Patents

Literature

144results about How to "Achieve forward and backward movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

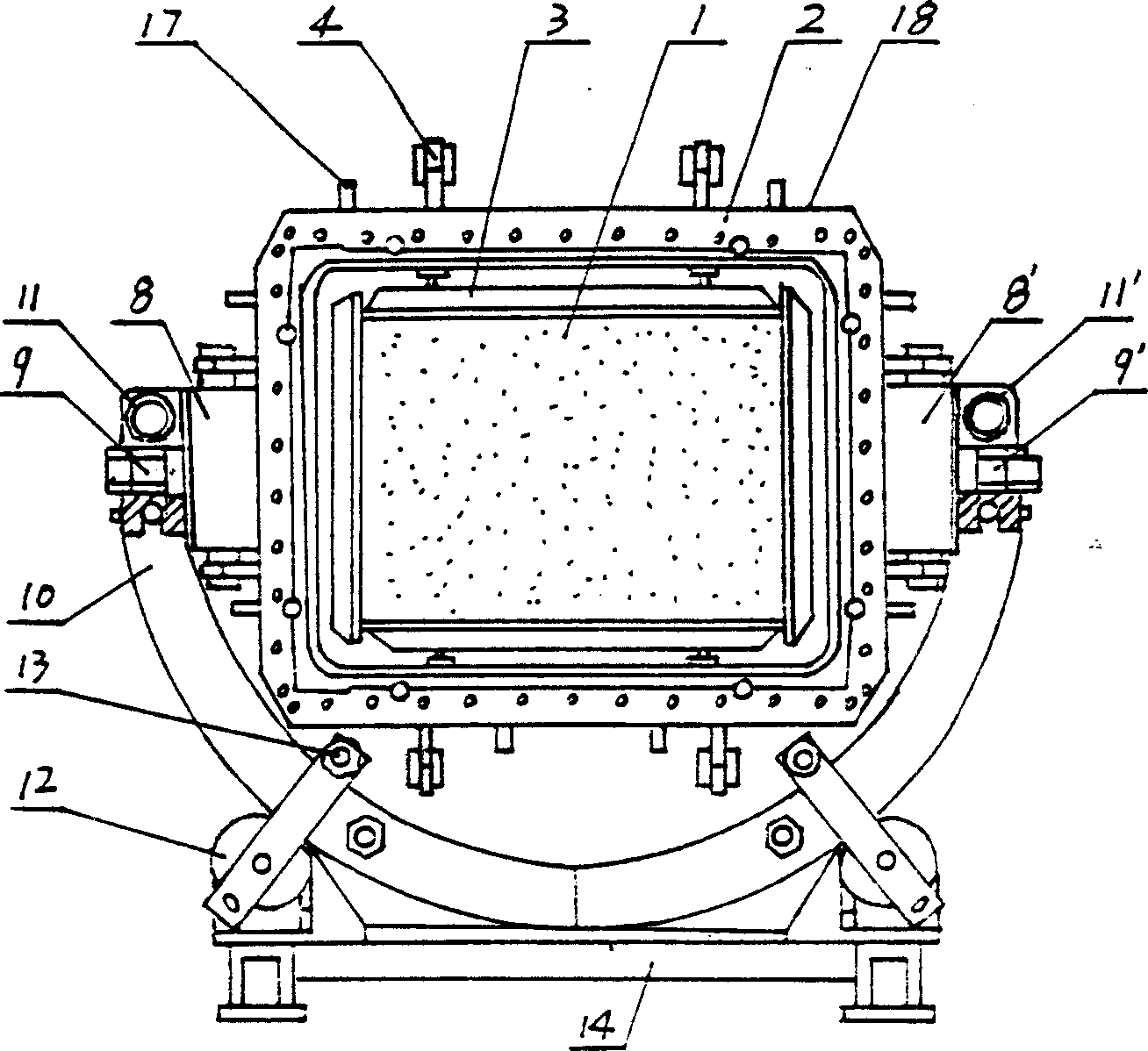

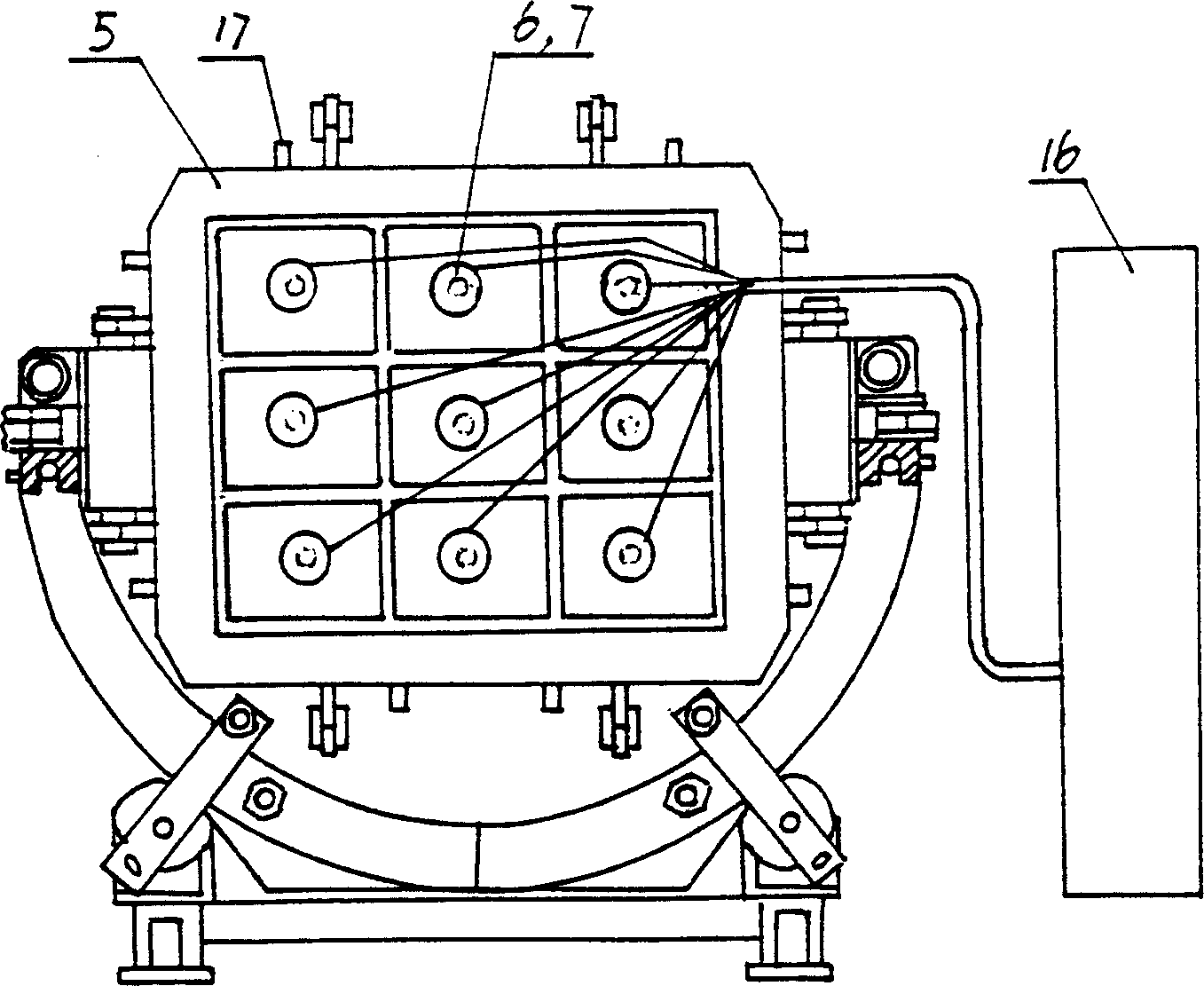

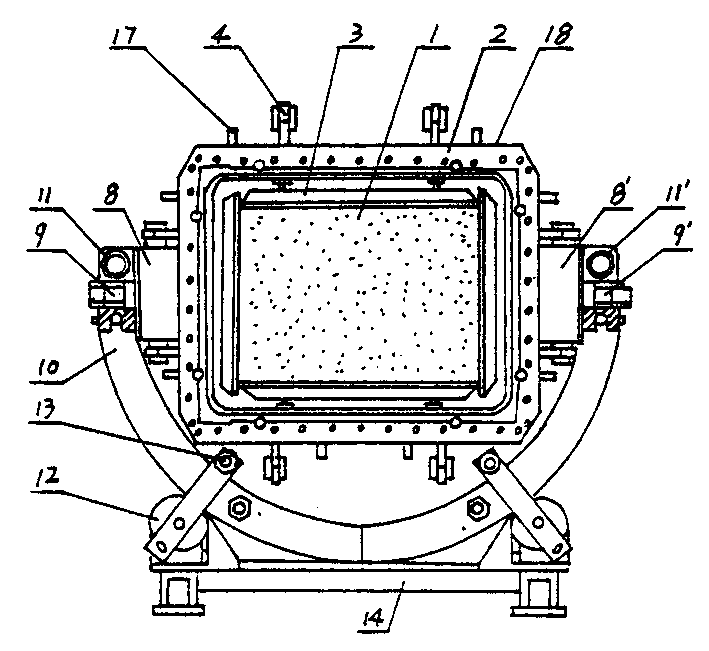

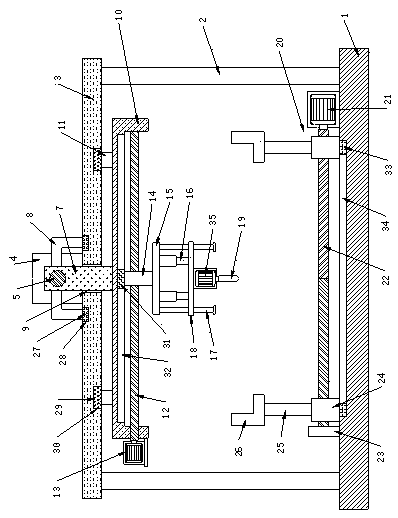

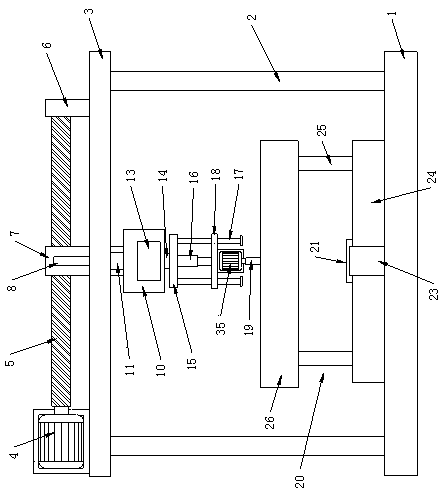

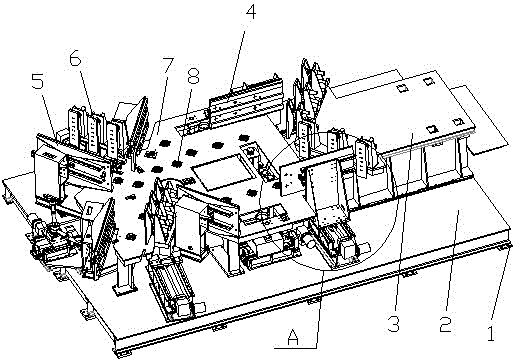

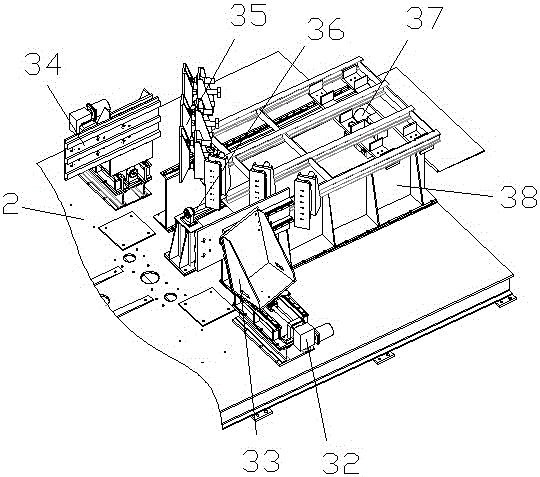

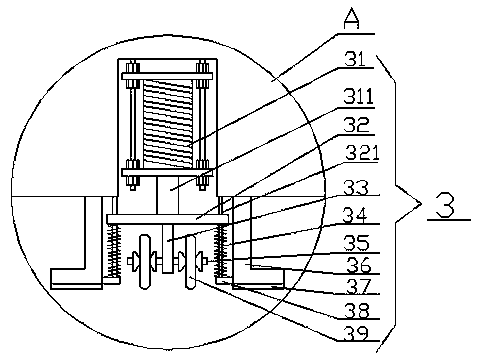

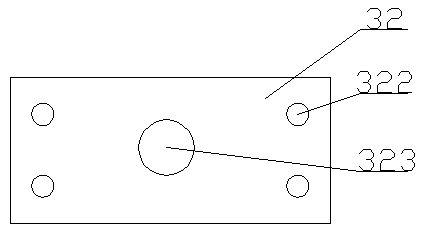

Bidimentional oil and gas migration and accumulation analogue experimental device

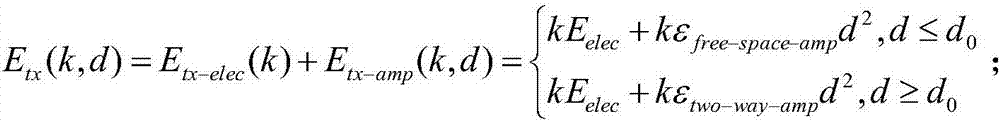

InactiveCN1410653AAchieve forward and backward movementHigh degree of automationSurveySoftware simulation/interpretation/emulationHydraulic cylinderData acquisition

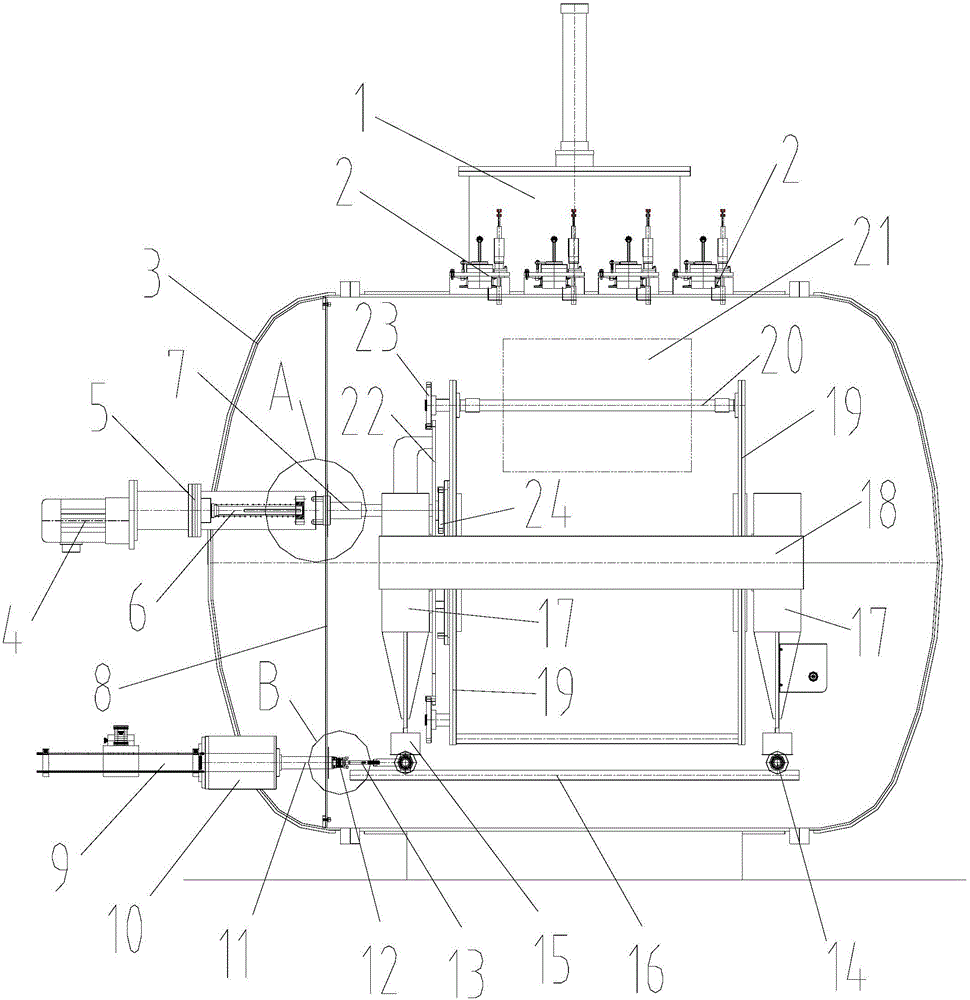

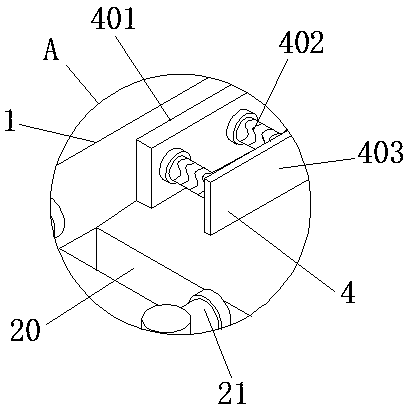

The experimental facility for simulating the migration and congeries of oil gas includes the experiment reality, the hydraulic unit, the rotation and hoisting device, the data acquisition as well as control device. The experiment reality consists of the front faceplate, back faceplate, the push plate and the frame. The hydraulic unit has the hydraulic cylinder. The rotation and hoisting device includes the disc with angle value being provides, the bearing and the curved bracket. The data acquisition and control device includes the sensor and the industrial control computer. The invented facility with high automatization can measure the temperature and pressure in the model. The simulating experimental facility makes the combination between the tectogenetic movement and the migration and congeries of oil.

Owner:石油大学(北京)盆地与油藏研究中心 +1

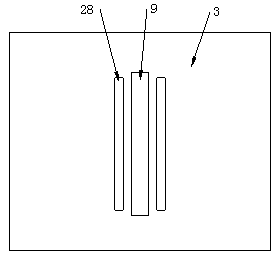

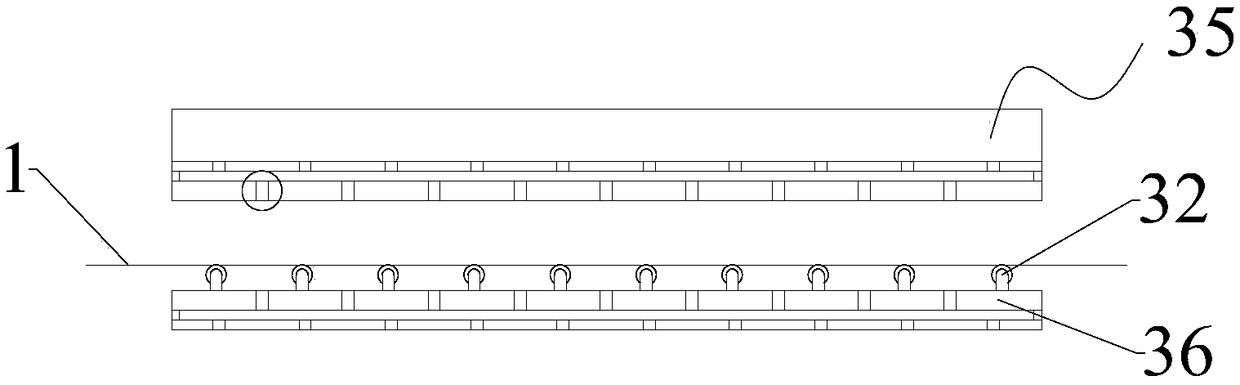

High-efficiency drilling machine for furniture production

PendingCN110103290AReduce labor intensityImprove processing efficiencyStationary drilling machinesEngineeringDrill bit

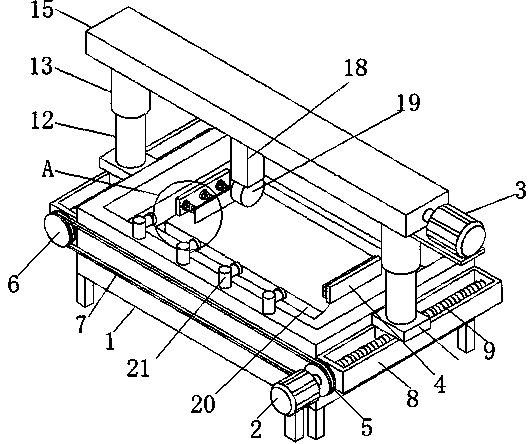

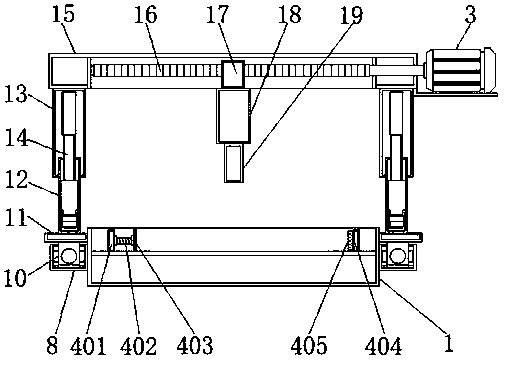

The invention discloses a high-efficiency drilling machine for furniture production. The drilling machine comprises a bottom plate, wherein supporting columns are fixedly arranged at the four cornersof the top of the bottom plate; a top plate is arranged at the upper portion of the bottom plate; the tops of the supporting columns are fixedly connected with the bottom of the top plate; and the topof the top plate is fixedly provided with a first servo motor. According to the high-efficiency drilling machine for furniture production, a drill bit can move back and forth by setting the first servo motor, a first threaded rod, a first bracket plate, a first connecting block and an L-shaped rod; the drill bit can move left and right by setting a U-shaped plate, a connecting rod, a second threaded rod, a second servo motor and a second connecting block; the drill bit can move up and down by setting an electric push rod, a T-shaped rod and a sliding plate, so that the drilling is carried outin any position of the board, and therefore, the labor intensity of workers is reduced and the machining efficiency is improved; and by setting a fixing device, the different sizes of boards can be fixed, so that the practicability is higher.

