Patents

Literature

32results about How to "Stable conveying speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

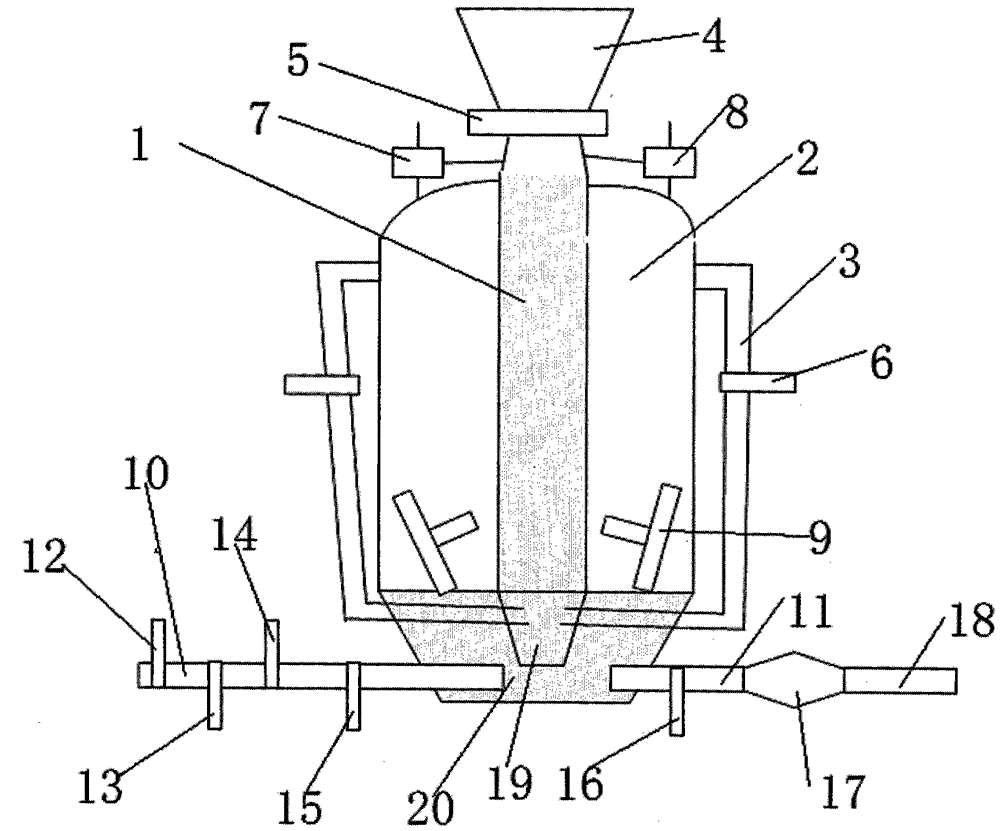

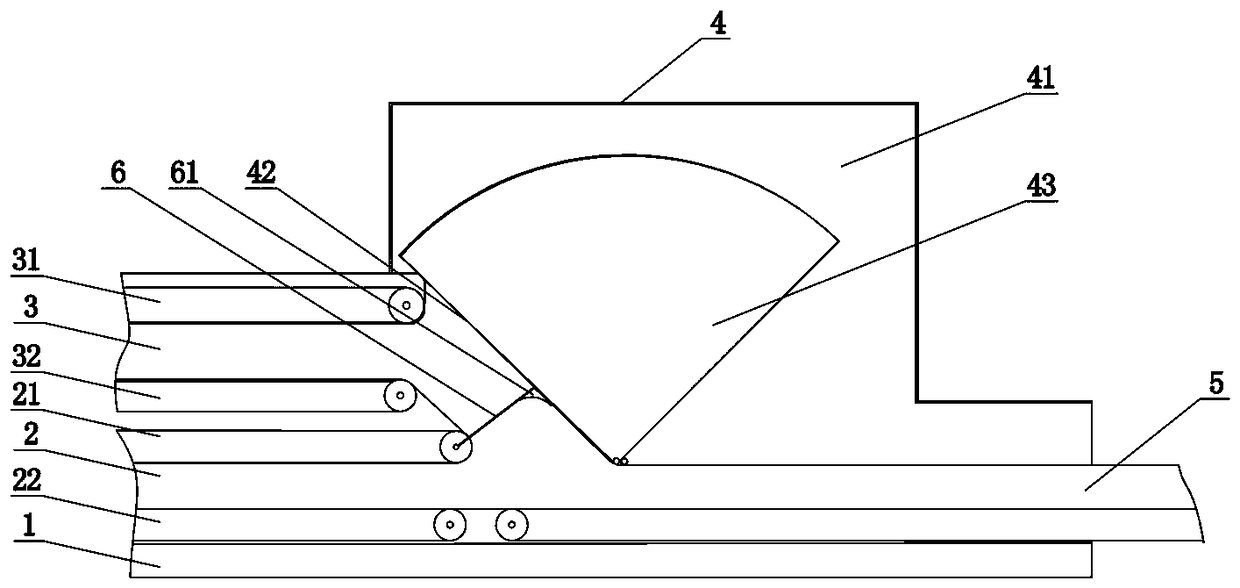

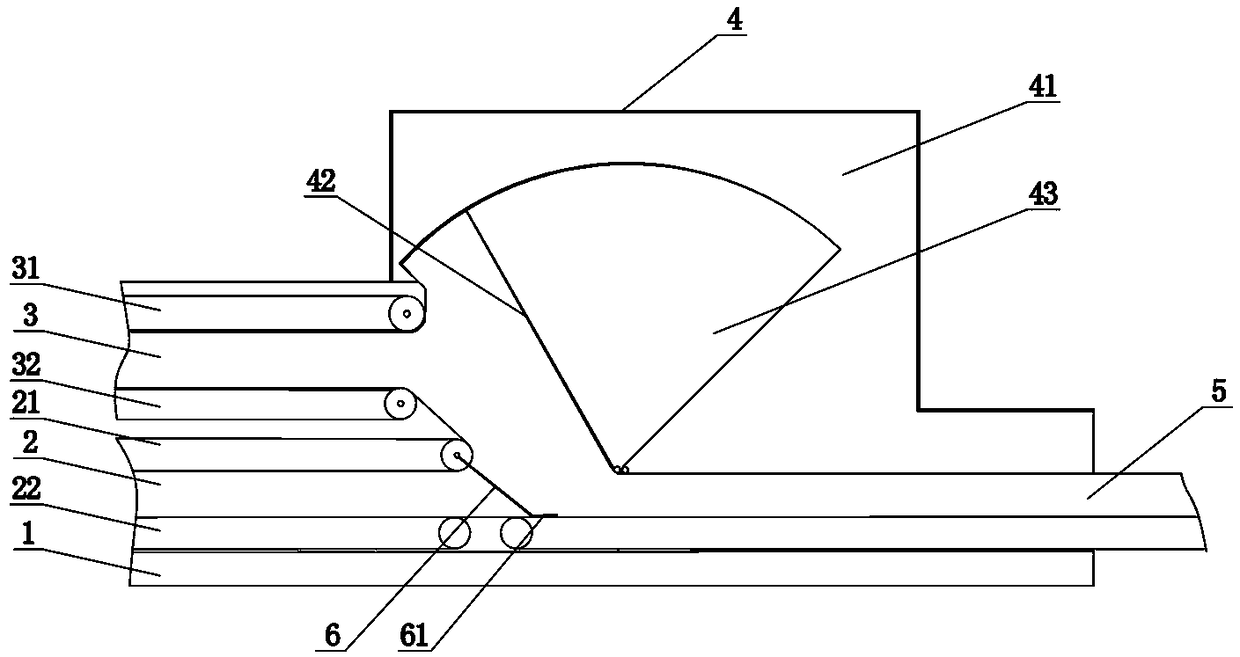

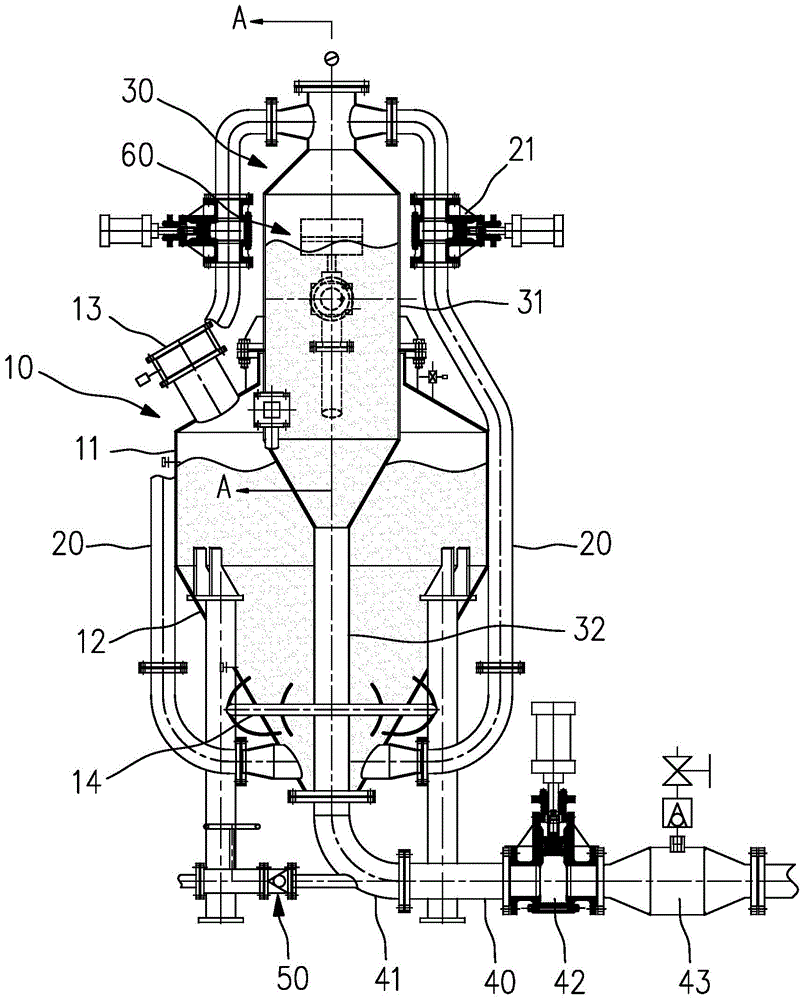

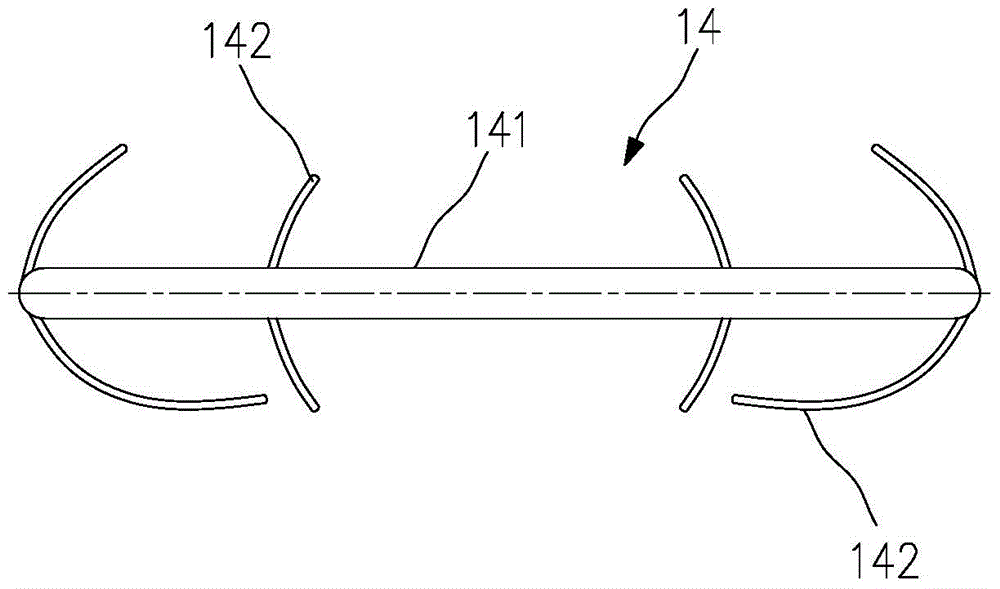

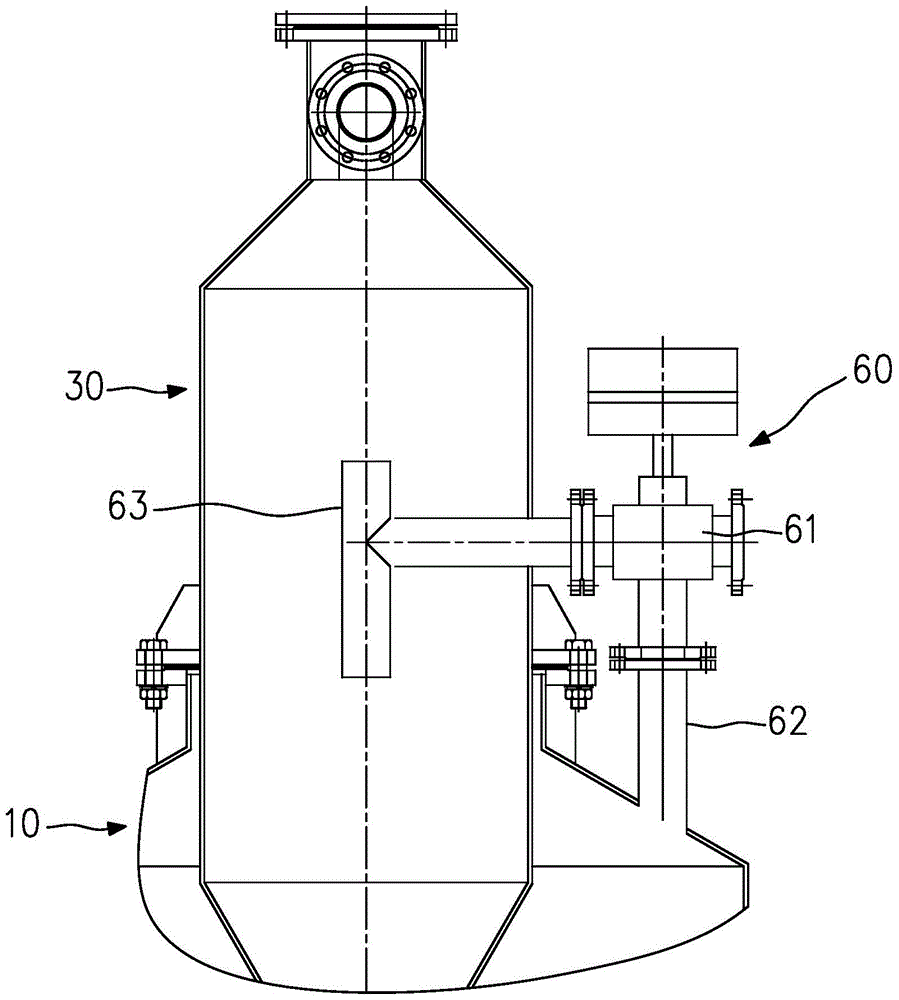

Heating furnace before forging

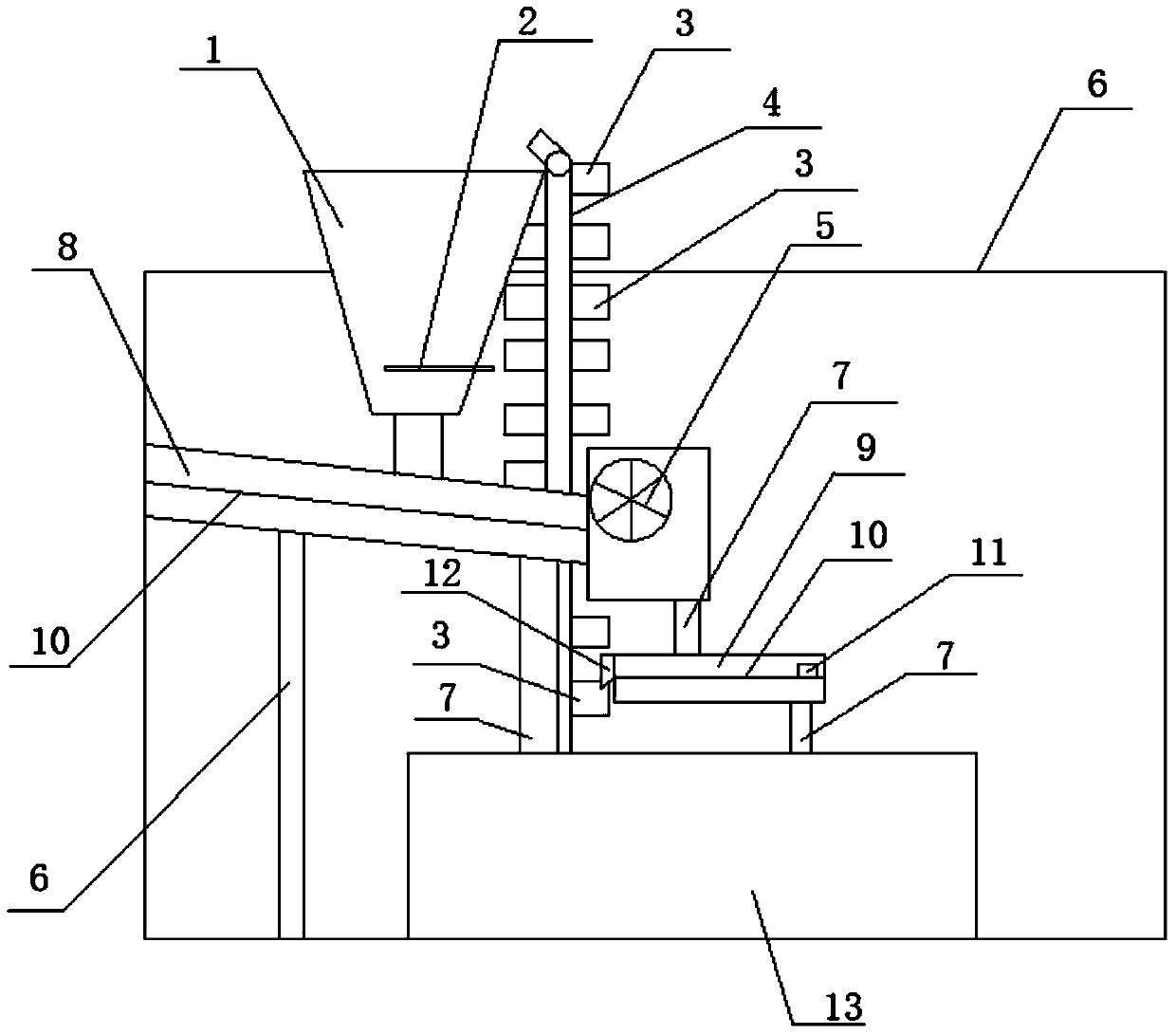

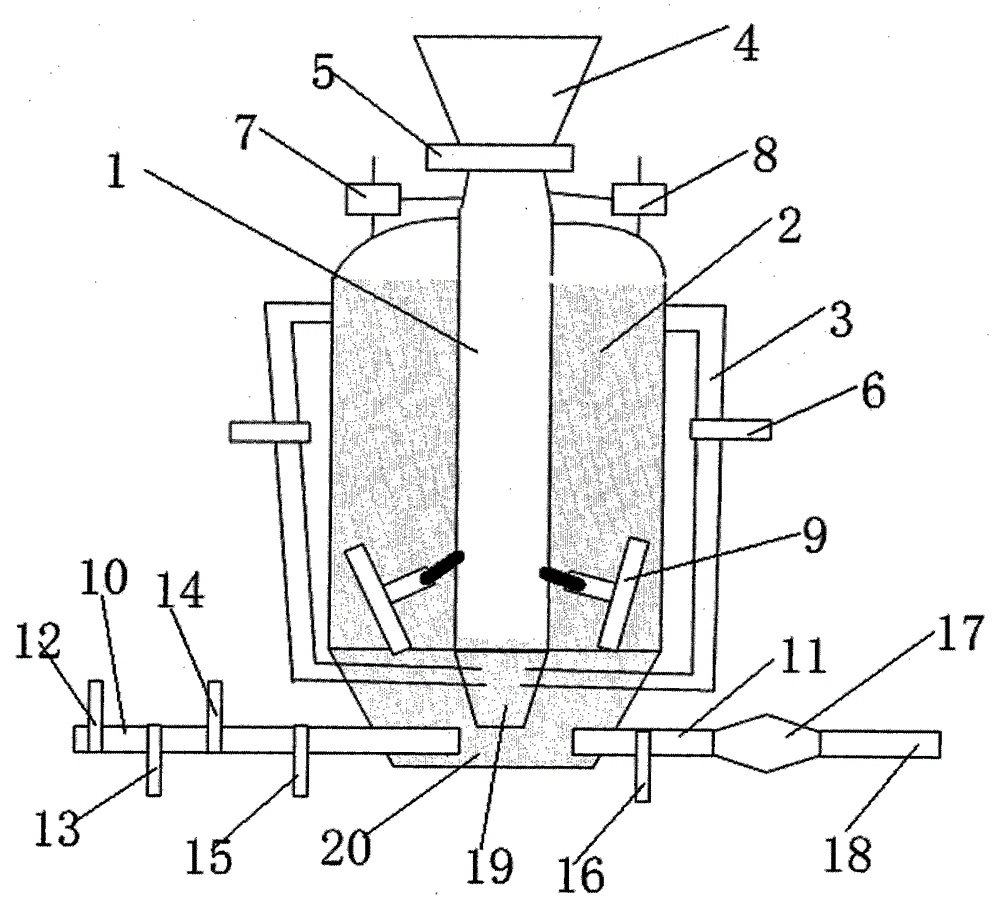

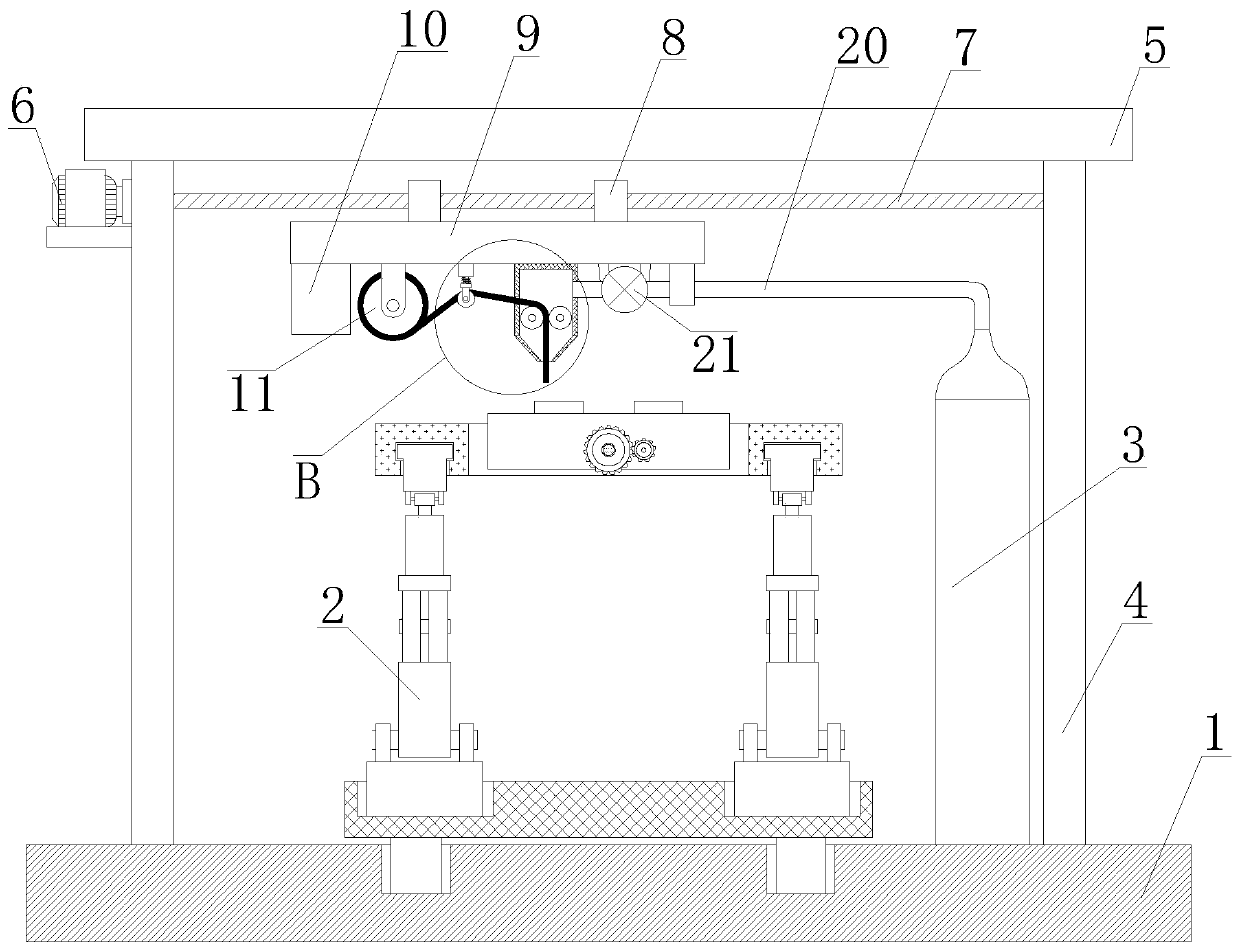

The invention provides a heating furnace before forging, which belongs to the technical field of machinery and solves the problems of severe production environment, low work efficiency and large energy waste when traditional heating equipment before forging works. The heating furnace before forging comprises a heating device and a furnace body, wherein the furnace body is provided with a feed opening and a discharge opening, an automatic feeding mechanism is arranged at the feed opening of the furnace body, a conveying device capable of conveying a blank from the feed opening to the discharge opening is arranged in the furnace body, the heating device is arranged on the furnace body and used for heating the blank conveyed in the furnace body, and a heat insulating device is also arranged on the side wall of the furnace body. When in working, the heating furnace before forging has the advantages of good working environment, simple operation, high work efficiency, less energy waste and high quality of processed products.

