Unit type glass curtain wall lifting device and construction method

A glass curtain wall, unitized technology, applied in the field of unitized glass curtain wall lifting devices, can solve the problems of secondary hoisting, complicated installation, insufficient installation accuracy, etc., and achieve the effect of accurate positioning, reduced process and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

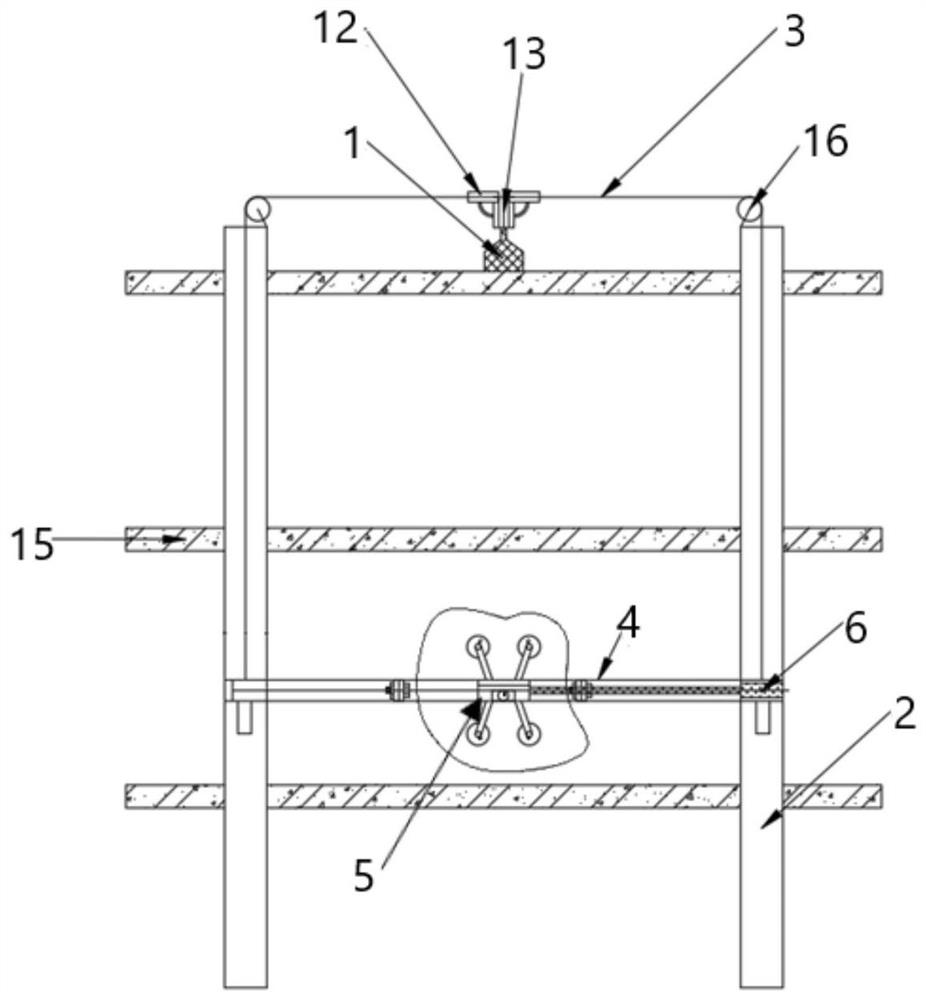

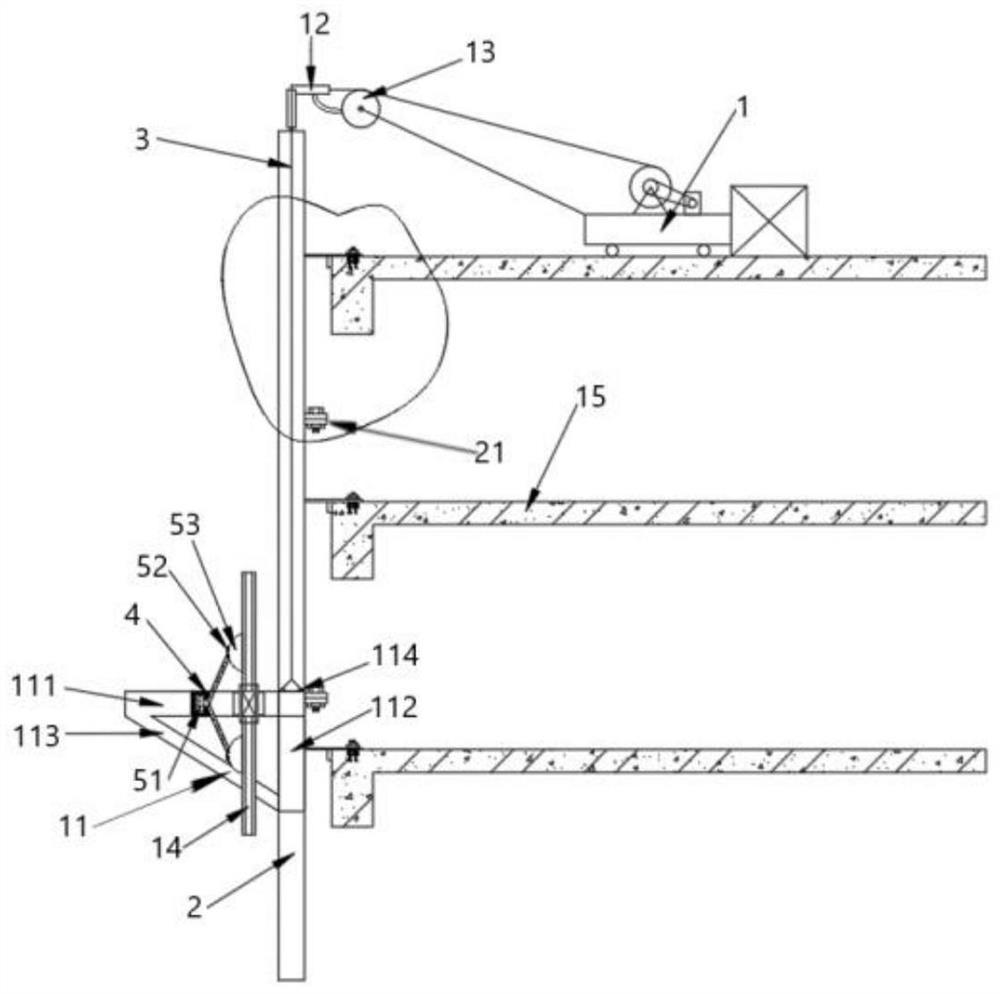

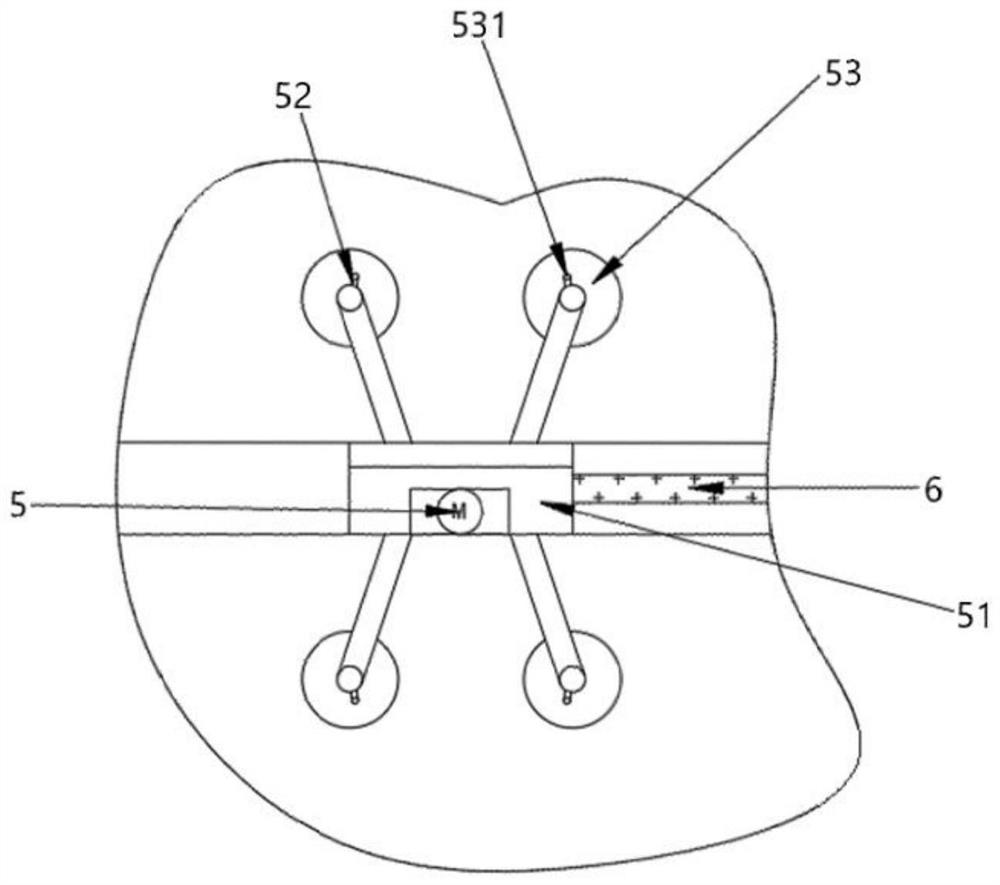

[0028]The unitized glass curtain wall lifting device shown in the figure includes a hoist 1, a guide rail 2 and a suction cup structure 5. The guide rail 2 is arranged on both sides of the hoist 1, and also includes a beam 4 and a steel wire rope 3 arranged on the guide rails 2 on both sides and passing through the hoist 1. Control the bracket module that moves up and down. The suction cup structure 5 is set on the beam 4 through the slider 51. The slider 51 is controlled by the electric telescopic rod 6 to slide on the beam 4. The two ends of the beam 4 are respectively connected to the bracket modules of the guide rails 2 on both sides. , and the crossbeam 4 can move horizontally and perpendicularly to the direction of the crossbeam 4 on the support module. The hoist is equipped with a wheel, which is used to lift the unitized glass curta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com