Owner:灌云德尼雅木业有限公司

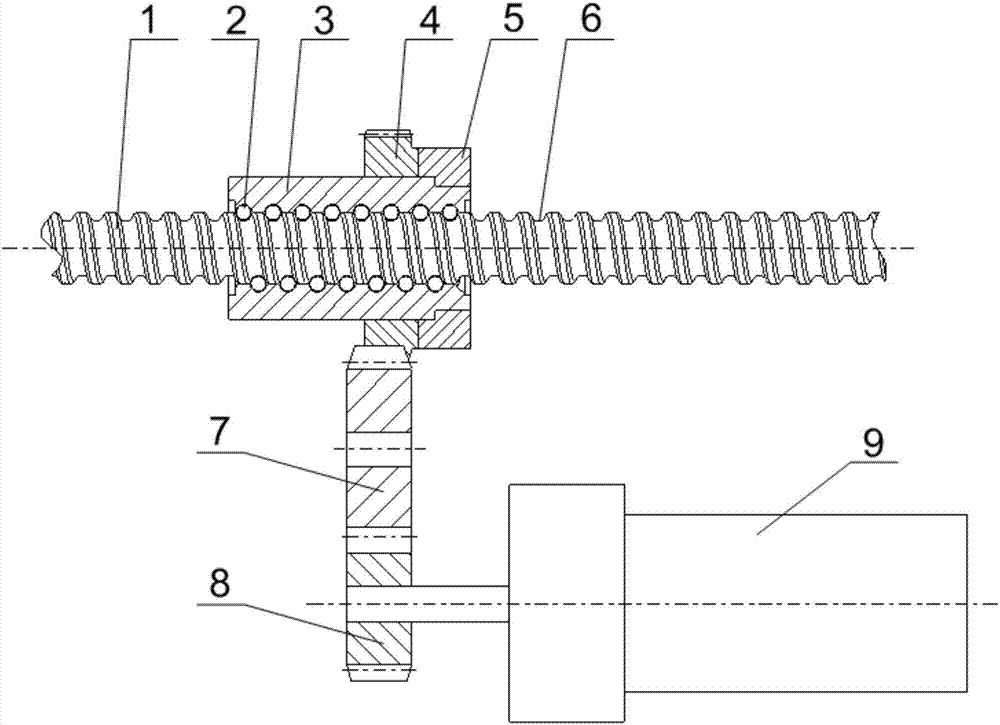

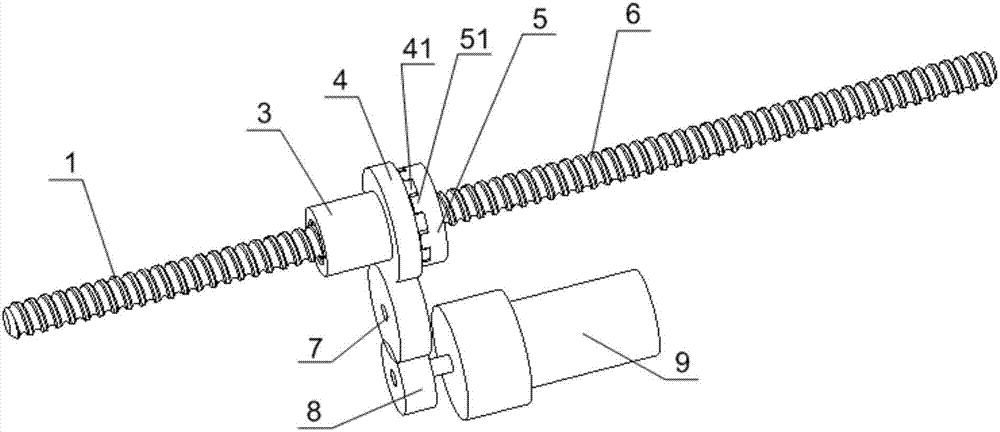

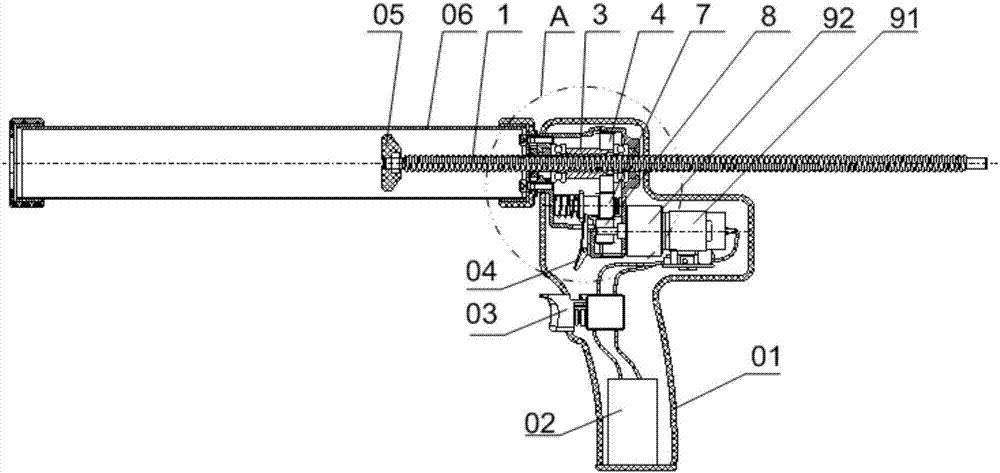

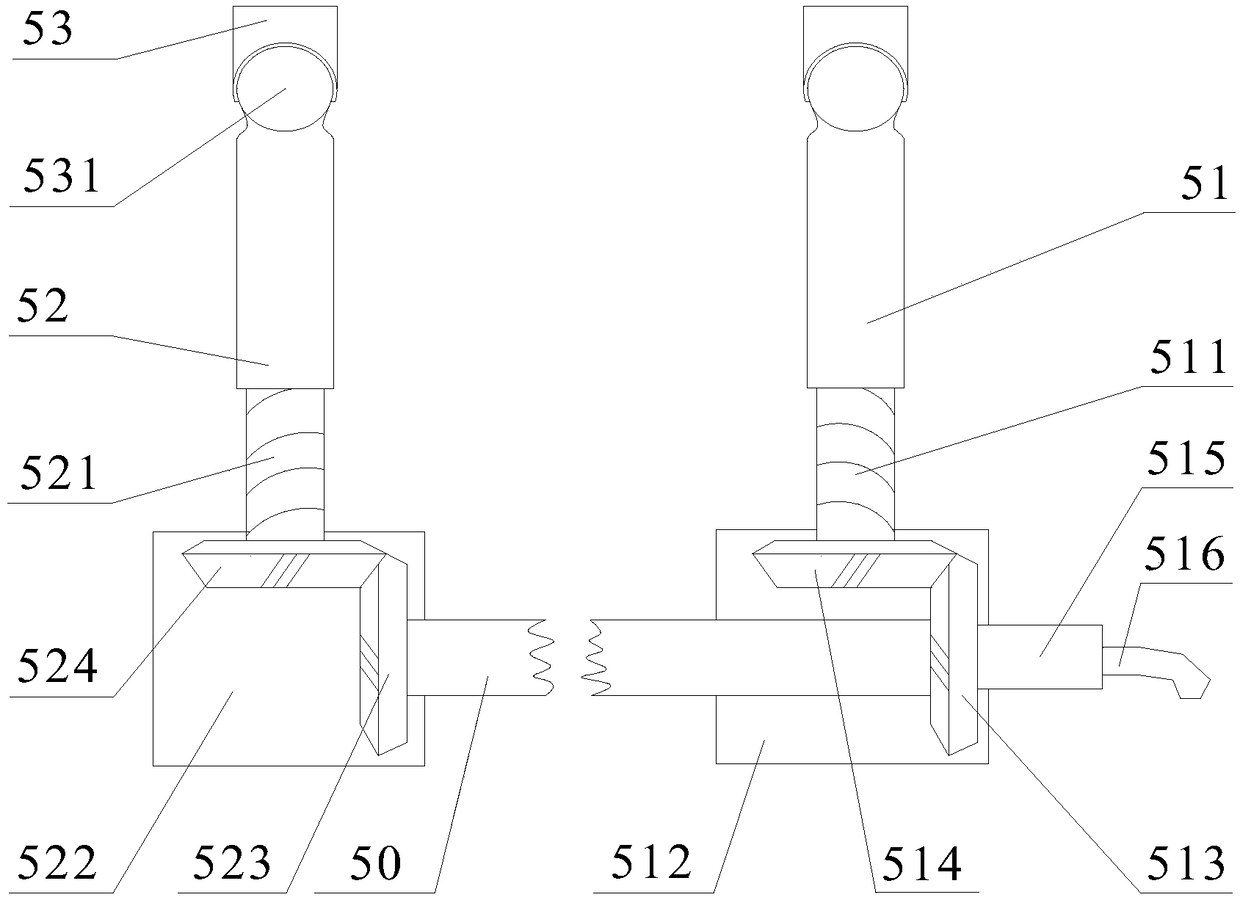

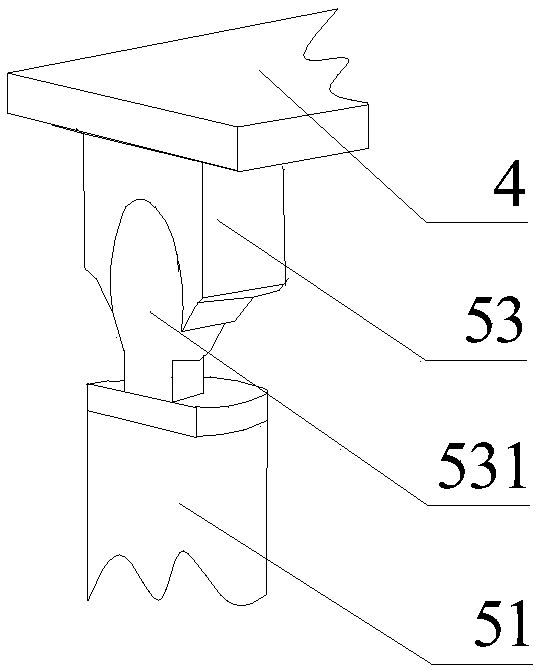

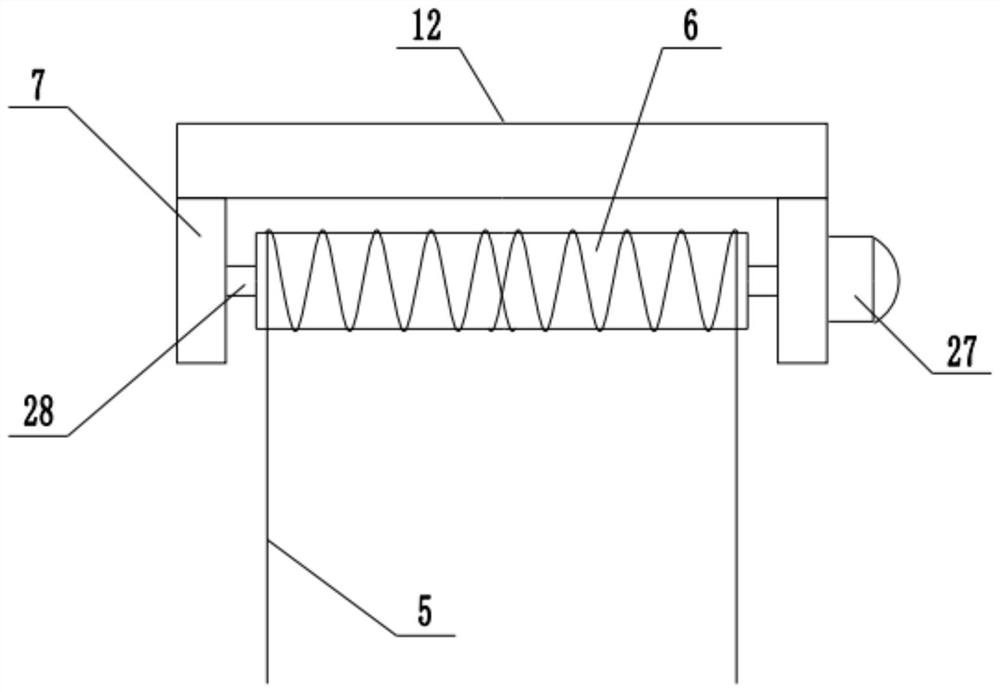

Rubber gun and driving device thereof

ActiveCN107282378ARealize transmissionClutch realizationLiquid surface applicatorsCoatingsEngineeringScrew thread

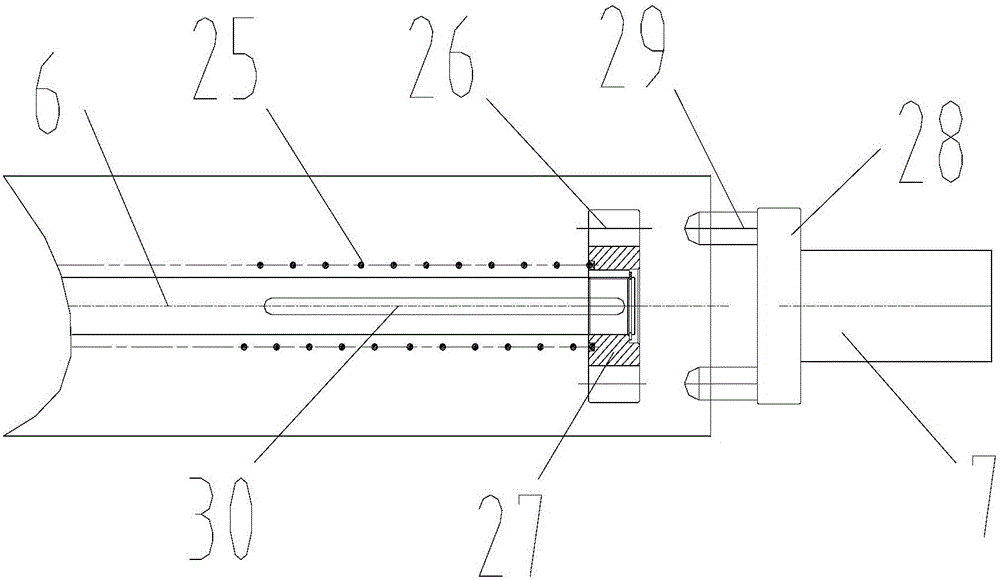

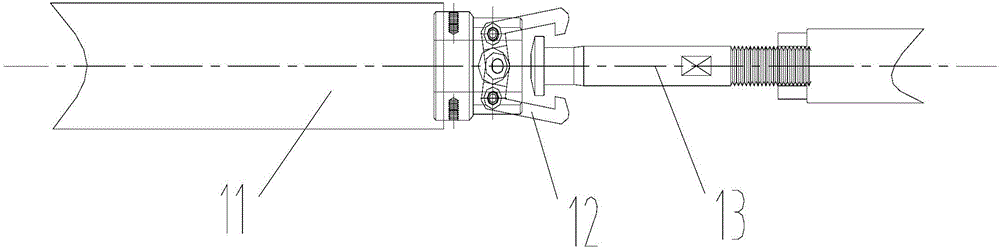

The invention discloses a rubber gun and a driving device thereof. The driving device of the rubber gun comprises a lead screw, a nut and a first gear, the nut is matched with the lead screw, and balls are arranged between the lead screw and a thread groove of the nut; the periphery of the nut is sleeved with the first gear in a sliding mode, the first gear is connected with the nut in a clutch mode, and a driving tooth used for being connected with the driving device in a driving mode is arranged on the periphery of the first gear. The driving device keeps a complete lead-nut mechanism, is simple in structure, and is provided with few parts; the balls will not fall off from the thread groove and also will not get stuck; the lead screw can move in the front-back direction, power transmission is reliable, large thrust can be provided, and reliable clutch driving can be achieved.

Owner:柏永茂

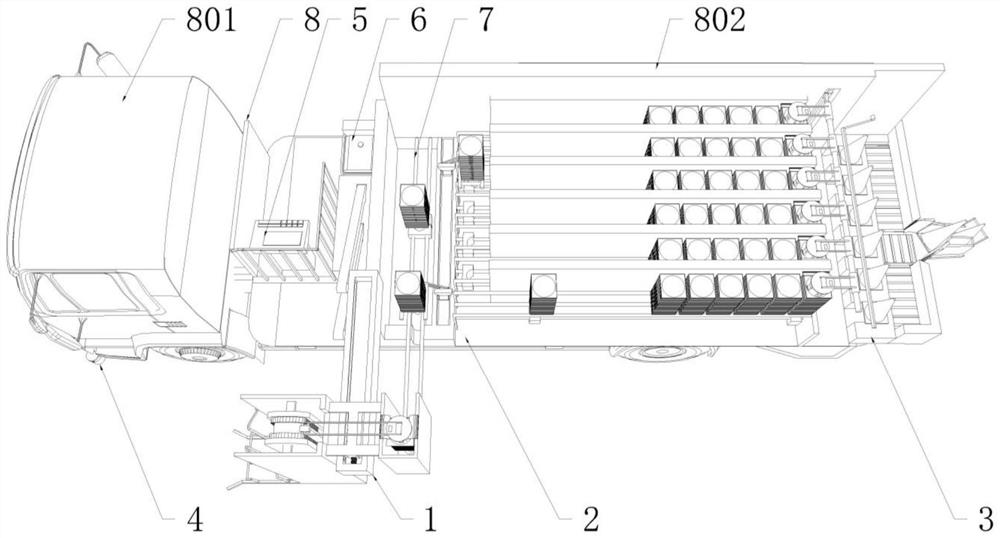

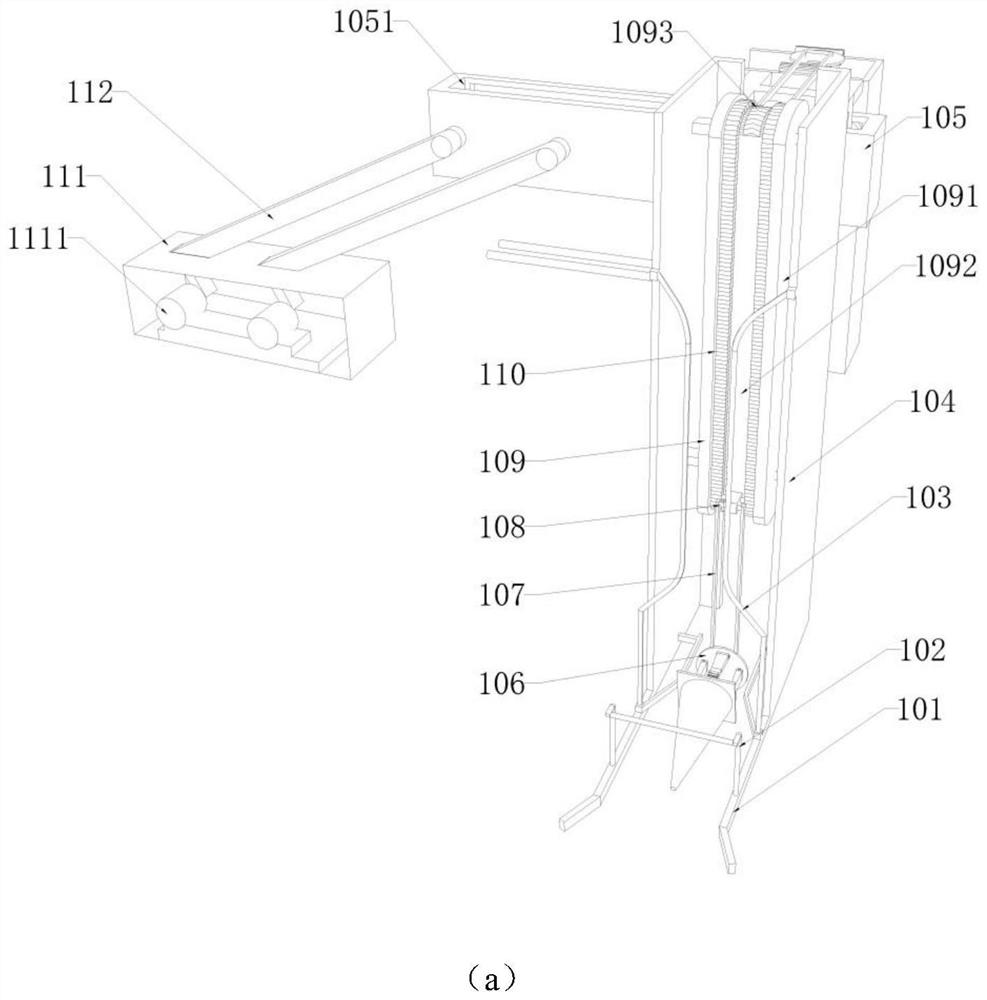

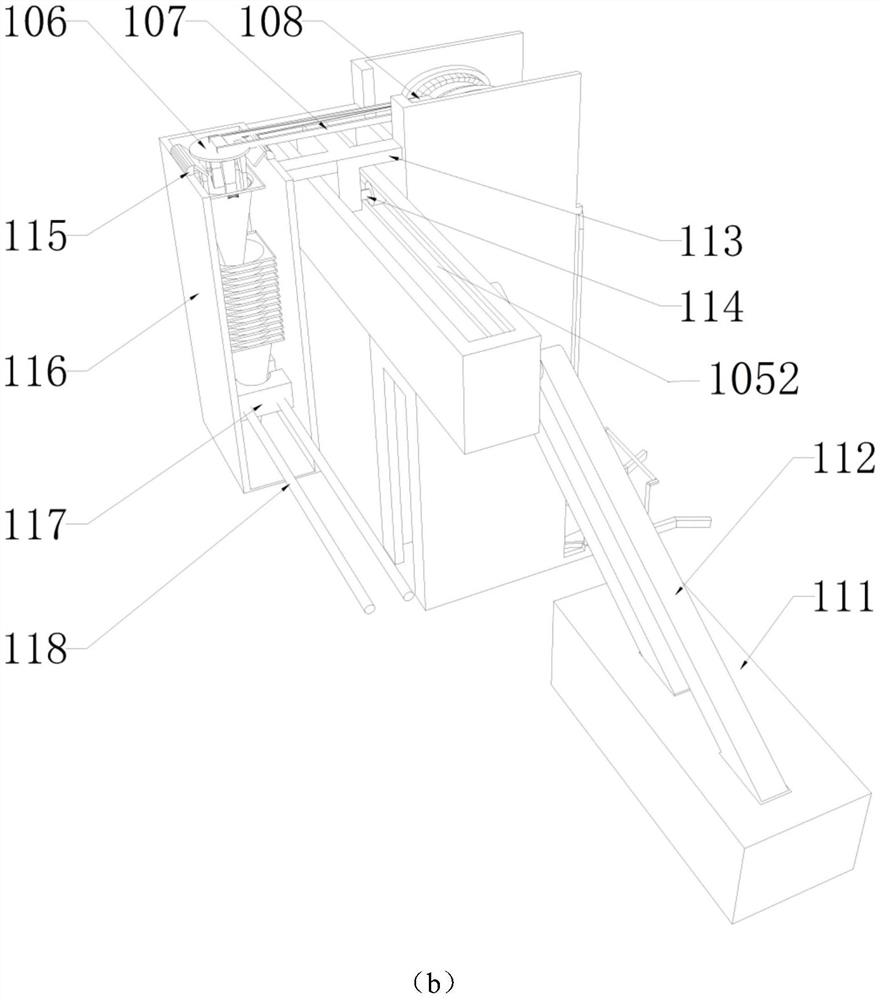

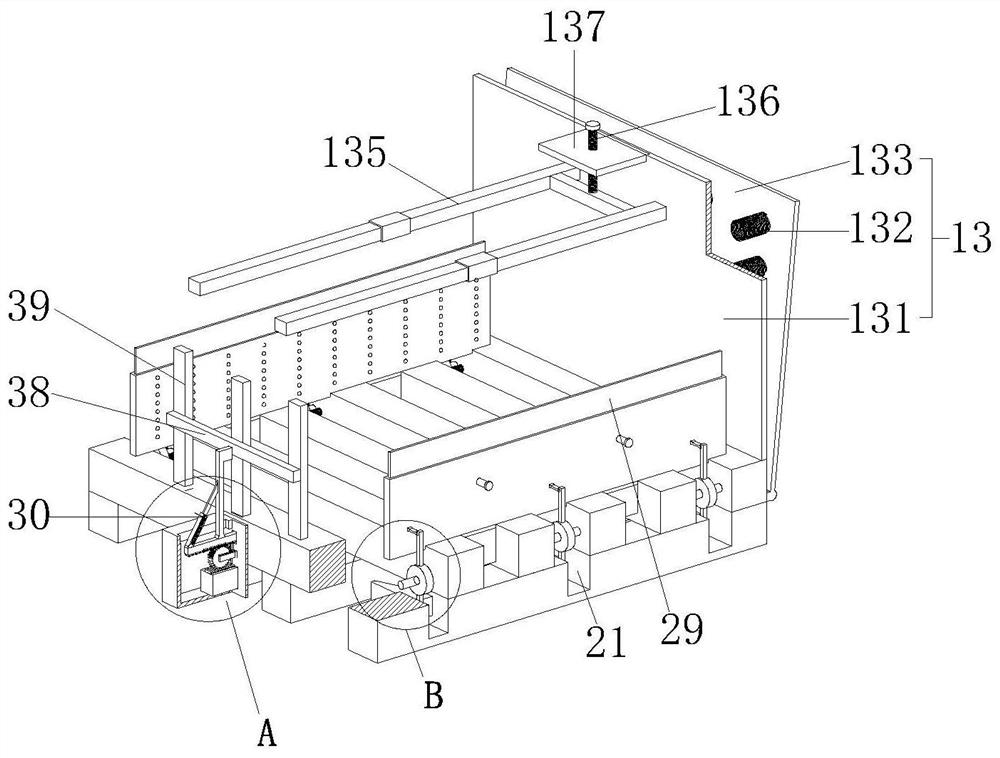

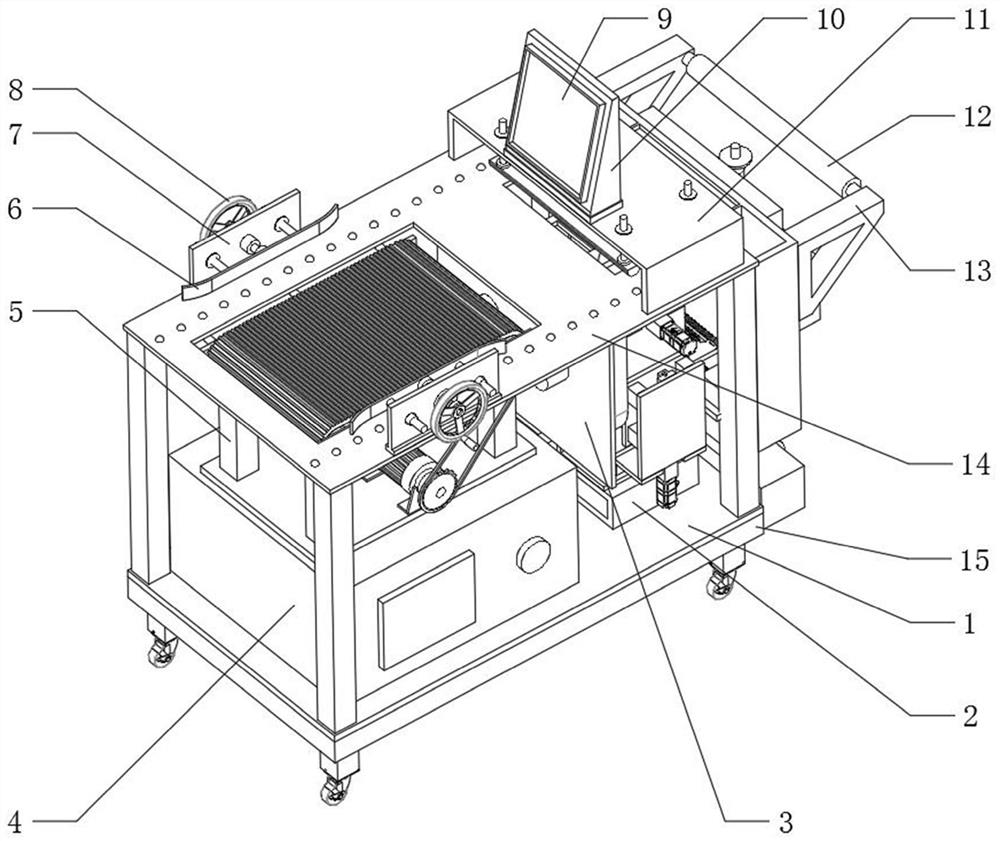

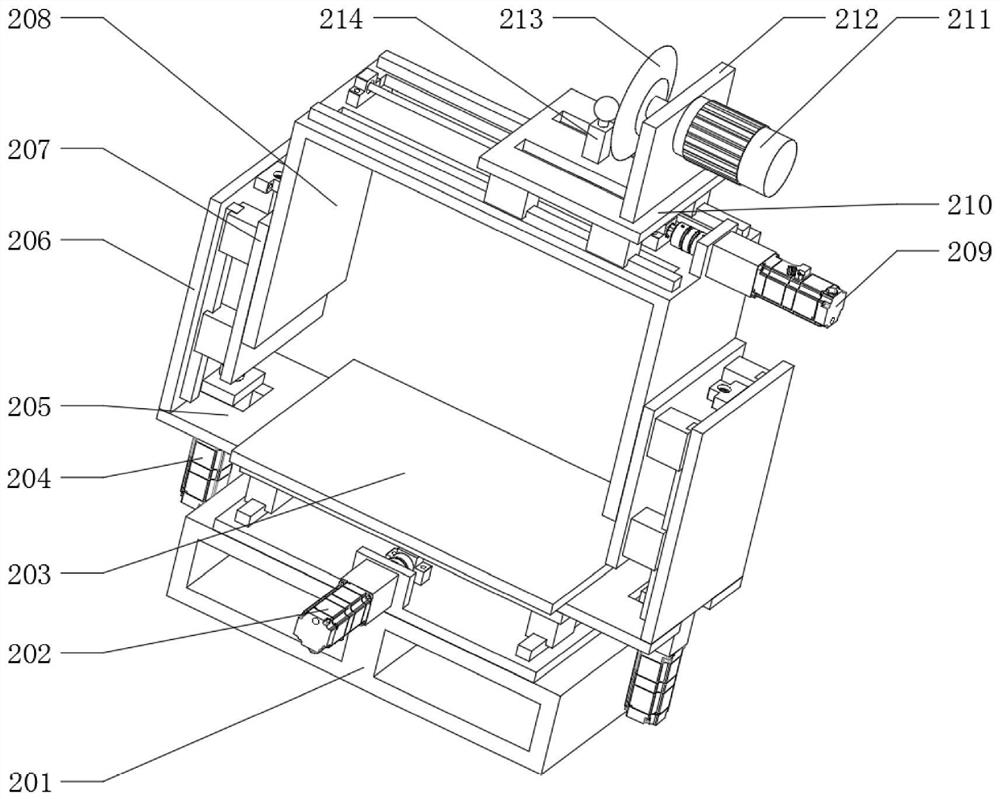

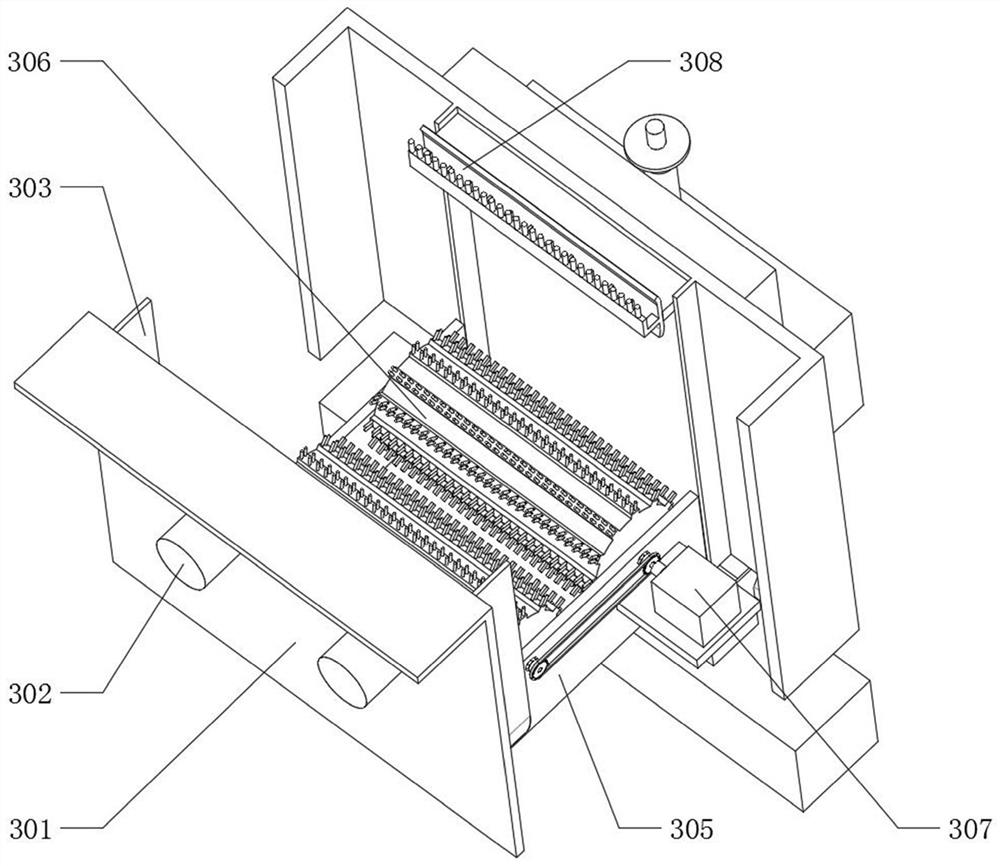

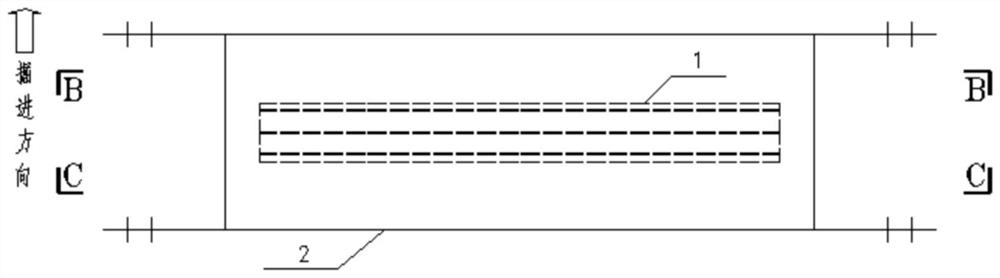

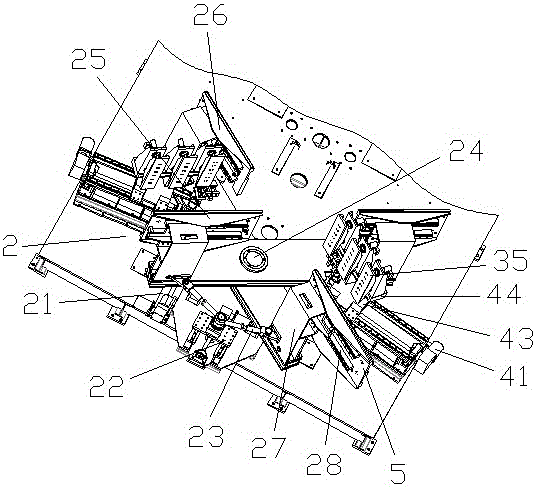

Traffic cone barrel full-automatic folding and unfolding storage vehicle and method

ActiveCN111827162AIncrease flexibilityIncrease profitTraffic signalsRoad signsStructural engineeringDriving mode

The invention provides a traffic cone barrel full-automatic folding and unfolding storage vehicle and method. According to the storage vehicle, a recovery device, a rail moving storage device and a releasing device are arranged on the vehicle body, and the traffic cone barrel full-automatic folding and unfolding storage vehicle is separated in folding and unfolding, adjustable in the transverse direction and capable of storing traffic cone barrels in an inverted mode. According to the device, the traffic cone barrels can be folded and unfolded in a forward driving mode, and the curved sectionfolding and unfolding operations can be met. And through an inverted stacking storage mode, the flexibility and the utilization rate of space use are improved. And meanwhile, the folding and unfoldingoperations can be performed simultaneously, so that the traffic cone barrel cross-lane transfer is realized.

Owner:CHANGAN UNIV

Uniformity multi-arc ion coating device

ActiveCN105986229AImprove uniformityReduce defects such as zebra stripesVacuum evaporation coatingSputtering coatingHydraulic cylinderEngineering

The invention relates to a uniformity multi-arc ion coating device, and belongs to the technical field of vacuum coating. The uniformity multi-arc ion coating device comprises multi-arc targets, a vacuum chamber, a path rail and a frame, wherein the path rail and the frame are arranged in the vacuum chamber. The frame is provided with a supporting piece, a center shaft and a rotation disc. The supporting piece used for supporting the frame is movably arranged on the path rail. The center shaft is sleeved with the rotation disc. The rotation disc is provided with a self-rotation shaft rotating relative to the rotation disc. The self-rotation shaft is provided with a clamp, and the multi-arc targets installed on the vacuum chamber face the clamp. The coating device further comprises a linear drive mechanism. The vacuum chamber is provided with a second sealing device, and the linear drive mechanism penetrates the second sealing device to be connected with the frame. A hydraulic cylinder penetrates the second sealing device to be connected to an extending-out arm. A grabbing claw used for grabbing the extending-out arm is arranged at the end portion of a piston rod of the hydraulic cylinder. According to the uniformity multi-arc ion coating device, correction of uniformity of workpiece coating can be achieved, and the overall quality of products is improved.