Owner:杨少华

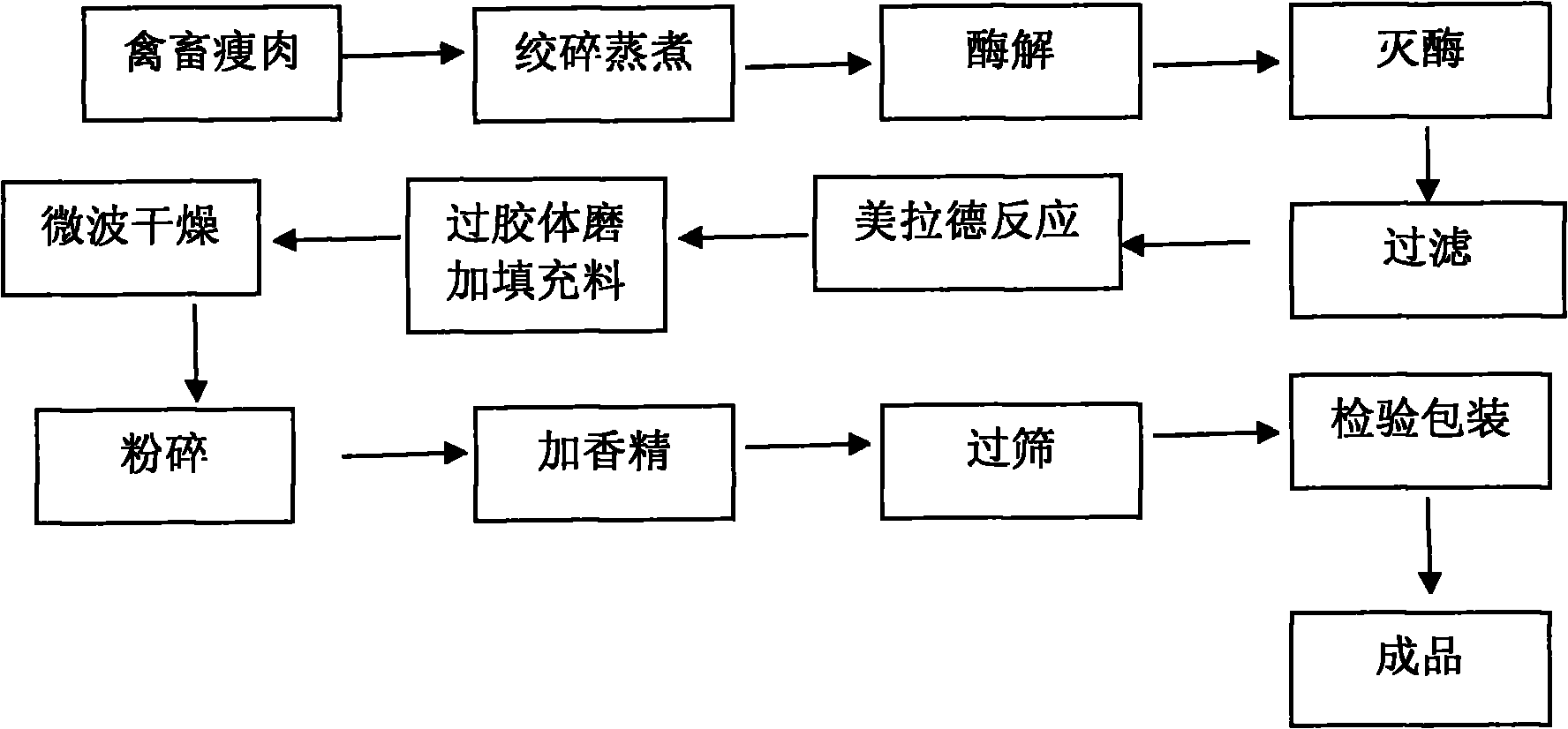

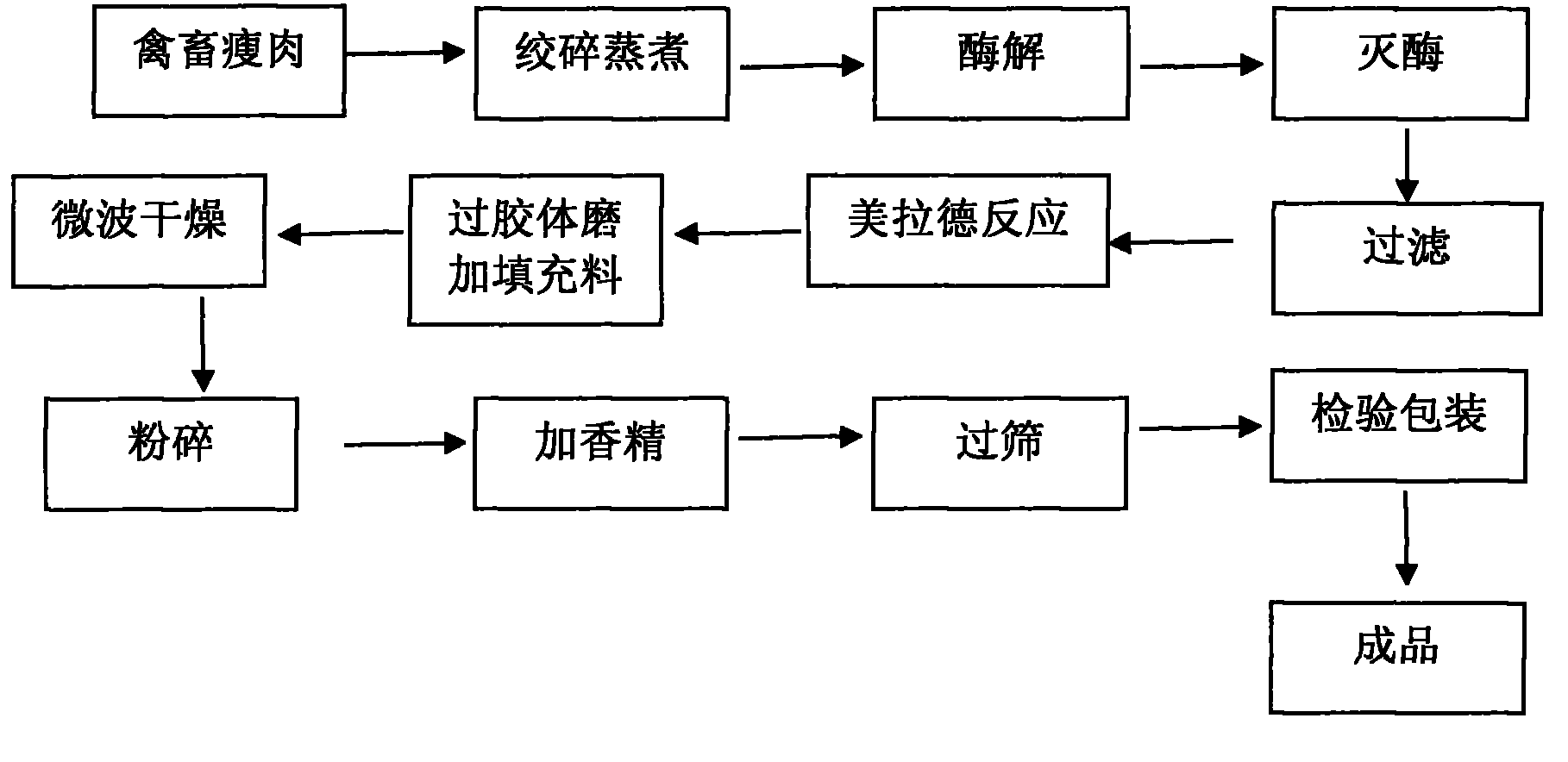

Aromatic meat gourmet powder and manufacturing process thereof

InactiveCN102150813AImprove deep processing utilizationShorten drying timeFood preparationMaillard reactionLean meat

The invention discloses aromatic meat gourmet powder and a manufacturing process thereof. Animal lean meat serving as a raw material is sequentially subjected to processes of mincing, cooking, enzymolysis, enzyme inactivation, Maillard reaction and microwave drying to form the aromatic meat gourmet powder. The aromatic meat gourmet powder contains the following components in percentage by weight: 0.3 to 0.4 percent of sodium inosinate, 0.3 to 0.4 percent of sodium guanylate, 13 to 16 percent of sodium glutamate, 12 to 15 percent of salt, 3 to 6 percent of glucose, 0.1 to 0.2 percent of vitamin B1, 5 to 7 percent of white sugar, 4 to 6 percent of amino acid, 20 to 25 percent of filler, and the balance of powdery animal meat. The aromatic meat gourmet powder has the aroma of the animal meat and special microwave dried aroma and mouthfeel, the microbial index is good compared with the like products, and the quality guarantee period is long; deep processing utilization of meat can be improved, and the additional value of the animal meat can be increased; and the process can be widely applied in the food processing industries of instant noodles, puffed food, cooked meat products and the like.

