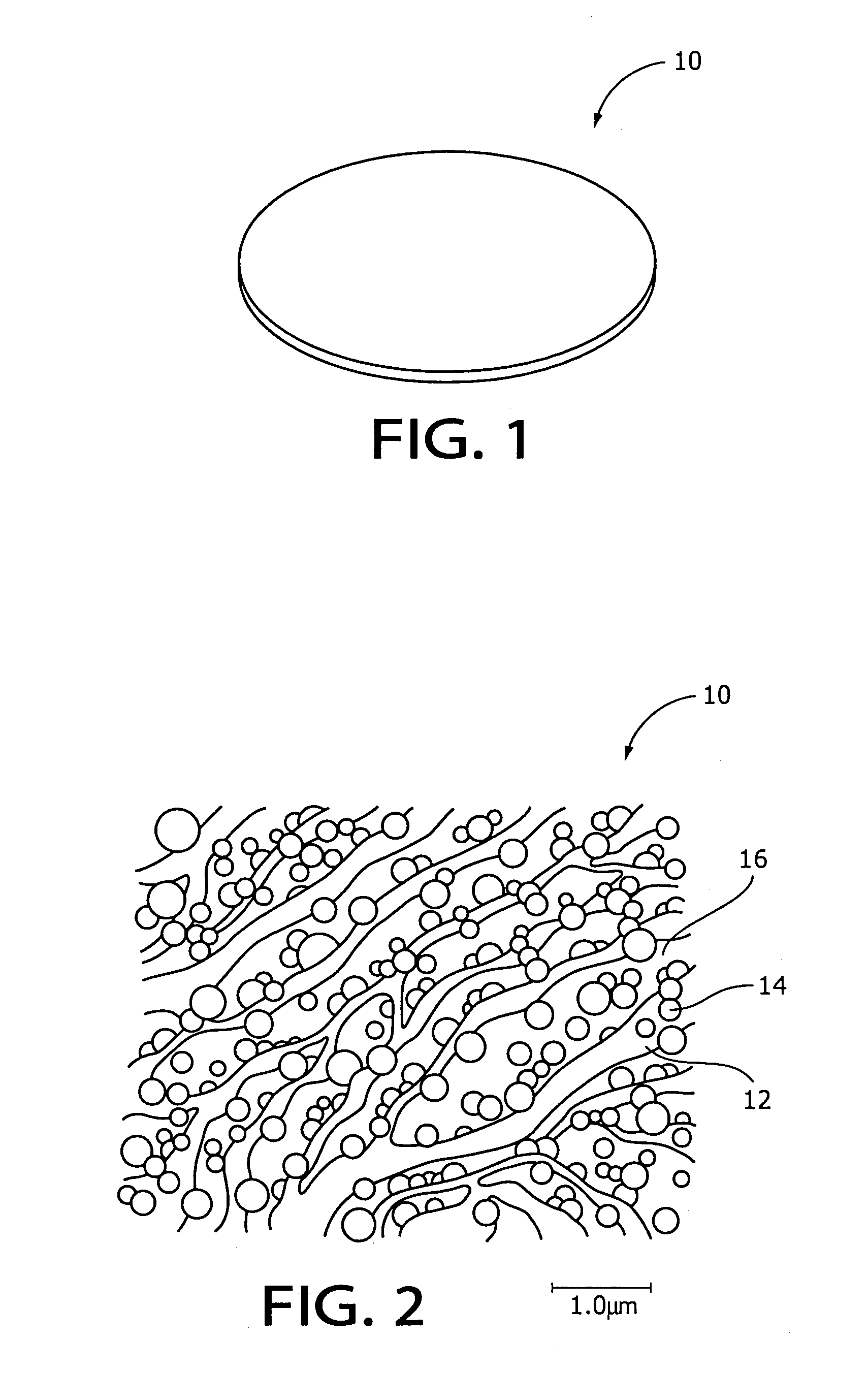

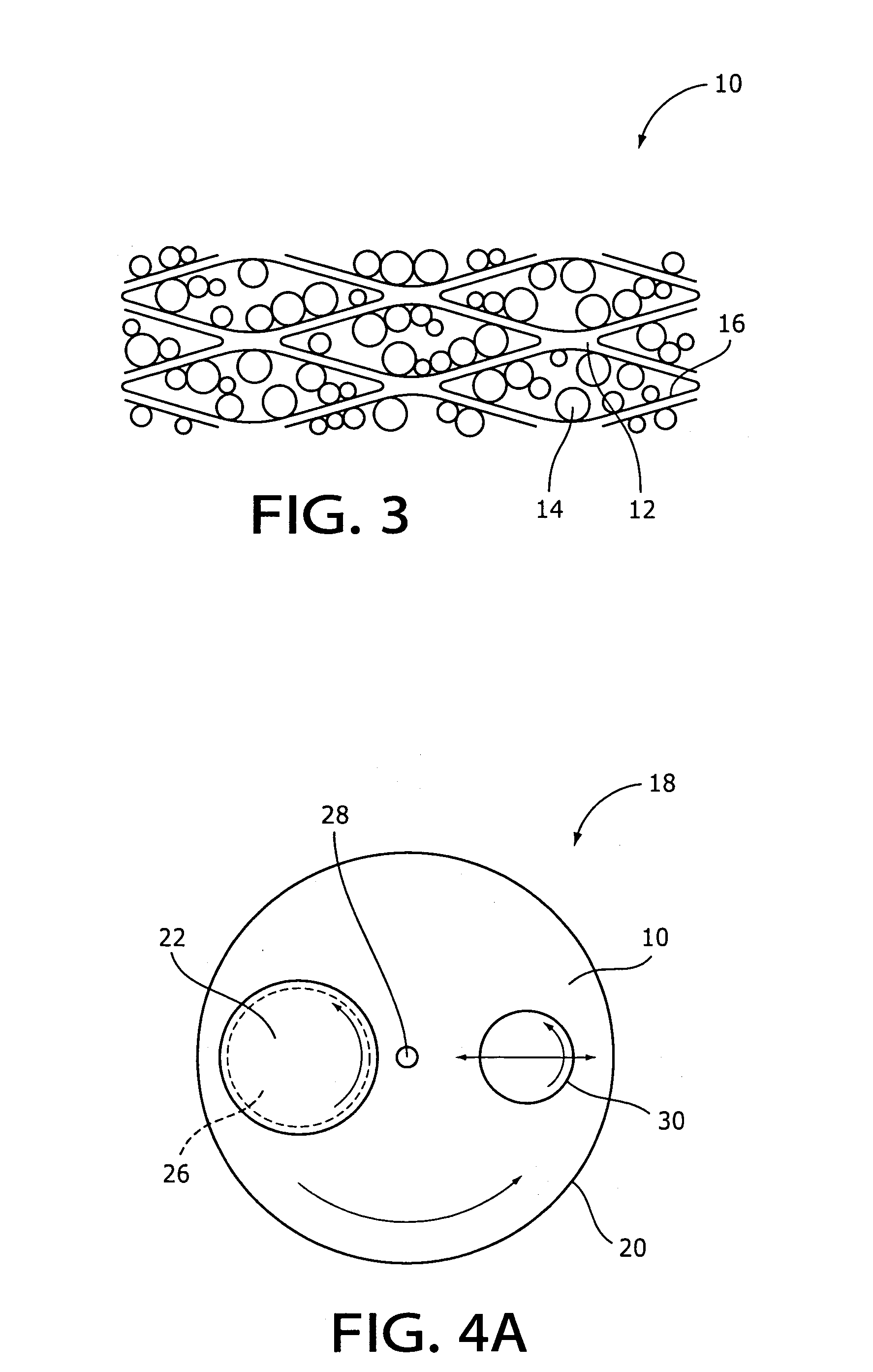

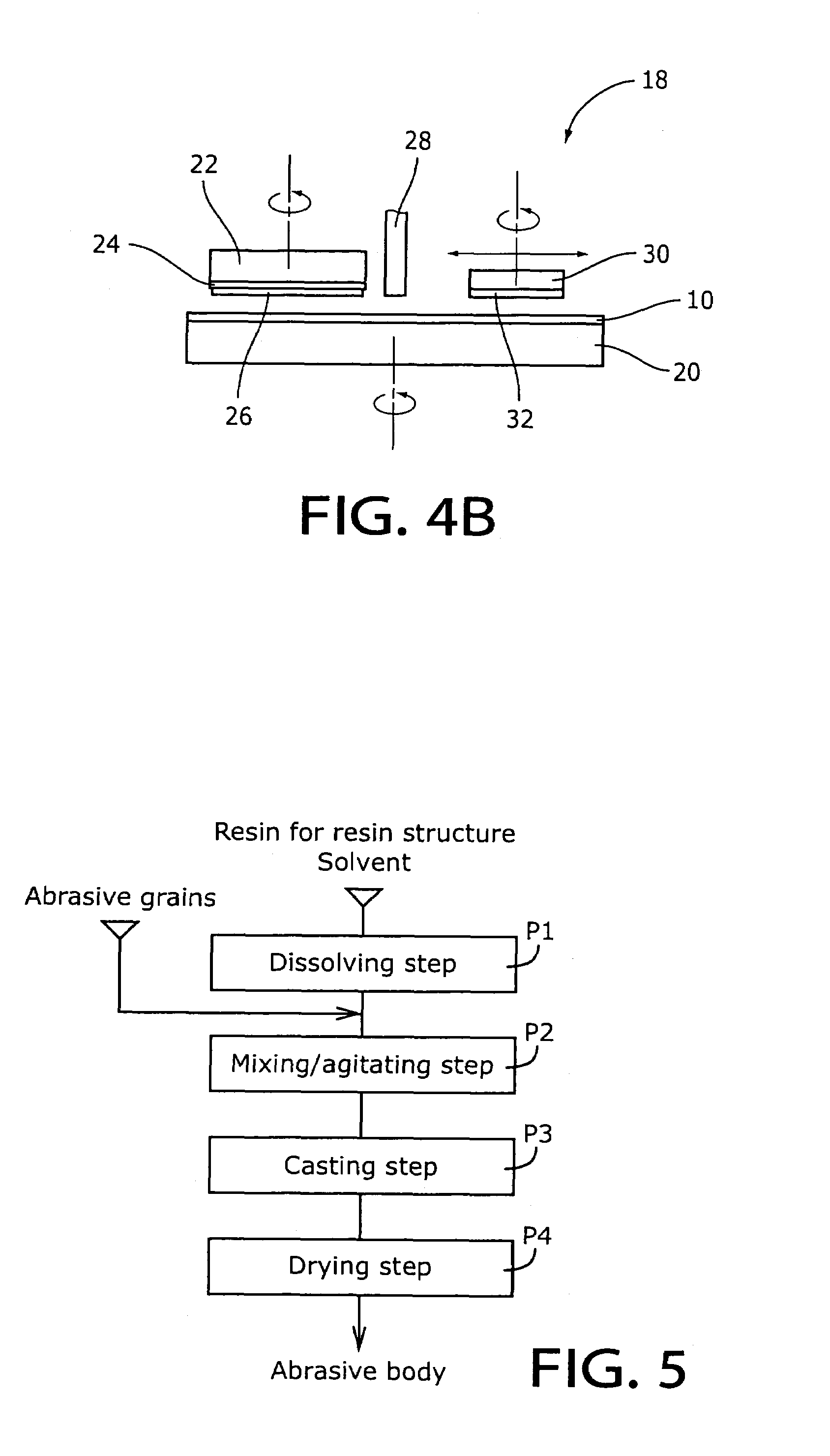

Abrasive body and method of manufacturing the same

ActiveUS7527662B2Preferable in efficiencyPreferable in of qualityPigmenting treatmentRevolution surface grinding machinesPolymer scienceCritical surface

An abrasive body for polishing includes a resin structure made of resin and a plurality of abrasive grains wherein a critical surface tension of the resin ranges from 1.6×10−2 to 4.0×10−2 N / m.

Owner:NORITAKE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com