Owner:广东腾胜科技创新有限公司

Hardware accessory polishing device

InactiveCN111015487AAchieve forward and backward movementAchieve left and right movementGrinding carriagesPolishing machinesPolishingElectric machinery

The invention discloses a hardware accessory polishing device and relates to the technical field of hardware accessory processing equipment. The hardware accessory polishing device comprises a worktable, wherein first connecting seats are connected to two side of the worktable, a first motor is mounted on one side of one first connecting seat, the output end of the first motor is connected to a first belt wheel, and one end of the first belt wheel is connected to a first lead screw. By arranging the first motor, a second motor, an electric push rod, the first connecting seats, a second connecting seat, a first slide block and a second slide block, the first motor drives the first slide block to move on the first lead screw in the first connecting seat, so that a polishing wheel moves frontand back; the second motor drives the second slide block to move on the second lead screw in the second connecting seat, so that the polishing wheel moves left and right; the electric push rod stretches , so that the polishing wheel moves up and down to polish a workpiece all around, and therefore, the operating labor force of staff is reduced and the production efficiency of the device is improved.

Owner:徐罗斌

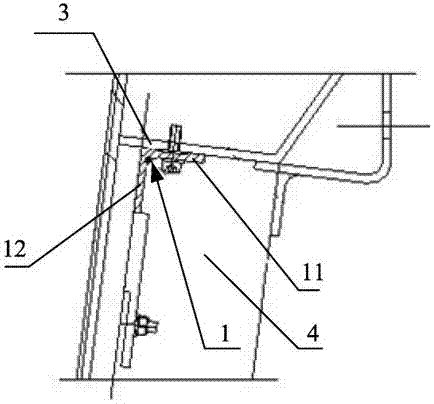

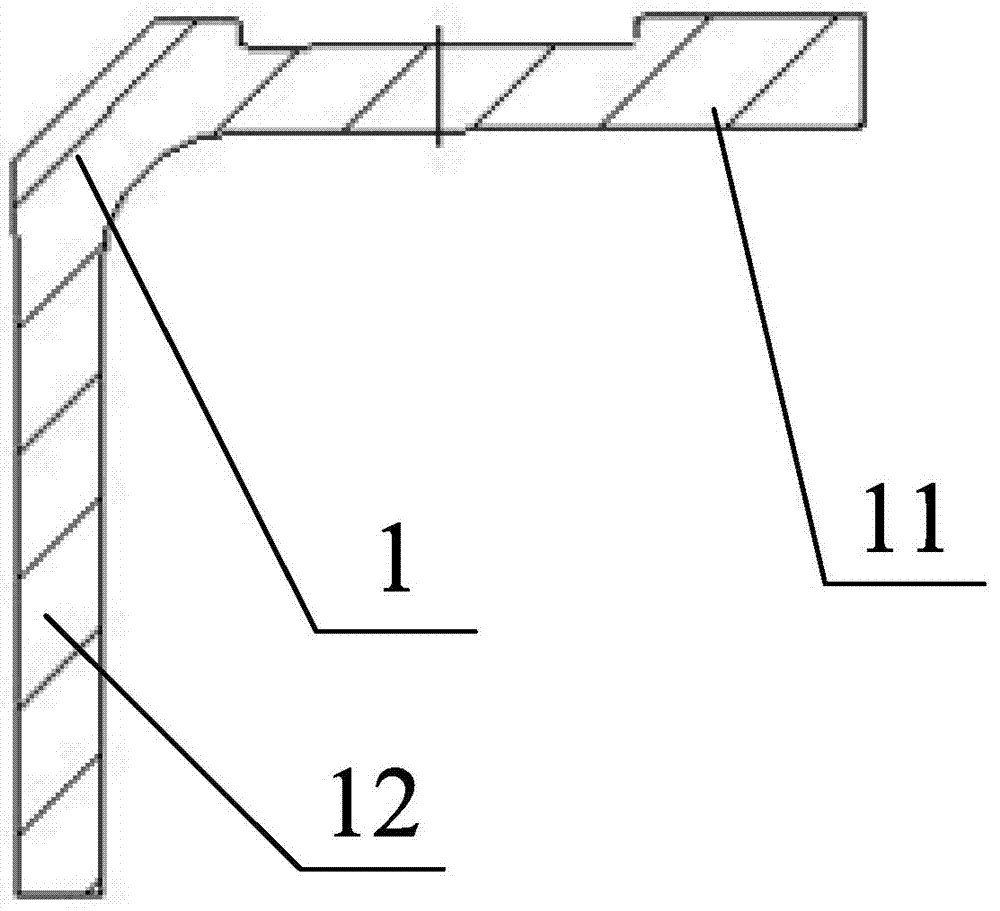

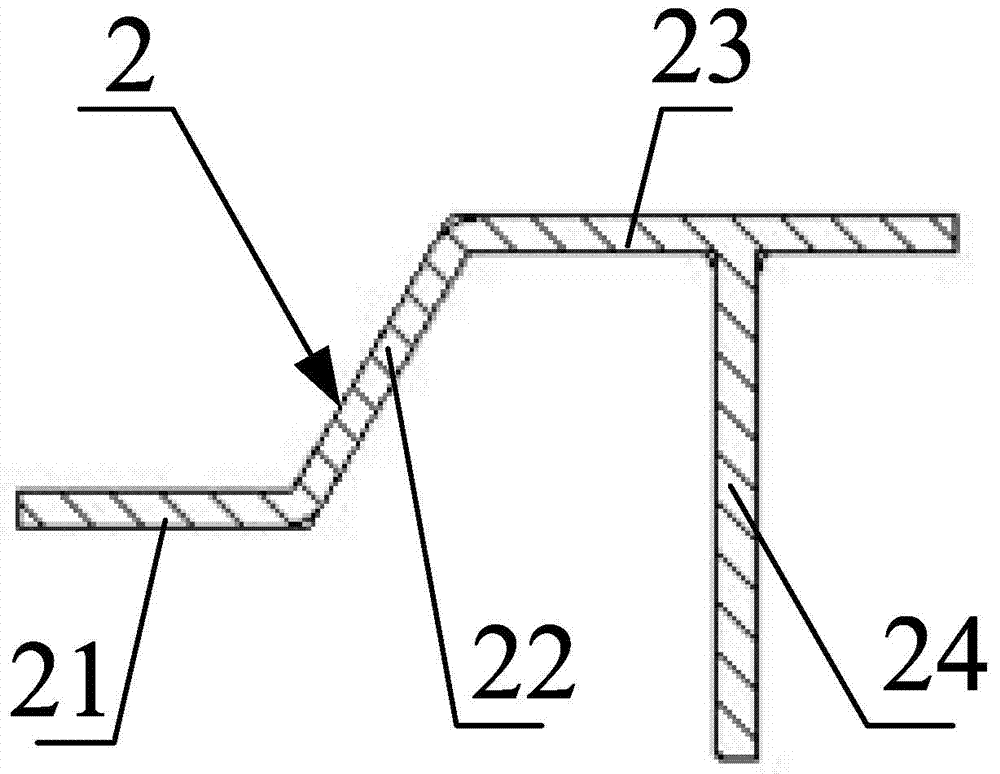

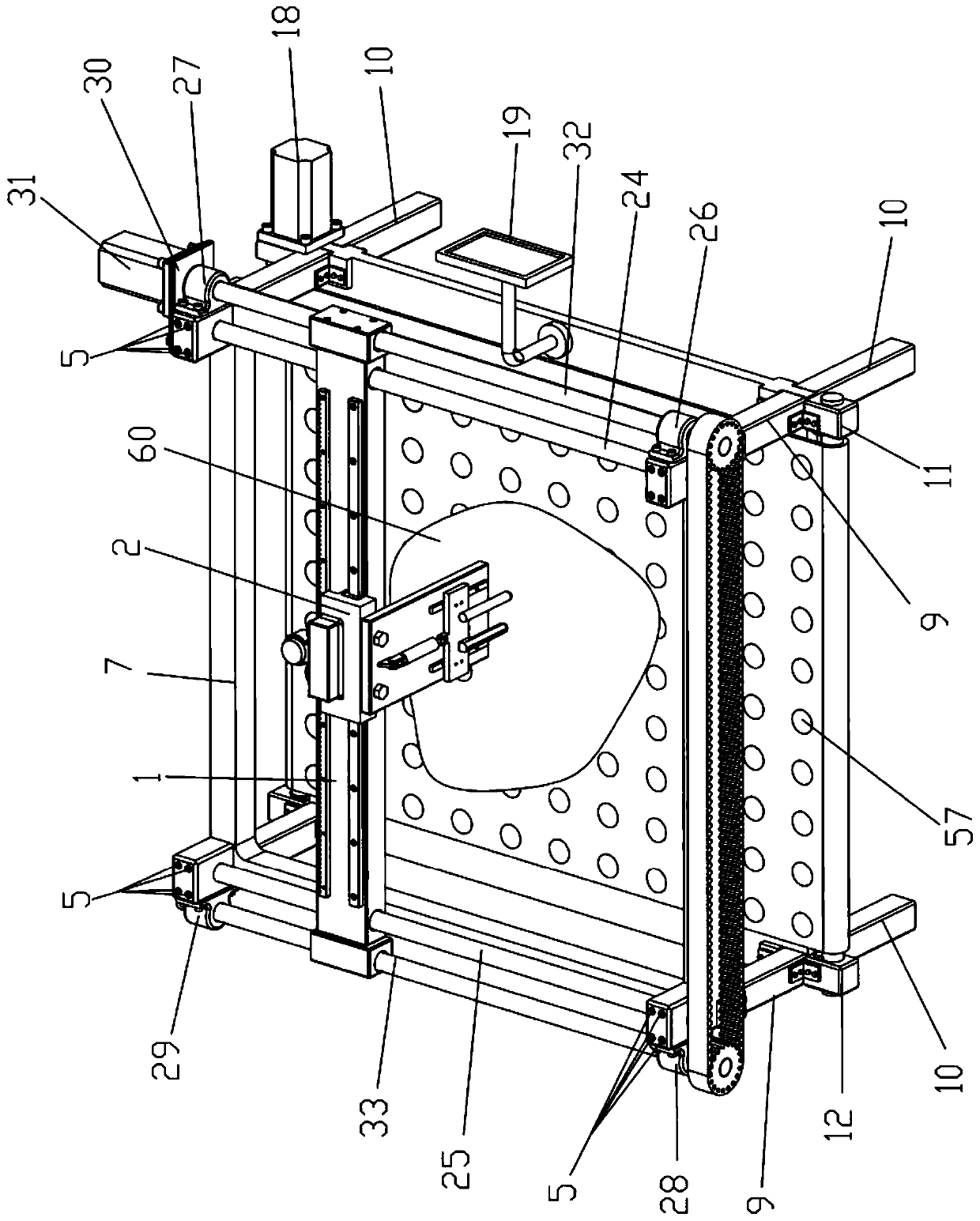

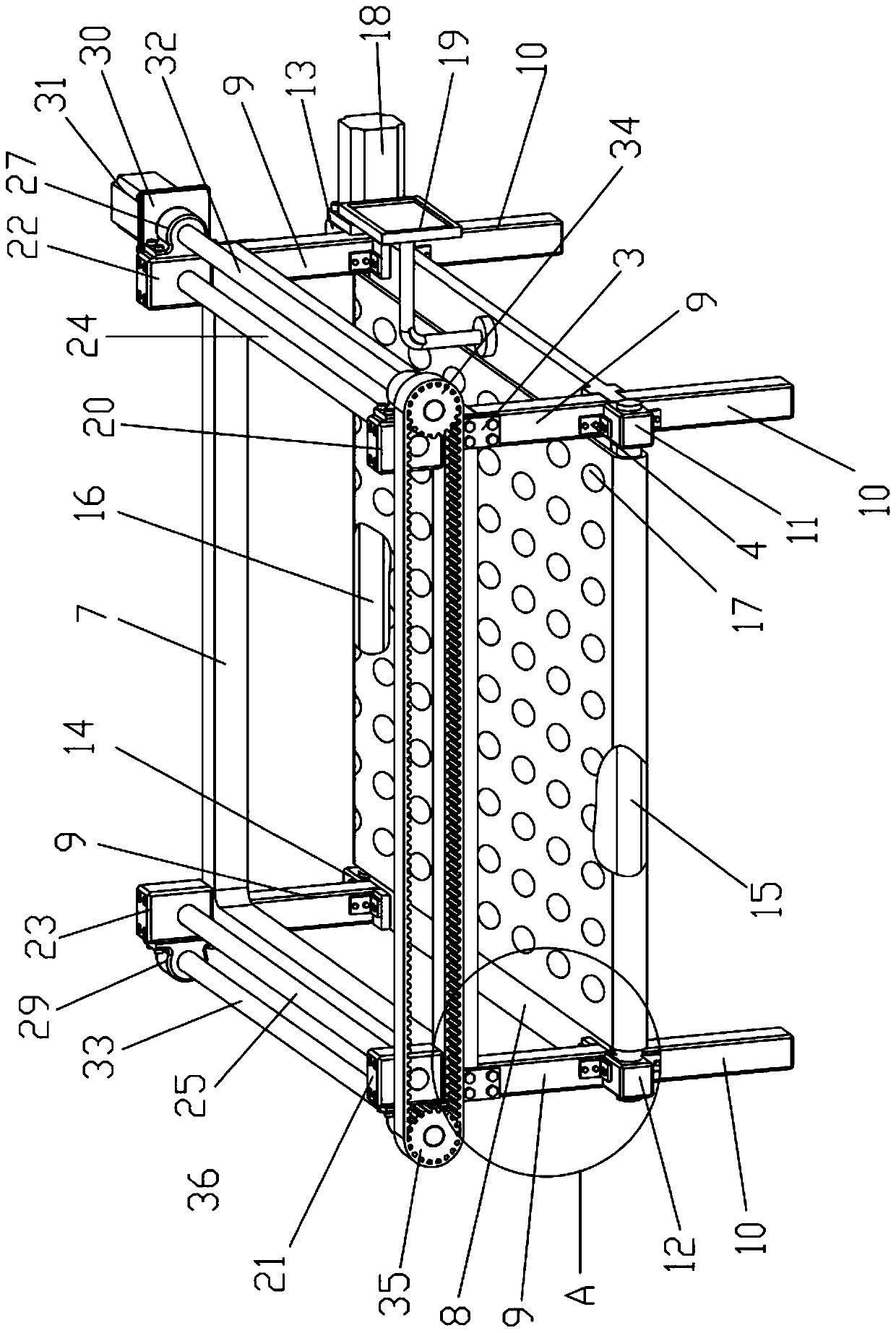

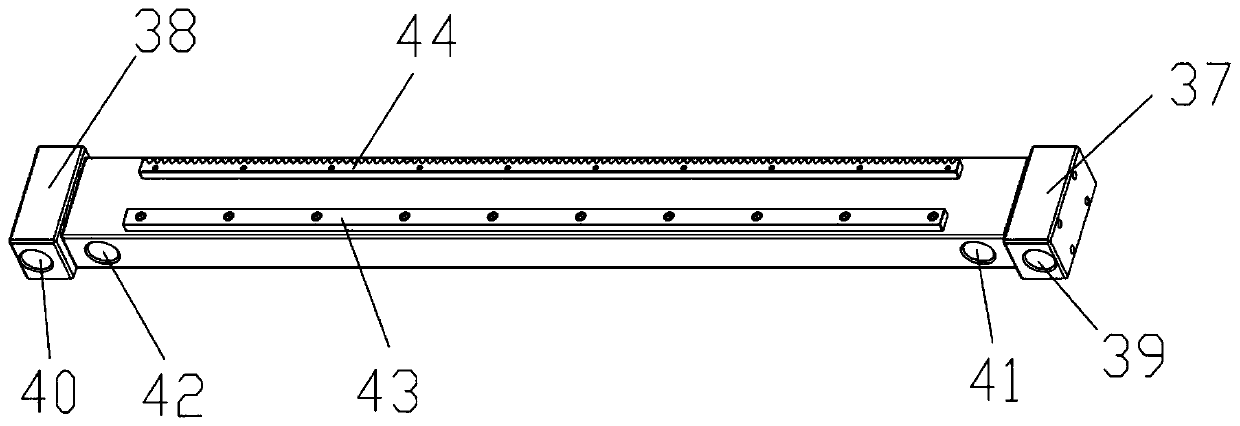

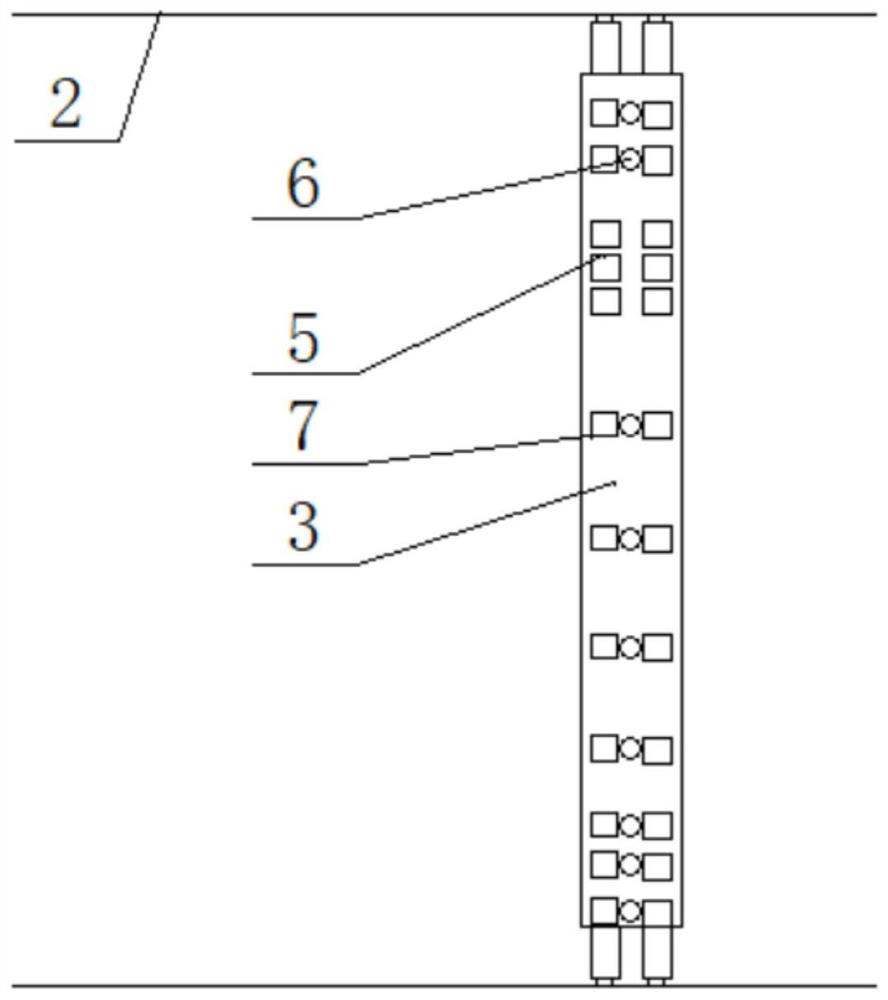

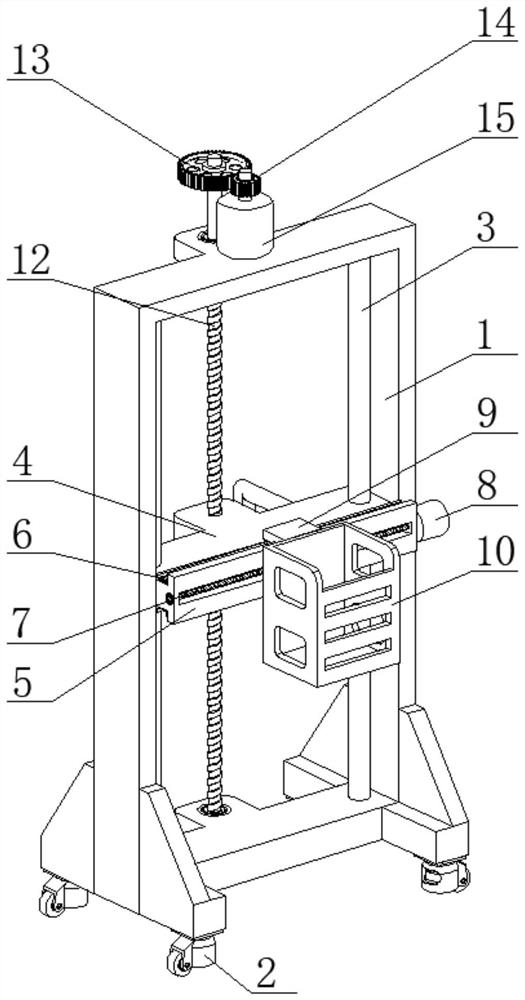

Unit type glass curtain wall lifting device and construction method

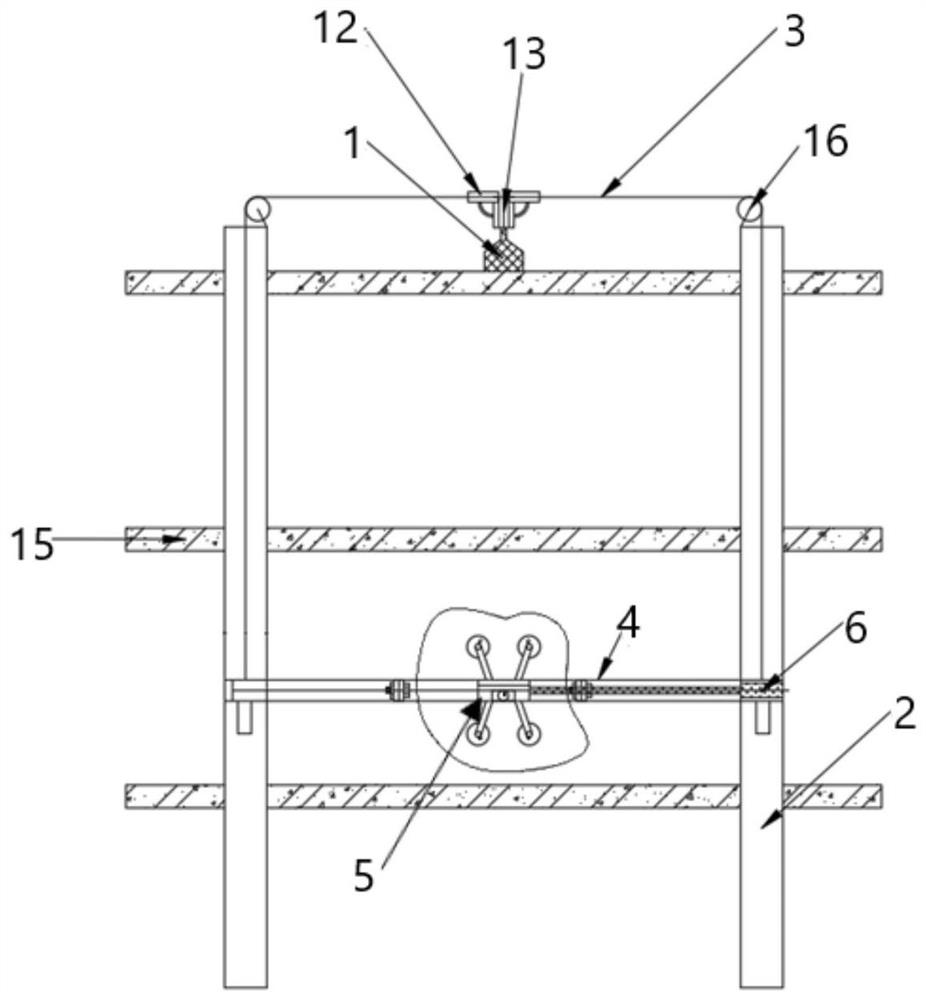

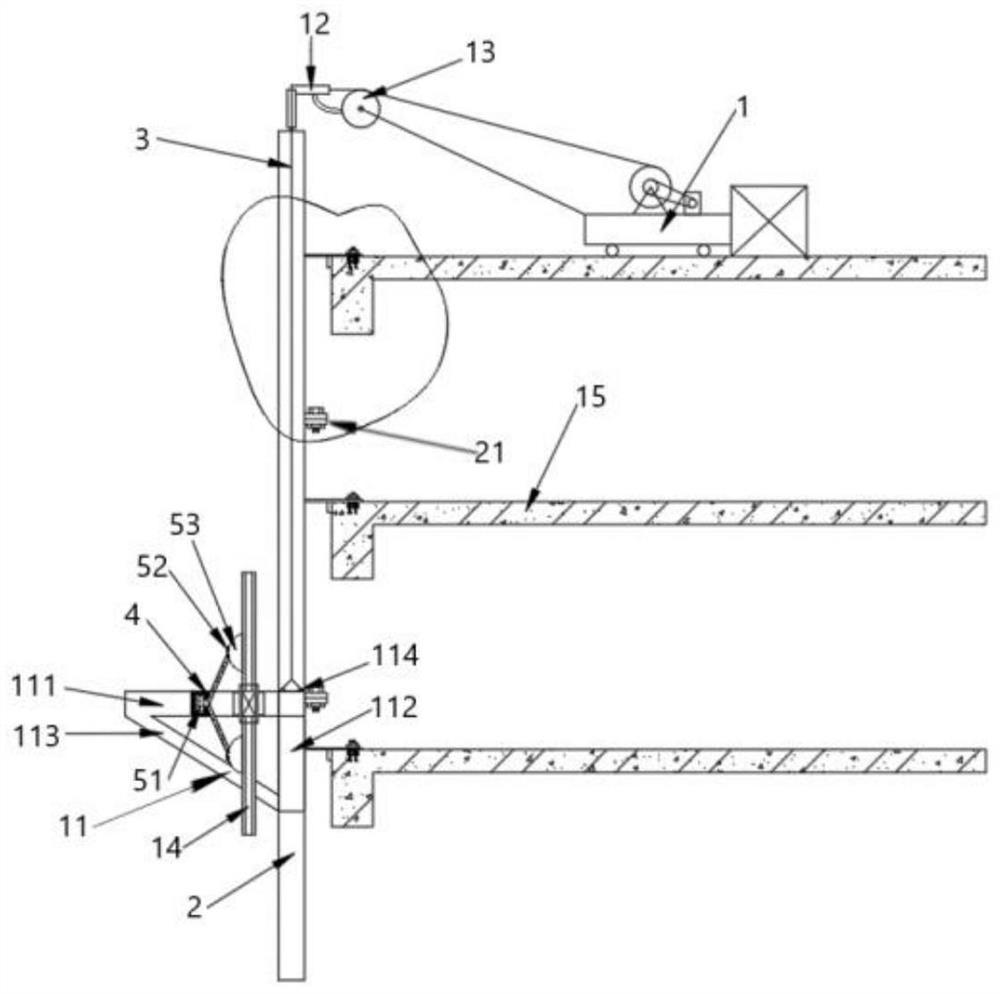

InactiveCN111704046AImprove stabilityGuaranteed stabilityWallsBuilding material handlingClassical mechanicsWinch

The invention relates to a unit type glass curtain wall lifting device. The unit type glass curtain wall lifting device comprises a winch, guide rails and a sucker structure, wherein the guide rails are arranged on two sides of the winch; the unit type glass curtain wall lifting device further comprises a cross beam and bracket modules which are arranged on the guide rails on the two sides and controlled by a steel wire rope to move up and down, the sucker structure is arranged on the cross beam through a sliding body, the sliding body is controlled by an electric telescopic rod to slide on the cross beam, two ends of the cross beam are connected to the bracket modules on the guide rails on the two sides respectively, and the cross beam on the bracket modules can move in the direction horizontally vertical to the cross beam. The cross beam is connected with the bracket modules, the bracket modules are controlled by the steel wire rope to move up and down, the cross beam and the suckerstructure can be driven to move up and down, so that height of a unit type glass curtain wall is accurately controlled, the cross beam on the bracket modules can move in the direction horizontally vertical to the cross beam, and the unit type glass curtain wall can move front and back. The unit type glass curtain wall lifting device can be positioned accurately and improves stability of the unit type glass curtain wall, and secondary hoisting is not needed, so that processes are reduced.