Owner:ZHEJIANG DINGWEI FOOD

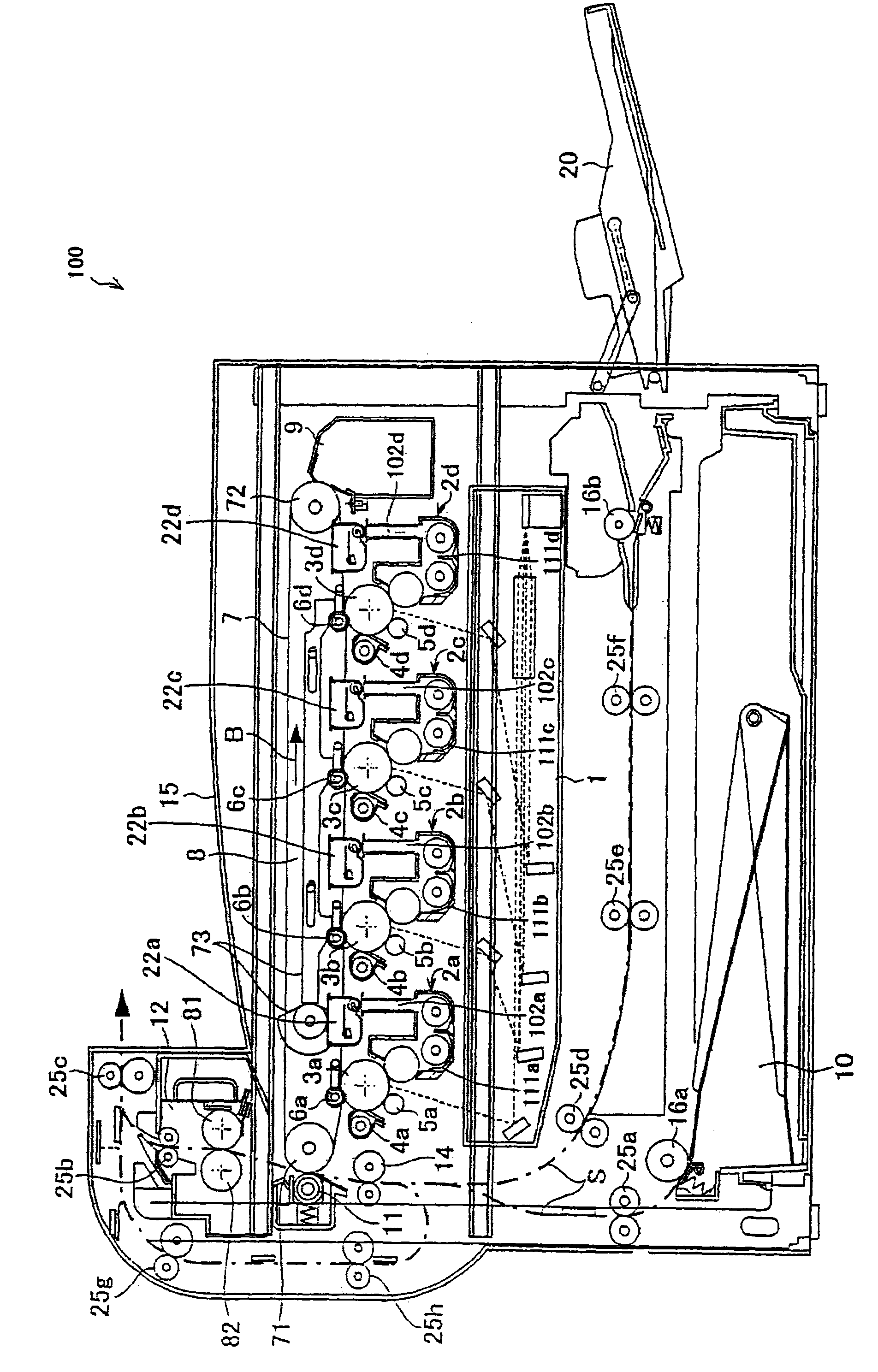

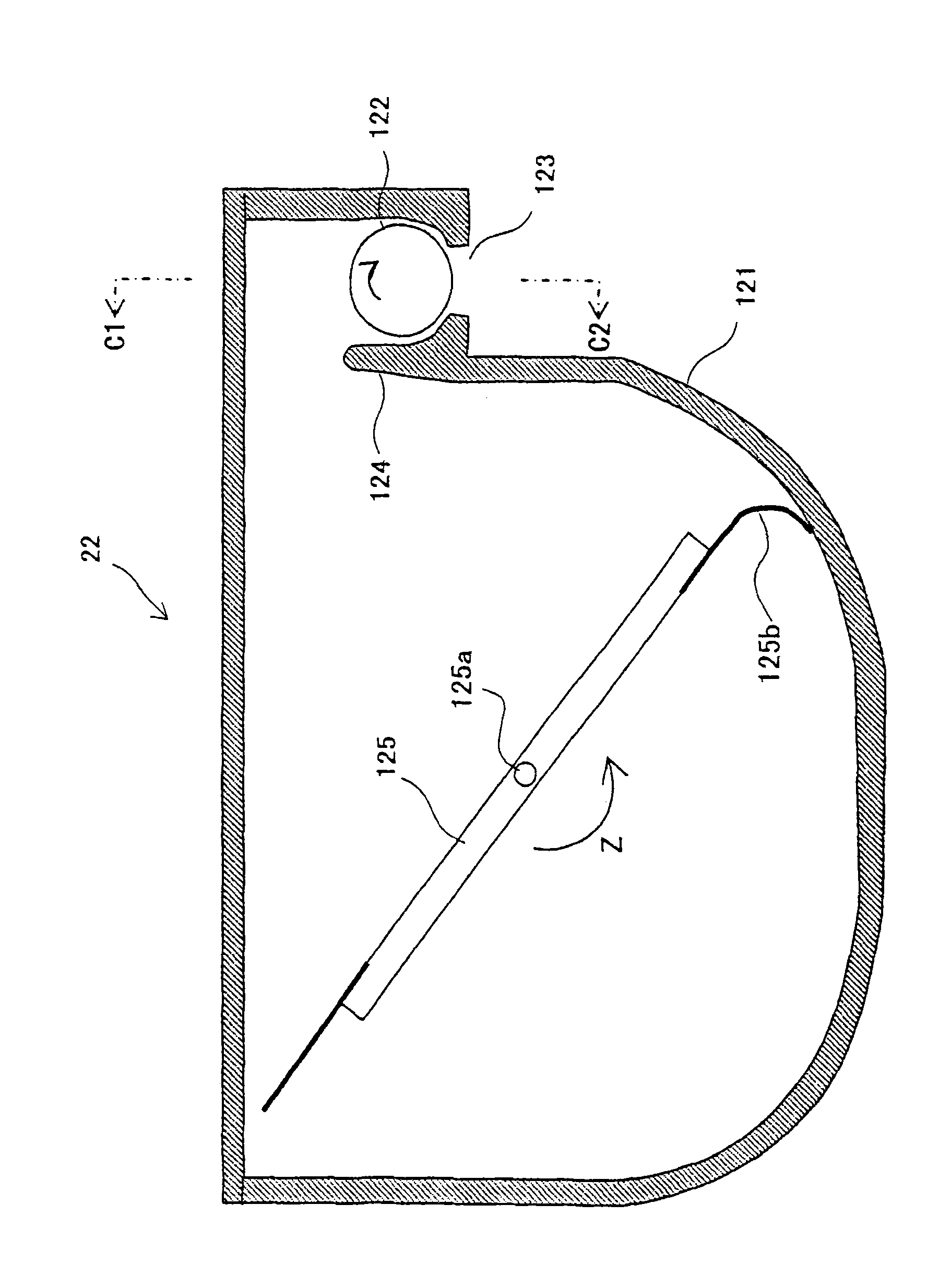

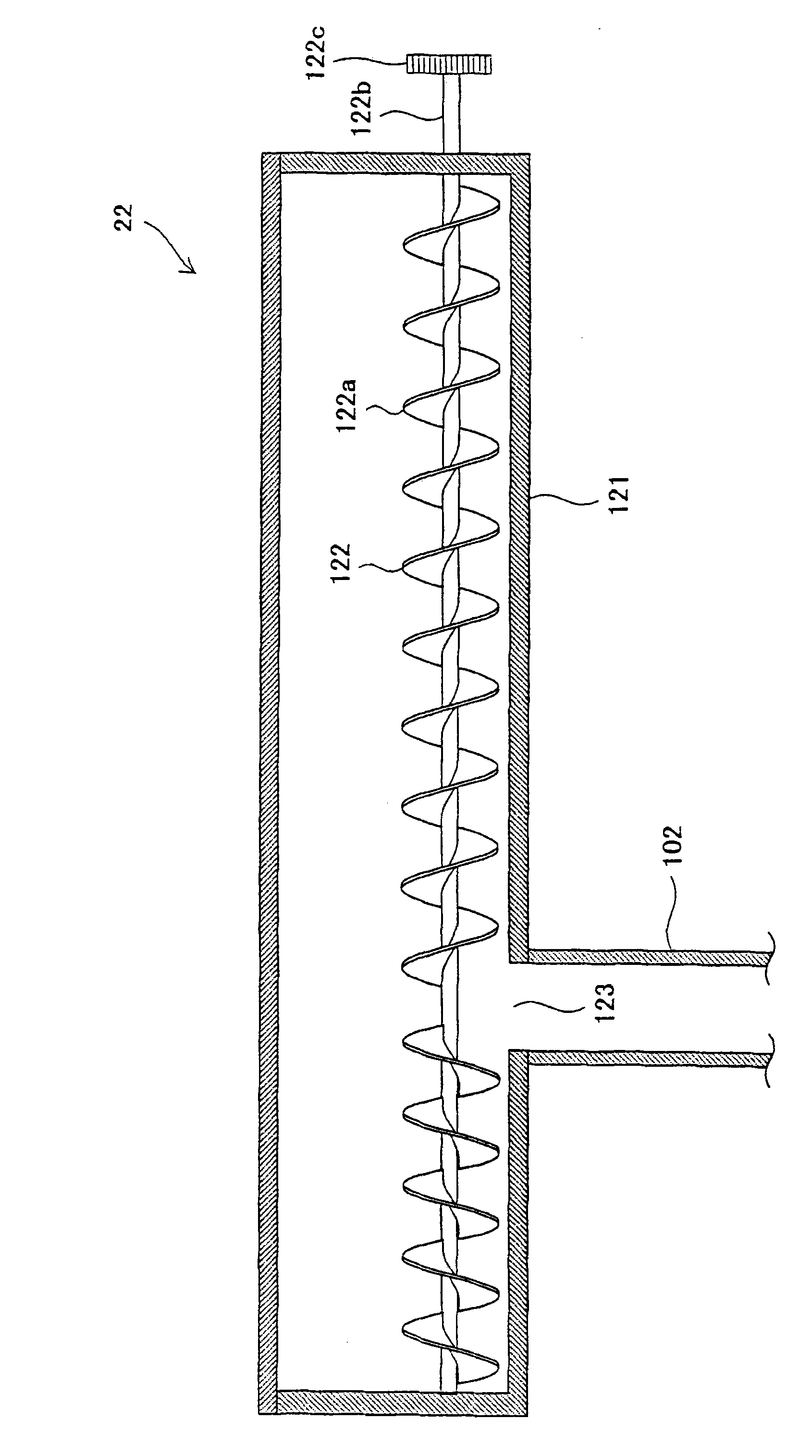

Developing device and image forming device using the same

InactiveCN101794102AIncrease surface areaReduce stressElectrographic process apparatusHelical bladeImage formation

The present invention relates to a developing device and an image forming device using the same. The developing device includes a developing vessel for storing a developer, a first conveying passage, a second conveying passage, a first conveying member, a second conveying member and a developing roller for supplying toner to a photoreceptor drum. The first conveying member has a first rotary shaft and a first conveying blade formed on the periphery of the first rotary shaft. The first conveying blade has a large-diametric ring-shaped helical blade and a small-diametric helical blade, forming a double-helical structure. Alternatively, the first conveying blade is formed of helical blades being different in phase; each helical blade is formed so that the radius varies on a cycle of the rotational angle of 180 degrees.

Owner:SHARP KK

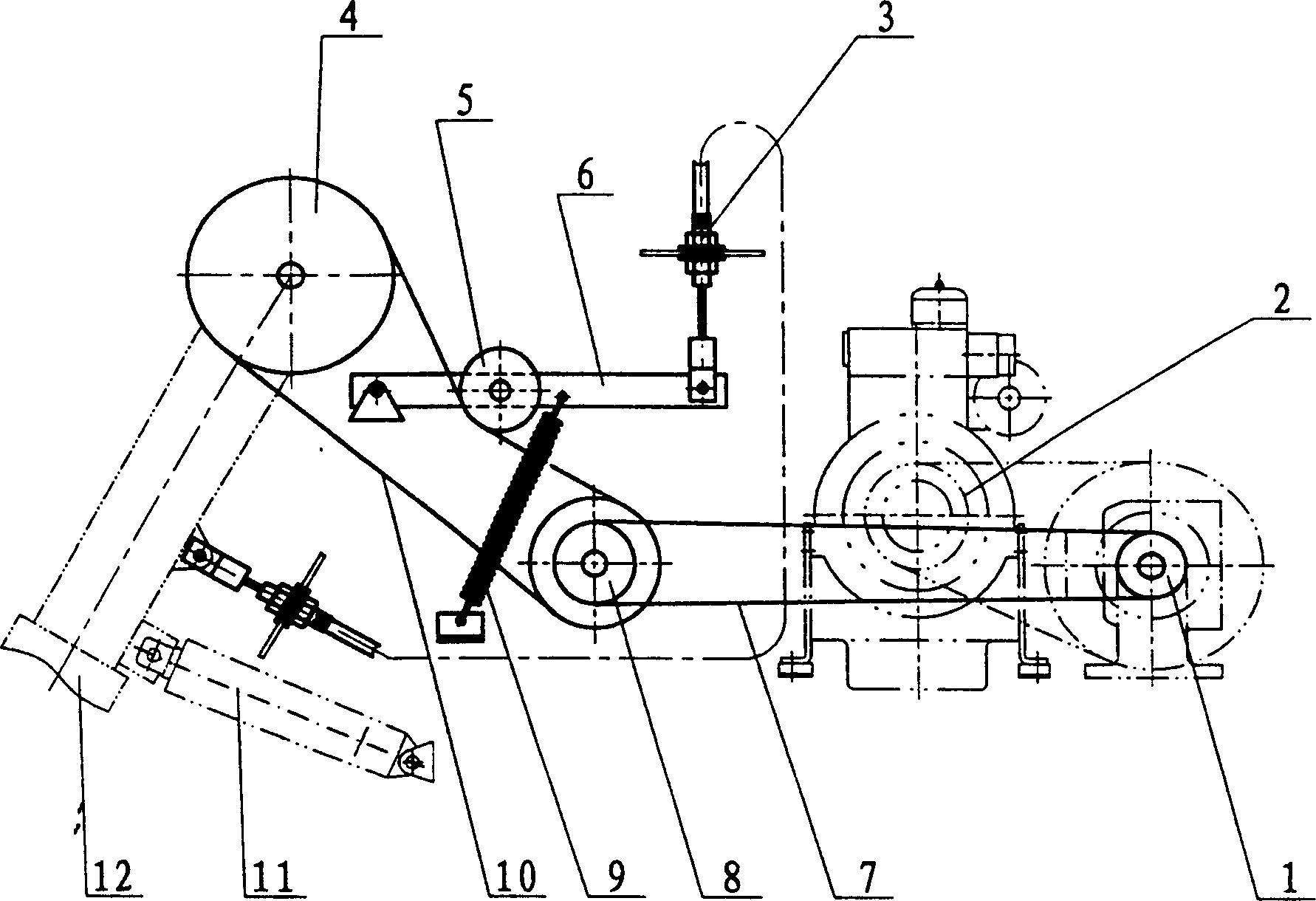

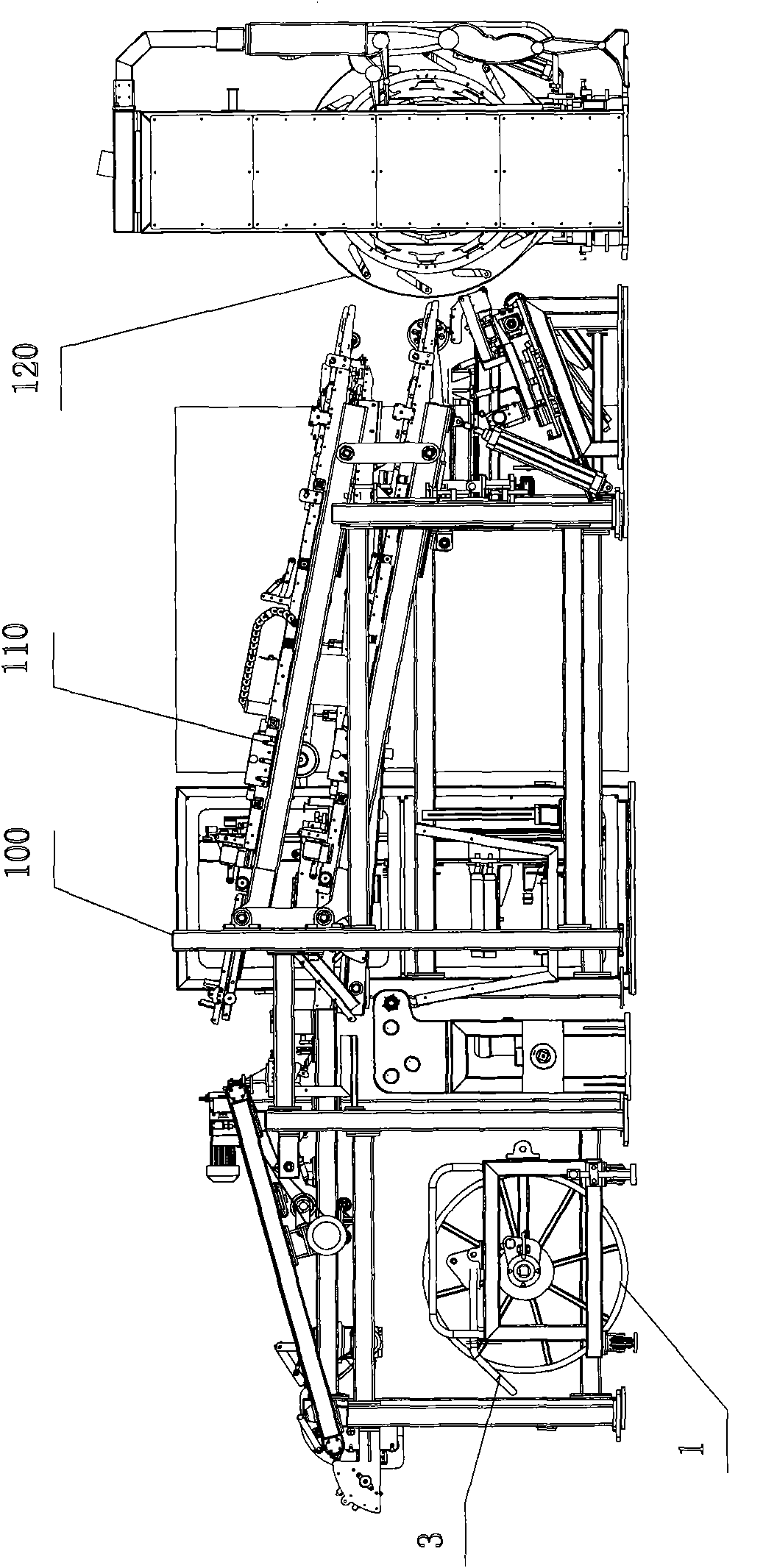

Cutting platform transmission device of half-feeding combine for rice and wheat

The invention discloses a transmission arrangement for half-feed-in type rice and wheat combine-harvester cutting platform which includes two-stages of speed reducing, the first stage being a chain drive, which is driven by intermediate gearing box and transitional drive shaft arranged on the housing through chains, the second stage being a belt drive which is driven by the transitional drive shaft and cutting platform power feed-in wheel through a belt. The invention can be applied to guarantee the stabilization cutting and transporting velocity for the harvesters.

Owner:TAIZHOU CHANGFA AGRI EQUIP

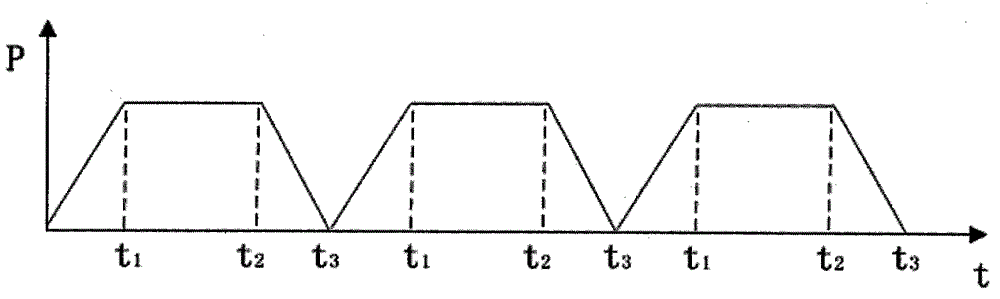

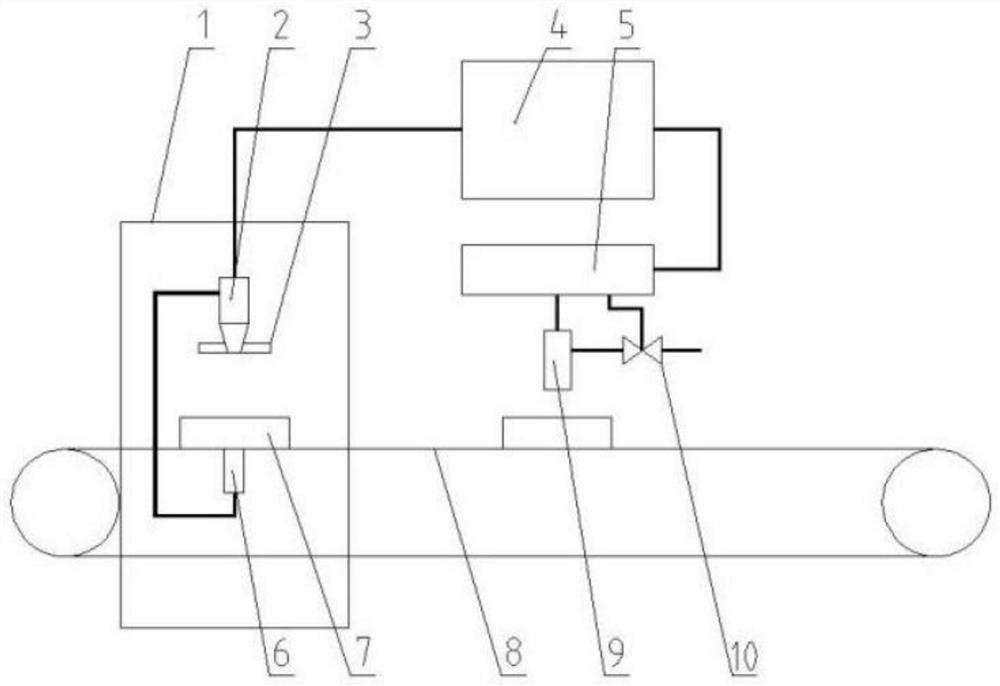

Material unwinding and winding device and speed regulating method thereof

InactiveCN102107796AStable conveying speedWind evenlyArticle deliveryWebs handlingEngineeringMechanical engineering

The invention discloses a material unwinding and winding device and a speed regulating method thereof. By adopting the device and the method for automatically monitoring and controlling the winding speed of mat cloth, the winding speed of the mat cloth can be reduced gradually in stages, so that the winding speed of the mat cloth is roughly kept stable and basically synchronous with the material conveying speed, the material is continuously and uniformly conveyed to a feeding rack on the premise that shutdown and speed limit are not needed, and the production efficiency of winding, jointing and fixed length cutting of the material is improved. The material unwinding and winding device comprises a material winding device, a mat cloth winding device and an unwinding bracket. A thickness detection device for detecting the winding thickness of the mat cloth and a driving device for driving a scroll to rotate and regulating the revolution speed of the scroll according to the thickness detection result are arranged on one side of the mat cloth winding device. The scroll continuously rotates to wind the mat cloth under the action of the driving device, and meanwhile, the material is separated from the mat cloth on the unwinding bracket and conveyed forwards to the feeding rack.

