Automatic feeding device

A technology of automatic feeding and transmission box, applied in the field of mechanical parts processing and manufacturing, can solve the problems of low degree of automation, low production efficiency, increase production cost, etc., and achieve the effect of stable conveying speed and low working noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific drawings and embodiments.

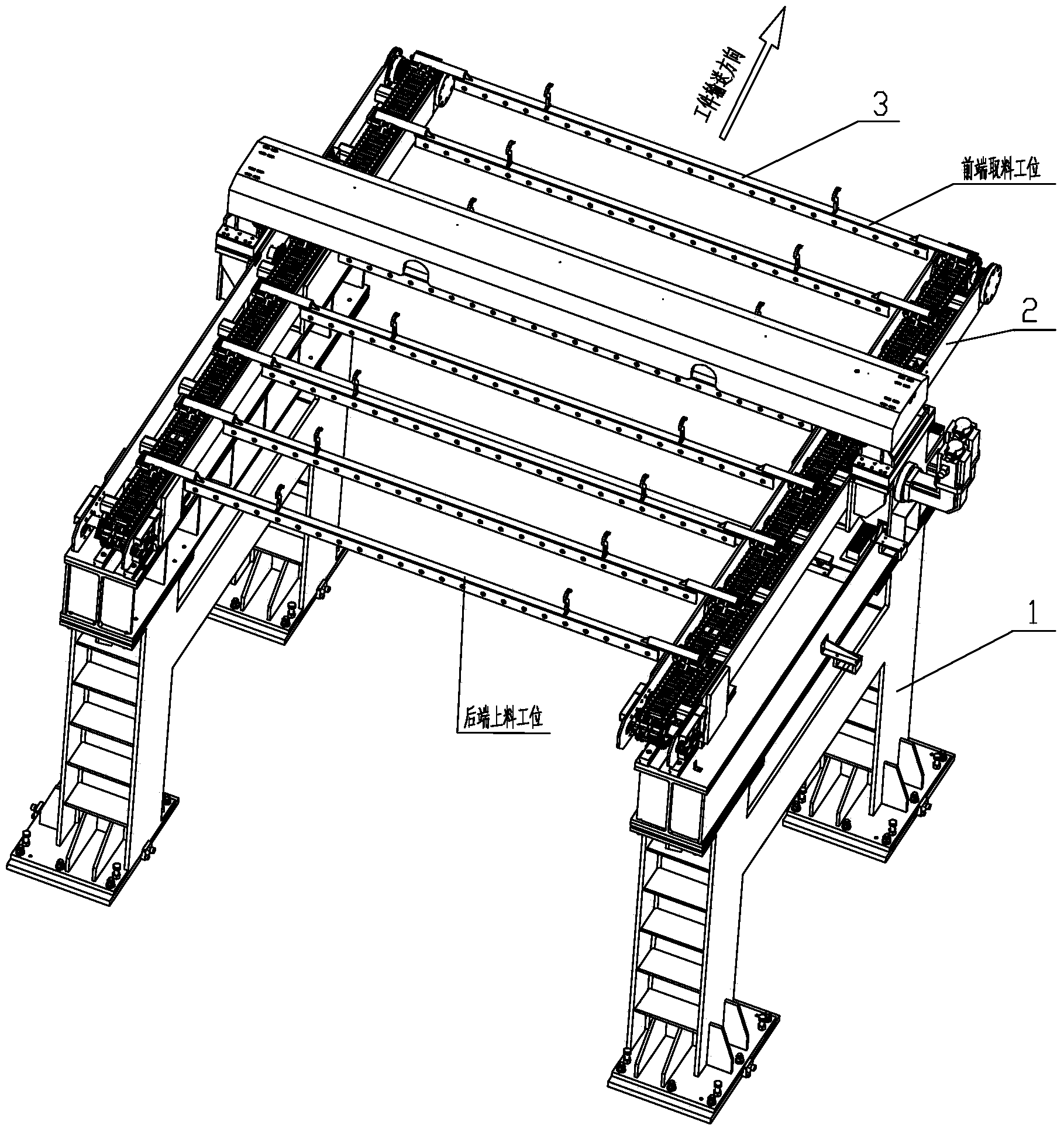

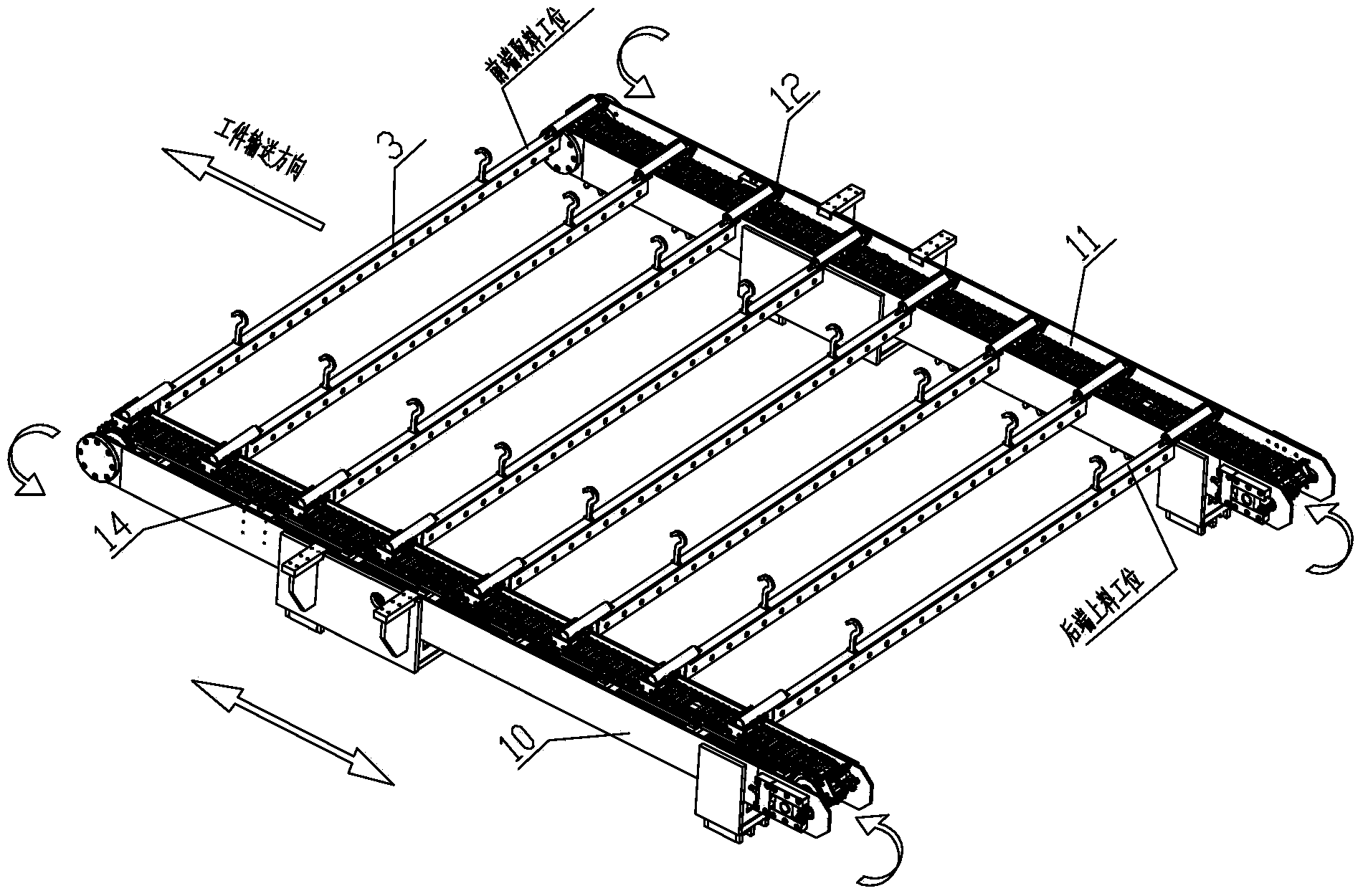

[0032] Such as figure 1 As shown, the automatic feeding device in the embodiment is an automatic equipment that realizes that the workpiece is automatically transported from the rear feeding station to the front reclaiming station. It is mainly composed of a bottom bracket part 1, an upper transmission part 2 and a conveying boom 3. composition.