Owner:CHINA FIRST METALLURGICAL GROUP

Side door sealing device

ActiveCN103935374AReasonable structural designSimple structureDoor arrangementVertical planeWelding deformation

The invention discloses a side door sealing device which is applied to trains. During specific arrangement, three sealing strips are adopted, and the three sealing strips comprise the upper pressing strip and the two side pressing strips. Due to the facts that a first pressing plate is provided with a horizontal plane longitudinal kidney-shaped hole, a top cover edge beam is provided with a horizontal plane transverse kidney-shaped hole, a first connecting piece connects the horizontal plane longitudinal kidney-shaped hole and the horizontal plane transverse kidney-shaped hole, and a first adjusting gasket is arranged between the horizontal plane longitudinal kidney-shaped hole and the horizontal plane transverse kidney-shaped hole, three-dimensional direction adjustment of the upper pressing strip can be achieved. Due to the facts that a sixth pressing plate is provided with a vertical plane transverse kidney-shaped hole, a C-shaped steel channel is fixed onto a side door column, a second connecting piece connects the vertical plane transverse kidney-shaped hole and the C-shaped steel channel, and a second adjusting gasket is arranged between the vertical plane transverse kidney-shaped hole and the C-shaped steel channel, three-dimensional direction adjustment of the side pressing strips can be achieved. Therefore, even if a stainless steel train body of a city rail train has large welding deformation, the best sealing position can be found out through three-dimensional direction adjustment of the upper pressing strip and the side pressing strips.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

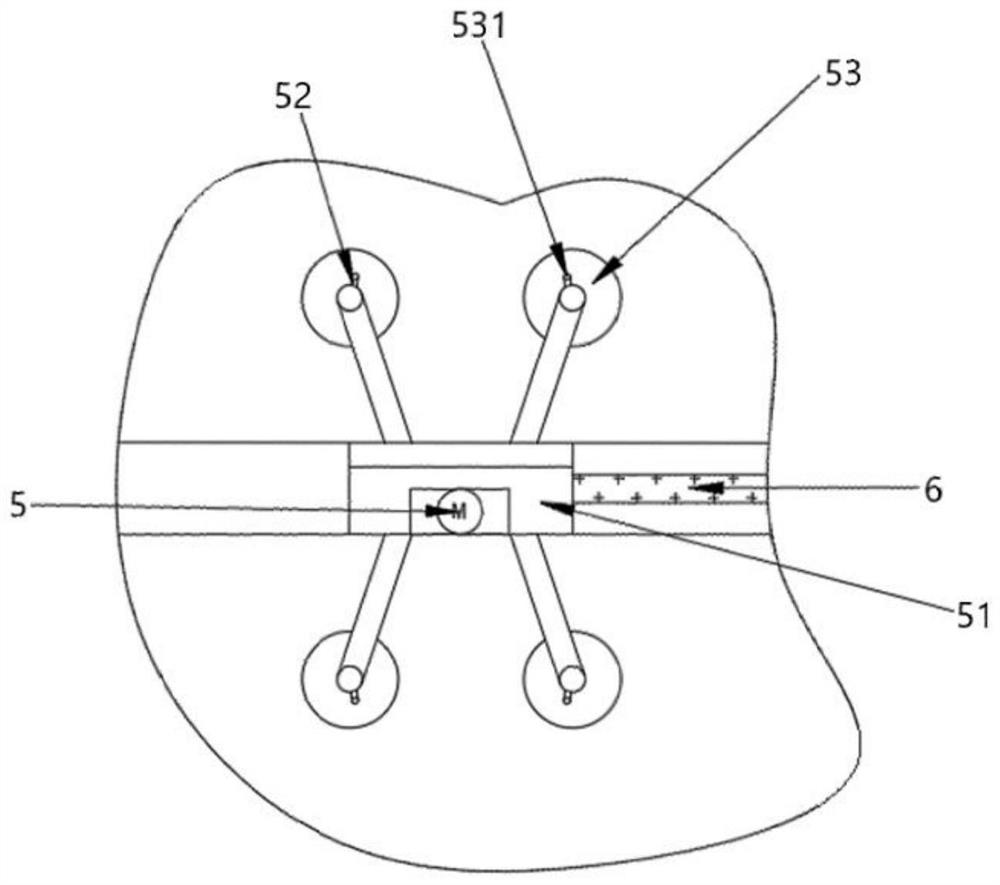

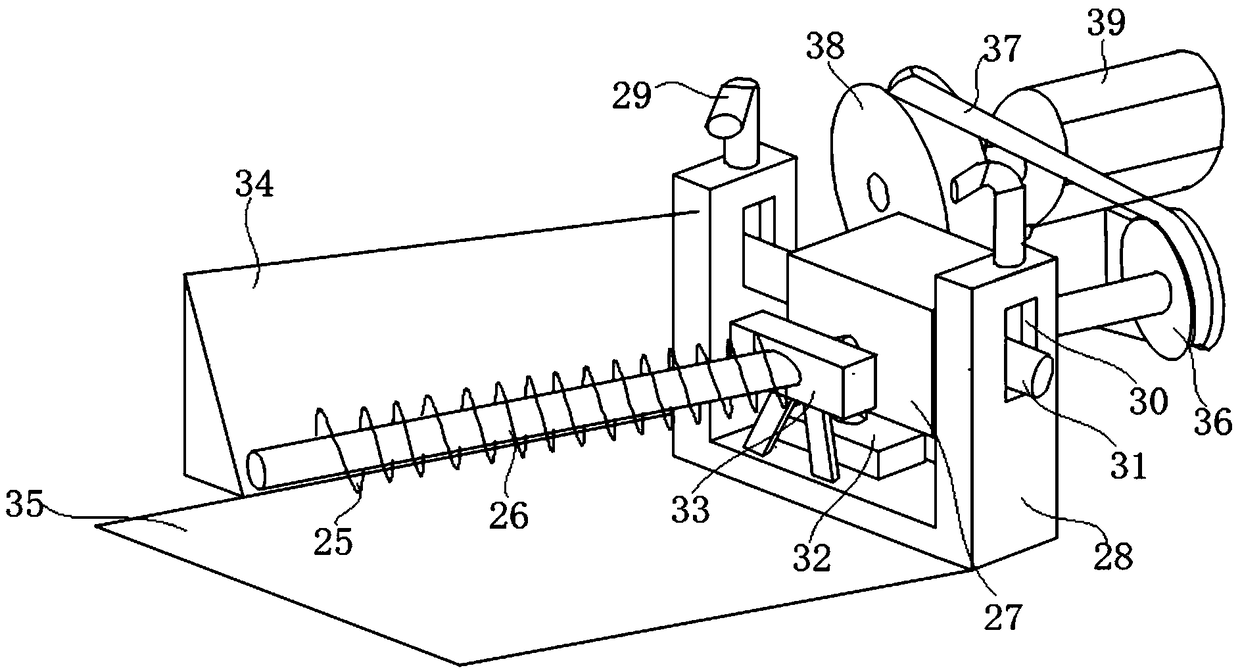

Floor tile seam beautifying machine

InactiveCN109853916AEasy to operateReduce volumeBuilding constructionsMechanical engineeringVacuum cleaner

The invention relates to a floor tile seam beautifying machine, and belongs to the field of home decoration tools. The floor tile seam beautifying machine is composed of a lifting mechanism, a translation mechanism, a material extrusion mechanism, a seam cleaning mechanism, a vacuum cleaner, a seam pressing mechanism and a base plate walking mechanism; the material extrusion mechanism and the lifting mechanism are connected by bolts; the lifting mechanism is welded to the upper part of the translation mechanism, and the translation mechanism is welded to the upper part of the base plate walking mechanism; and the seam cleaning mechanism is fixed to the front end of the base plate walking mechanism by bolts, the vacuum cleaner is fixed to the rear side of the seam cleaning mechanism by screws, and the seam pressing mechanism is fixed to the rearmost end of the base plate walking device by bolts. According to the floor tile seam beautifying machine, the operation is easy, the size is compact, four processes of seam cleaning, dust absorbing, seam beautifying and seam pressing are combined together, the seam beautifying can be carried out precisely, the efficiency of seam beautifying personnel can be improved, the labor force is reduced, and the labor intensity of workers is reduced.

Owner:WEIFANG UNIV OF SCI & TECH

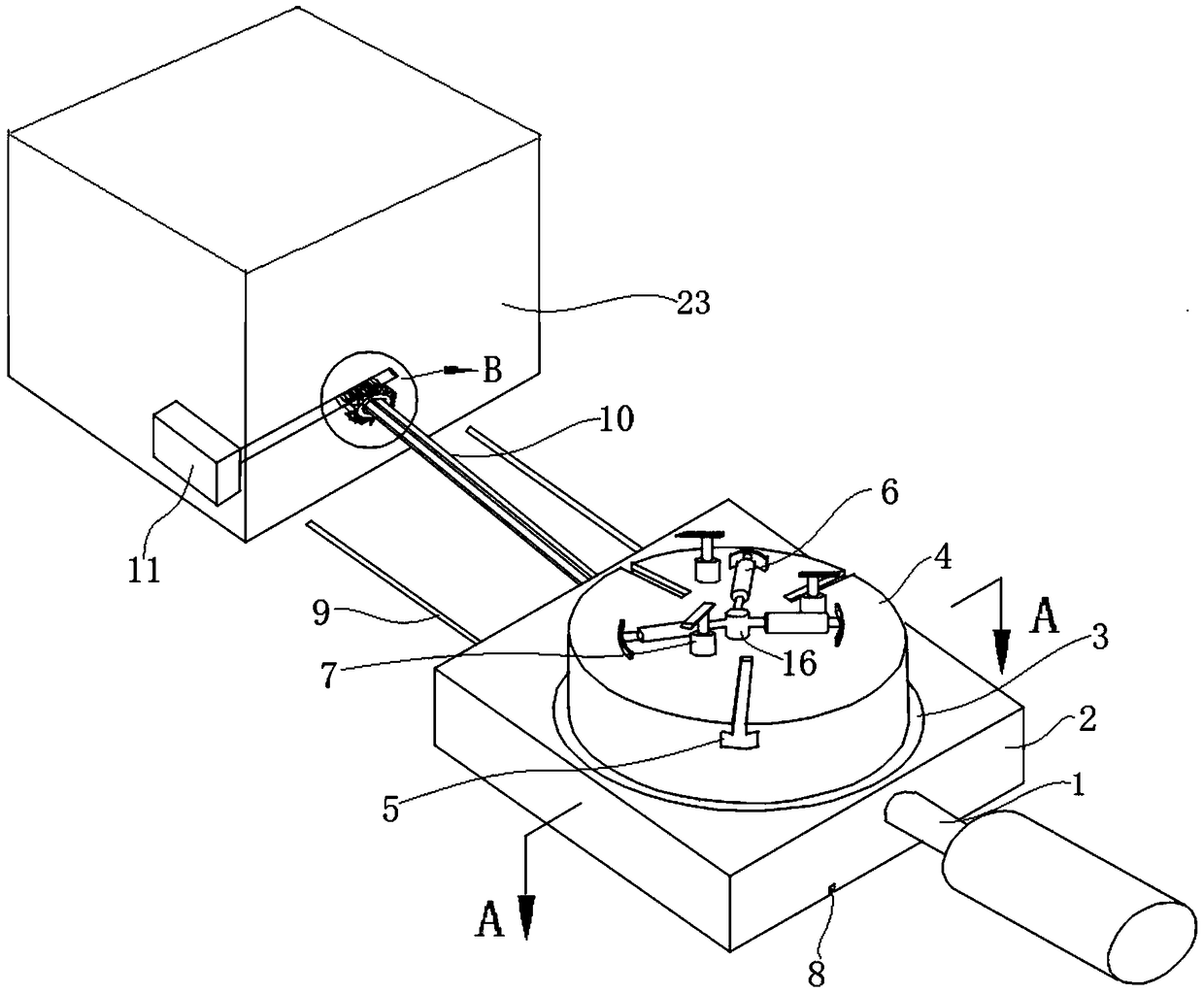

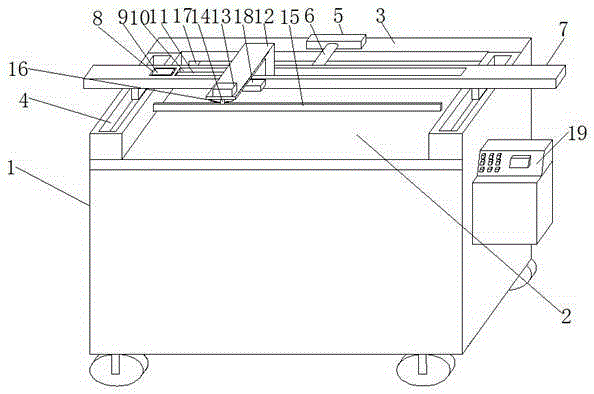

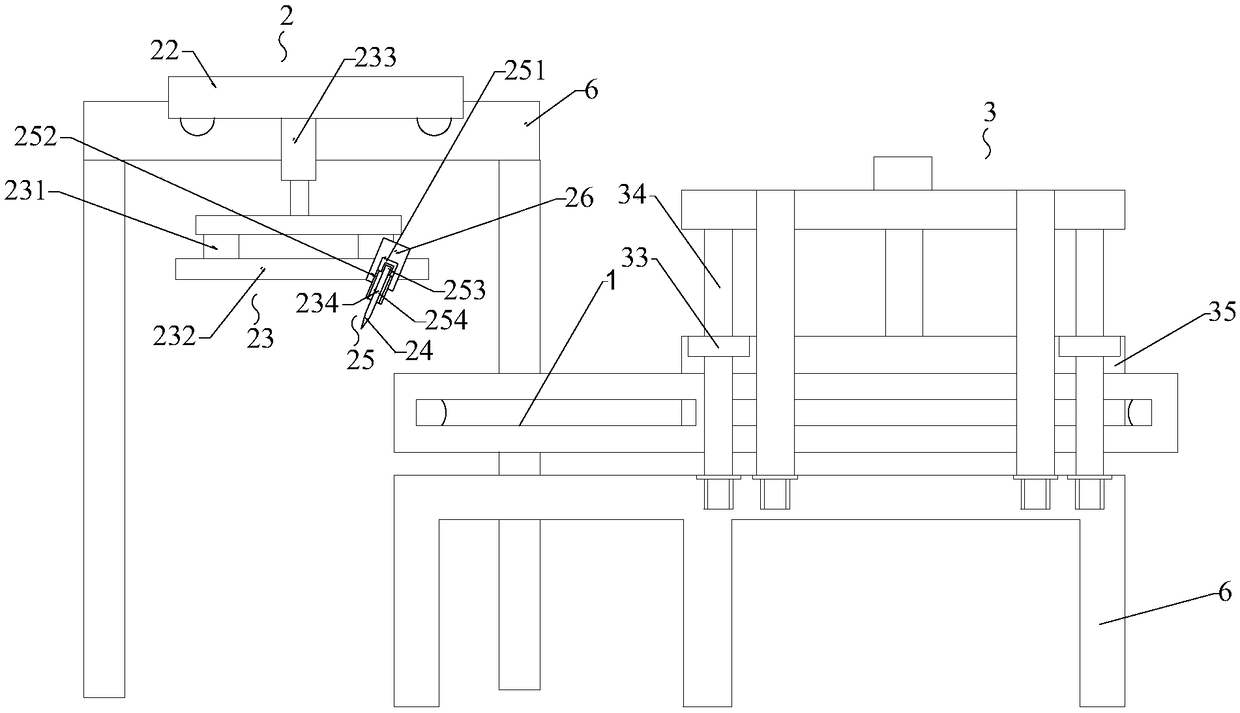

Drilling and milling machining system with drill bit self-cooling function

ActiveCN109128307AEnsure stabilityEasy dischargeTransportation and packagingLarge fixed membersEngineeringMachining system

The invention discloses a drilling and milling machining system with a drill bit self-cooling function, and belongs to the field of drilling and milling machining devices. The drilling and milling machining system comprises rotary pressing mechanisms, a worktable mechanism, a drilling and milling mechanism and chip removal mechanisms mounted on the two sides of the worktable mechanism correspondingly. The worktable mechanism comprises a rotary table, a plurality of telescopic cylinders are mounted on the upper top face of the rotary table, and the central axes of output shafts of the telescopic cylinders penetrate through the circle center of the upper top face of the rotary table. Arc plates are mounted at the ends of the output shafts of the telescopic cylinders. The drilling and millingmechanism comprises a base which is mounted above a transmission box. A rack is arranged on the base and provided with a milling and drilling machine. The milling and drilling machine comprises a self-cooling drill bit. The multiple rotary pressing mechanisms are mounted on the upper top face of the rotary table and comprise outer cylinder bodies, bearing seats and pressing plates. The drilling and milling machining system has the high integration level.

Owner:东台升华工具有限公司

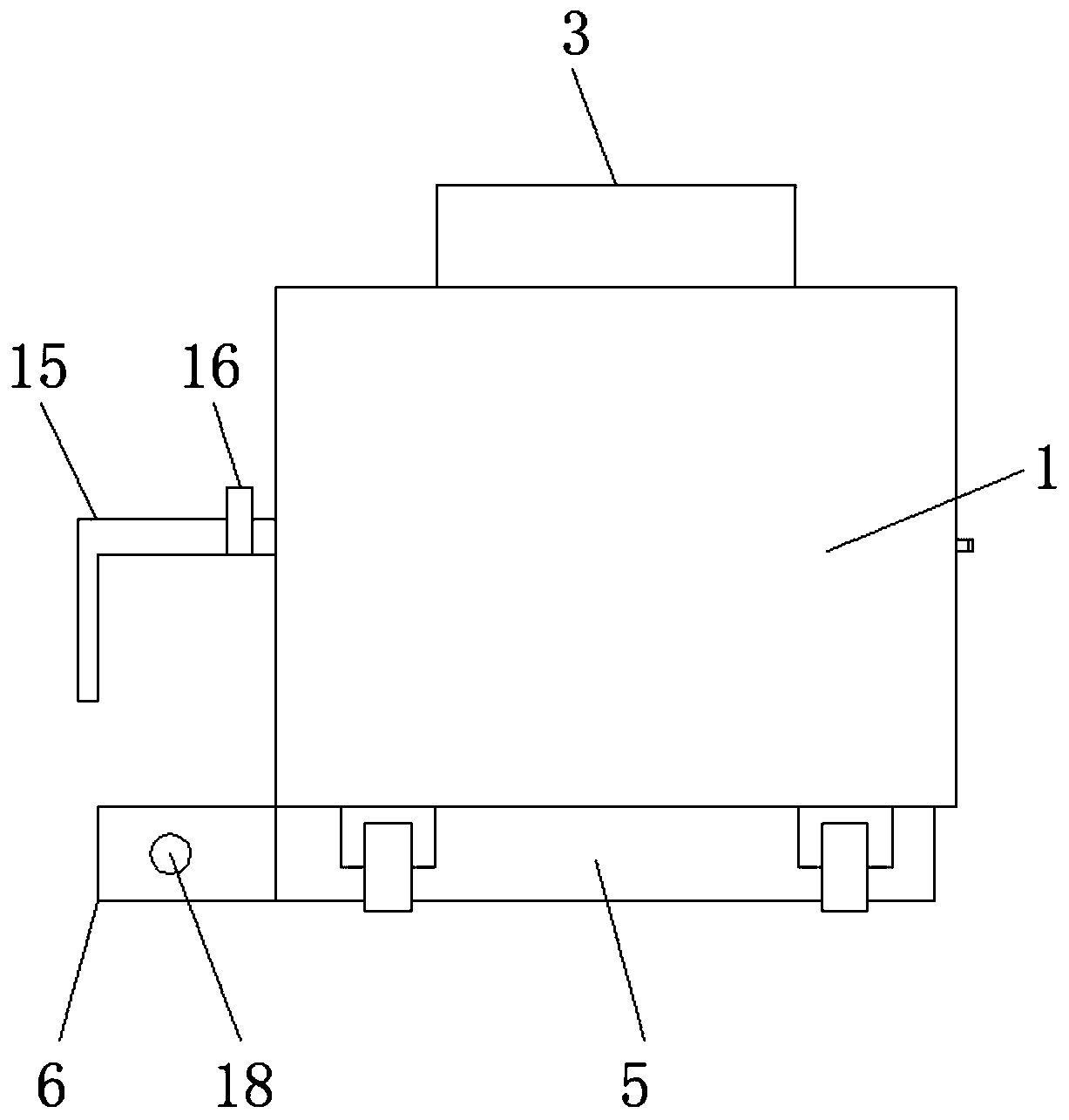

Building pavement kerb accurate laying device capable of avoiding dislocation

ActiveCN111287051AAvoid Precise LayingAchieve forward and backward movementRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a building pavement kerb accurate laying device capable of avoiding dislocation. The laying device comprises a laying device body, a feeding port, a protective cover, a door plate, a handrail, a control box, a contact and a control cabinet. A feeding opening is formed in the top of the laying device body; a protective cover is arranged on one side of the feeding opening; adoor plate is arranged on the front side of the laying device body; a kerb containing cover is welded to the bottom of the laying device body, a guide hopper is welded to the lower end of one side ofthe kerb containing cover, a conveying belt is arranged on the front side of the pushing mechanism, a discharging mechanism is arranged in the side, away from the interior of the pushing mechanism, ofthe conveying belt, and a discharging plate is arranged at the output end of the discharging mechanism. According to the building pavement kerb accurate laying device capable of avoiding dislocation,kerbs can be hoisted into the laying device body, the kerbs can be accurately aligned with kerbs laid at road shoulders, the labor intensity of construction workers is relieved, and the laying efficiency is improved.