Owner:MESNAC

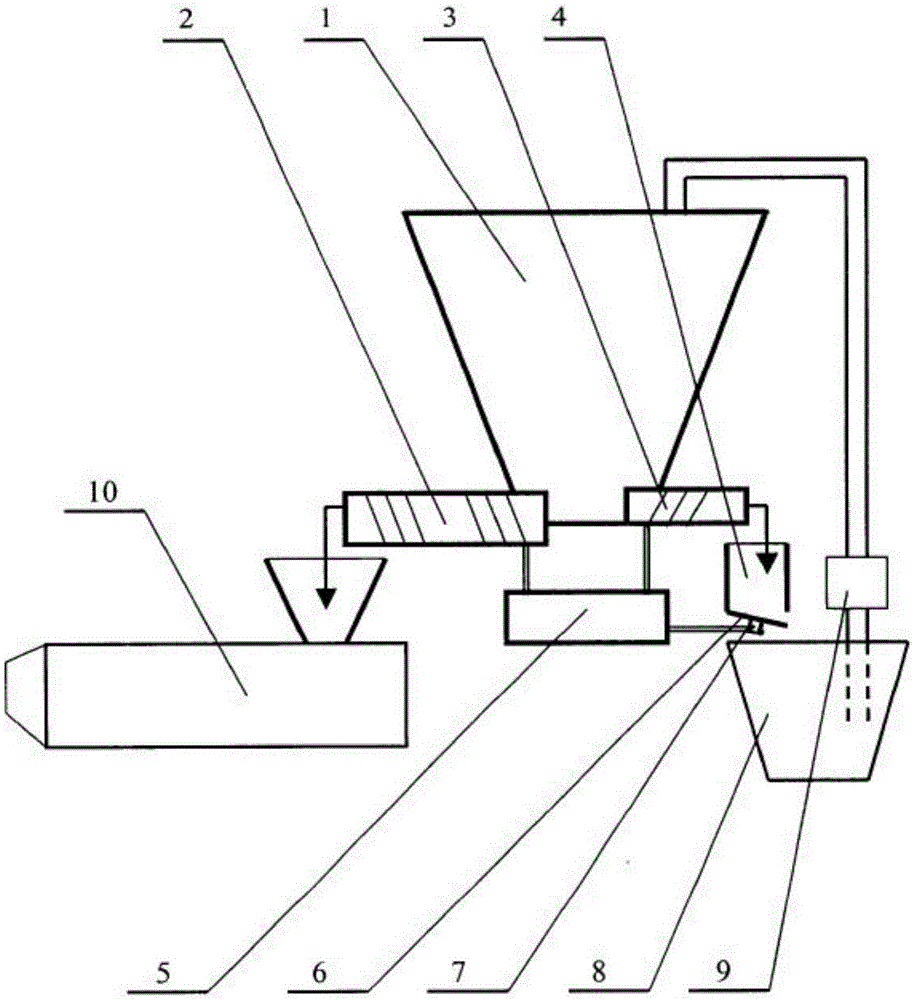

An ore sorting device

InactiveCN104084288ARealize sortingRealize secondary crushingSievingScreeningEngineeringConveyor belt

The invention relates to the field of ore separation production equipment, and particularly relates to an ore sorting device. The ore sorting device comprises a hopper, a first sorting mechanism, a smasher, a second sorting mechanism, a storing box, a rack and a conveyor belt. The hopper is fixedly installed on the rack. The bottom of the hopper is connected to the first sorting mechanism. The first sorting mechanism is connected to the storing box through a conveying pipeline. The first sorting mechanism is also connected to the smasher. The smasher is connected to the second sorting mechanism through a conveying pipeline. The second sorting mechanism is connected to the storing box through a conveying pipeline. The second sorting mechanism is also provided with a material outlet. The material outlet leads to the conveyor belt. The conveyor belt is communicated with the top of the hopper. The beneficial effects of the ore sorting device are that: the structure of the device is simple, operation is convenient, ore sorting is achieved by utilization of the simple device and secondary smashing processing of the ore is achieved at the same time.