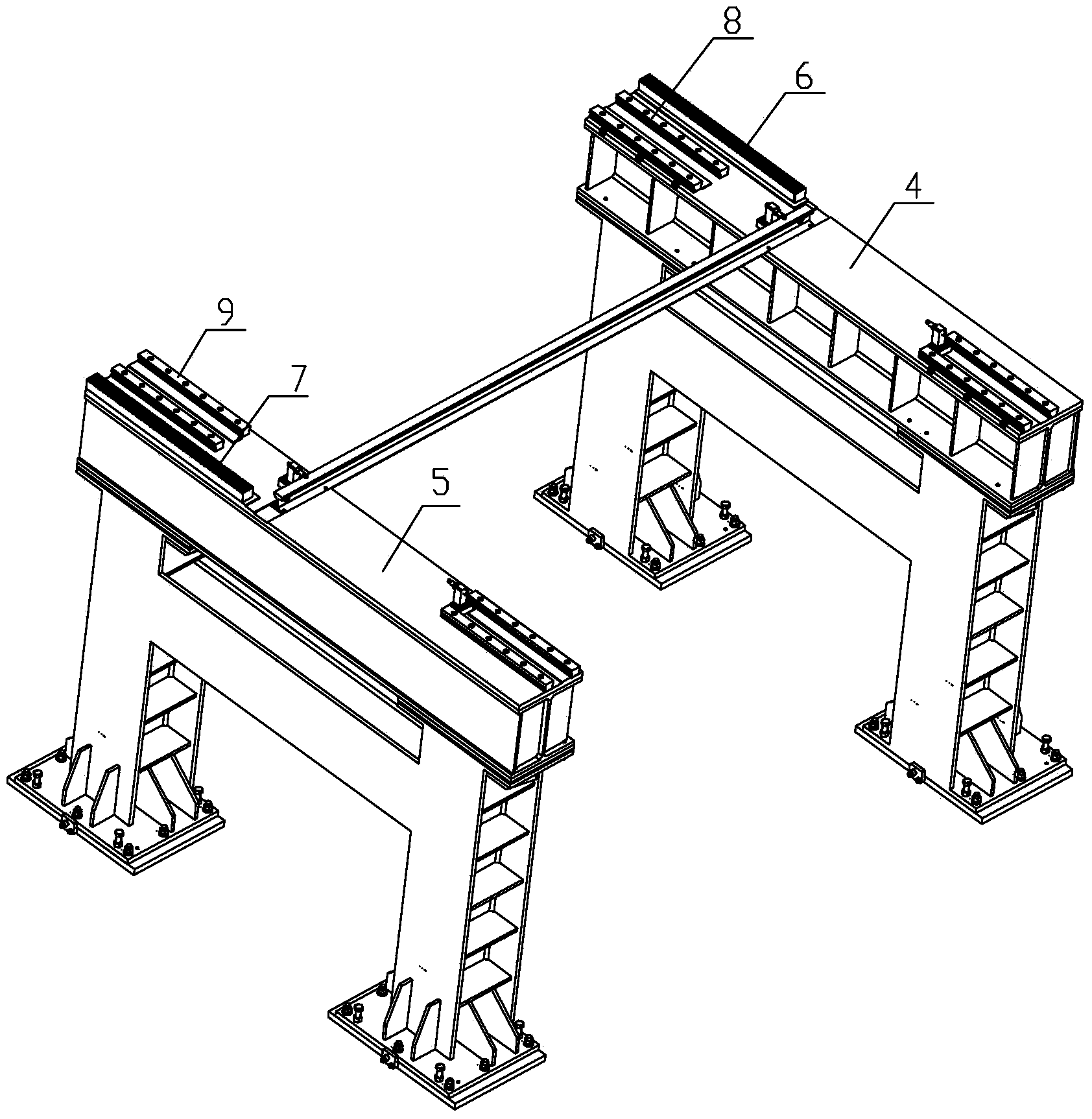

[0033] The structure of the bottom bracket part is as figure 2 As shown, it mainly includes two parts: the left side bracket 5 and the right side bracket 4. The left side bracket 5 is equipped with a left rack 7; the right side bracket 4 is equipped with a right rack 6 and a left rack 7 is used. To mesh with the left transmission gear 22 in the left driven transmission box 20, the right rack 7 is used to mesh with the right transmission gear 32 in the right driving transmission box 21; through the left transmission gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com