Owner:吴龙翔

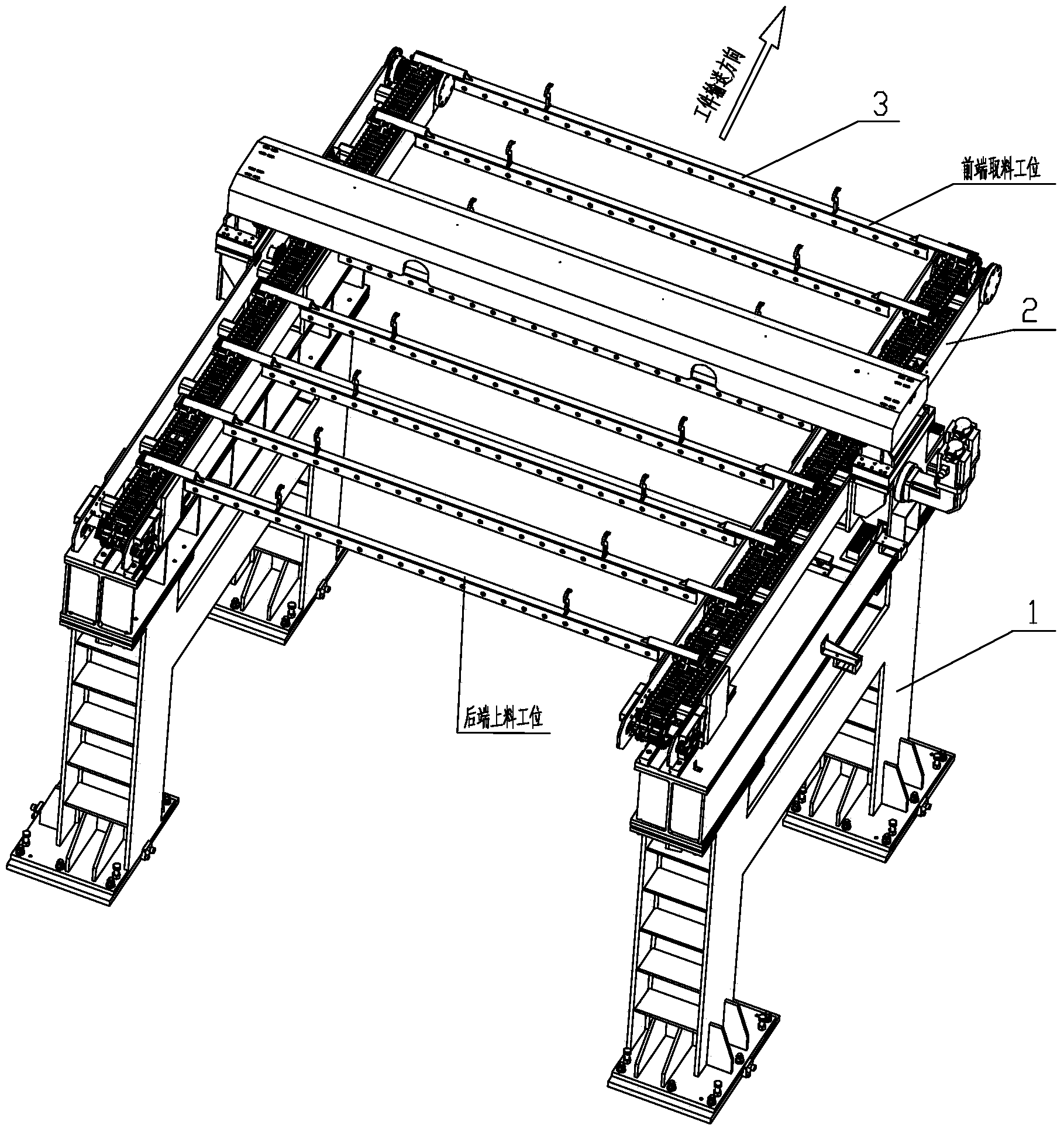

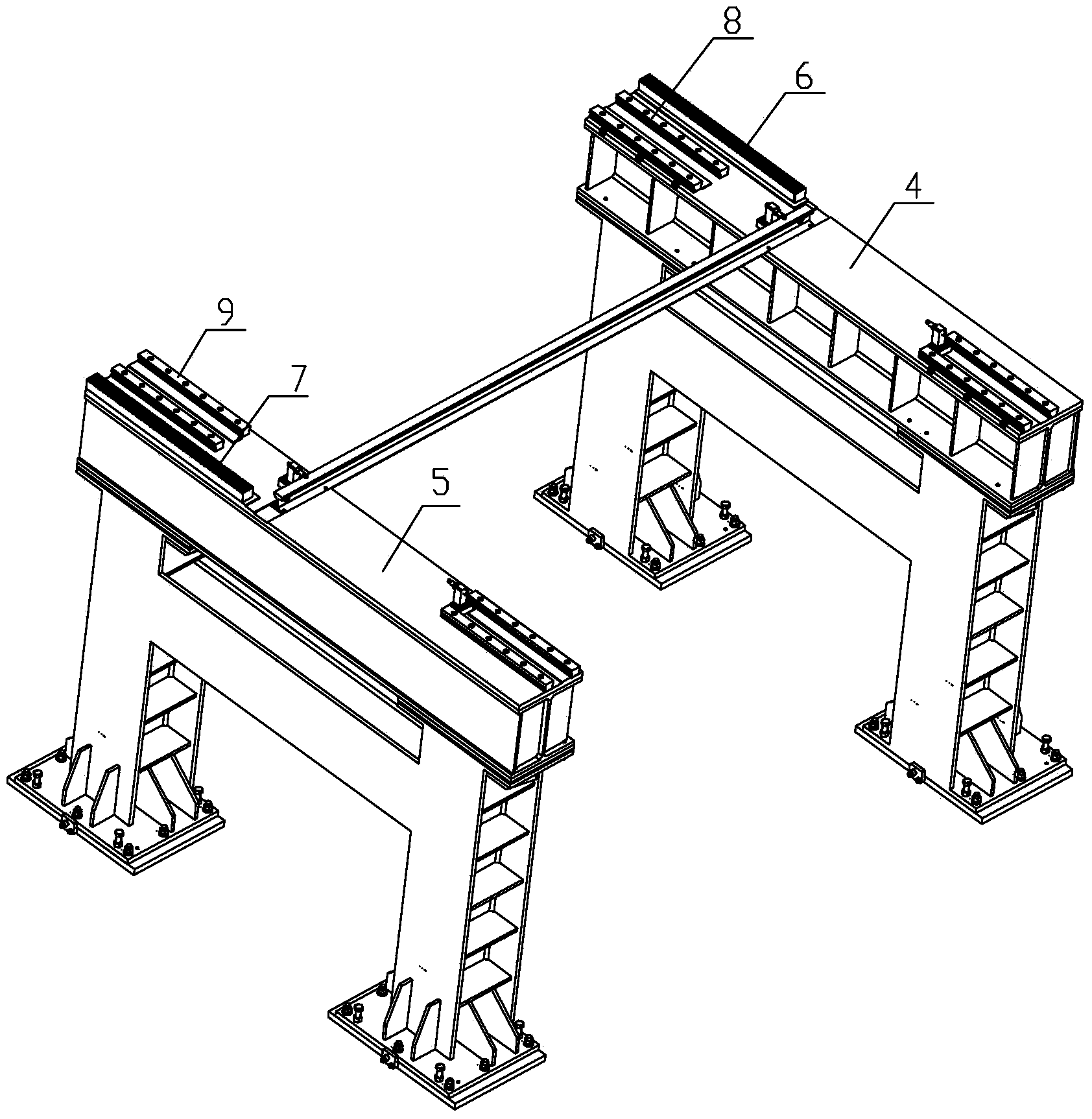

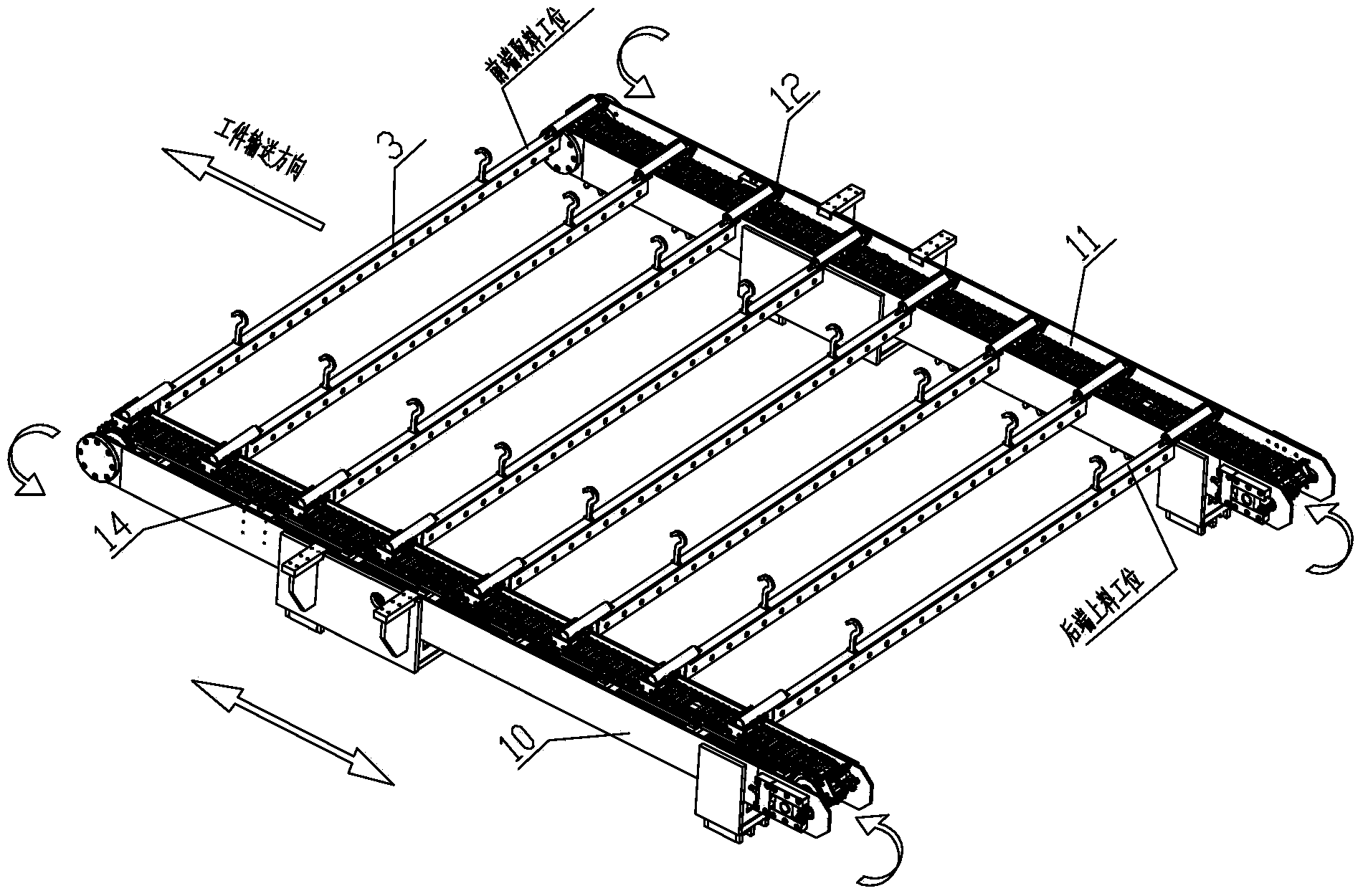

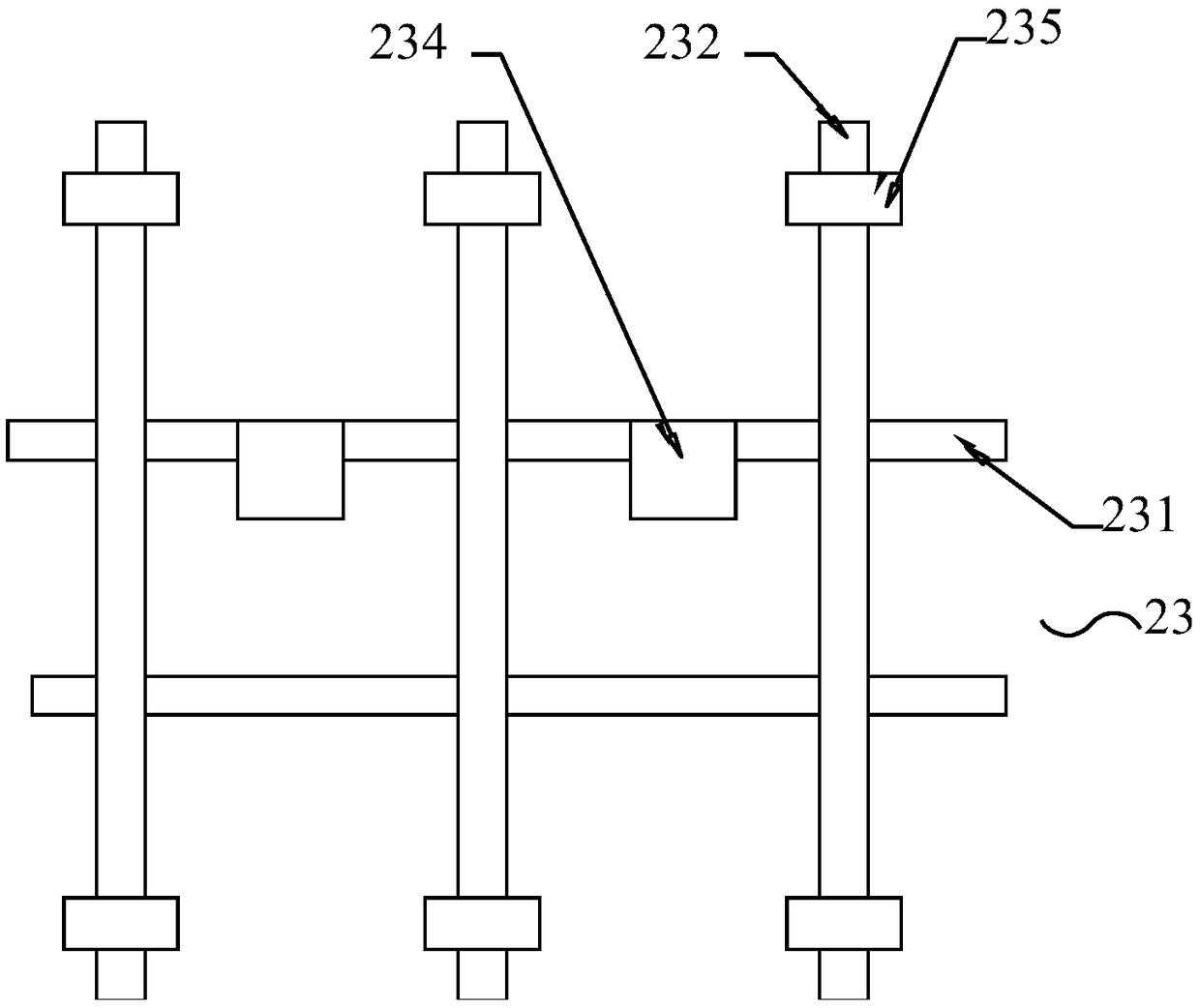

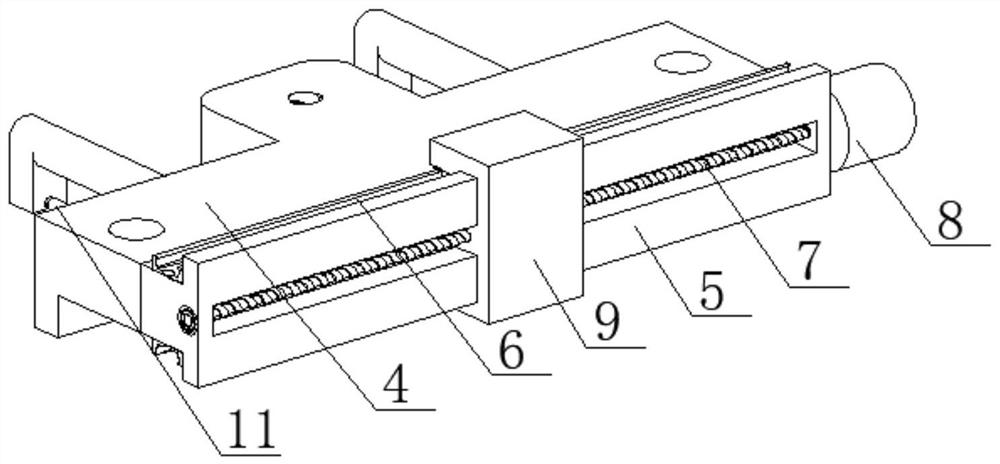

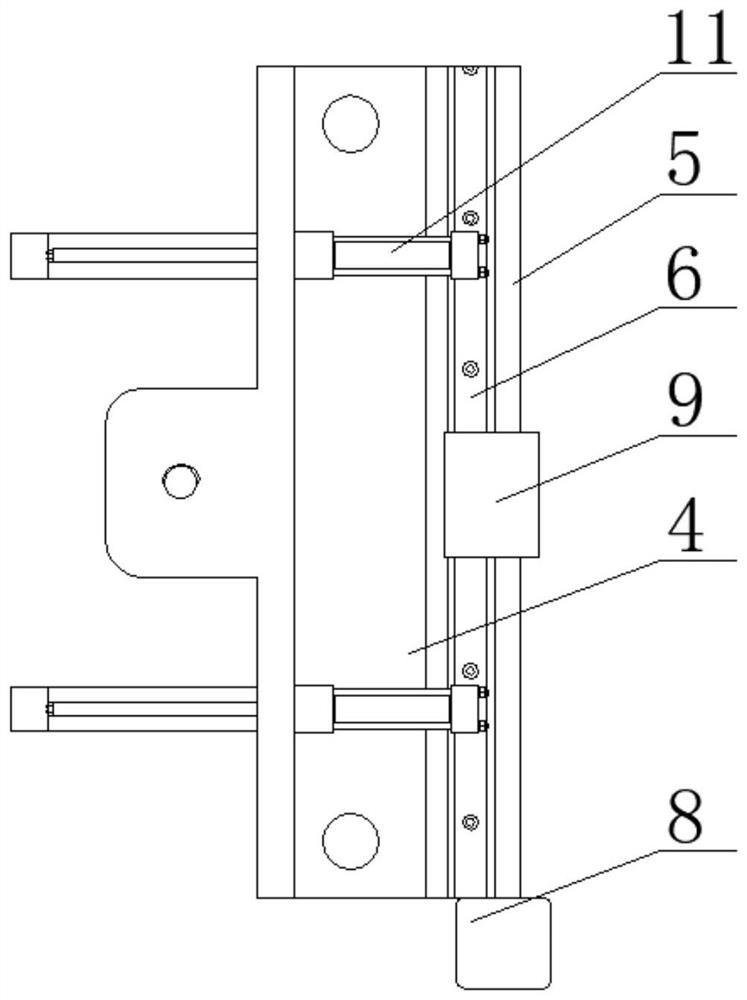

Automatic feeding device

ActiveCN103708177APrecise position controlStable conveying speedConveyorsStructural engineeringMechanical engineering

The invention relates to an automatic feeding device. The automatic feeding device comprises a bottom support part, an upper transmission part and a conveying suspender. The bottom support part comprises a left support and a right support, a left rack is installed on the left support, and a right rack is installed on the right support. Left guide strips are installed at the front end of the left support and the rear end of the left support and right guide strips are installed at the front end of the right support and the rear end of the right support. The upper transmission part comprises a left transmission assembly and a right transmission assembly. Left sliding blocks on the left transmission assembly are matched with the left guide strips, right sliding blocks on the right transmission assembly are matched with the right guide strips, left conveying boat bodies on the left transmission assembly and right conveying boat bodies on the right transmission assembly are equal in number and corresponding in position in a left-and-right mode, and the left end of the conveying suspender and the right end of the conveying suspender are supported by the left conveying boat bodies and the right conveying boat bodies respectively. The automatic feeding device is ingenious in structure, reasonable in design and capable of realizing automatic feeding between a phosphorization line and a powder spraying line, improves the production efficiency and lowers the labor intensity.

Owner:WUXI BEST PRECISION MACHINERY

Cave mining device of finishing-use granite

InactiveCN104818990AAvoid destructionHigh degree of automationConstructionsReciprocating drilling machinesEngineeringCave

The invention discloses a cave mining device of finishing-use granite, wherein the cave mining device includes a machine body and a rock drilling mechanism thereon. The machine body includes an outer rack, a movable frame which can move vertically in the outer rack, and a moving bench which is arranged on the movable frame and can move left-and-right. The rock drilling mechanism can move front-and-back along the moving bench. The movements of the movable frame, the moving bench and the rock drilling mechanism are all controlled by a controller. The device is designed for cave mining of rock material, can achieve horizontal mining of rock materials, can avoid damage on vegetation and protect environment, is high in automation degree, and is stable and is accurate in positioning.

Owner:林永强

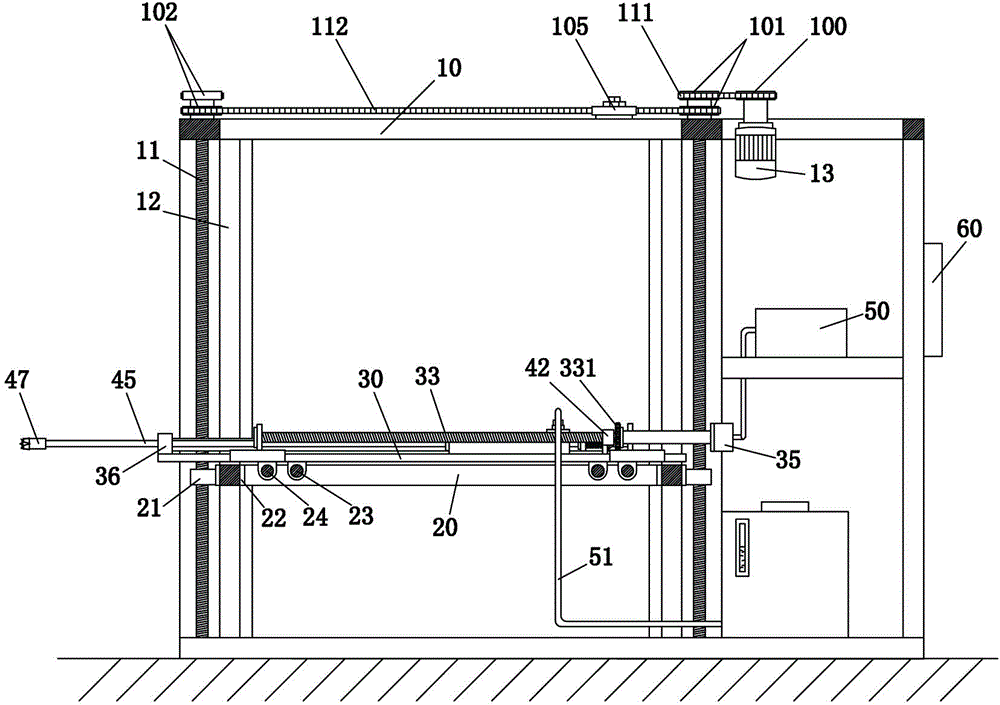

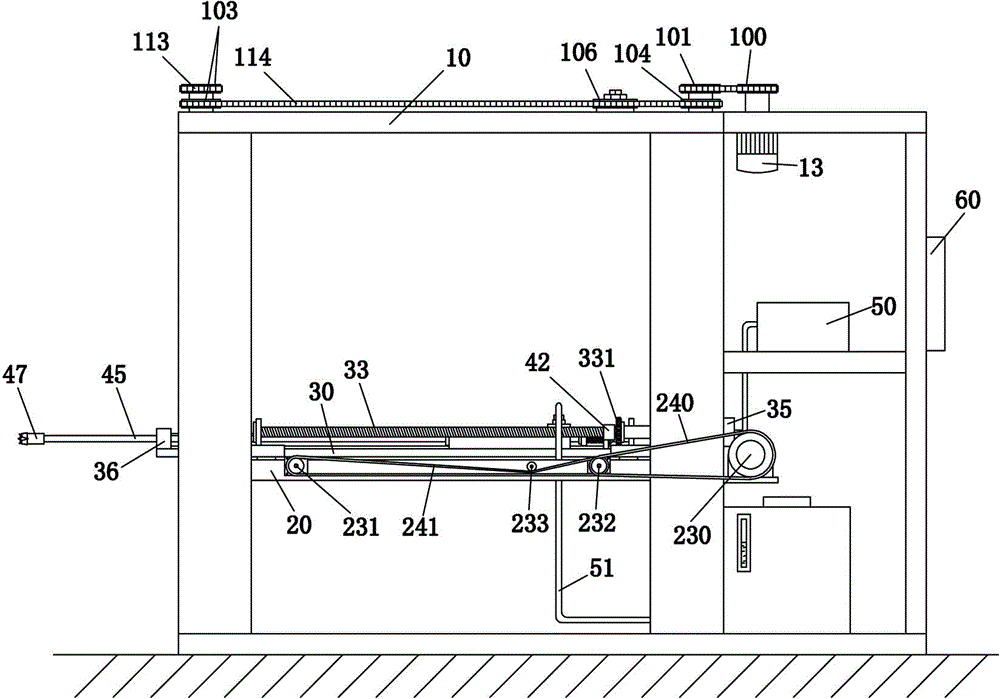

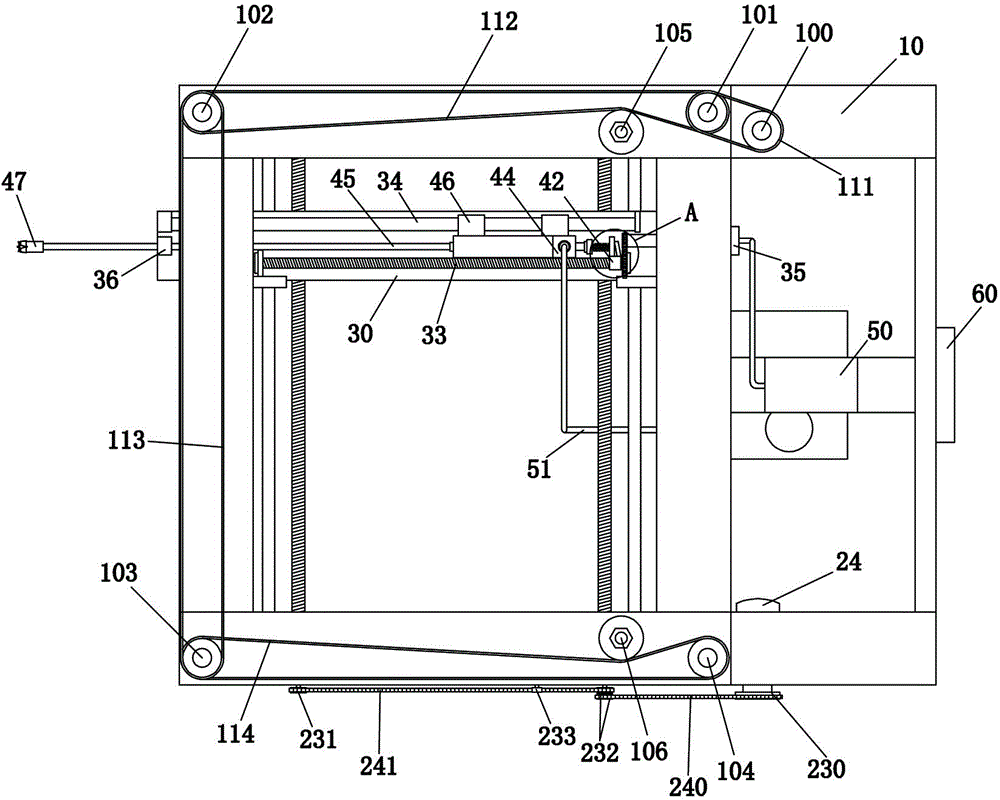

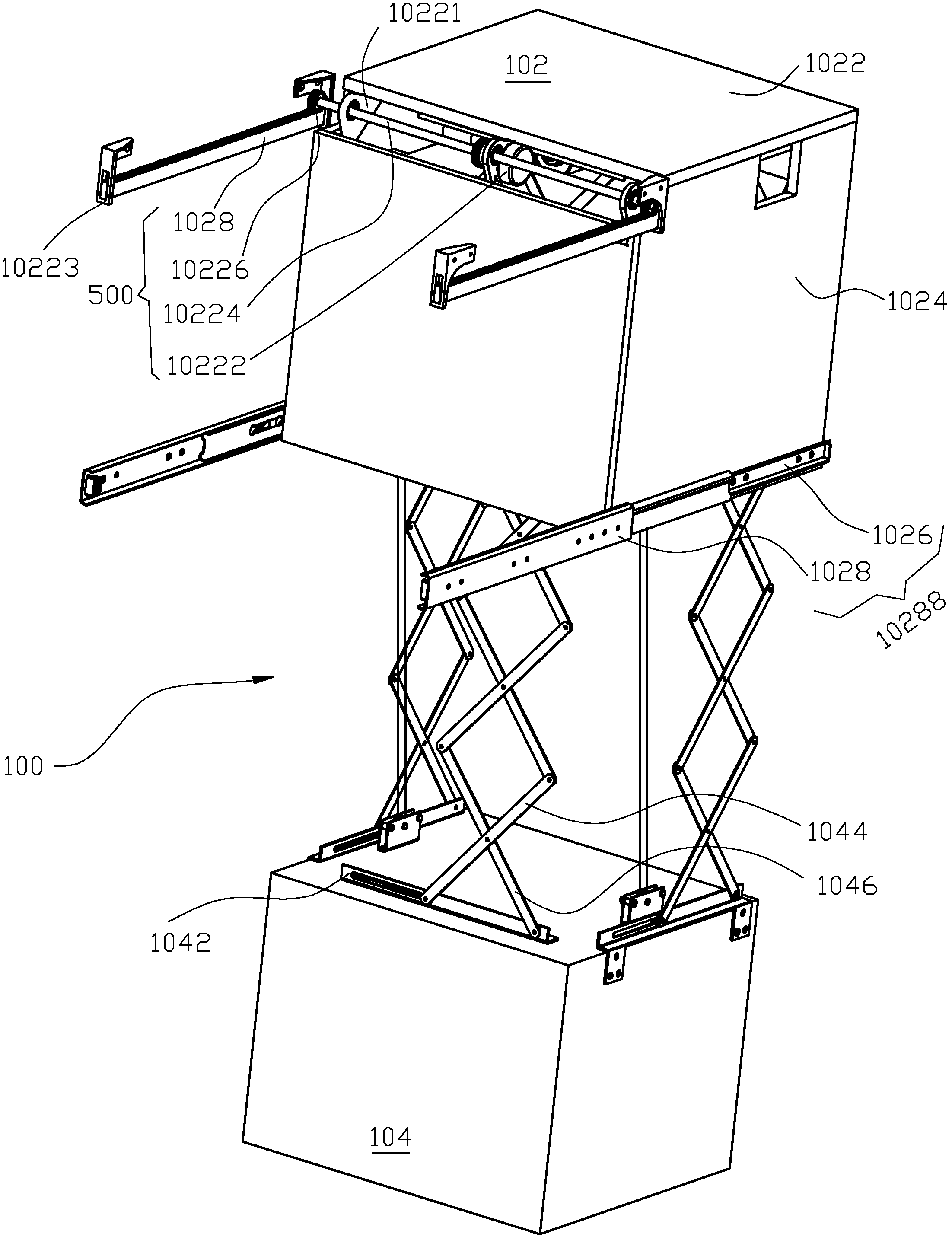

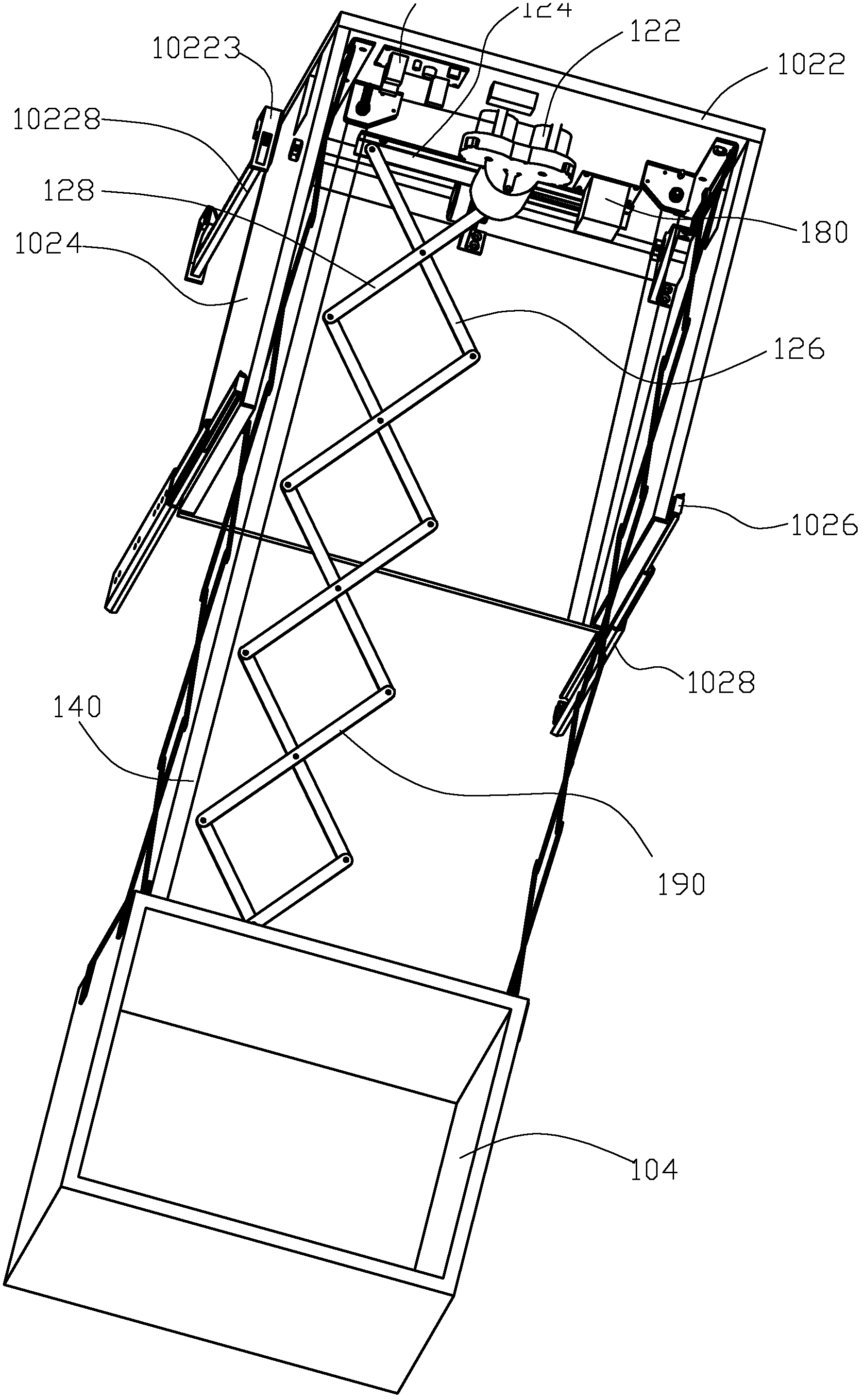

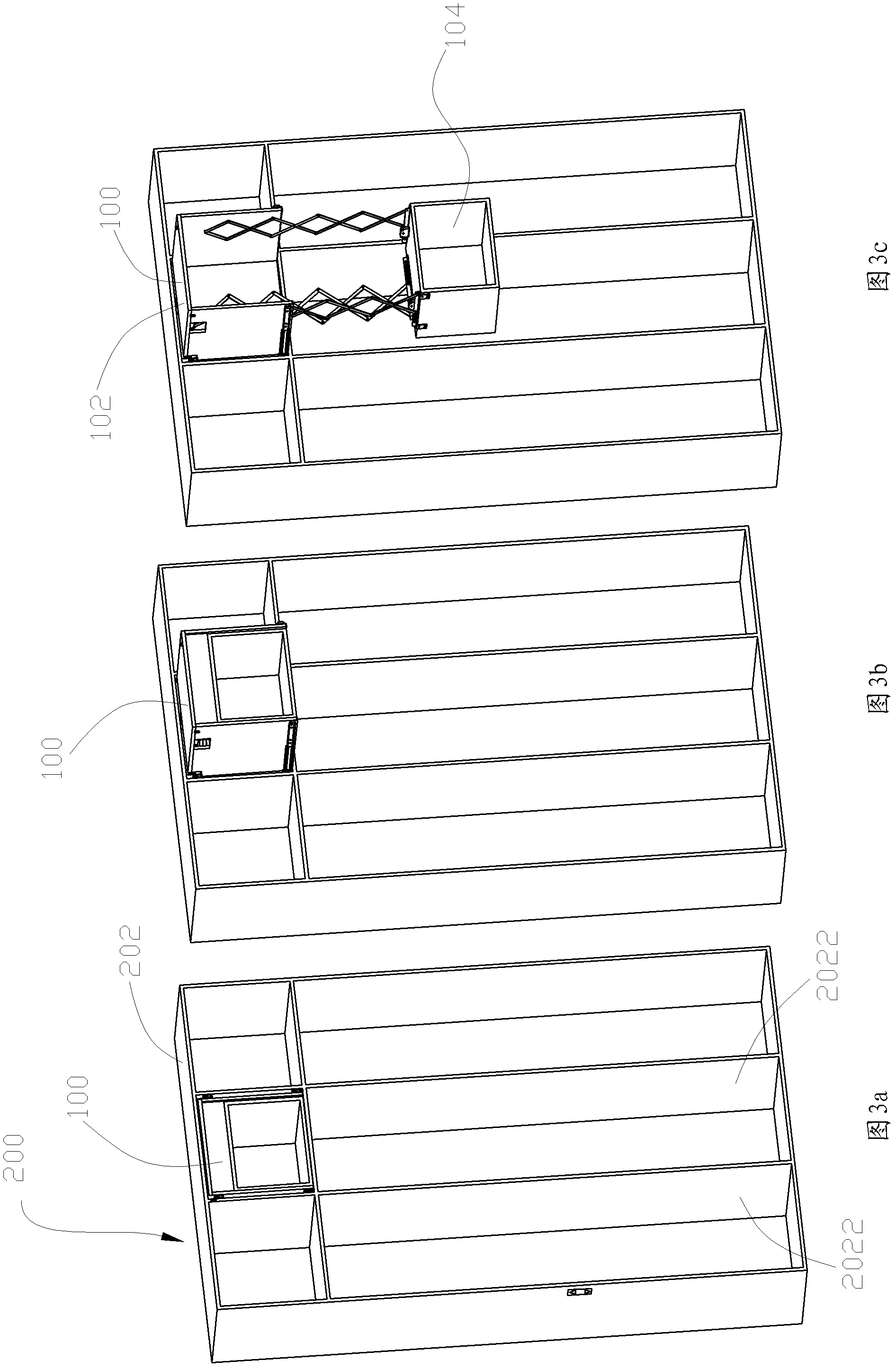

Storage box unit and storage cabinet with same

ActiveCN102631081AAchieve forward and backward movementImprove convenienceLifting devicesFurniture partsEngineering