Owner:GUANYANG CHENGONG ORE DRESSING MACHINERY MFG

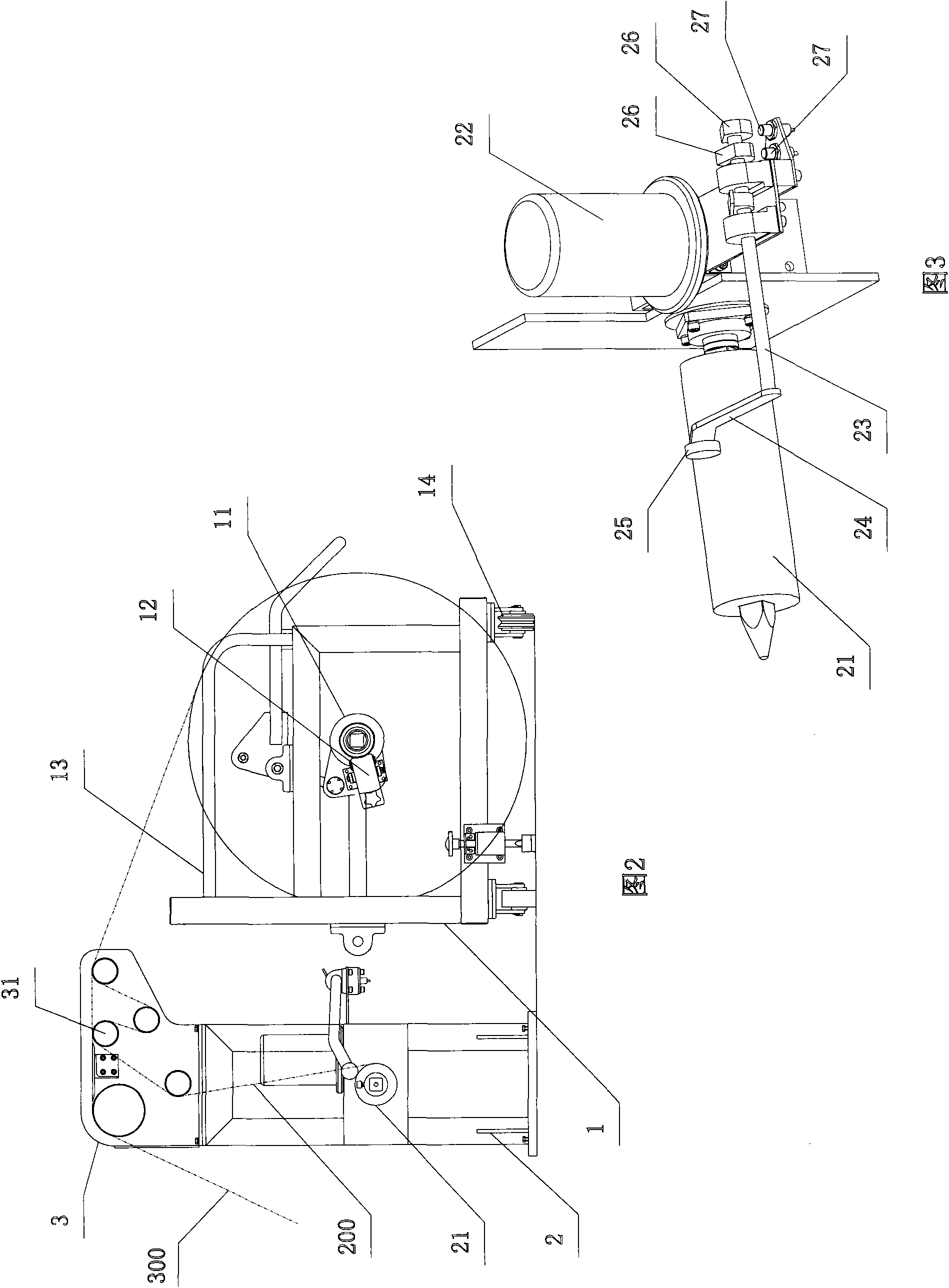

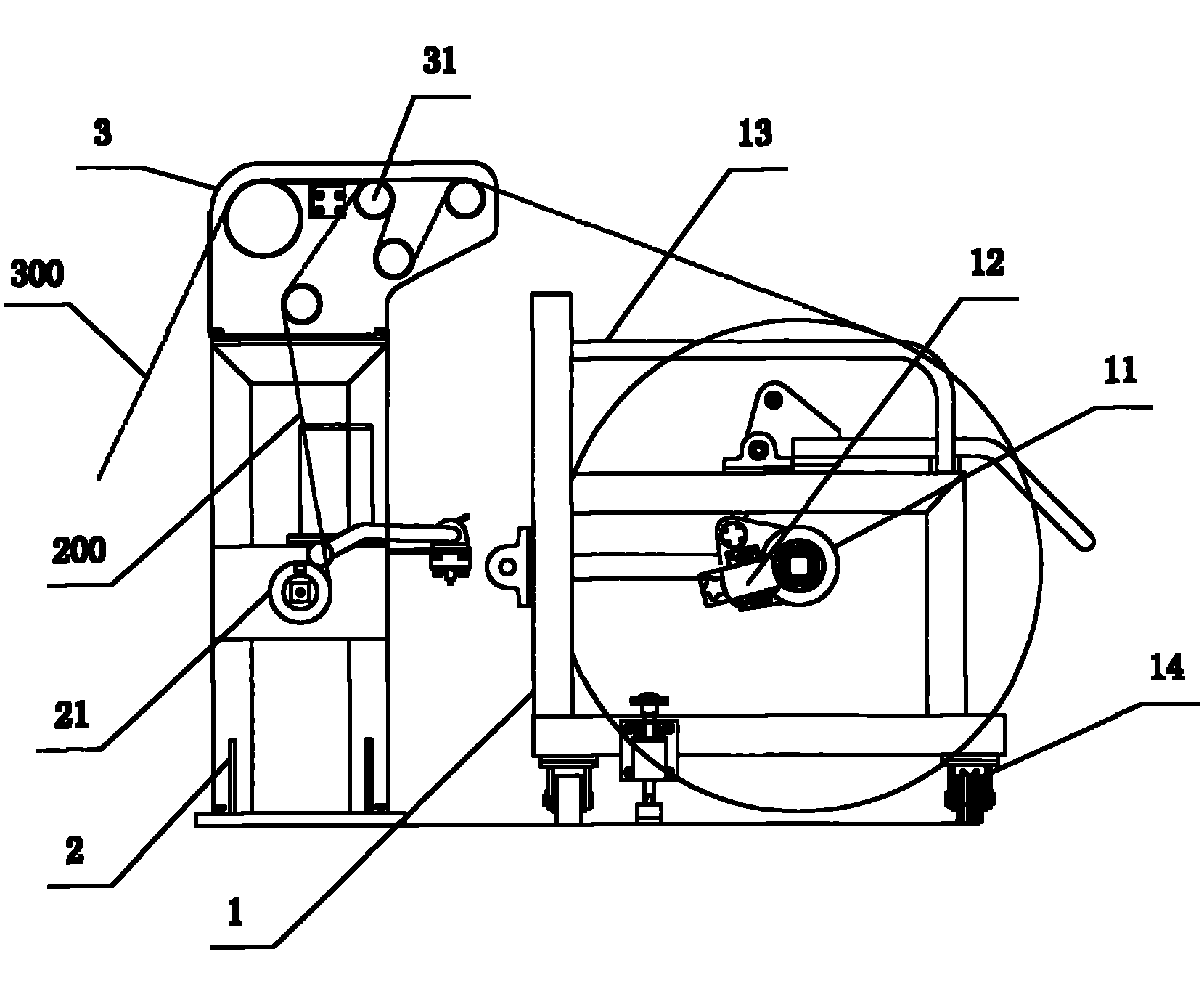

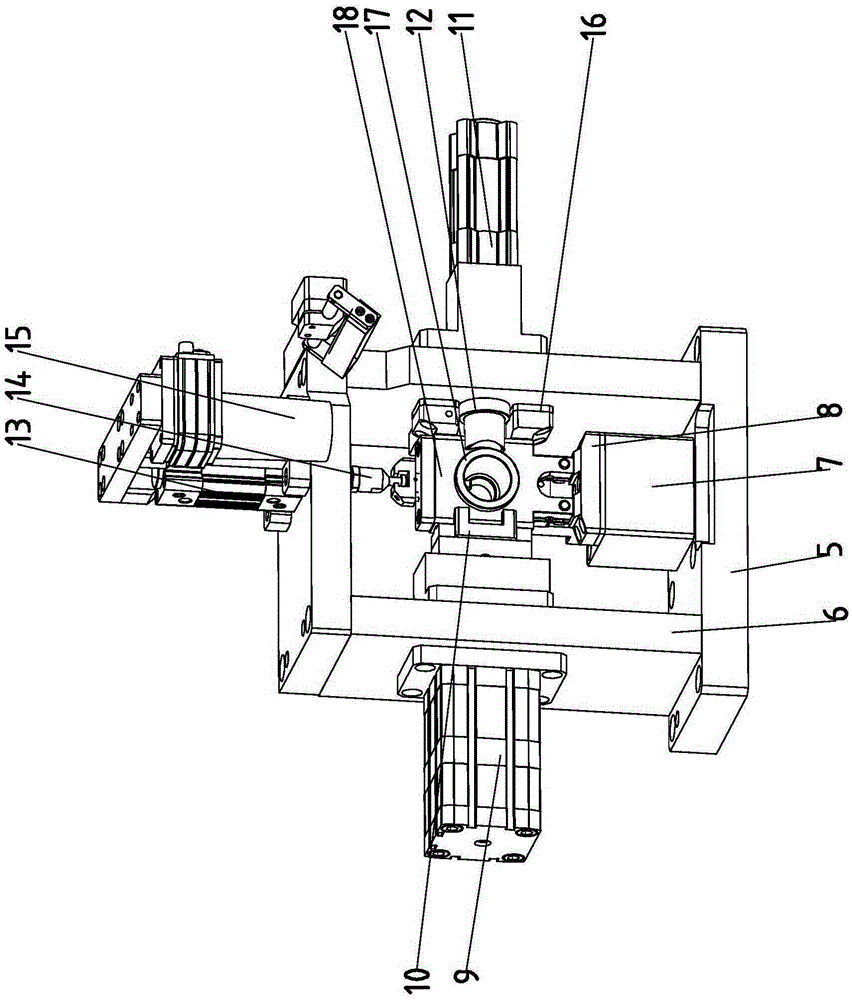

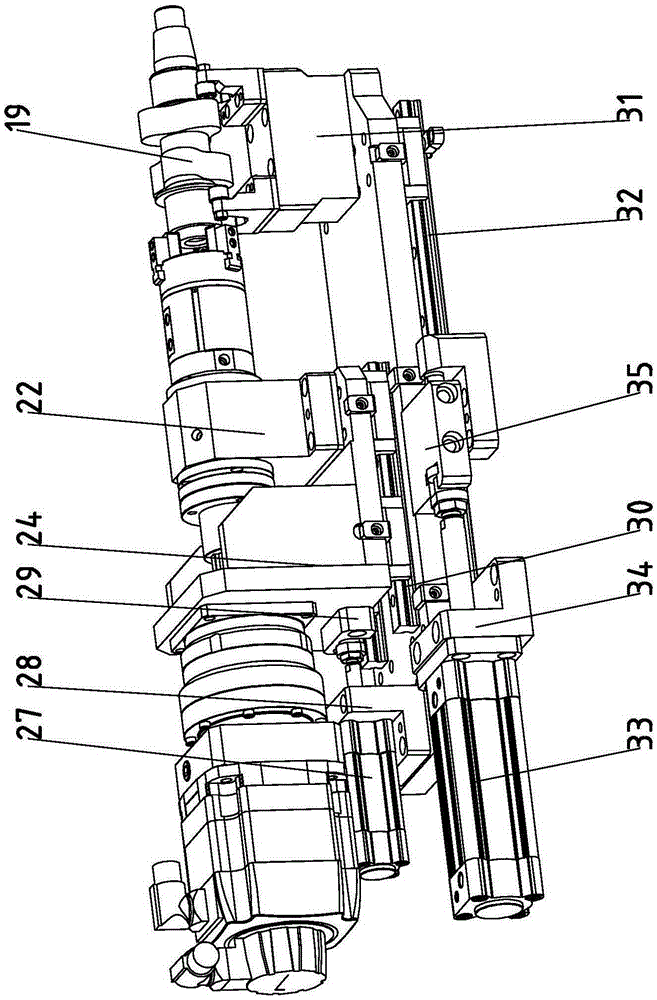

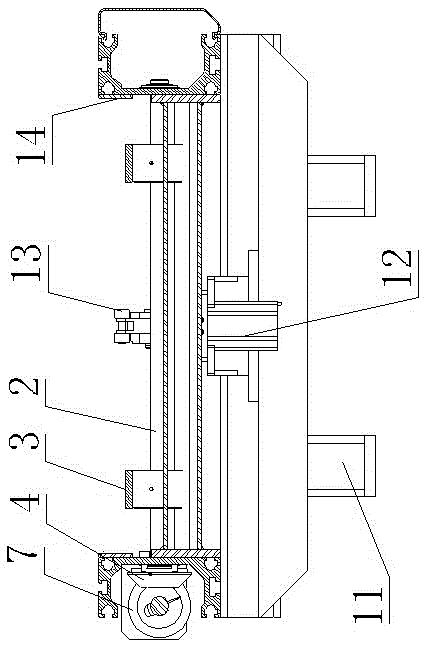

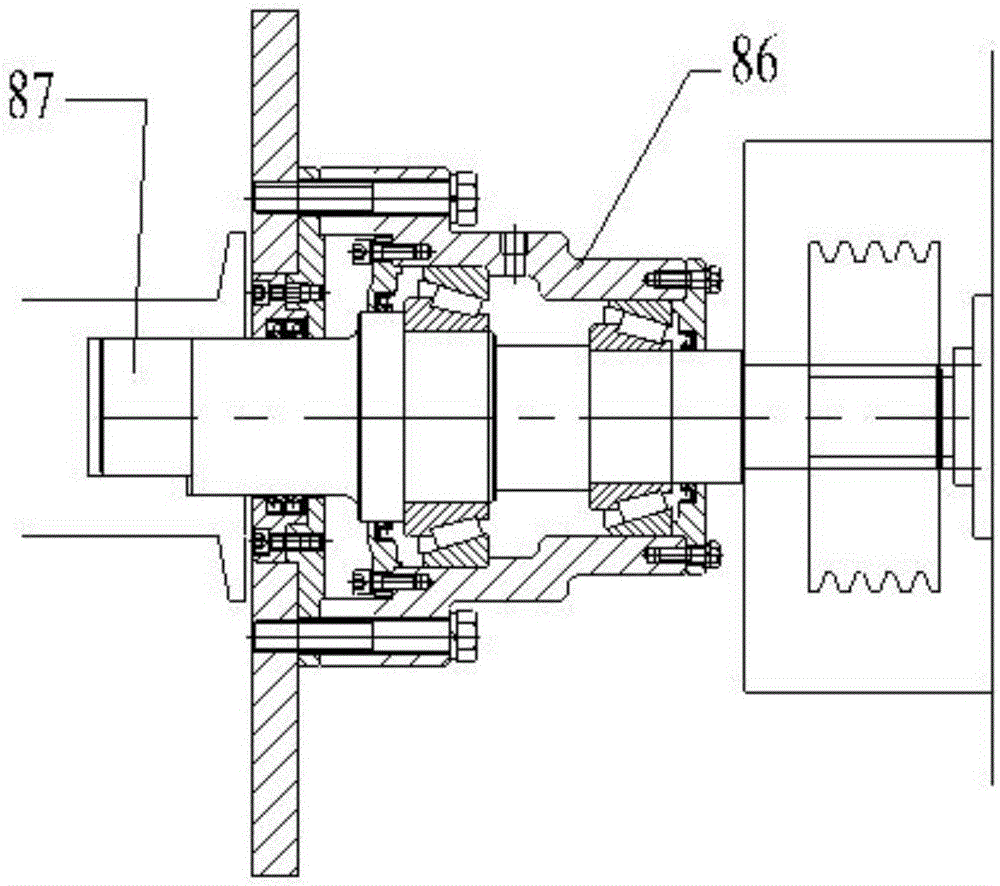

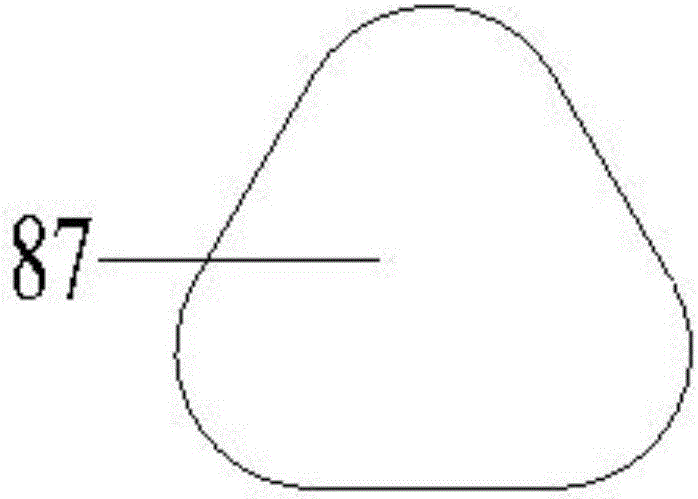

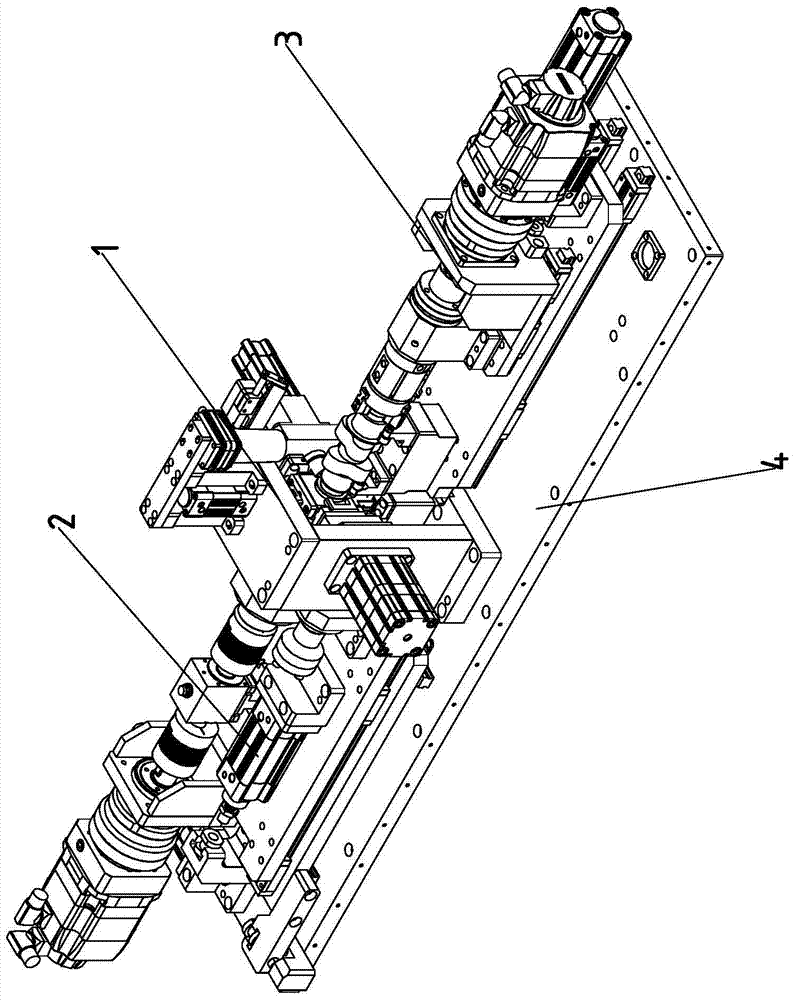

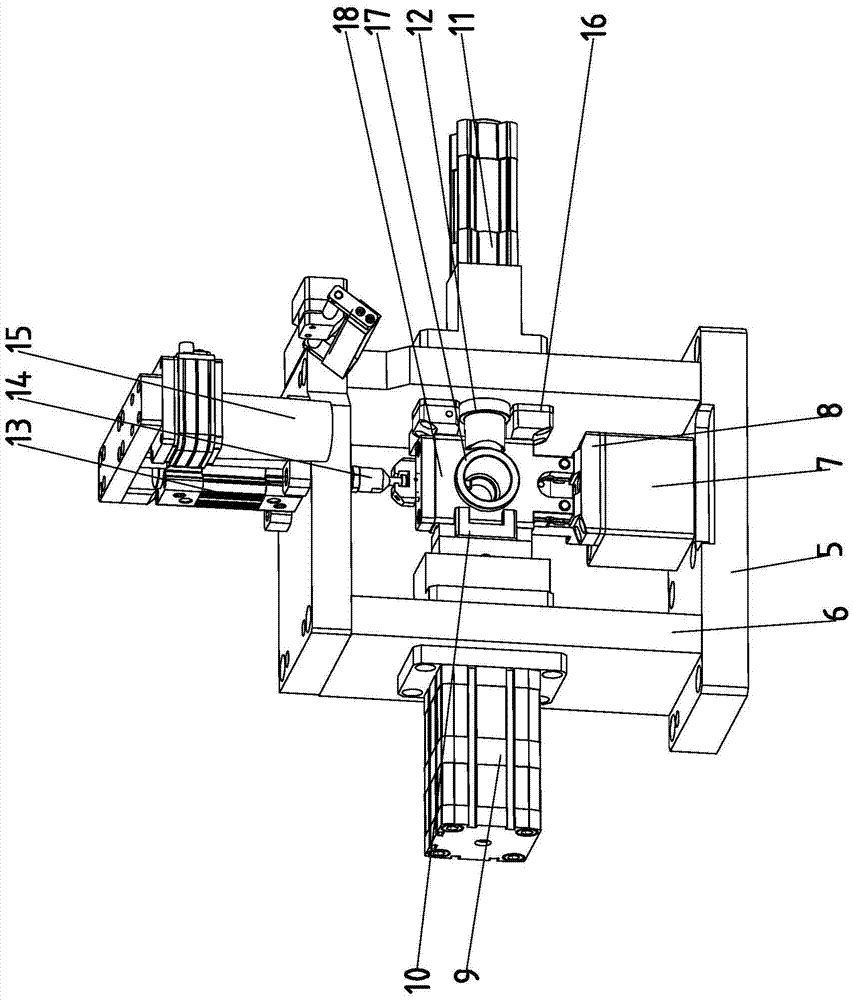

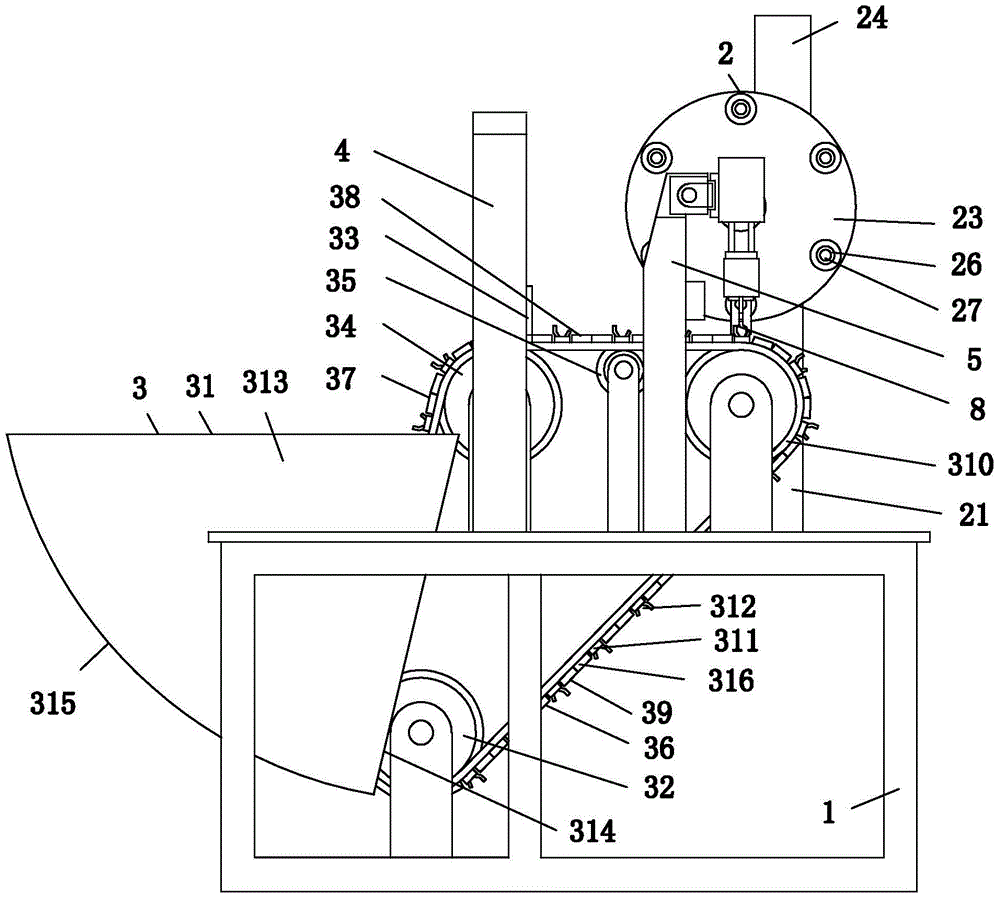

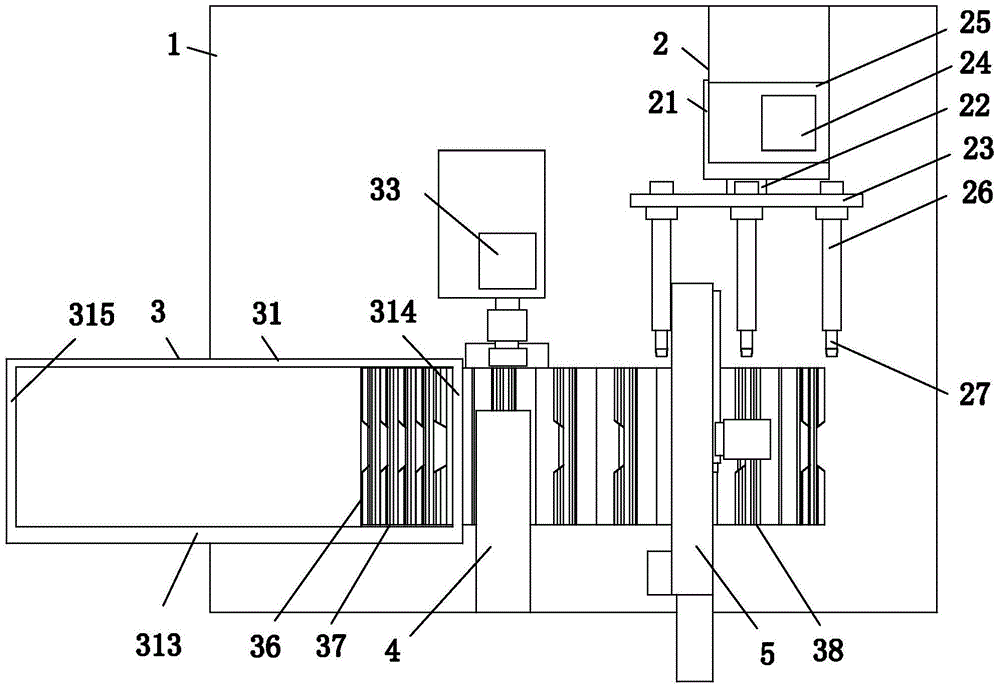

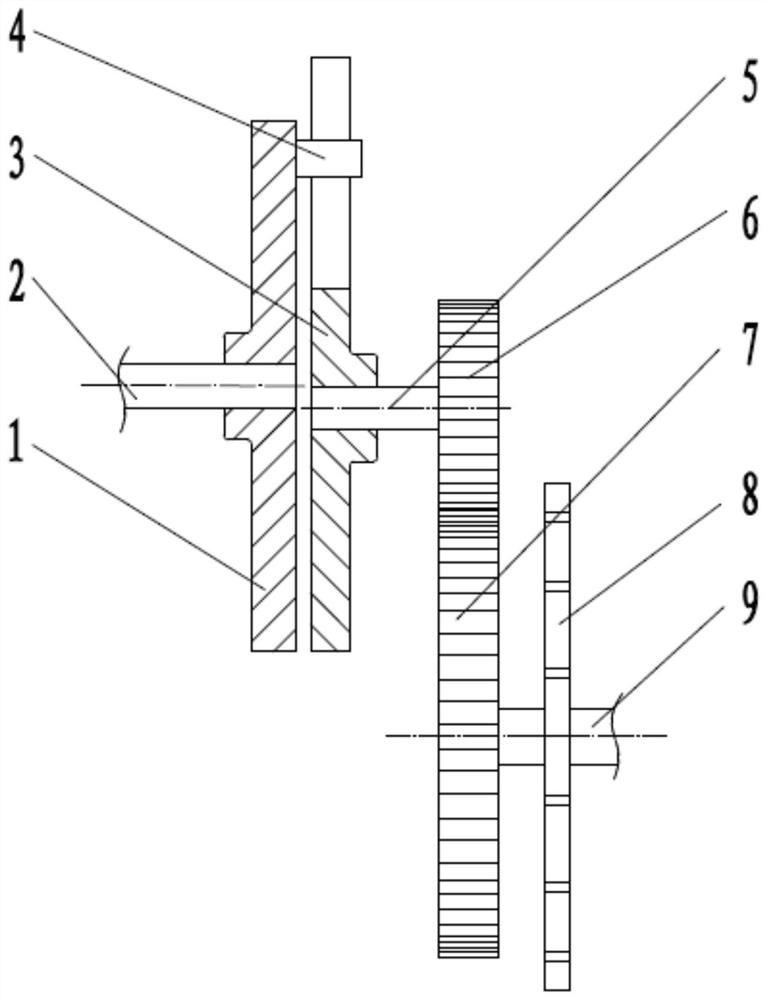

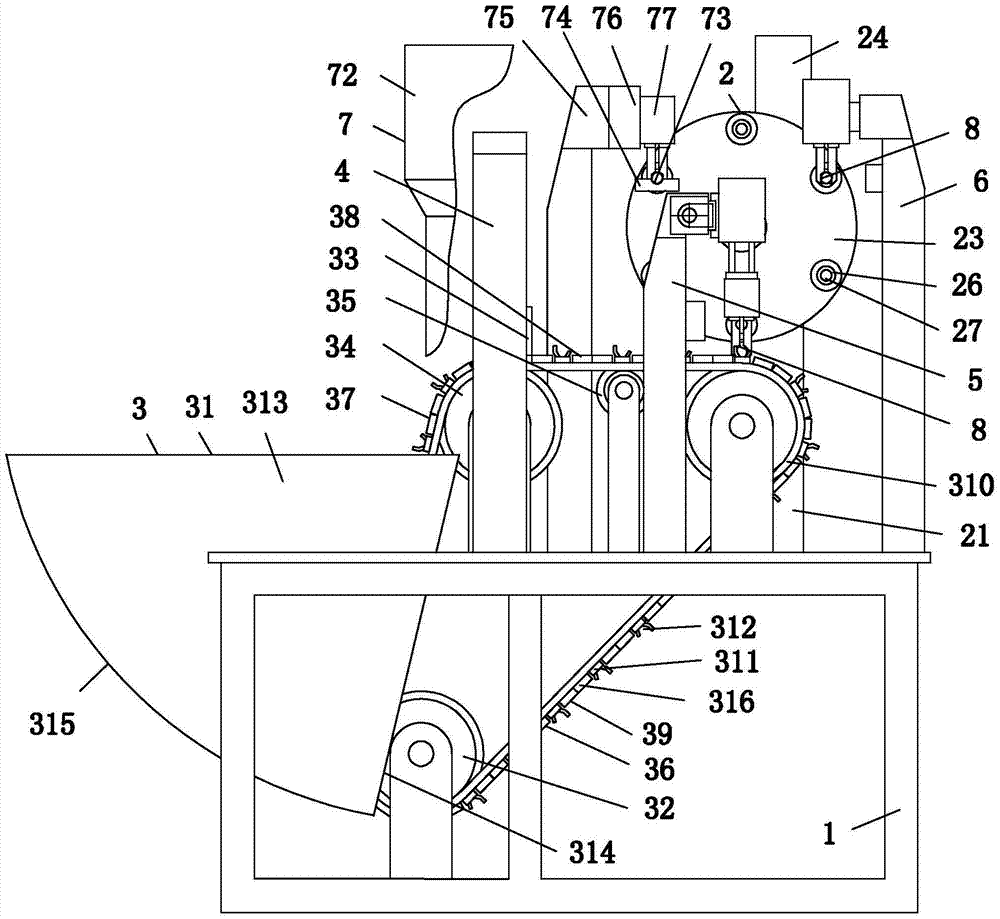

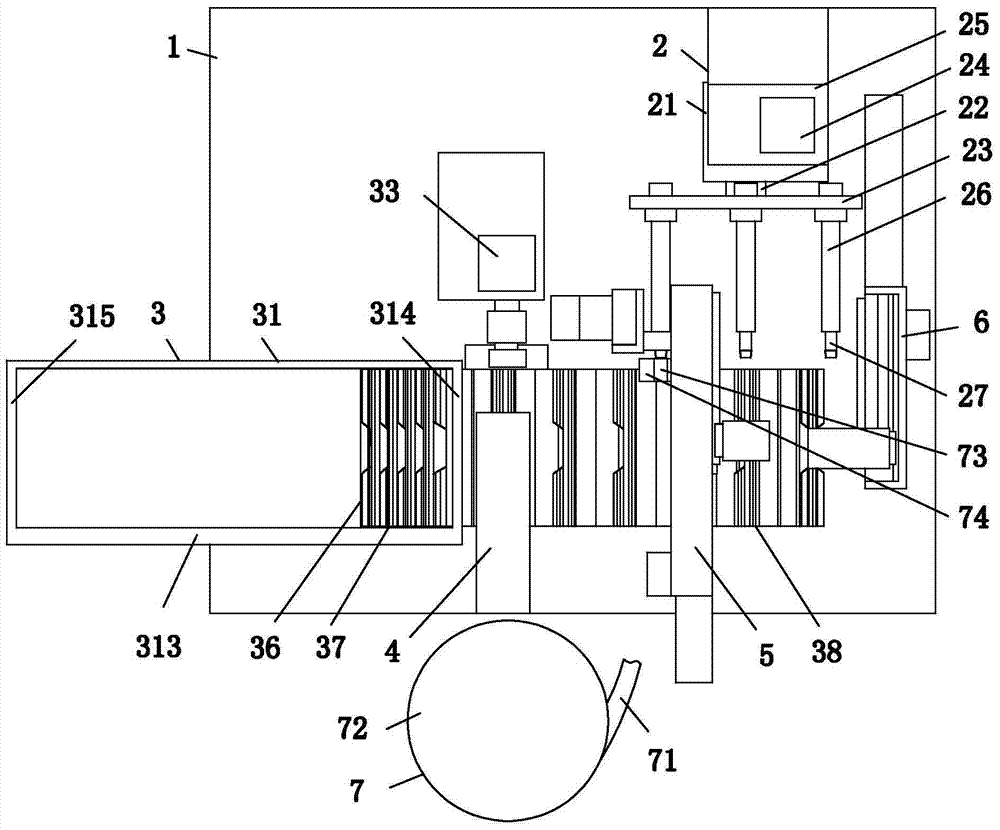

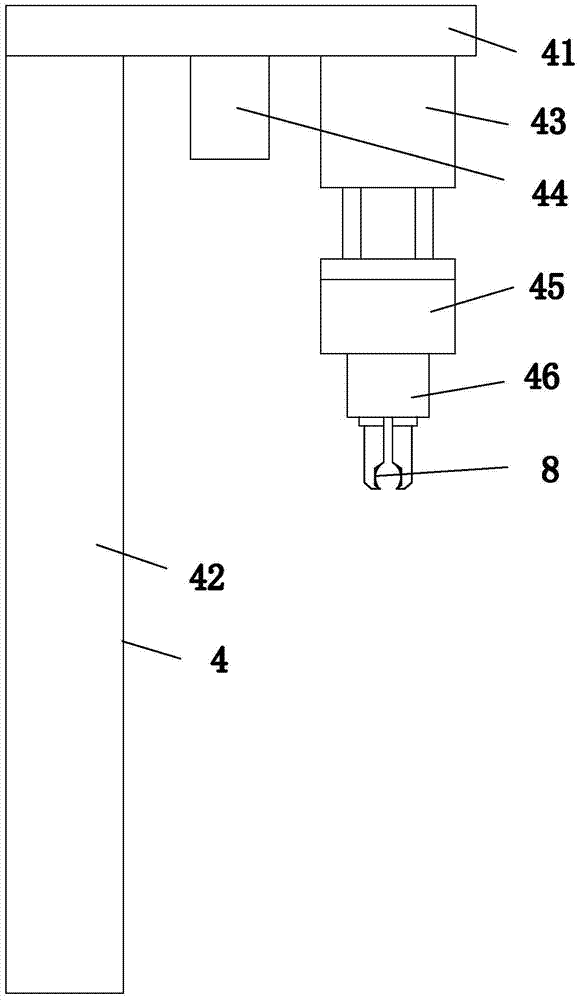

Automatic assembling and disassembling mechanism for camshaft grinding chuck

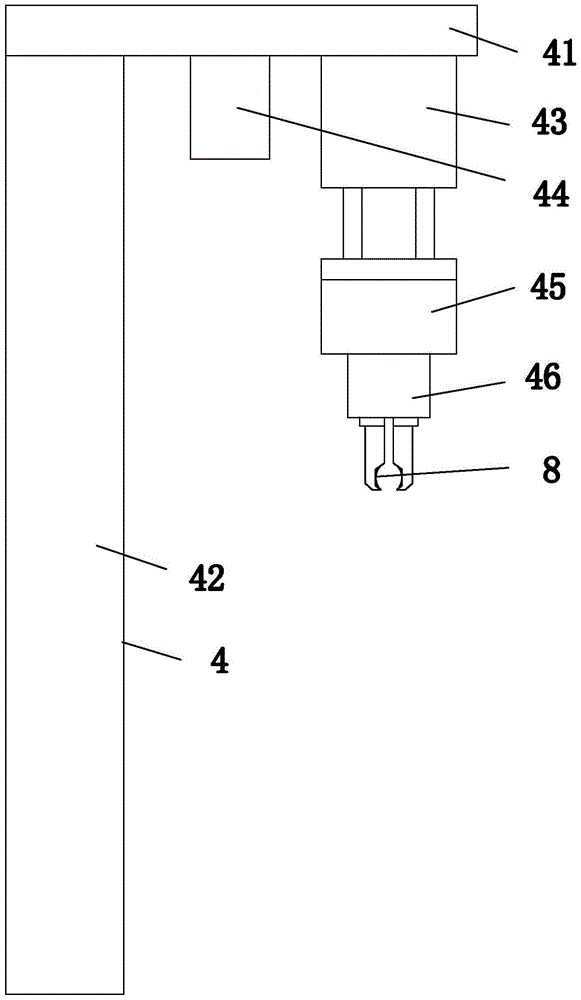

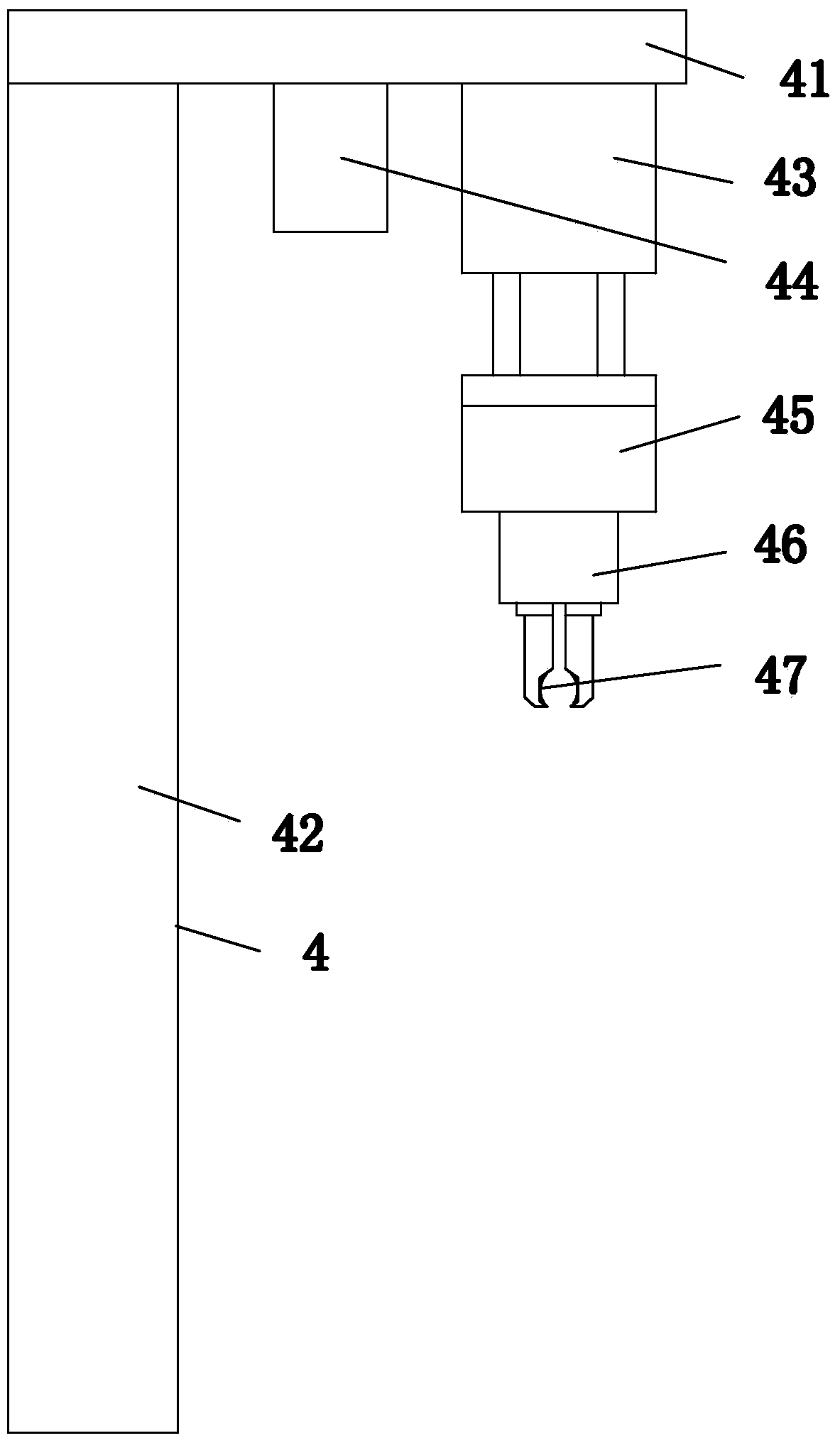

ActiveCN105397449APrecisely control the delivery positionReduce loadMetal working apparatusManufacturing technologyMechanical components

The invention relates to an automatic assembling and disassembling mechanism for a camshaft grinding chuck and particularly relates to a mechanism for automatic assembling and disassembling between the camshaft grinding chuck and a camshaft, and belongs to the technical field of mechanical part processing and manufacturing in an automatic production line. The automatic assembling and disassembling mechanism comprises a chuck fixing device, a nut tightening device and a camshaft fixing device, wherein the chuck fixing device, the nut tightening device and the camshaft fixing device are fixed on a fixing base plate from the left to the right in sequence. The automatic assembling and disassembling mechanism provided by the invention can achieve automatic assembling and disassembling between the grinding chuck and the camshaft in an automatic grinding production line of the camshaft, the work efficiency is improved, and the labor intensity is lowered.

