Polishing robot used for external surface of iron pan

An external surface and robot technology, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding racks, etc. The effect of good fixation, saving manpower and material resources, and saving enterprise costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment, and present embodiment is based on the premise of technical scheme of the present invention, has provided detailed implementation and specific operation process, but protection scope of the present invention is not limited to following implementation example.

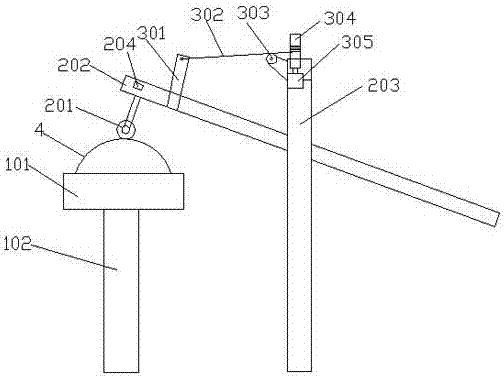

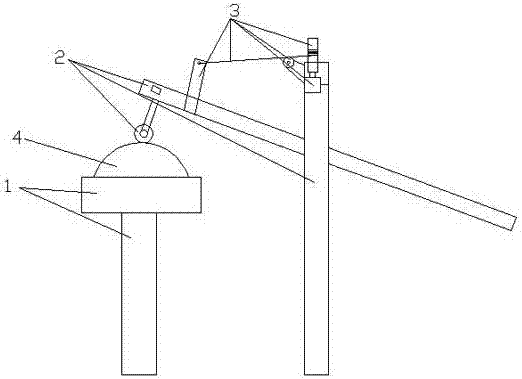

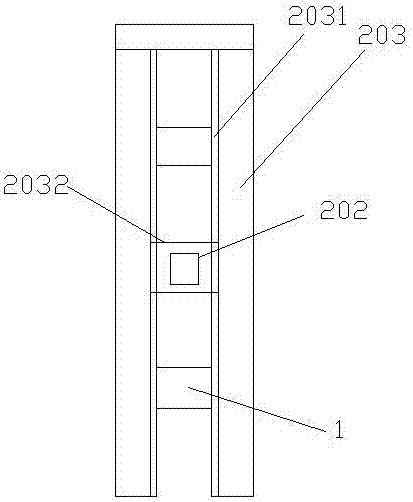

[0021] As shown in the figure, the present invention is the technical solution adopted by the present invention in order to solve the above problems: a polishing robot for the outer surface of an iron pan, the polishing robot includes a rotating mechanism 1 that drives the rotation of the pan blank 4 to be polished, a The polishing mechanism 2 for polishing the pot blank 4, the adjusting mechanism 3 for adjusting the polishing direction, and the control system for controlling the operation of the polishing mechanism 2. The rotating mechanism 1 includes a rotary table 101 driven by a motor I and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com