Owner:广东顶固集创家居股份有限公司

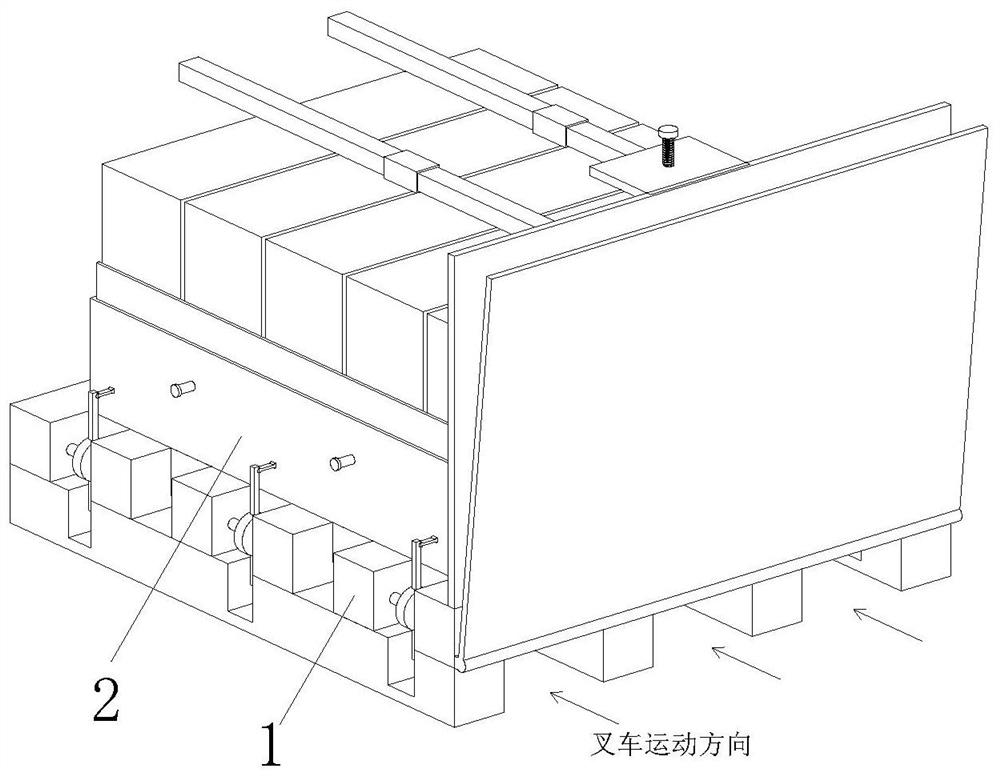

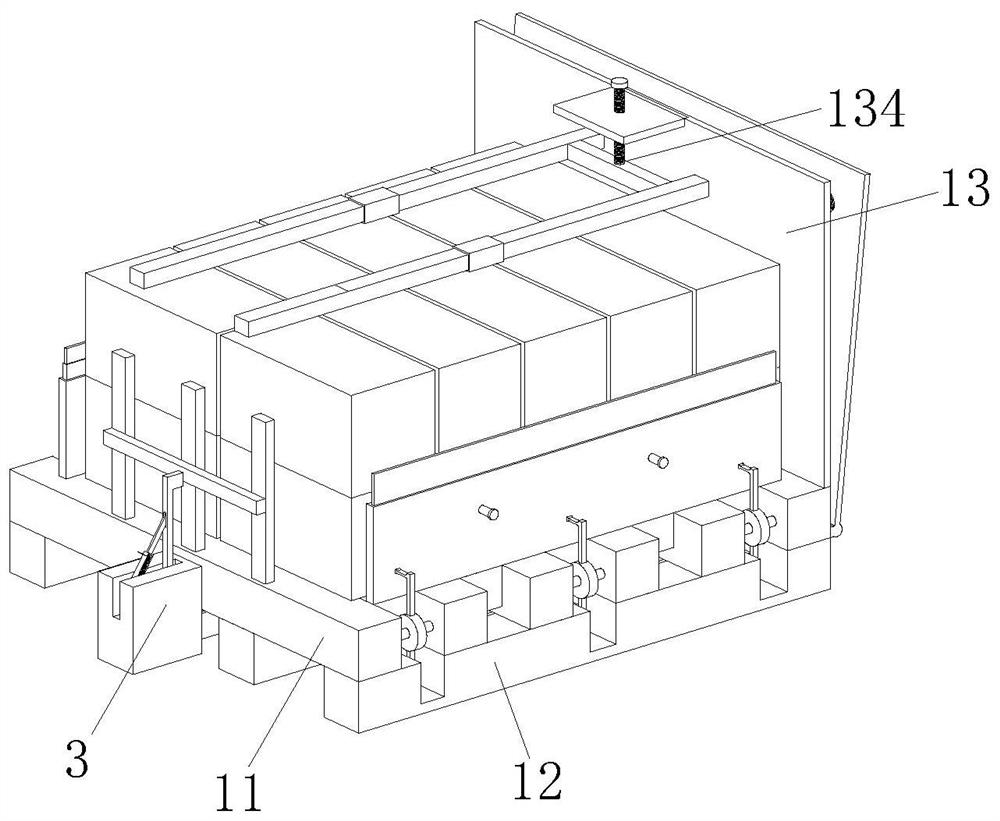

Intelligent carrying and transferring pallet for logistics distribution center

The invention provides an intelligent carrying and transferring pallet for a logistics distribution center, and relates to the field of pallets. The intelligent carrying and transferring pallet comprises a supporting pallet, a fixing mechanism and a moving mechanism, wherein the fixing mechanism is arranged on the supporting pallet, the moving mechanism is arranged on the supporting pallet, and the moving mechanism is located behind the fixing mechanism. The intelligent carrying and transferring pallet can solve the following problems that a, firstly, an existing pallet can be used for placing goods, but the goods are extremely easy to incline after being vibrated and bumped in the carrying process, so that the goods are easy to fall off and damage; and b, secondly, when the existing pallet is carried through a forklift, placement between the pallet and the forklift is not stable enough, and the pallet is prone to fall off from the forklift.

Owner:平顶山市嘉韬科技有限公司

High-uniformity glue sprayer

InactiveCN105413922AAchieve forward and backward movementAchieve left and right movementSpraying apparatusDrive shaftEngineering

The invention discloses a high-uniformity glue sprayer. The high-uniformity glue sprayer comprises a glue sprayer body. A workbench is arranged at the top of the glue sprayer body. A protection cover is arranged on the surface of the workbench. First sliding grooves are formed in the surface of the protection cover and are symmetrically arranged. A first motor is arranged on the surface of the protection cover and connected with one side of a cross beam through a first transmission shaft. The bottom of the cross beam is clamped in the two first sliding grooves through protruding blocks respectively, and the cross beam can slide in the first sliding grooves. A motor storage groove and a second sliding groove are formed in the surface of the cross beam. A second motor is arranged in the motor storage groove and connected with a glue gun through a second transmission shaft. A third motor is arranged on the surface of the glue gun. According to the high-uniformity glue sprayer, the forward and backward movement of the glue gun can be achieved through the first motor, and leftward and rightward movement of the glue gun can be achieved through the second motor.

Owner:无锡万能胶粘剂有限公司

Physical training aid with mechanical detecting function

InactiveCN106964135AAchieve forward and backward movementImplement testNetwork topologiesSport apparatusEngineeringCantilever

The invention relates to a physical training aid with a mechanical detecting function. The physical training aid comprises a mounting substrate, a cantilever and a mechanical sensor, a locating hole is formed in the mounting substrate, and the mounting substrate is welded to the cantilever. A plurality of sliding grooves are formed in the middle of the cantilever, a sliding rod is mounted between the sliding grooves, and a sand bag is hung in the middle of the sliding rod. A locating bolt is mounted at one end of each sliding groove, one end of the cantilever is fixedly connected with the mechanical sensor through a bolt, and the middle of the mechanical sensor is sleeved with a handheld rod. Through the cooperation of the sliding rod and the sliding grooves, front-back movement of the sand bag is achieved, the sand bag is located through the locating bolts, the progress of other movement is not hindered, meanwhile, the device is simple in structure and convenient to mount, and has the long service life, mechanical testing is achieved through the mechanical sensor, and good use prospects are achieved.

Owner:BINZHOU UNIV

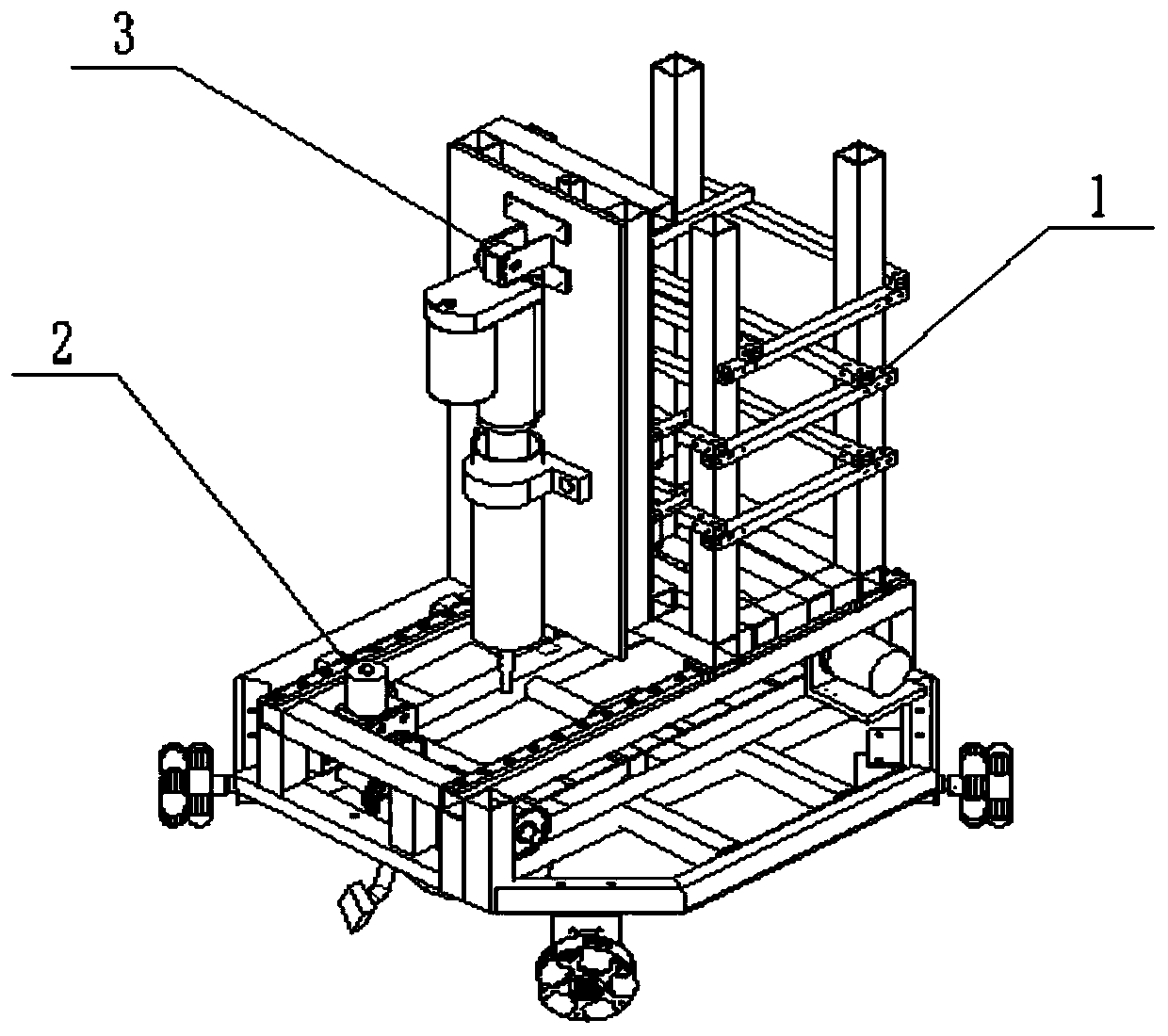

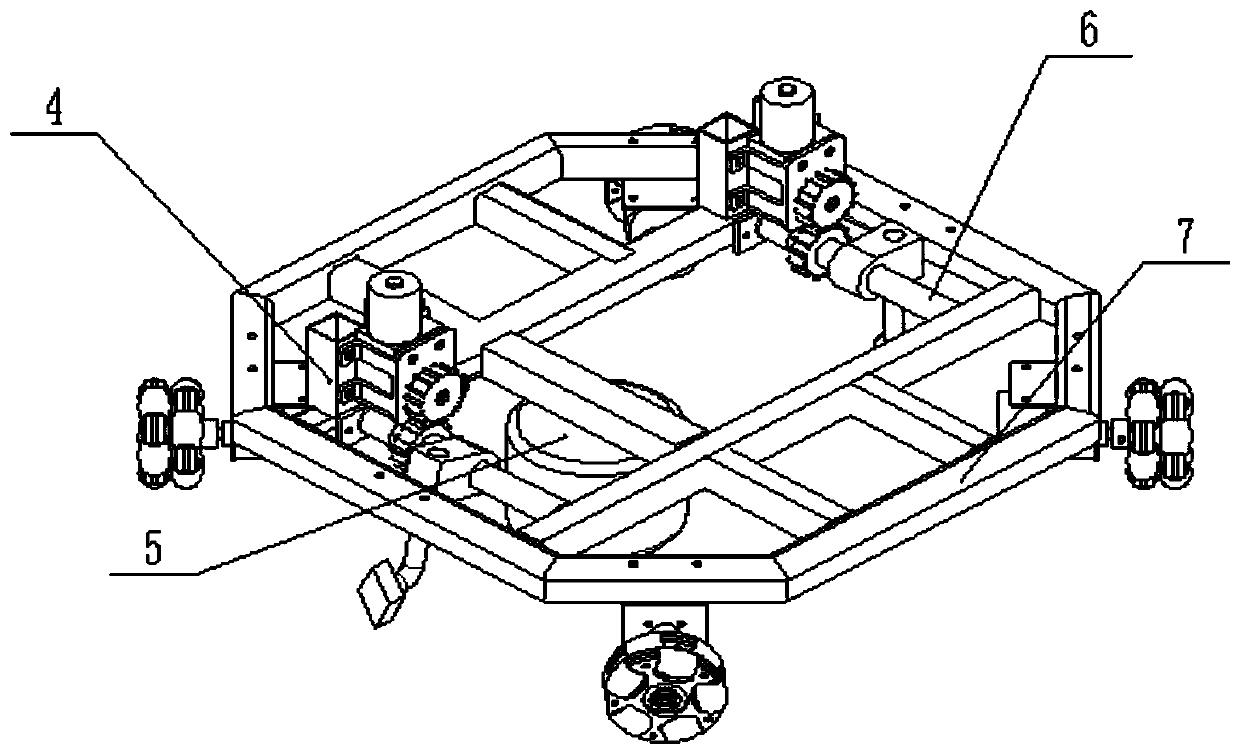

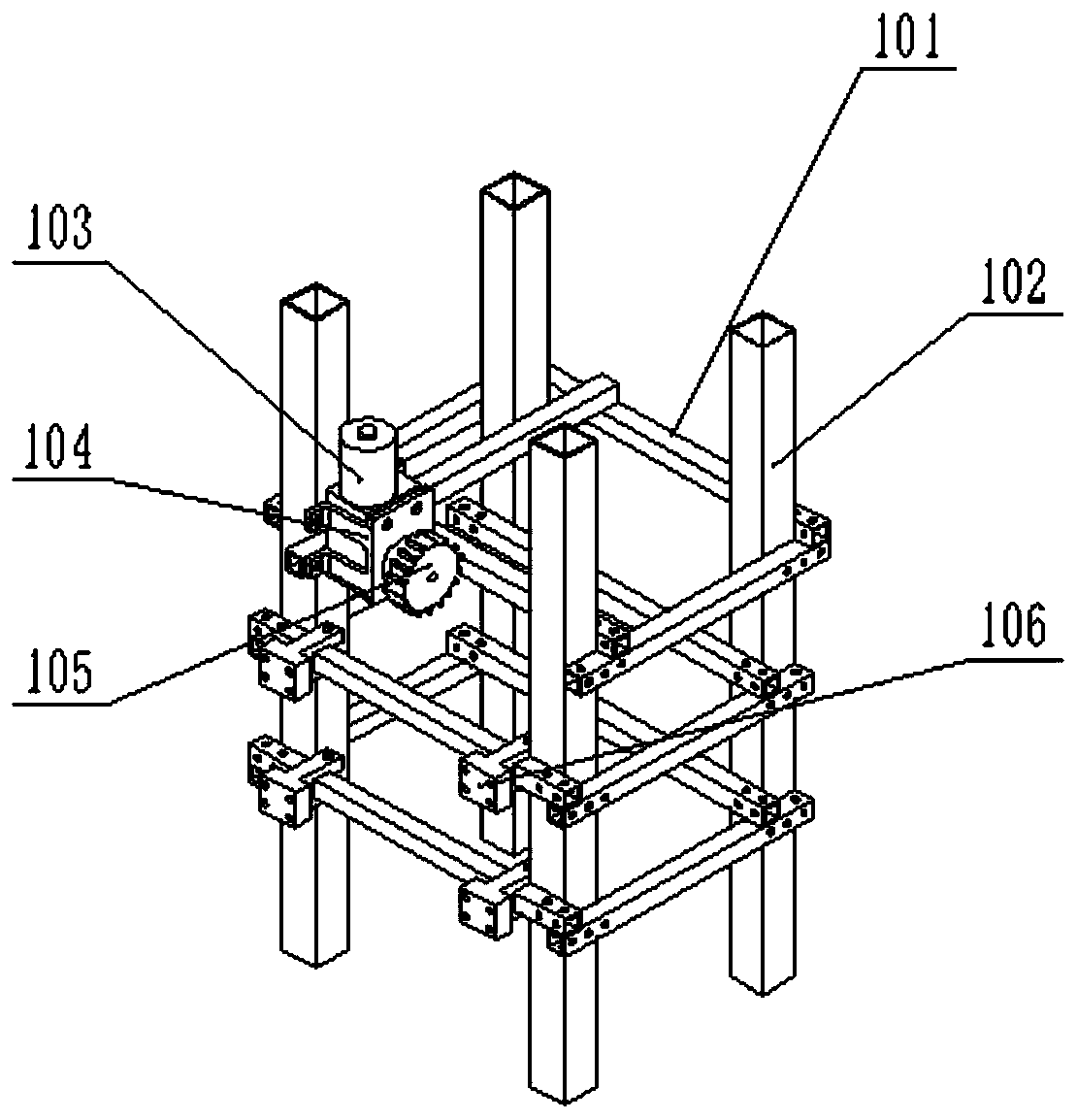

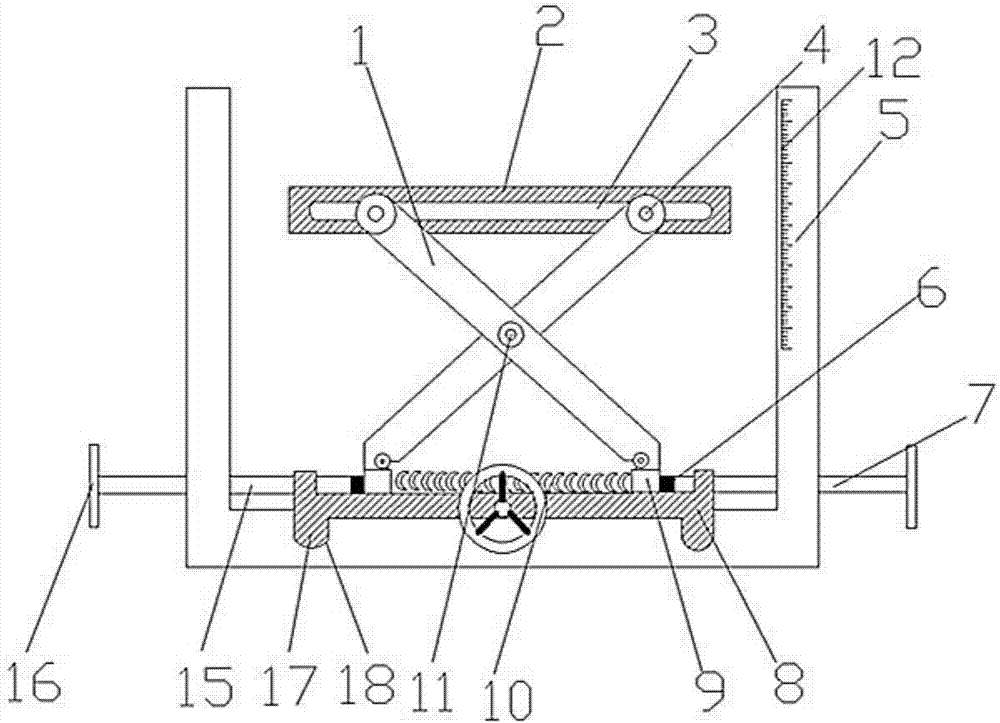

Mobile device for 3D printer

InactiveCN107351399AFlexible moving processEasy to adjustManufacturing platforms/substrates3d printerMobile device

The invention discloses a mobile device for a 3D printer. The mobile device for the 3D printer comprises lifting rods, a lifting platform, a sliding groove, sliding wheels, an outer frame, cross rods, ejector rods, a movable base, sliding blocks, a spring and movable shafts, the movable base is arranged in the outer frame in a sliding mode, the two sliding blocks are arranged in the movable base, the cross rods are fixedly arranged on the sliding blocks, the spring is arranged between the two sliding blocks, the two lifting rods are arranged in a crossed mode and are connected through one movable shaft, the sliding wheels are arranged on one ends of the lifting rods, the other ends of the lifting rods are arranged on the sliding blocks through two movable shafts, the lifting platform is arranged on the top ends of the lifting rods, the sliding groove is formed in the side wall of the lifting platform, the sliding wheels fixedly arranged on the lifting rods are embedded into the sliding groove, two ejector rods are arranged on the two sides of the outer frame and abut against the cross rods, and the other two ejector rods are arranged on the front portion and the rear portion of the outer frame and abut against the movable base. The mobile device for the 3D printer can realize up-and-down lifting and front-back movement of a lifting device, so that the movement of the 3D printer is more flexible.

Owner:江苏天泽教育咨询有限公司

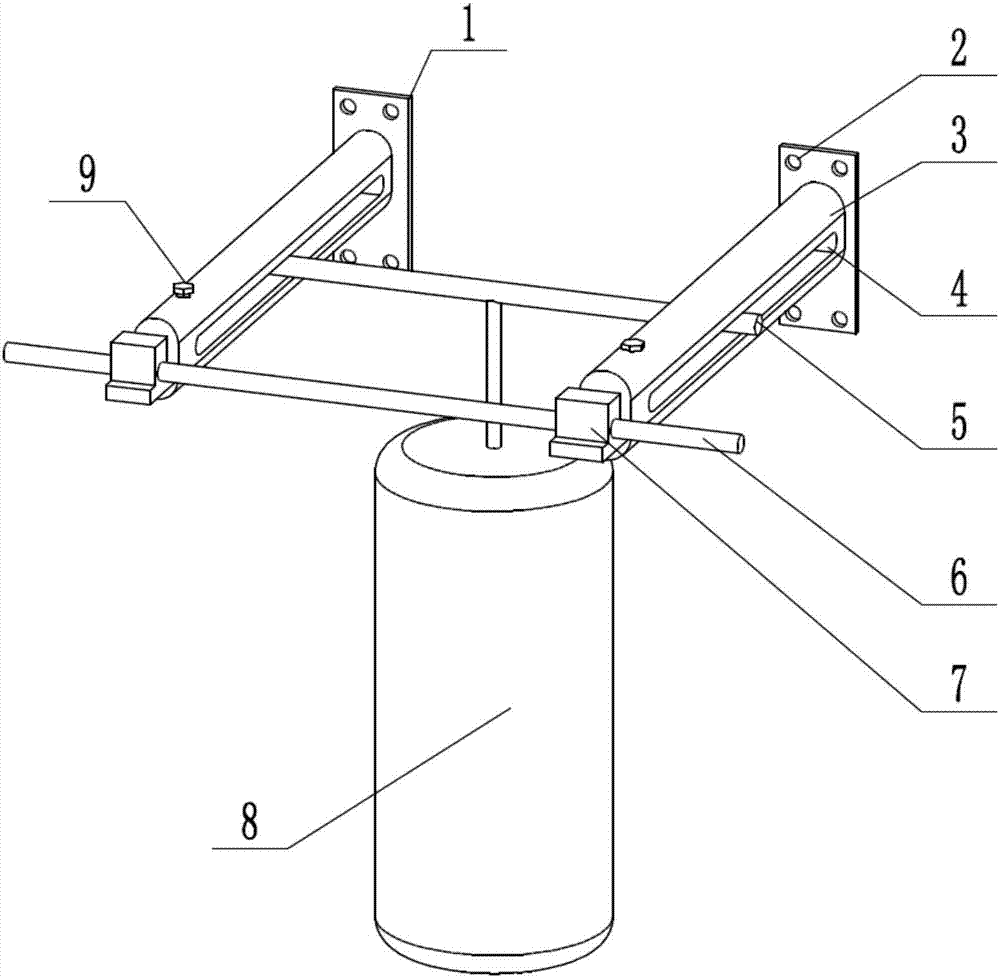

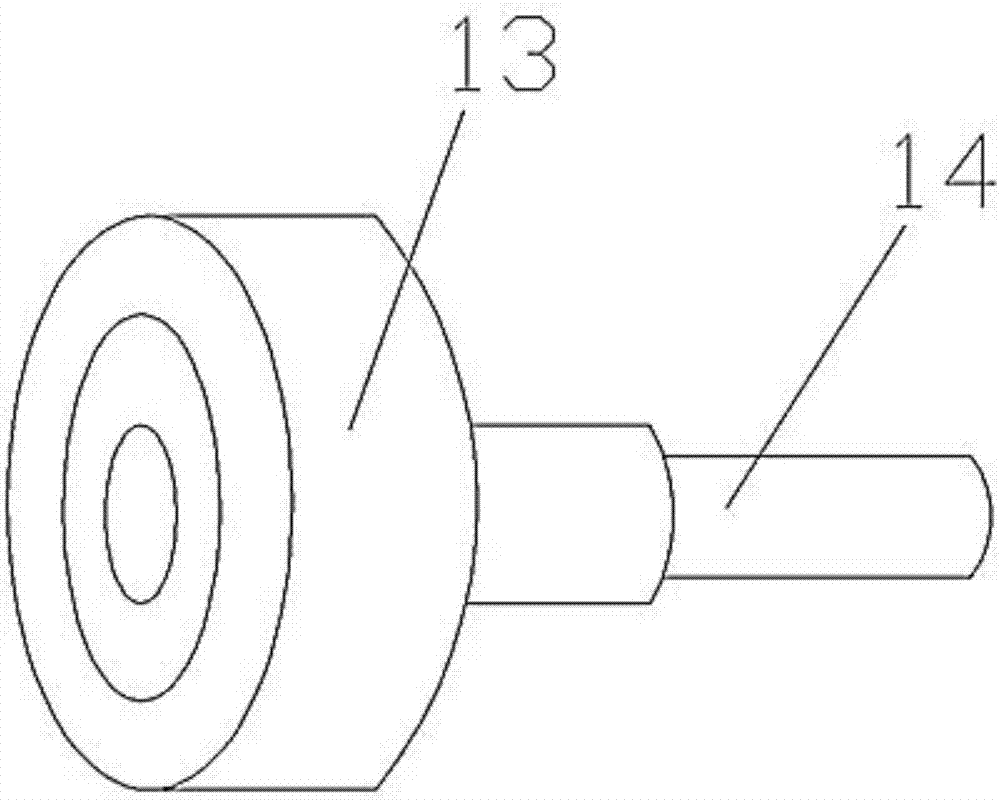

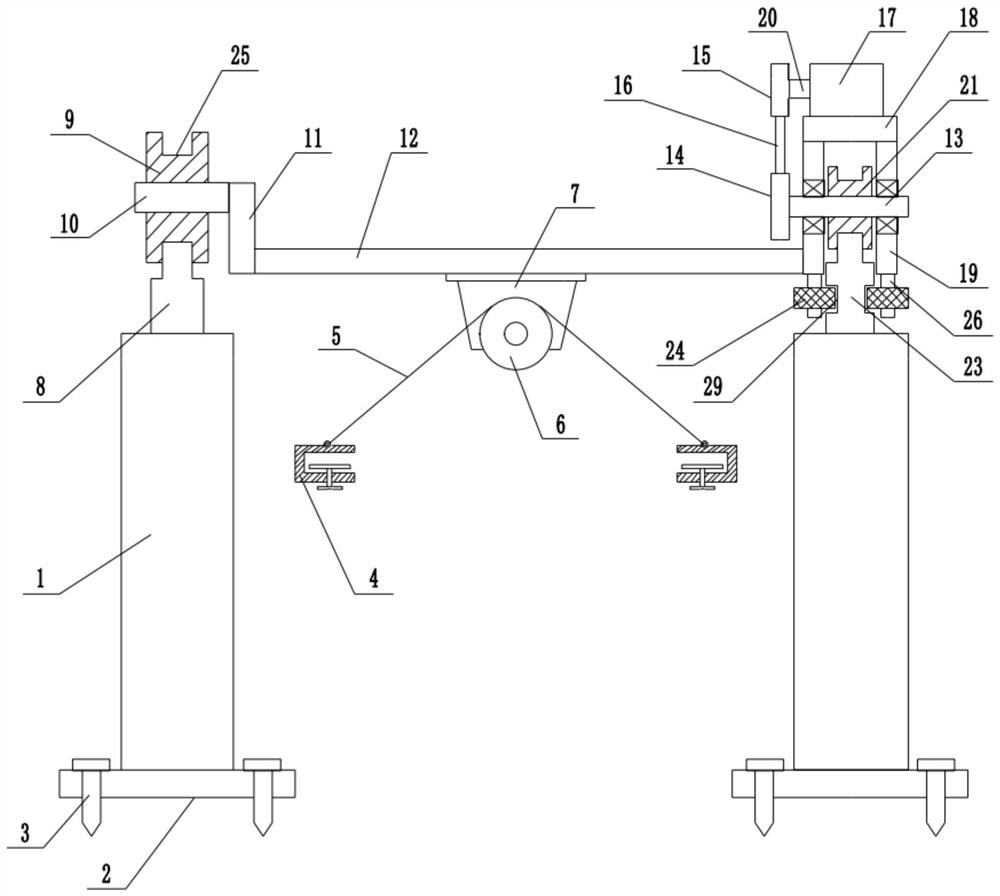

Concentricity measuring instrument stabilizing bracket

InactiveCN109458526APrevent movementAvoid repositioning the standStands/trestlesMeasuring instrumentPulp and paper industry

The invention belongs to the technical field of measuring instruments, and provides a concentricity measuring instrument stabilizing bracket. The concentricity measuring instrument stabilizing bracketcomprises a bottom plate; the upper portion of the bottom plate is connected with a bracket plate through a rough adjusting structure, the bracket plate is connected with an instrument fixing plate through a fine adjusting structure, the instrument fixing plate is slidably connected with an instrument body through an instrument bottom plate, and the interior of the bottom plate is provided with astabilizing structure; the stabilizing structure comprises a suction cup of which the middle is provided with an air extraction pipe, the top of the air extraction pipe is connected with an air extractor, the air extractor is fixed into a limiting plate, and the side surface of the suction cup is provided with an air exhaust hole; the fine adjusting structure comprises a fine adjusting assembly,a second fine adjusting assembly and a third fine adjusting assembly; and the instrument fixing plate is provided with a plurality of fixing grooves, and the instrument bottom plate is slidably connected with the fixing grooves through fixing pieces. Thus, the concentricity measuring instrument stabilizing bracket can achieve fine adjusting of the height and angle of a concentricity measuring instrument and is suitable for the working conditions high in measuring requirement, and meanwhile, the bracket moving situation can be avoided.