Owner:WUXI BEST PRECISION MACHINERY

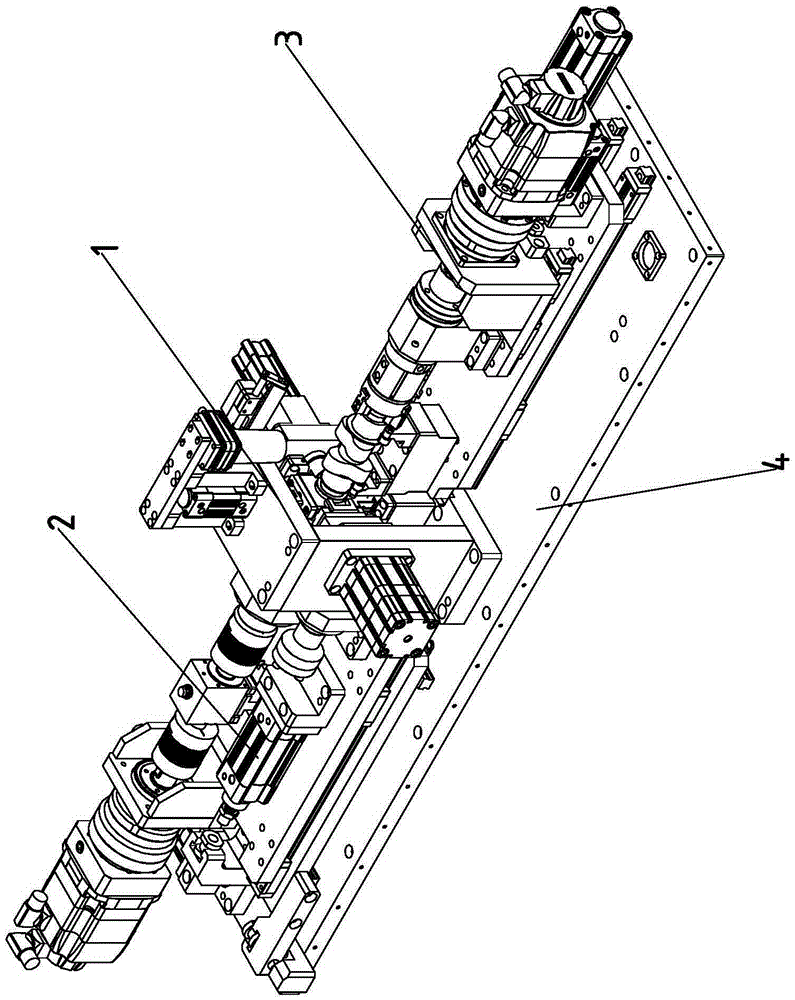

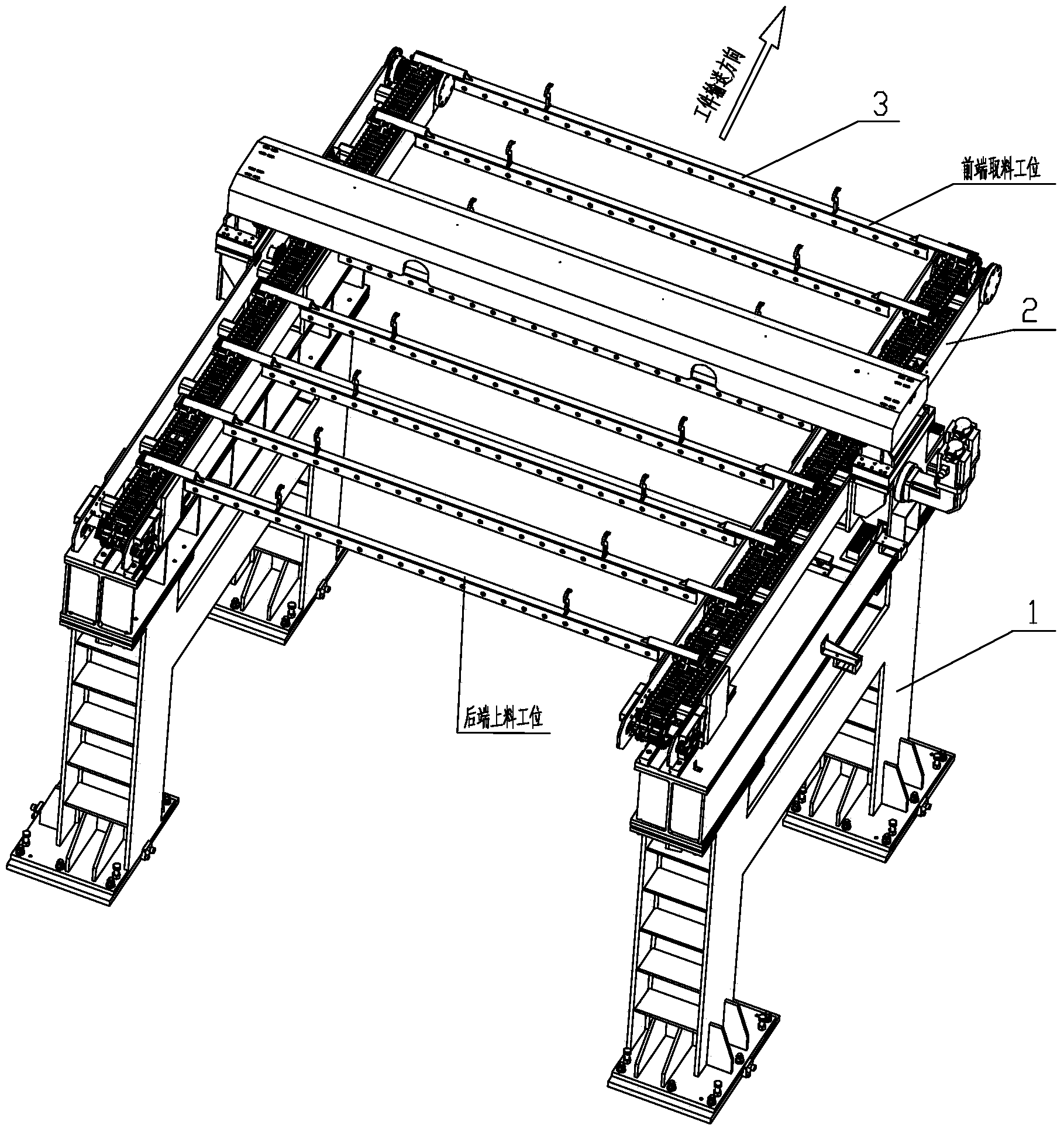

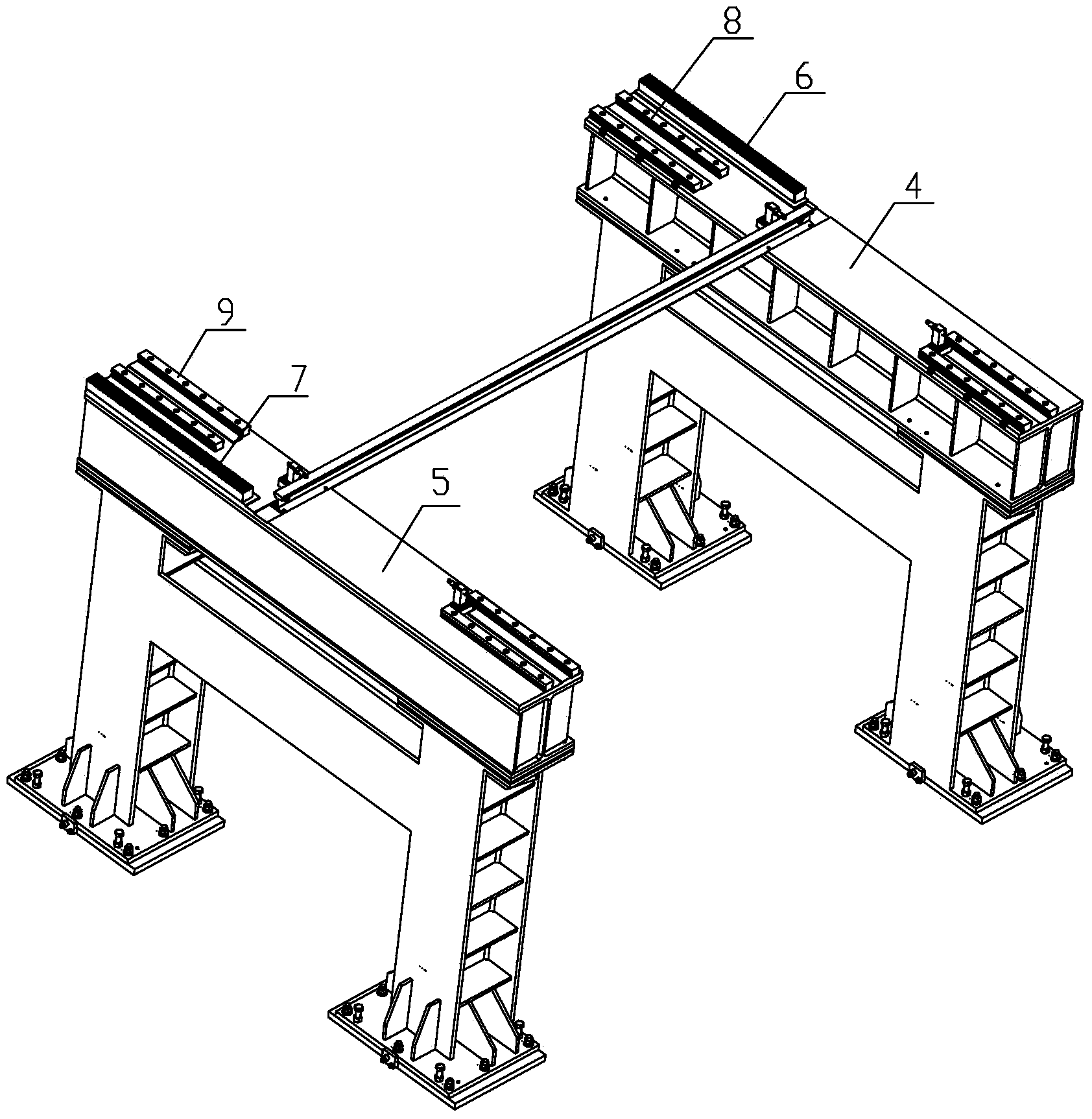

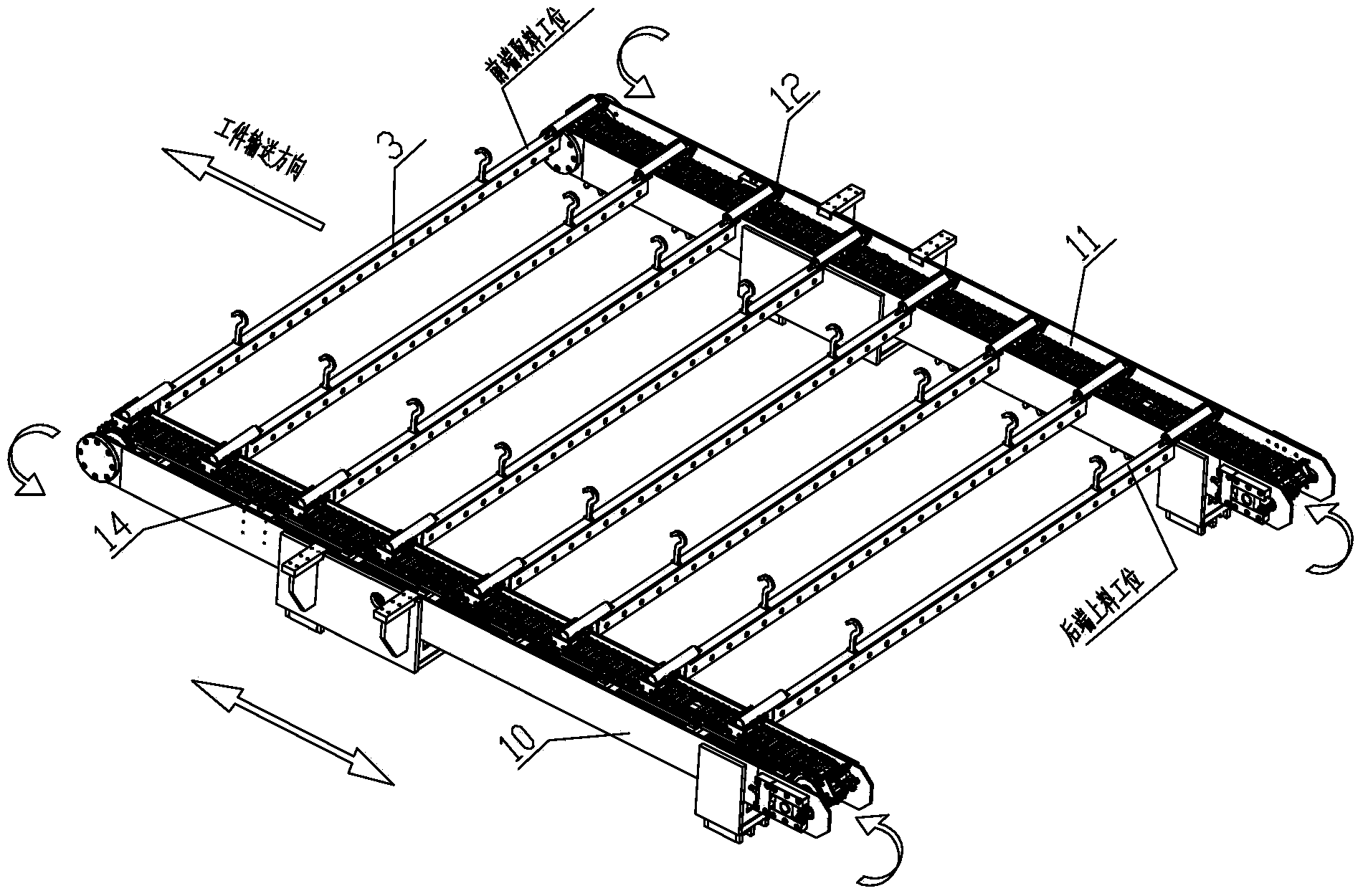

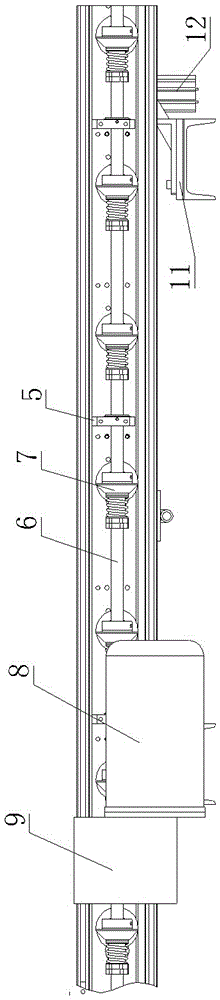

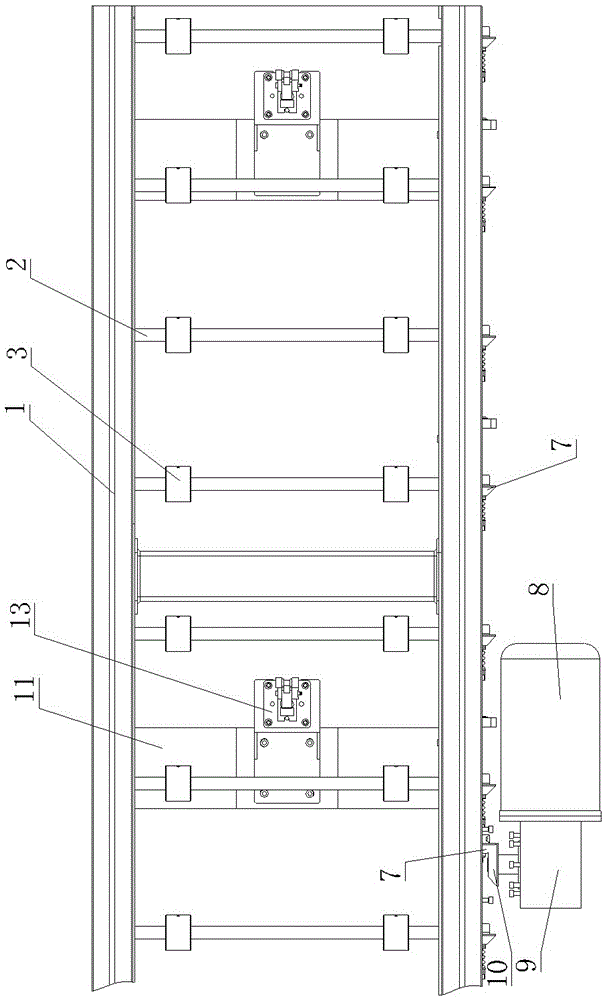

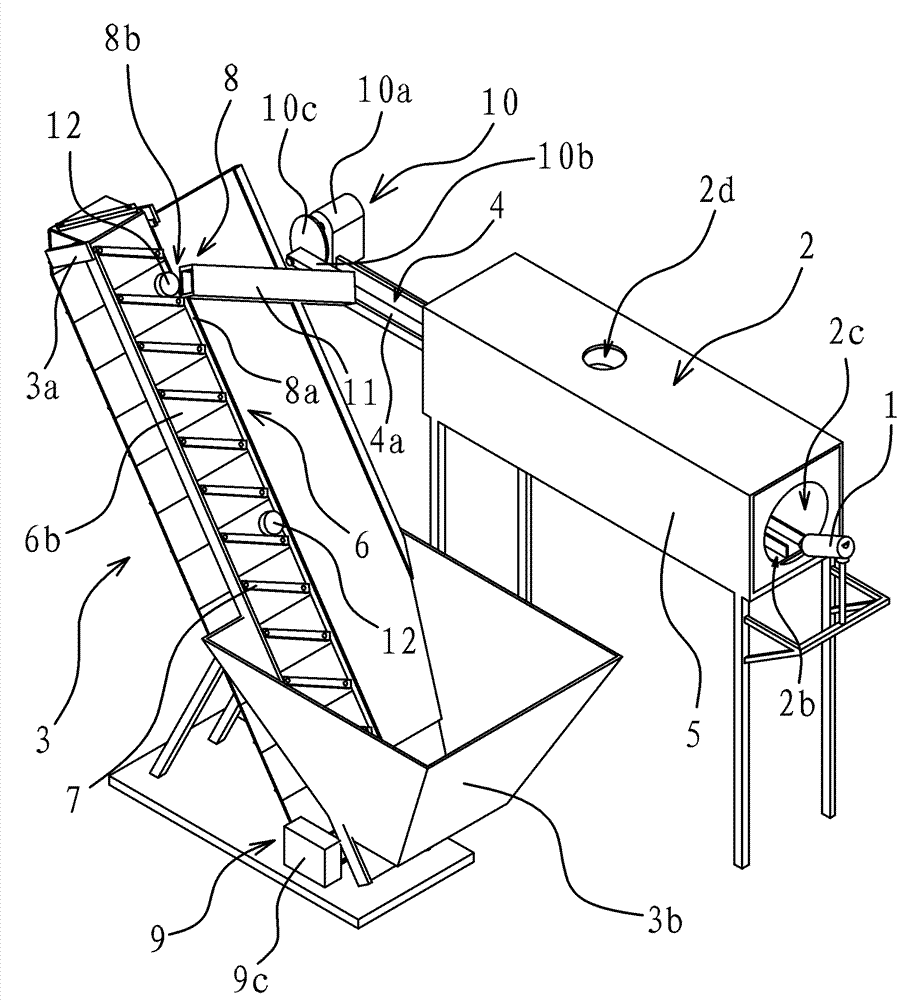

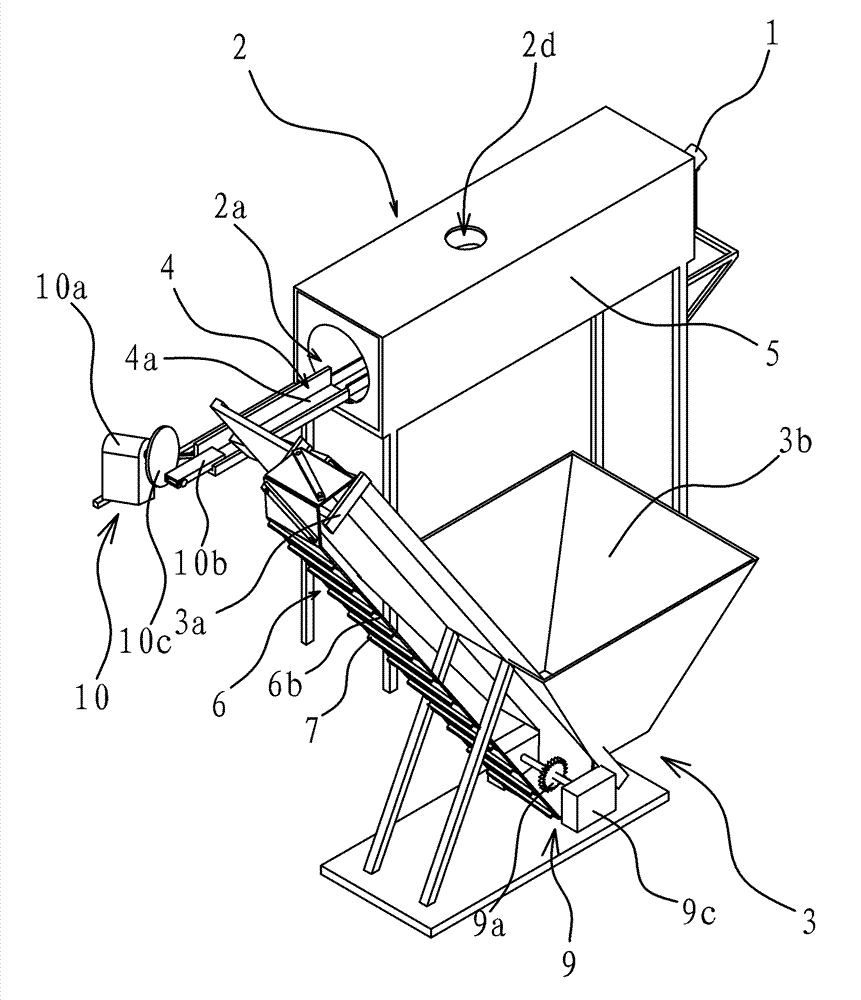

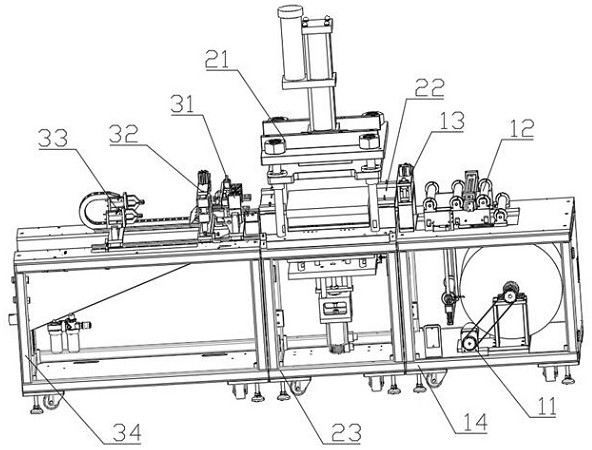

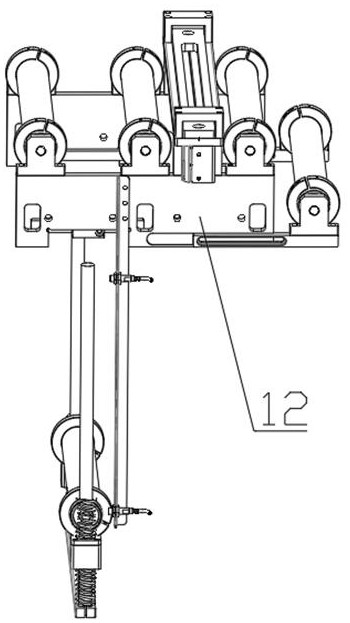

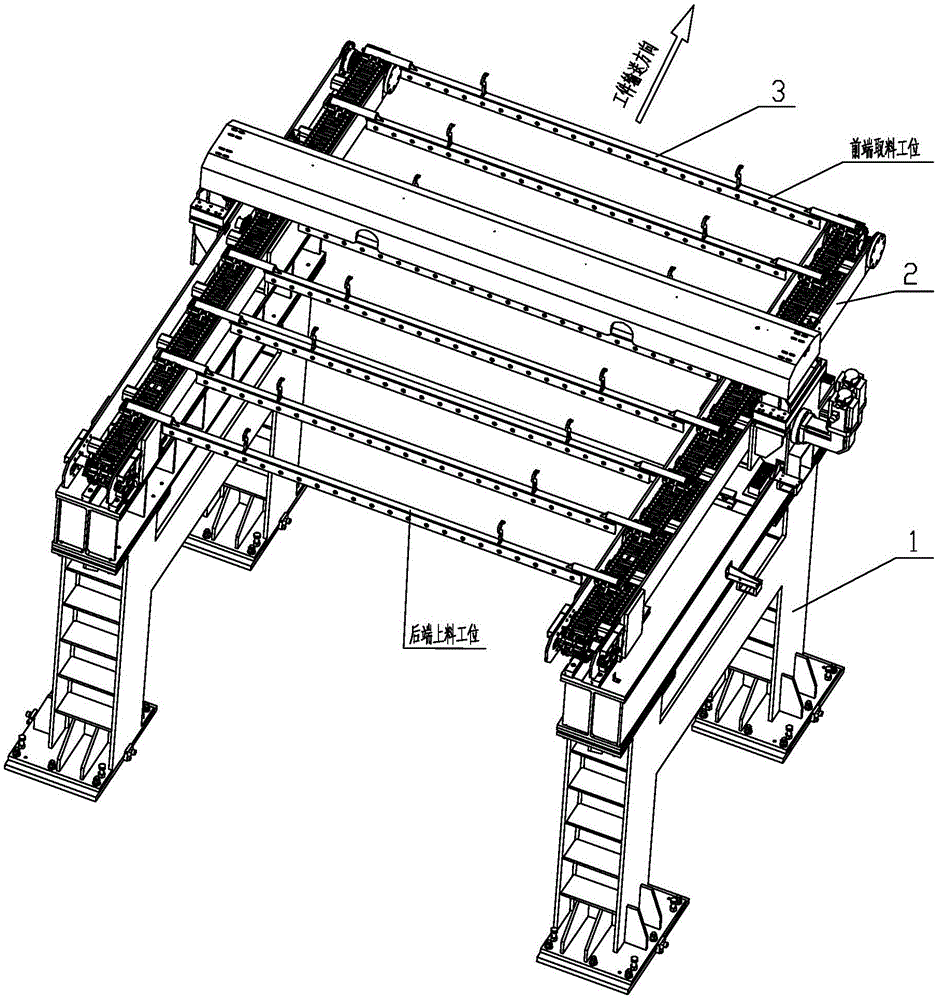

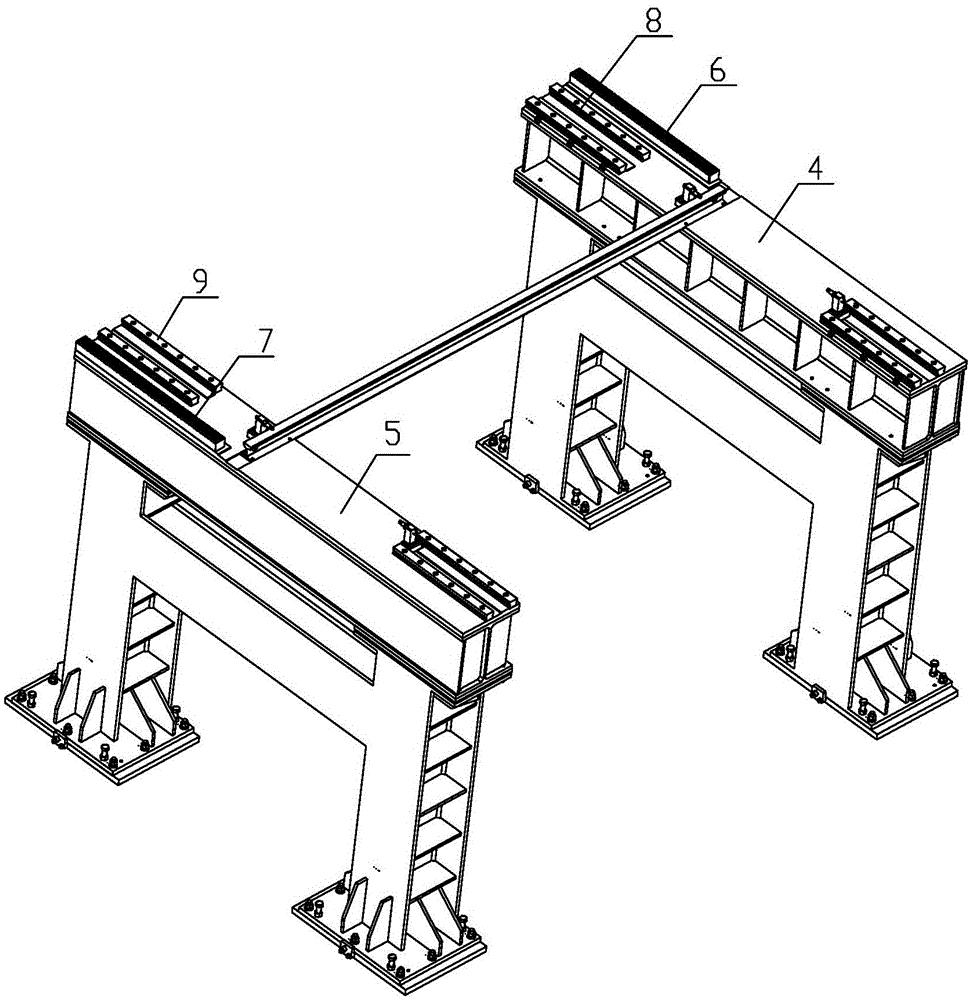

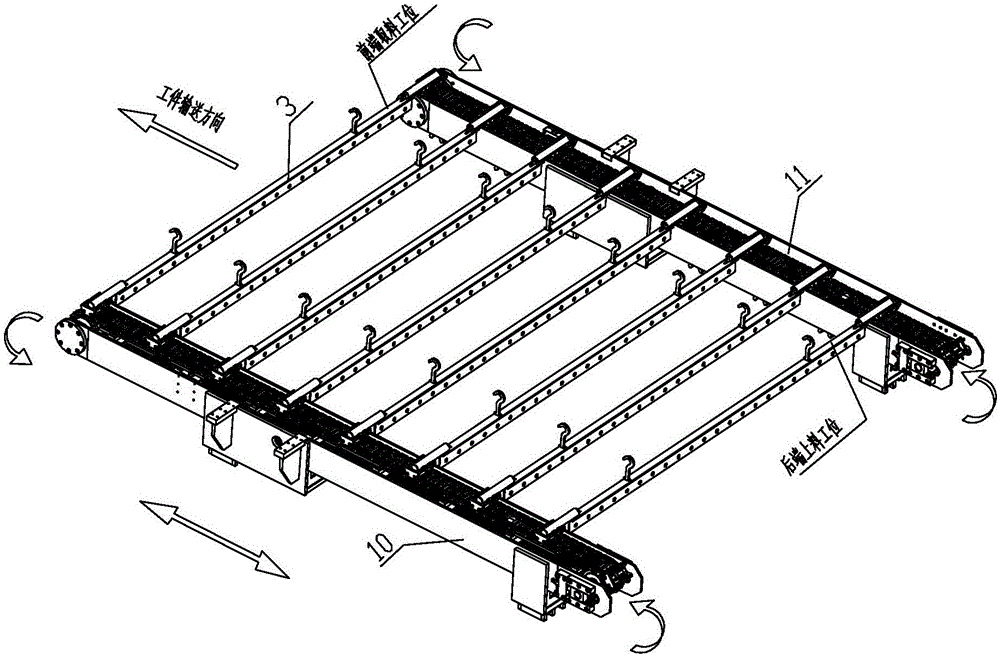

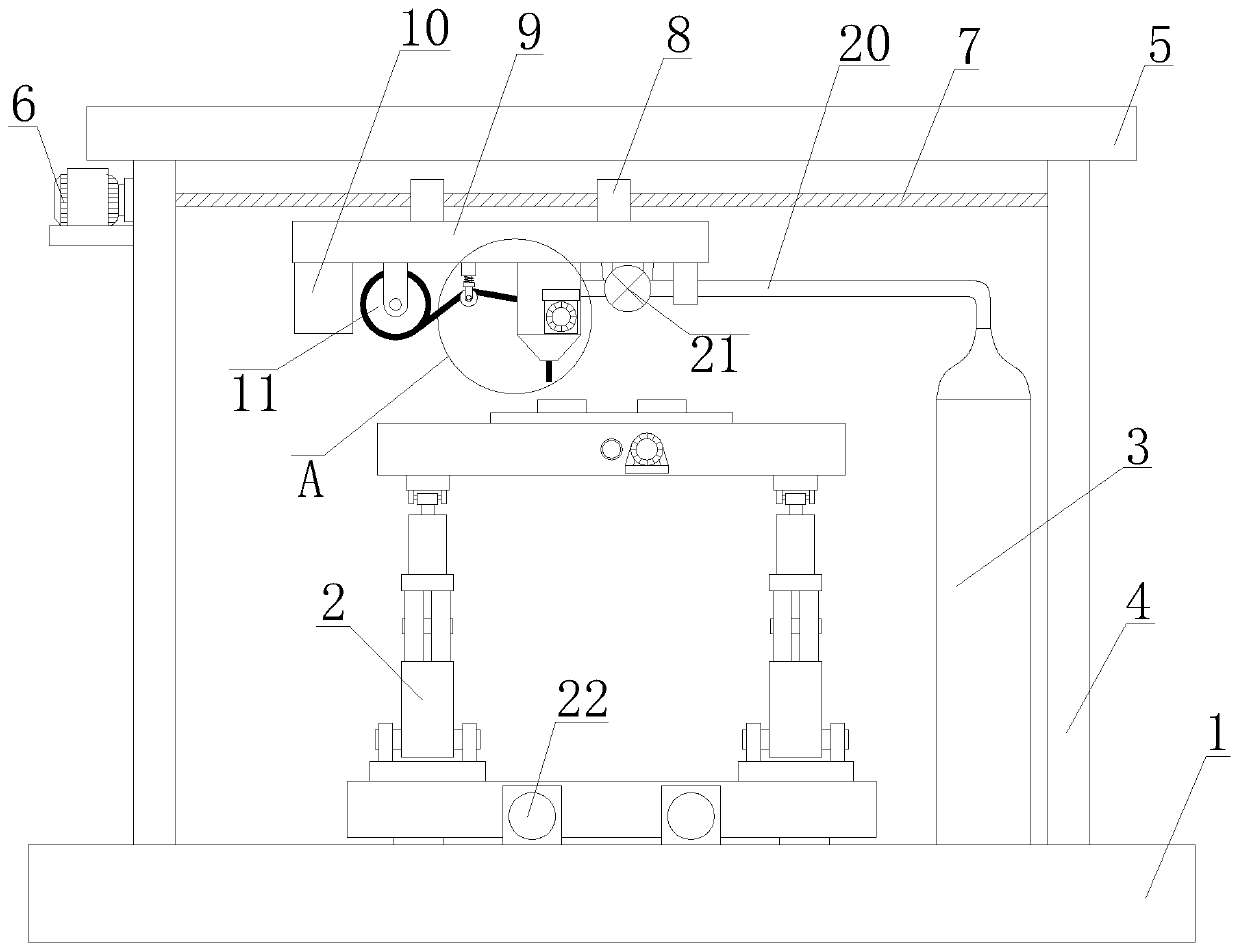

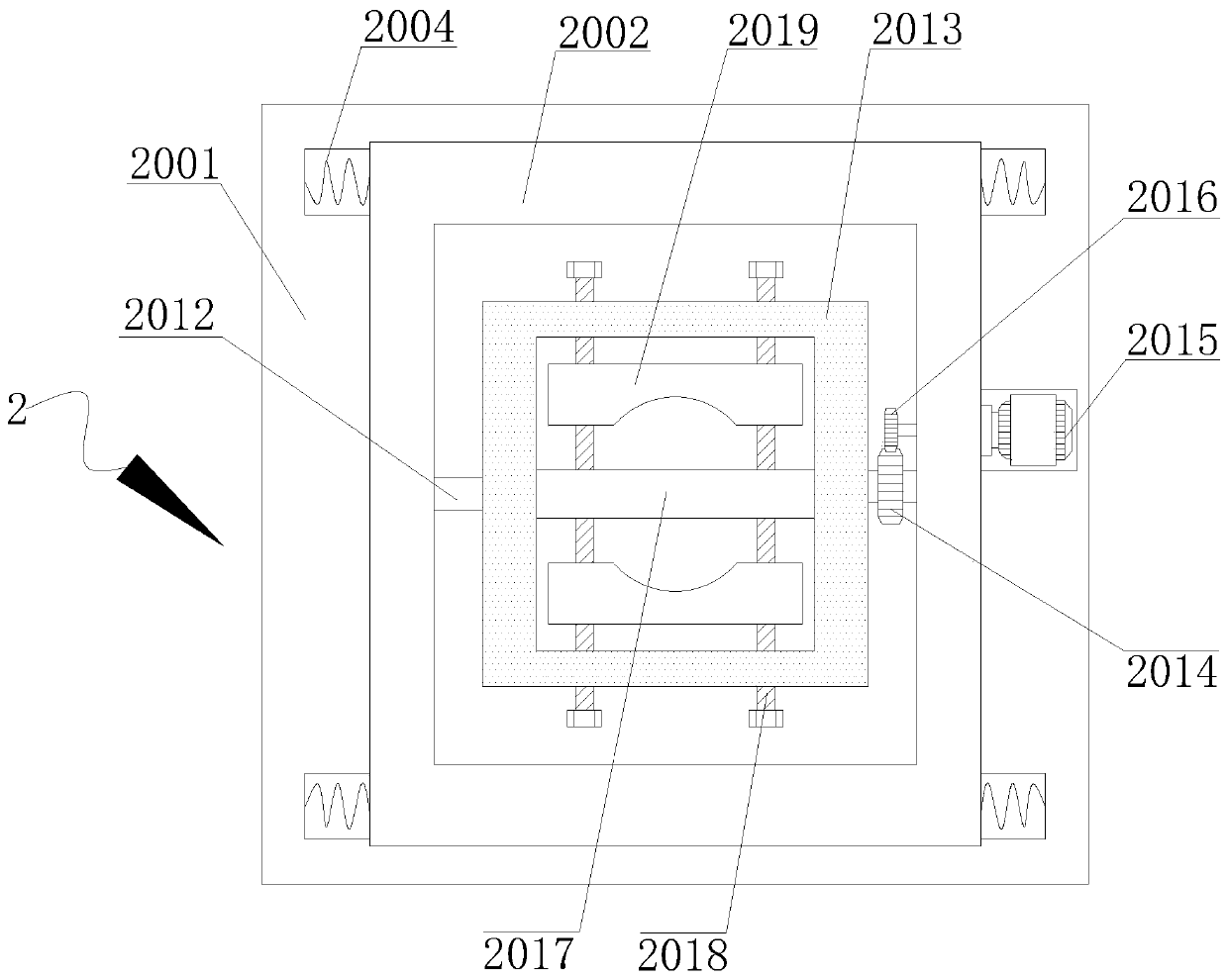

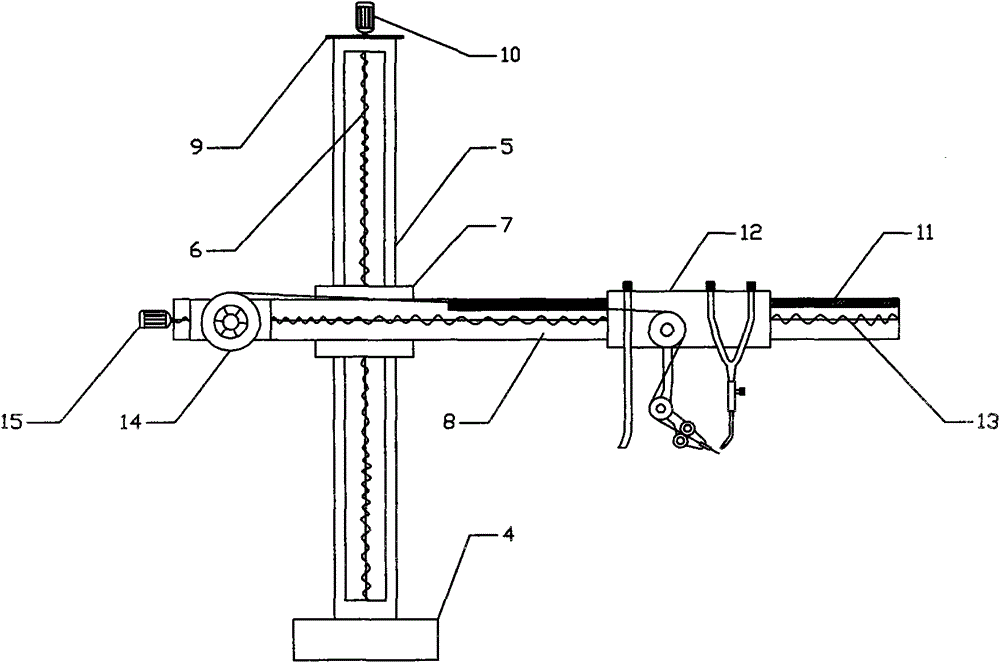

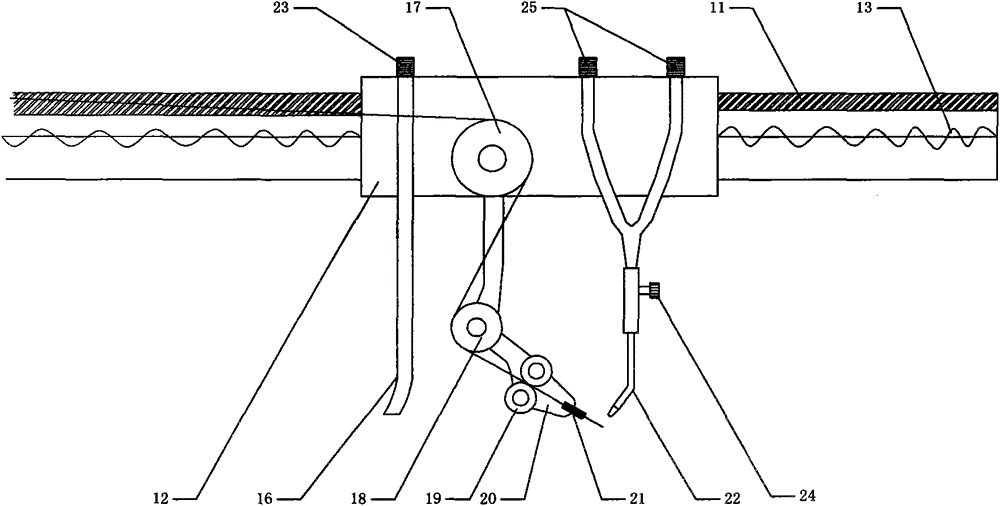

Automatic feeding device

ActiveCN103708177APrecise position controlStable conveying speedConveyorsStructural engineeringMechanical engineering

The invention relates to an automatic feeding device. The automatic feeding device comprises a bottom support part, an upper transmission part and a conveying suspender. The bottom support part comprises a left support and a right support, a left rack is installed on the left support, and a right rack is installed on the right support. Left guide strips are installed at the front end of the left support and the rear end of the left support and right guide strips are installed at the front end of the right support and the rear end of the right support. The upper transmission part comprises a left transmission assembly and a right transmission assembly. Left sliding blocks on the left transmission assembly are matched with the left guide strips, right sliding blocks on the right transmission assembly are matched with the right guide strips, left conveying boat bodies on the left transmission assembly and right conveying boat bodies on the right transmission assembly are equal in number and corresponding in position in a left-and-right mode, and the left