Polishing pad and methods for manufacturing and using the same

a technology of abrasive blocks and a manufacturing method, which is applied in the field of can solve the problems of low utilization ratio of slurry, poor polishing, environmental pollution, etc., and achieve the effects of complementing the polishing effect, reducing the height of the abrasive blocks with the biggest height, and reducing the polishing ra

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

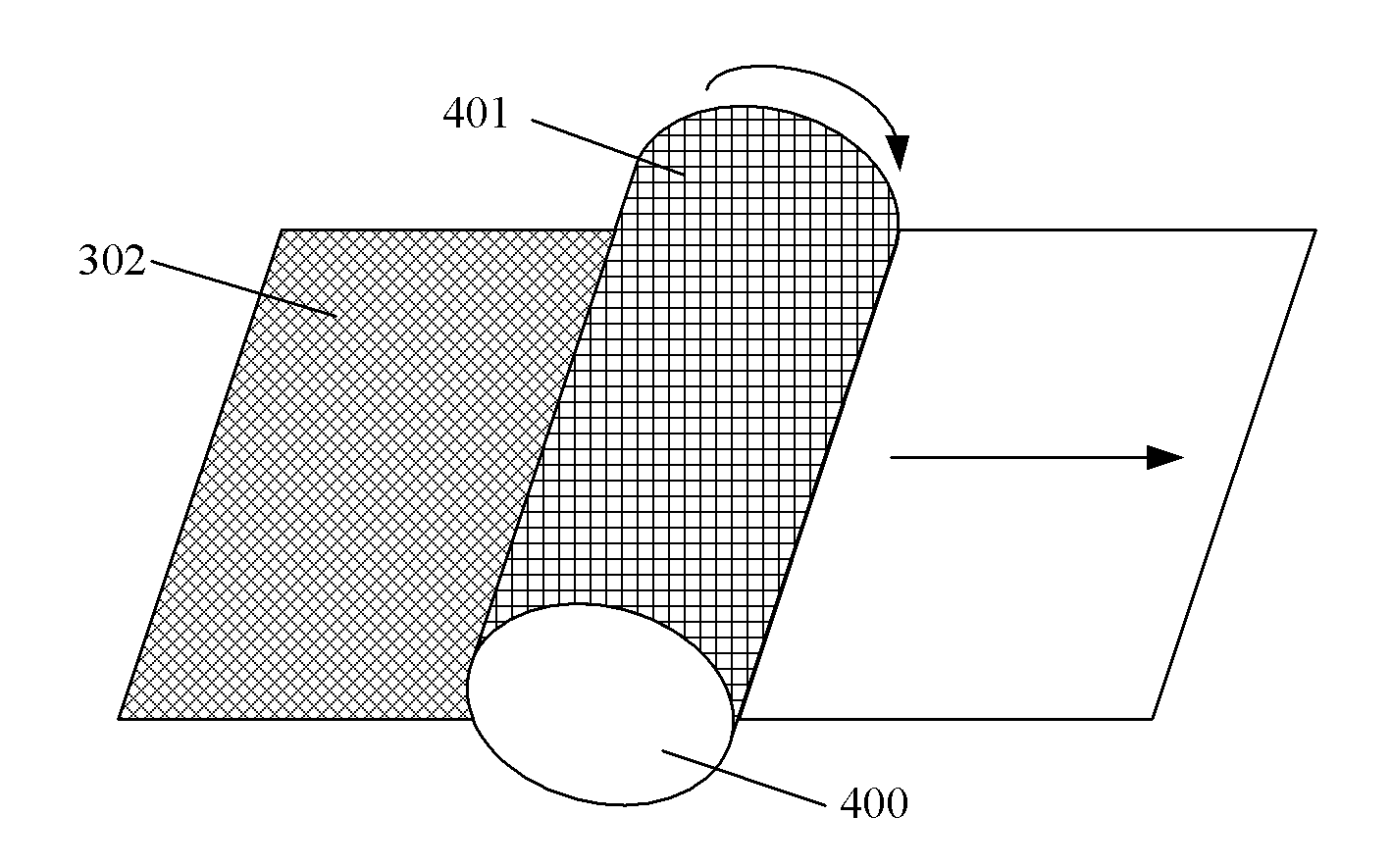

[0040]FIG. 5 is a cross-sectional view of a polishing pad according to the present invention. Referring to FIG. 5, the polishing pad includes a substrate 301 and a plurality of abrasive blocks 302 fixed on the substrate 301. The abrasive blocks 302 are of two kinds of heights, which include abrasive blocks 3021 having a first height h1 and abrasive blocks 3022 having a second height h2. The first height h1 is from about 3 μm to about 5 μm greater than the second height h2. The first height h1 and the second height h2 may be ranging from about 10 μm to about 50 μm, preferably, the first height h1 may be about 30 μm. A width of the abrasive blocks 302 having the first height h1 and the second height h2 may be from about 50 μm to about 200 μm, preferably, the width may be about 100 μm

[0041]In this embodiment, the abrasive blocks 302 having different heights may be arranged from highest to lowest height, from lowest to highest height, or alternating high and low height on the substrate ...

second embodiment

[0048]FIG. 6 is a cross-sectional view of a polishing pad according to the present invention. Referring to FIG. 6, a polishing pad includes a substrate 301 and a plurality of abrasive blocks 302 fixed on the substrate 301. The abrasive blocks 302 are of more than two kinds of heights, which include a first height h1, a second height h2, . . . , a nth height hn (n is a natural number from 3 to 20). The height hn of the abrasive blocks 302 may be ranging from about 10 μm to about 50 μm. A height difference between any two kinds of the abrasive blocks 302 is at least from about 3 μm to about 5 μm. In other words, the absolute value of the difference between the height hn and the height hi (i is not equal to n, and i is a natural number from 3 to 20) is from about 3 μm to about 5 μm. A width W of the abrasive blocks 302 may be from about 50 μm to about 200 μm.

[0049]In this embodiment, the substrate 301 includes materials as described in the first embodiment. The materials and shapes of ...

third embodiment

[0054]FIG. 7 to FIG. 10 schematic diagrams illustrating a method for manufacturing a polishing pad according to the present invention. Referring to FIG. 7, a substrate 301 is provided, and coated uniformly with a mixture 3021 comprising a plurality of abrasive particles and resin adhesives.

[0055]In this embodiment, the substrate 301 may be a rigid substrate, such as a substrate comprising organic glass (PMMA), polyvinyl chloride (PVC), polycarbonate (PC), polyethylene terephathalate (PET), and the like. Optionally, the substrate 301 may be a resilient substrate, which includes polyurethane, polyolefin, phenylethylene, polyester, polyamide, black damping cloth, and the like. Optionally, the substrate 301 may be a multilayer substrate which is formed by combining the rigid substrate with the resilient substrate.

[0056]In this embodiment, the abrasive particles may include one or more materials selected from silicon dioxide, cerium dioxide, aluminium oxide, silicon carbide, boron carbid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heights | aaaaa | aaaaa |

| heights | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com