Owner:潍坊永利量具有限公司

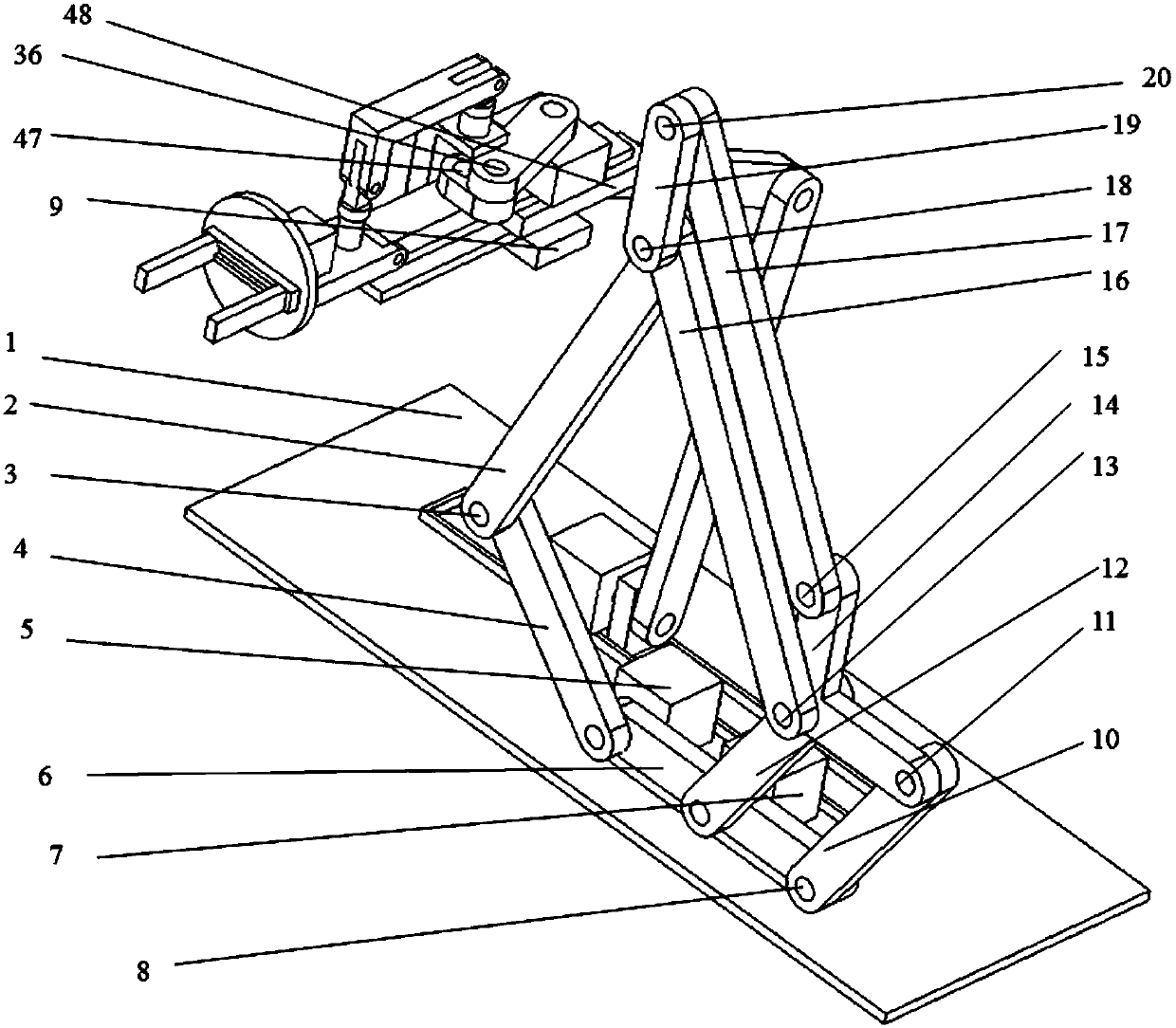

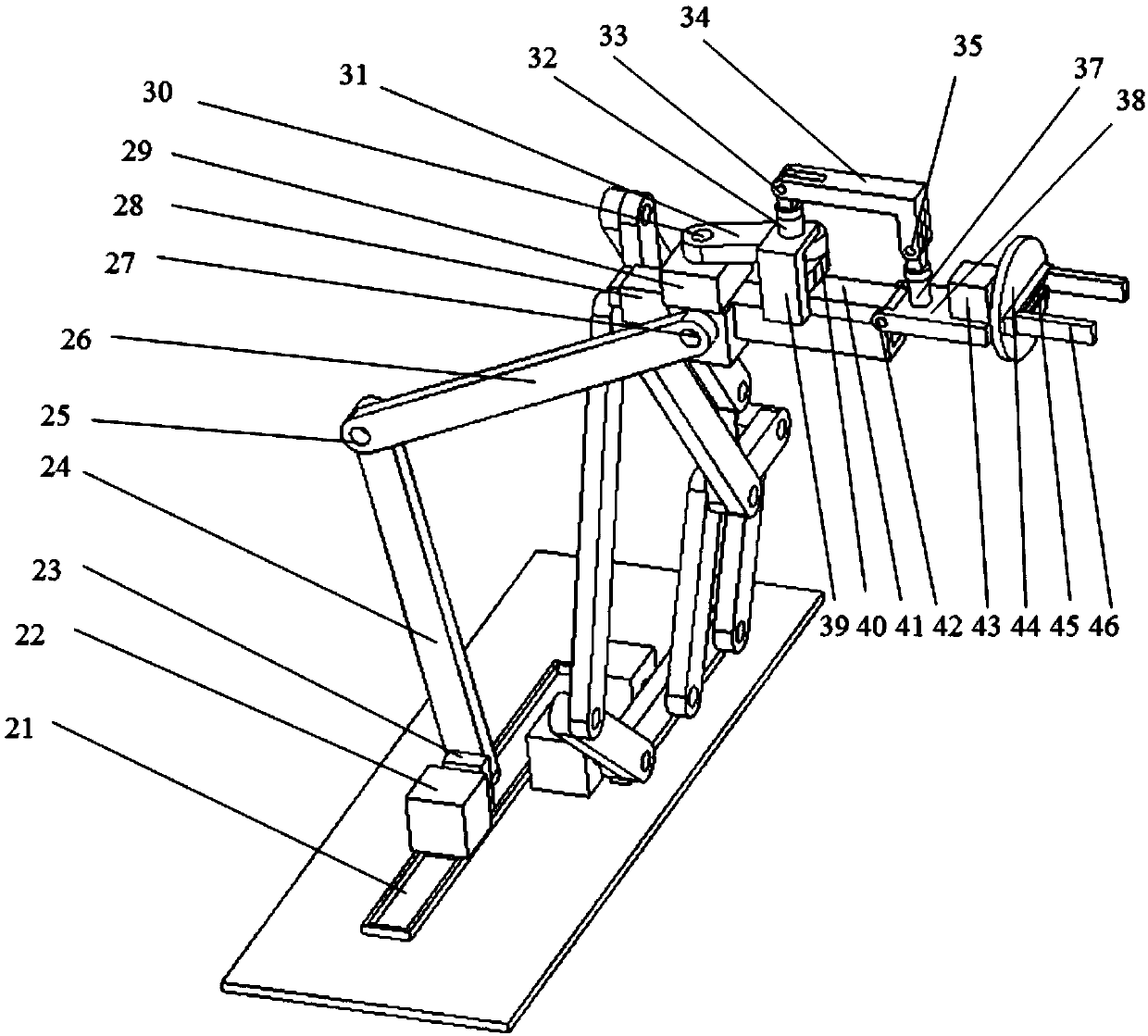

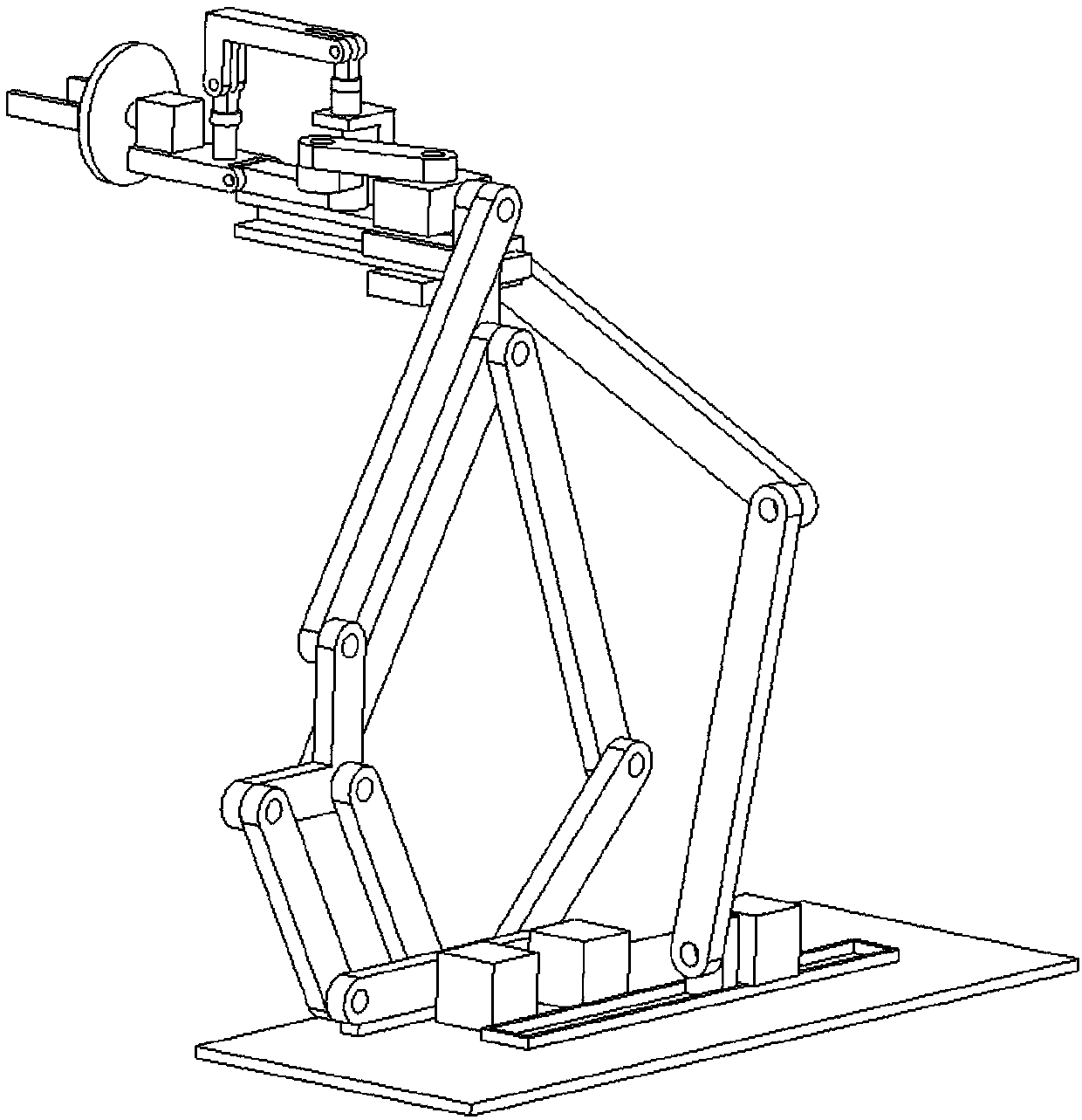

Full-degree-of-spatial-freedom metamorphic mechanism type palletizing robot mechanism

ActiveCN107932477ARealize six degrees of freedom positioningAchieve forward and backward movementProgramme-controlled manipulatorStacking articlesWork taskEngineering

A full-degree-of-spatial-freedom metamorphic mechanism type palletizing robot mechanism comprises a platform, a planar locating mechanism, a spatial driving mechanism and a manipulator assembly, wherein a first controllable motor and a second controllable motor are fixedly mounted on the platform; a platform fixing rod is fixed on the platform to realize assembly of the planar locating mechanism and the platform; a chute is fixed on the platform to realize assembly of the spatial driving mechanism and the platform; a horizontal output fixing rod is horizontally fixed on a vertical rod to realize assembly of the spatial driving mechanism and the planar locating mechanism; and a horizontal rotary slider sleeves a horizontal output slide rod to realize assembly of the manipulator assembly andthe spatial driving mechanism. The full-degree-of-spatial-freedom metamorphic mechanism type palletizing robot mechanism is simple in structure and convenient to machine, manufacture and mount, can realize full-degree-of-spatial-freedom location according to functional demands or environmental changes, and can deal with different work tasks under different working occasions.

Owner:GUANGXI UNIV

Leather defect detecting conveying table

InactiveCN110749602AAchieve forward and backward movementRealize sliding up and downOptically investigating flaws/contaminationUsing optical meansGear wheelTransmission belt

The invention discloses a leather defect detecting conveying table, belongs to the technical field of automatic detection. Forward-back movement of a Y-axis moving seat can be realized by mounting a right guide rod between a right guide rod front supporting seat and a right guide rod rear supporting seat, mounting a left guide rod between a left guide rod front supporting seat and a left guide rodrear supporting seat, driving a right screw rod through a driving motor and synchronously driving a left screw rod through a transmission belt; transverse movement of an X-axis moving seat on the Y-axis moving seat can be realized by mounting transverse sliding rails on the Y-axis moving seat and driving a gear to rotate through a transverse moving motor; up-down sliding of a small sliding platecan be realized by arranging an electric pushing rod on the X-axis moving seat and matching the stretching and retracting of the electric pushing rod with vertical sliding rails; and forward-backwardmovement of leather on a conveying belt can be realized by mounting a front leather conveying shaft and a rear leather conveying shaft at the front end and the rear end of a lower mounting frame, andmatching the conveying belts mounted on the front leather conveying shaft and the rear leather conveying shaft.

Owner:绍兴海滨皮革有限公司

Edge cutting device for paperboard processing and using method of edge cutting device

InactiveCN112092075AConvenient for long-distance observationClear visionMetal working apparatusPaperboardElectric machinery

The invention discloses an edge cutting device for paperboard processing and a using method of the edge cutting device, and relates to the technical field of paperboard processing. The edge cutting device aims to solve the problem of multi-degree-of-freedom adjustment of a blade. The device comprises a bottom plate, a cutting assembly, a clearing assembly, a feeding assembly and a pressing assembly, wherein the cutting assembly comprises a supporting frame and a first motor. The using method of the device comprises the following steps of fixing the position, placing a paperboard, adjusting theblade, carrying out edge cutting in a pressing mode, carrying out fine adjusting on a hand wheel, recovering waste materials and carrying out discharging after completion of edge cutting. According to the edge cutting device for paperboard processing and the using method of the edge cutting device, by arranging the cutting assembly, firstly, front-and-back movement of the blade can be achieved, secondly, up-and-down movement of the blade can be achieved, thirdly, left-and-right movement of the blade can be achieved, to sum up, according to the three effects, multi-degree-of-freedom adjustmentof the blade can be achieved, and adaptive adjustment can be carried out according to different edge cutting requirements; and meanwhile, adjusting driving force is provided by the first motor, second motors and a third motor, and manual adjustment and control can be replaced, so that accurate positioning of the blade is achieved.

Owner:京山双王纸板技术服务有限公司

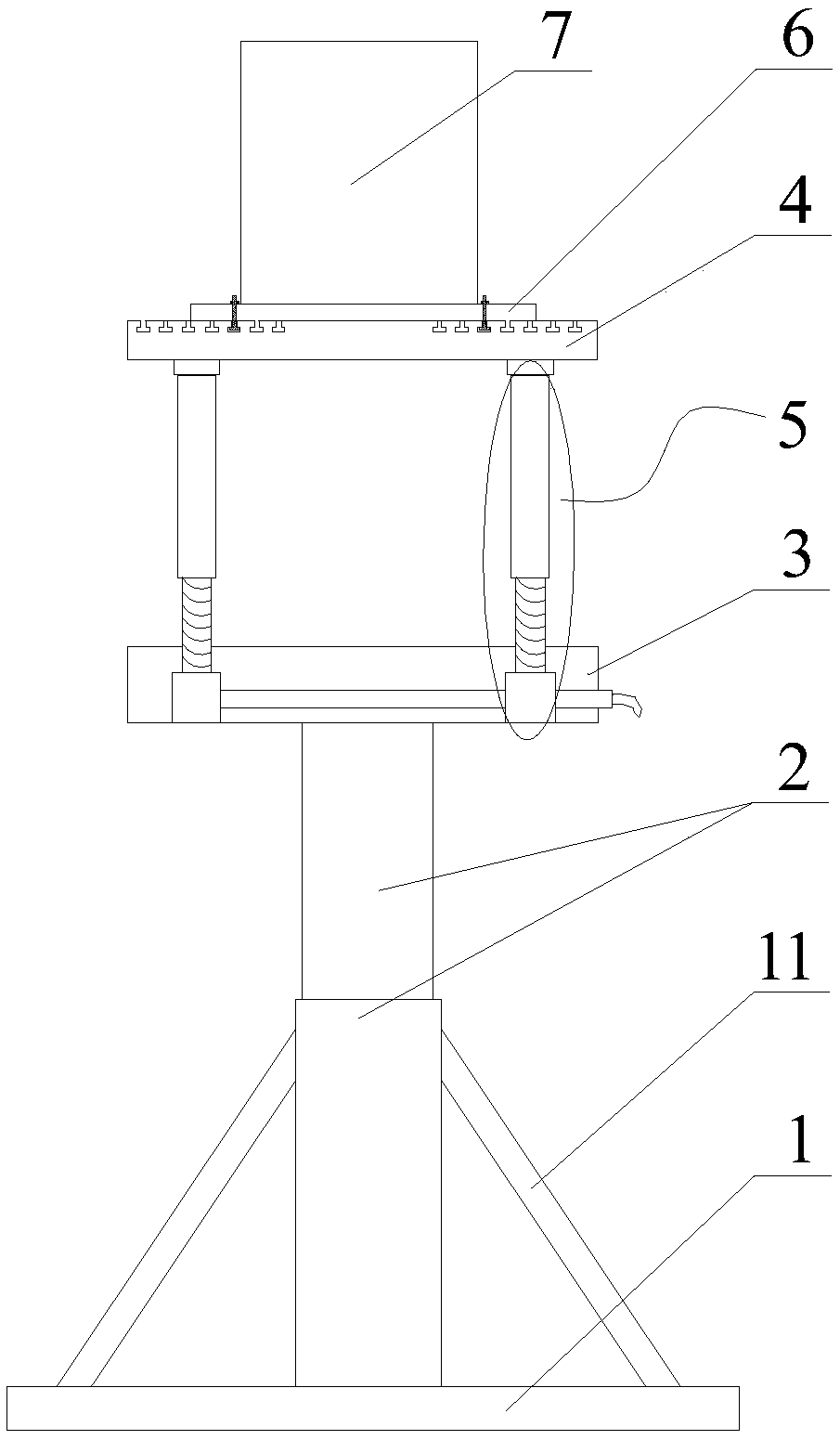

Lifting device used for building prefabricated slabs

InactiveCN112374377AEnsure lifting functionGuaranteed stabilityBase supporting structuresBraking devices for hoisting equipmentsRotational axisElectric machine

The invention relates to the technical field of building construction, and discloses a lifting device used for building prefabricated slabs. The lifting device comprises a fixed bottom plate, fixed columns are mounted at the upper end of the fixed bottom plate, a left rail is mounted at the upper end of the fixed column on the left side, a left rolling wheel is rotatably arranged at the upper endof the left rail, and a guide column is rotatably arranged in the middle of the left rolling wheel. A right rail is mounted at the upper end of the fixed column on the right side, a right rolling wheel is rotatably arranged at the upper end of the right rail, a rotating shaft is fixedly installed in the middle of the right rolling wheel, walking frames are installed at the two ends of the rotatingshaft through bearings, a motor plate is installed at the upper ends of the walking frames, a rotating motor is installed at the upper end of the motor plate, an output shaft of the rotating motor isconnected with a driving belt wheel, and the lower end of the driving belt wheel is connected with a driven belt wheel through a belt. According to the lifting device, lifting operation to the building prefabricated slabs is ensured, the lifting device has a power source and is good in maneuverability, the lifting range is further widened, and meanwhile the stability of the building prefabricatedslabs in the lifting process is ensured by arranging balance columns and balance wheels.

Owner:陈平英

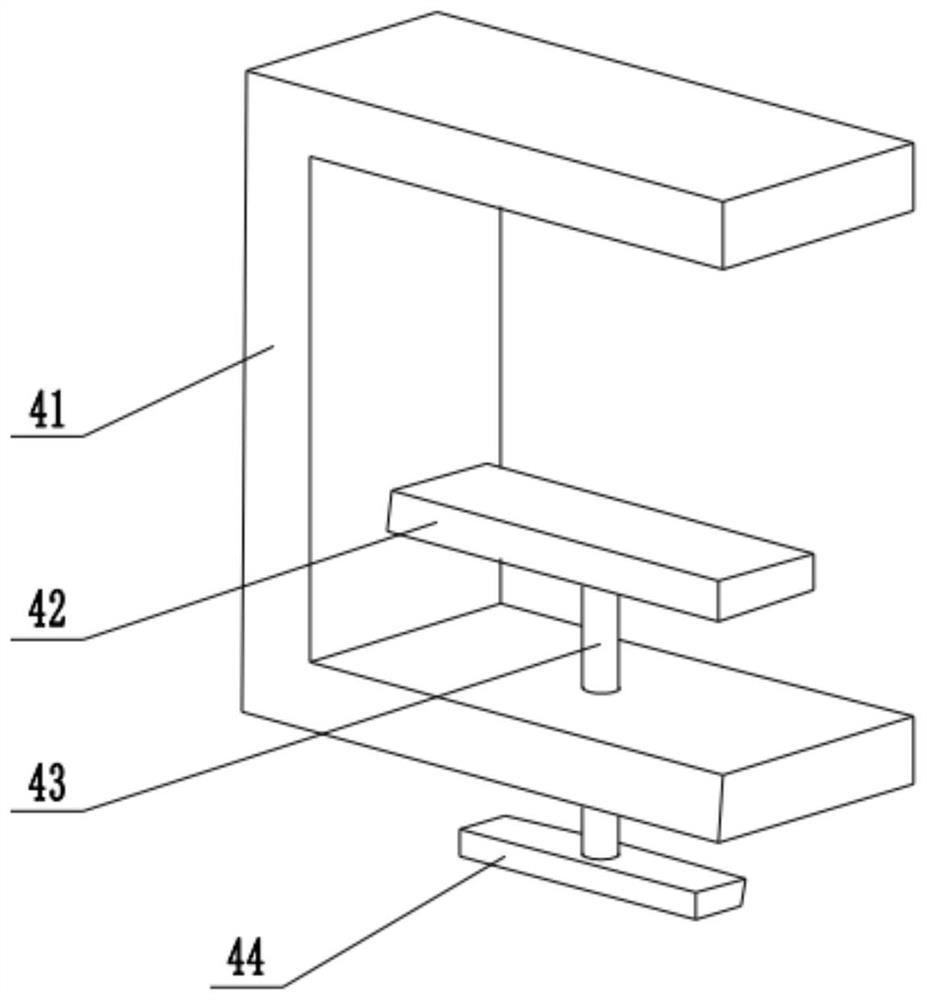

Die pressing production line

The invention belongs to the technical field of sound-absorbing cotton, and provides a die pressing production line. The die pressing production line comprises a rack. The rack is provided with a feeding device, a baking box and a die pressing machine, all of which are sequentially distributed and connected through a conveying belt. The feeding device comprises a material taking device arranged onthe rack. The material taking device comprises transverse parts connected with the rack through a walking device. Longitudinal parts and a first grabbing device are arranged at the bottoms of the transverse parts. Second grabbing devices are arranged at the two ends of the longitudinal parts. The transverse parts are connected with the walking device through a telescopic rod. The 2-5 longitudinalparts are arranged, and the first grabbing device is arranged in the center of the area defined by the second grabbing devices. The first grabbing device is a needle type inserting rod, and the second grabbing devices are suction cups or mechanical arms. A conical inserting head is arranged at one end of the first grabbing device, and a connecting part is arranged at the other end of the first grabbing device, wherein the connecting part is connected with the transverse parts through an installing base. The die pressing production line solves the technical problems that in the prior art, a sound-absorbing cotton production line is simple in structure, and usage is not convenient.

Owner:保定棉金汽车饰件制造有限公司

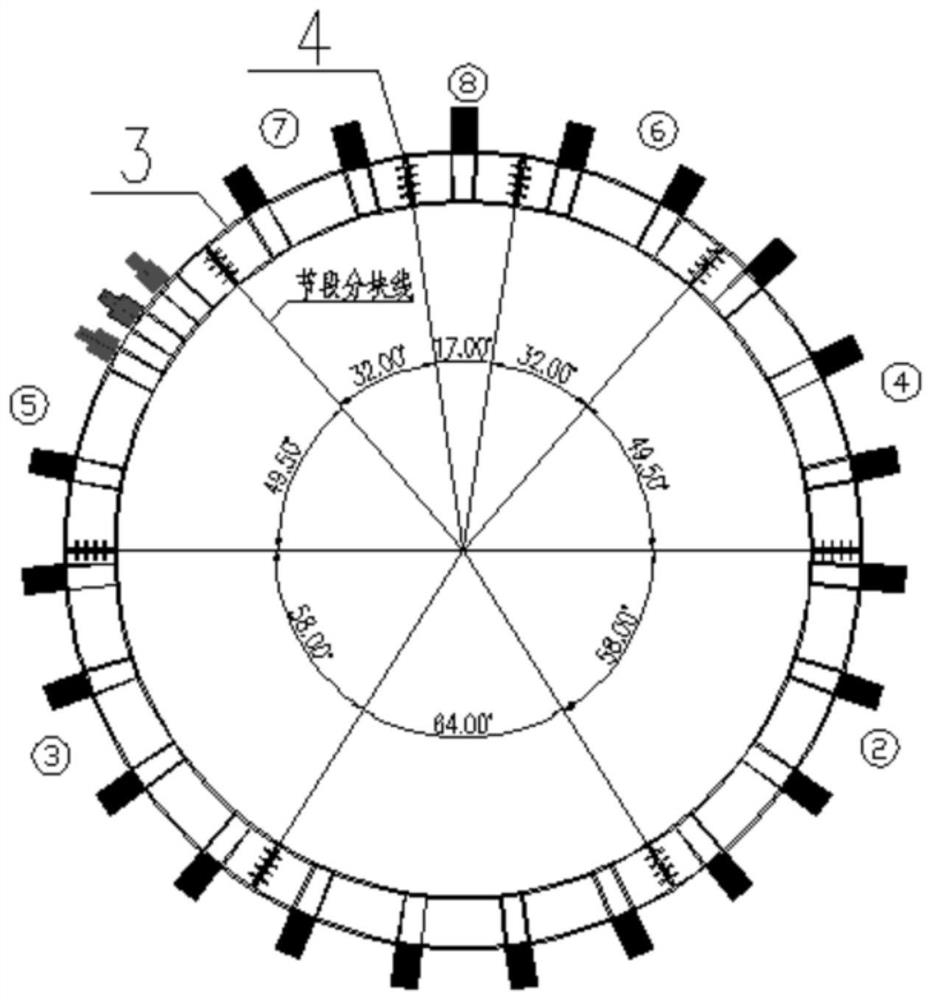

Annular tool and method for deformation straightening of highly permeable sand layer large-diameter shield tail shield

PendingCN111779492ARealize deformation correctionRealize full circleMachine part testingUnderground chambersButtressClassical mechanics

The invention discloses an annular tool and method for deformation straightening of a highly permeable sand layer large-diameter shield tail shield. The annular tool comprises a counterforce support frame, a base plate and a meniscus structure. The counterforce support frame is of an annular structure. The outer cambered surface of the counterforce support frame is provided with first buttresses at intervals in the longitudinal and circumferential directions. A pre-tightening jack is arranged between the first buttresses located in the longitudinal direction of the counterforce support frame.A plurality of straightening jacks are arranged in a tail shield deformation area corresponding to the outer cambered surface of the counterforce support frame. A gap between the first buttresses andthe tail shield is filled with the base plate. The meniscus structure is installed on the inner cambered surface, corresponding to the tail shield deformation area, of the counterforce support frame.Through the annular tool and method, the problems of tail shield deformation and tail shield rounding straightening of a shield tunneling machine are solved.

Owner:CCCC SECOND HARBOR ENG

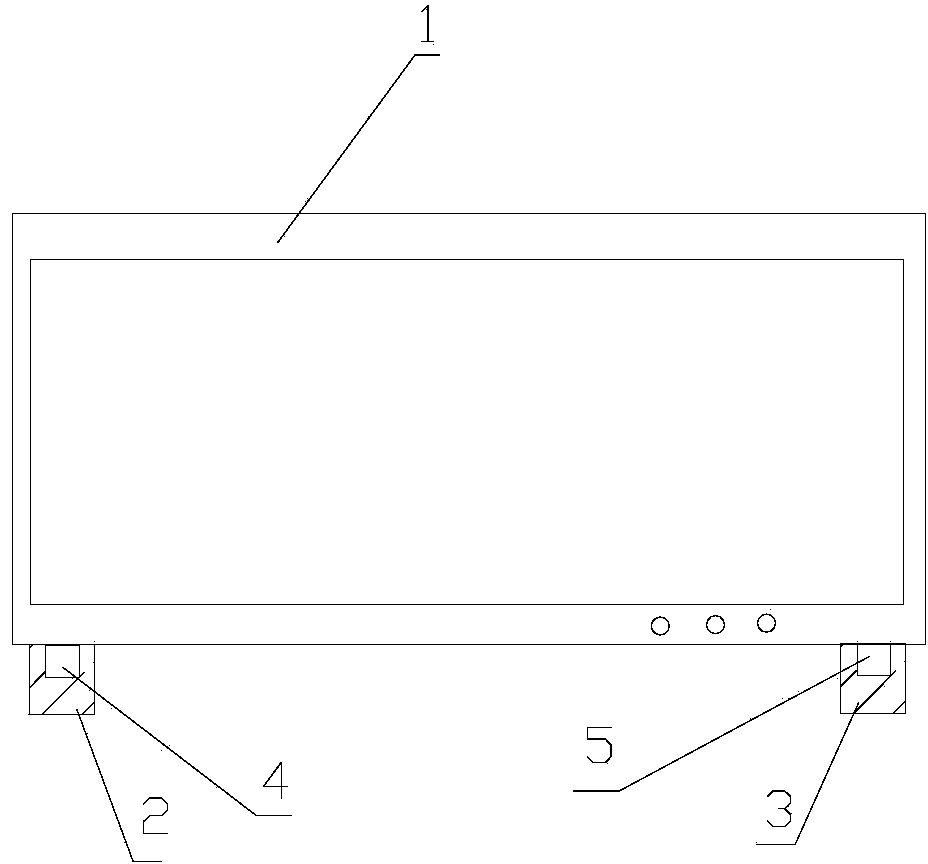

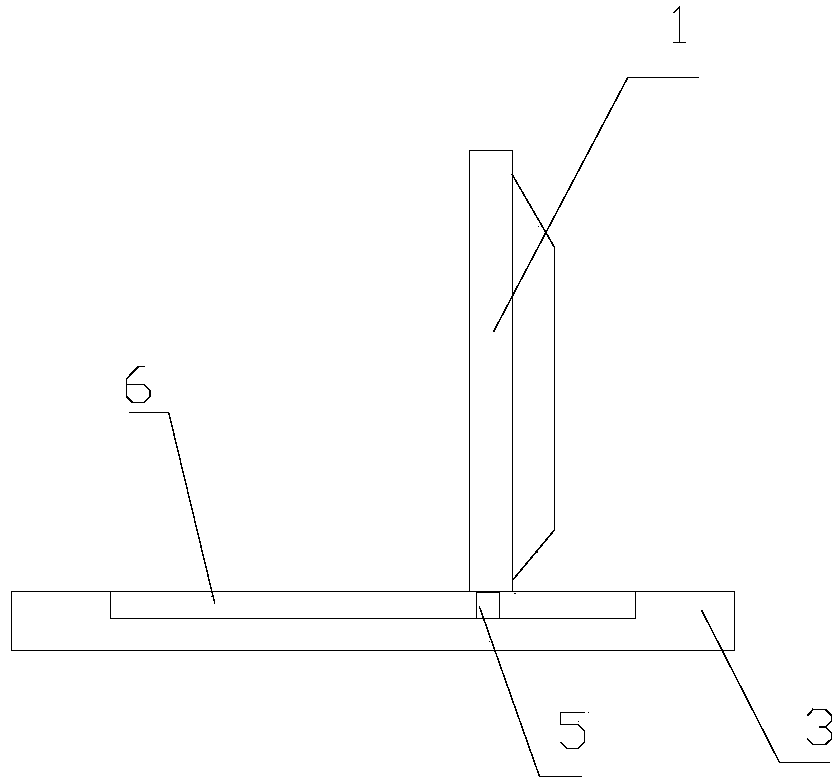

Computer display

InactiveCN103631337AAchieve forward and backward movementMeet the needs of useDigital data processing detailsDisplay deviceEngineering

Owner:TIANJIN XINTONGAN TECH

Turret welding device for welding steel plates

ActiveCN106563907ASave human effortImprove work performanceWelding/cutting auxillary devicesAuxillary welding devicesBlade plateSheet steel

The invention relates to a turret welding device for welding steel plates. The turret welding device for welding the steel plates comprises a base plate. Fixing blade plates are arranged on the lower side of the base plate. An installation plate is arranged in the middle of the base plate. A turret mechanism is arranged on the left portion. A left-right movement mechanism is arranged on the right portion of the base plate. First locating devices are arranged on the front and back sides of the base plate. Suction cups are arranged on the installation plate. A third locating device is arranged on the right side of the turret mechanism. A second locating device is arranged on the left side of the turret mechanism. The second locating device is matched with a clamping device arranged on the left portion of the installation plate. A clamping device matched with the first locating device is arranged at the left end of the left-right movement mechanism. The turret welding device for the welding steel plates aims to achieve the effects that the steel plates large in volume are fixed to the installation plate through the turret and the suction cups on the installation plate, the steel plates to be welded are located through the locating devices and clamped through the clamping devices, and then welding is conducted; and in this way, manpower is greatly saved, and the work effect is improved.

Owner:华安钢宝利高新汽车板加工(常熟)有限公司

Three-dimensional lifting platform for machining

InactiveCN112225136AAchieve left and right movementAchieve forward and backward movementLifting devicesHydraulic cylinderThree-dimensional space

The invention relates to the technical field of lifting platforms, and discloses a three-dimensional lifting platform for machining. The three-dimensional lifting platform for machining comprises a supporting device, wherein four mutually symmetrical universal wheels are fixedly mounted at the bottom of the supporting device, two mutually symmetrical guide rods are fixedly connected between the top and the bottom of an inner cavity of the supporting device, the two guide rods are movably sleeved with a lifting device, and the front face of the lifting device is movably sleeved with a translation device. According to the three-dimensional lifting platform for machining, left-right movement of the platform is achieved through mutual cooperation of a first driving motor, a translation lead screw and a lead screw nut II, front-back movement of the platform is achieved through mutual cooperation of a hydraulic cylinder and the translation device, the platform can move up and down through mutual cooperation of a second driving motor, a lifting lead screw and a lifting device, so that the platform can move in a three-dimensional space at the same time and the three-dimensional lifting platform for machining is simple in structure, safe and reliable,.

Owner:无锡杰岳机械制造有限公司

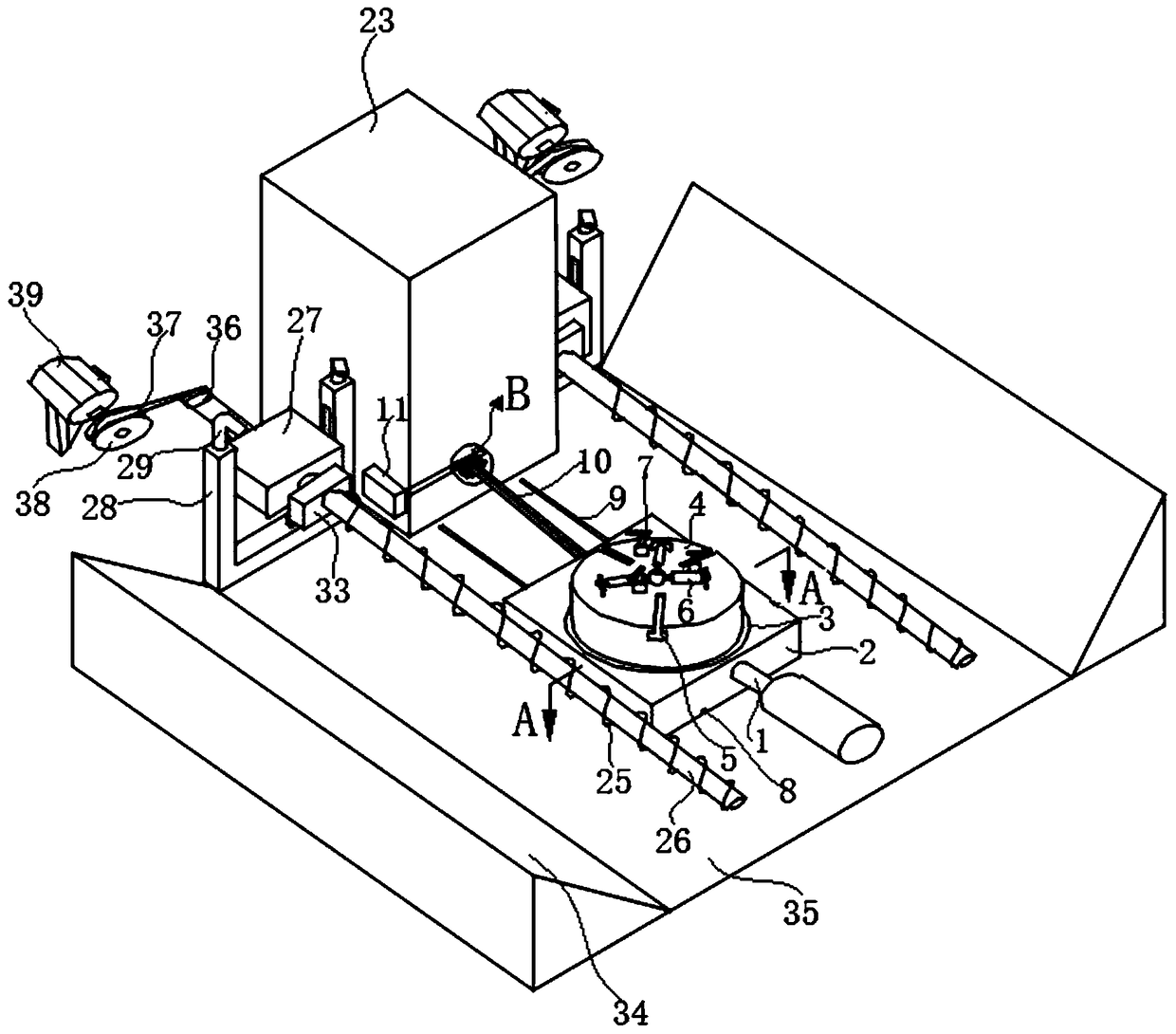

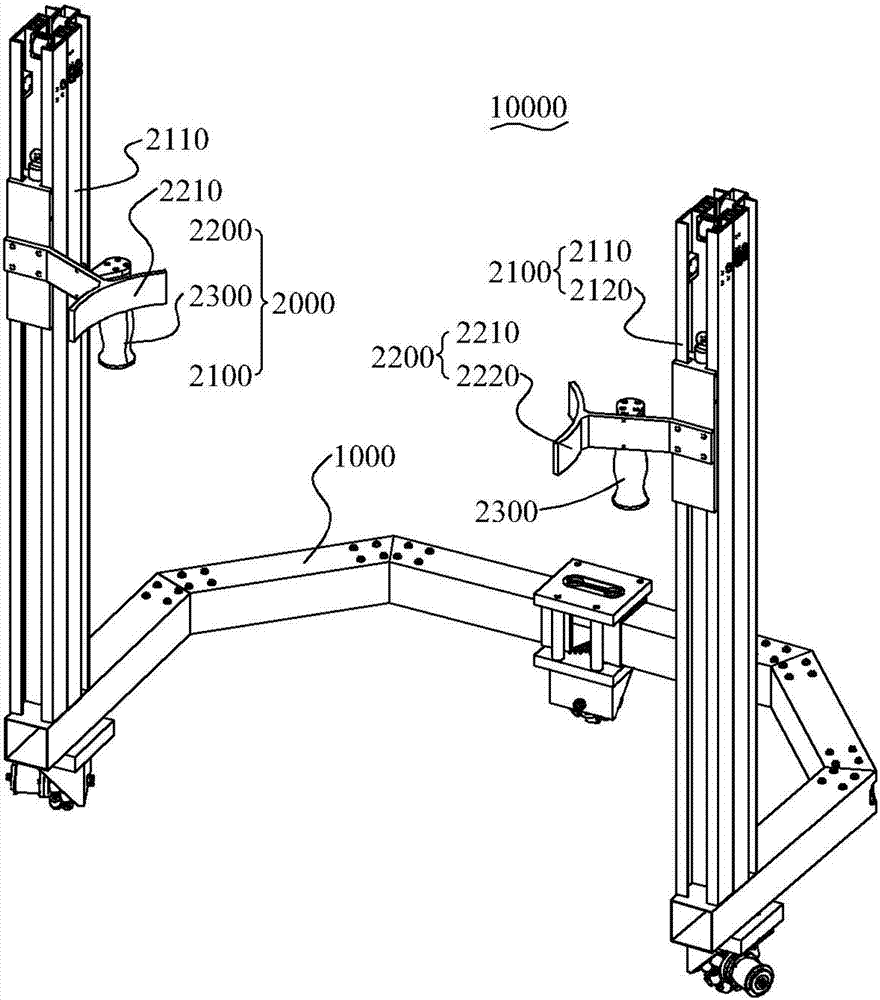

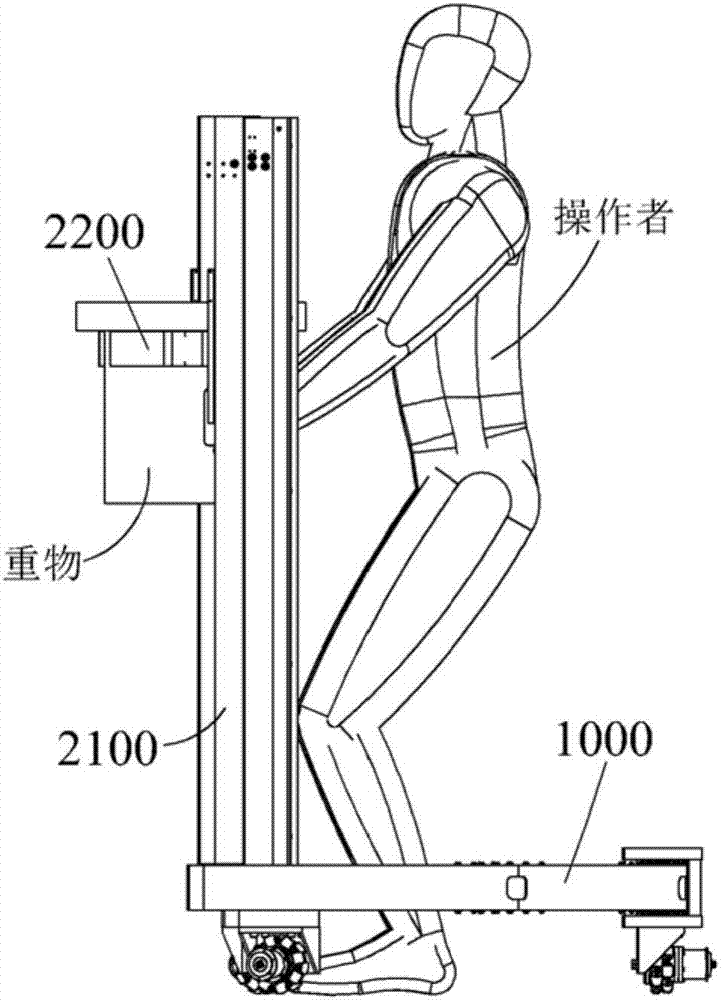

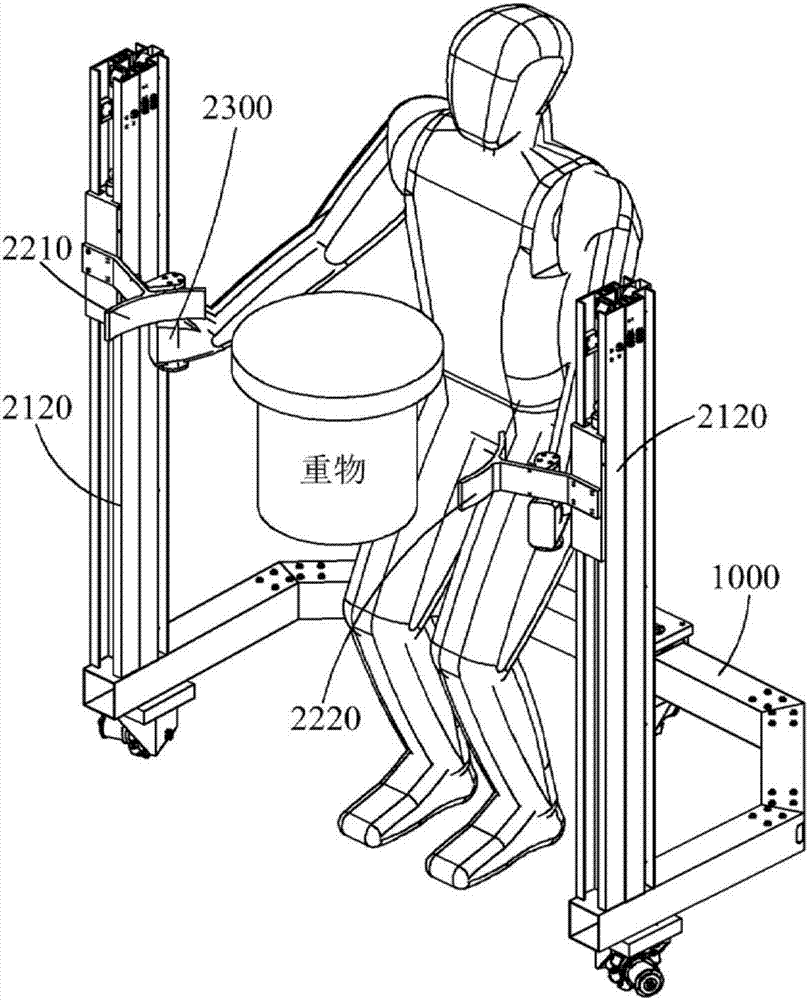

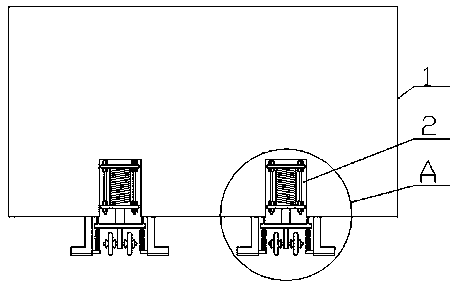

Assisting robot

ActiveCN107199551AAchieve forward and backward movementProgramme-controlled manipulatorEngineeringMechanical engineering

The invention discloses an assisting robot which comprises a multidirectional motion car body and a clamping device, wherein the multidirectional moving car body is provided with a first motion arm, a second motion arm and a transmission part connecting with the first motion arm and the second motion arm; each of the first motion arm, the second motion arm and the transmission part is provided with at least one multidirectional rolling device; the multidirectional rolling device is provided with a plurality of coaxial rolling units and a plurality of coaxial driving units; each of the rolling units is provided with a circular ring shaped bracket; a plurality of rotating wheels are annularly distributed on the circular ring shaped bracket in the circumferential direction of the circular ring shaped bracket; the rotation axis of the rotating wheel is parallel with the tangential direction of the outer circumference of the circular ring shaped bracket and is perpendicular to the rotation axis of the circular ring shaped bracket; a plurality of circular ring shaped brackets are fixedly connected one by one; the driving units are used for driving the circular ring shaped brackets to rotate; the clamping device is provided with a clamping mechanism and a handheld part; the clamping mechanism is used for clamping an object; and the handheld part is used for receiving applied force inputted by a user. The assisting robot realizes multidirectional flexible motion and turning through an integrated structure.

Owner:SHENZHEN ACAD OF AEROSPACE TECH

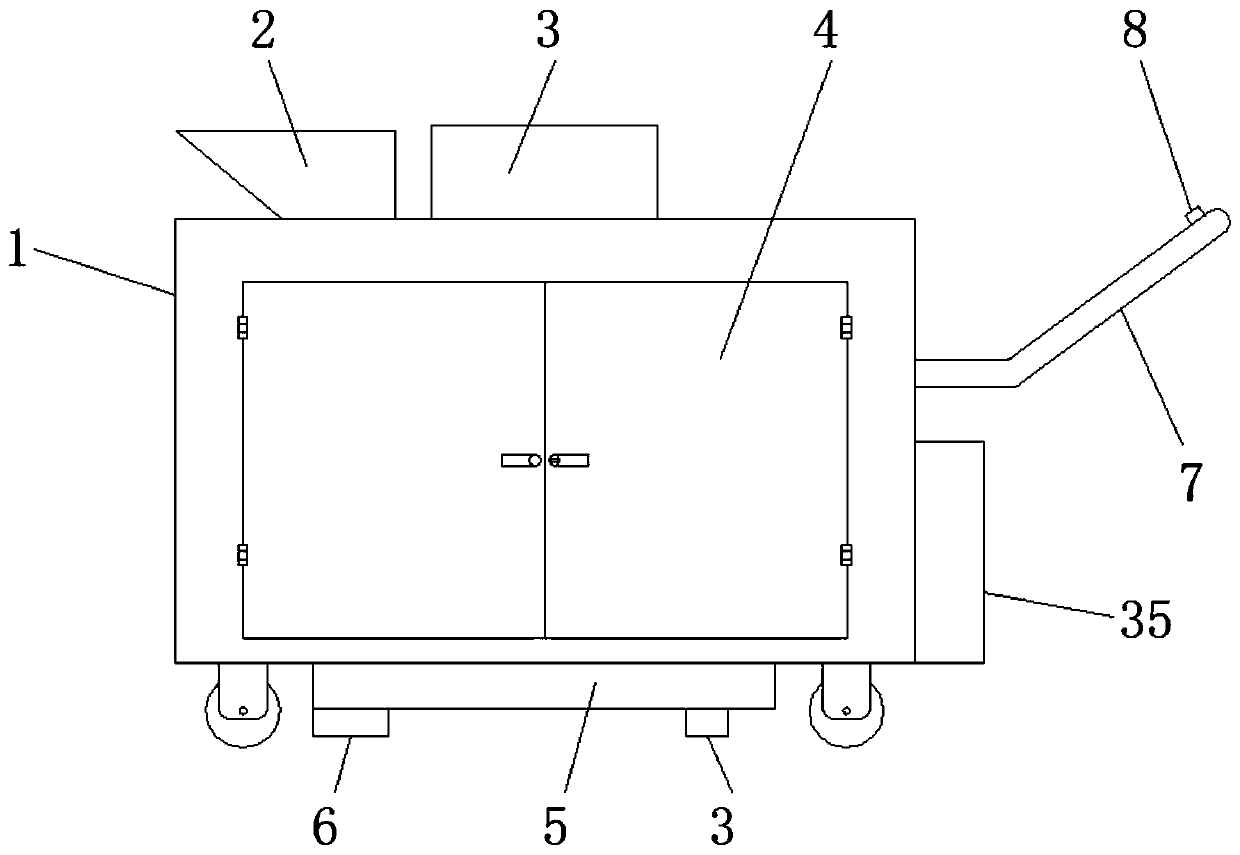

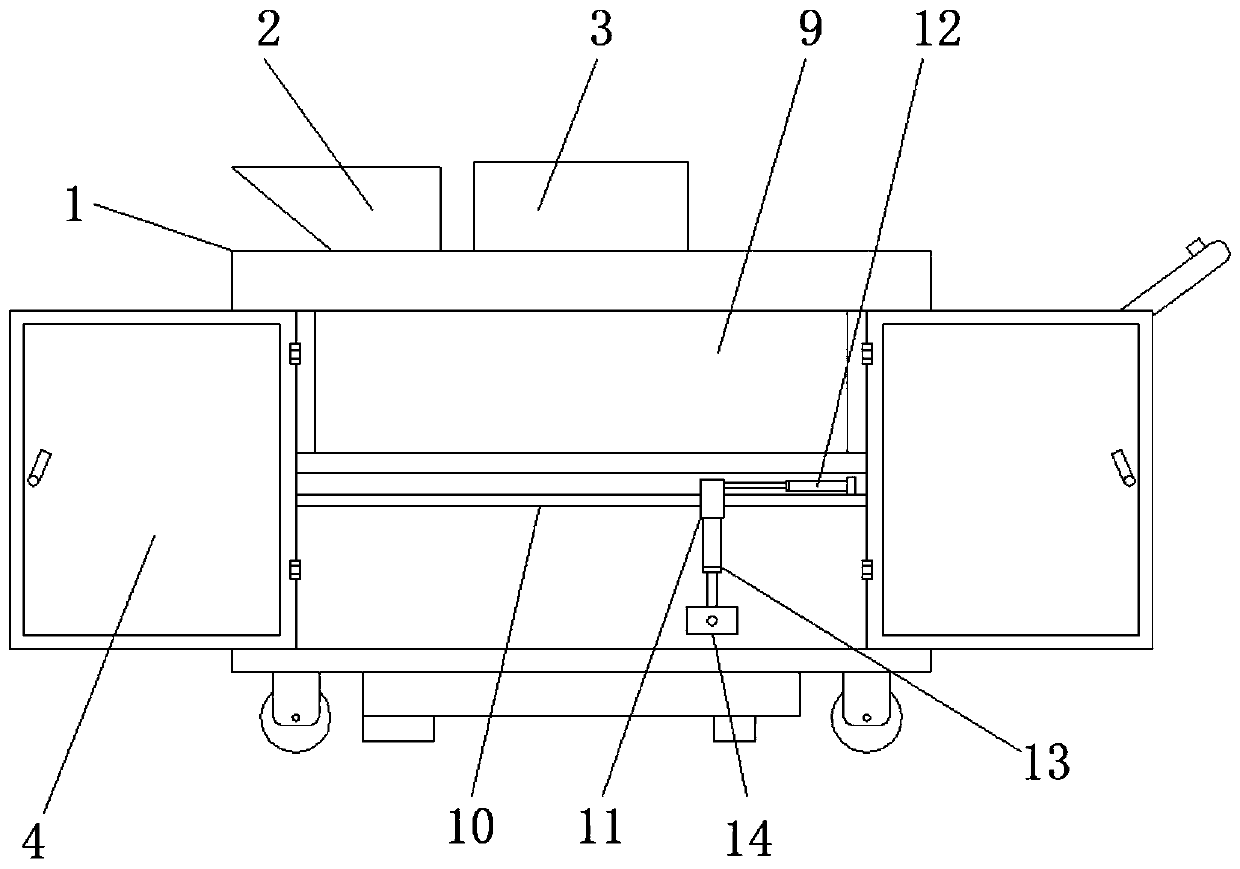

Mobile medical device storage cabinet

InactiveCN108714050AAchieve forward and backward movementRealize up and down contractionSurgical furnitureHydraulic cylinderEngineering

The invention relates to the technical field of medical equipment, especially to a mobile medical device storage cabinet. The cabinet includes a cabinet body, a plurality of first grooves arranged onthe bottom of the cabinet body and moving devices arranged in the first grooves. Each moving device includes a hydraulic cylinder. Each hydraulic cylinder is fixed to the top groove wall of the corresponding first groove. According to the invention, rollers can move up and down through the arrangement of the moving devices on the bottom of the cabinet body. When the rollers move up, the cabinet can be supported from the ground by a support frame. Since an anti-slip mat is arranged on the bottom of the support frame, the cabinet cannot move. When the rollers move down, the cabinet can be supported from the ground by the rollers so as to realize the movement of the cabinet body. Through the arrangement of a second groove in each push plate and a rotating device in each second groove, a rotating plate can rotate in each second groove, thereby realizing the movement of fixed shafts and the rollers mounted on the fixed shafts in any direction.

Owner:佛山市健群生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com