end of the conveying suspender and the right end of the conveying suspender are supported by the left conveying boat bodies and the right conveying boat bodies respectively. The automatic feeding device is ingenious in structure, reasonable in design and capable of realizing automatic feeding between a phosphorization line and a powder spraying line, improves the production efficiency and lowers the labor intensity.

Owner:WUXI BEST PRECISION MACHINERY

Conveying device of production line

InactiveCN106743073AConstant conveying speedAvoid collisionRollersRoller-waysProduction lineGear wheel

The invention provides a conveying device of a production line. The conveying device is simple in structure, the conveying speed of a conveying rail is constant, conveying can be carried out in cooperation with the production takt of an assembly line, and the conveying stability is good. The conveying device comprises the conveying rail, conveying rollers are distributed on the conveying rail at intervals, the two ends of each conveying roller are installed on the side walls of the two ends of the conveying rail through bearings, and one end of each conveying roller extends into the corresponding side wall of the conveying rail to be provided with a first bevel gear wheel; the outer side of the conveying rail is provided with a driving shaft through a supporting frame in the length direction of the conveying rail, the supporting frame is provided with a bearing to be matched with the driving shaft to rotate, and second bevel gear wheels meshed with the corresponding first bevel gear wheels are arranged on the driving shaft in the manner of corresponding to the first bevel gear wheels; and a conveying motor is arranged on the outer side of the conveying rail and is connected with a conveying reduction box, a third bevel gear wheel is arranged on an output shaft of the conveying reduction box and is meshed on one second bevel gear wheel, and therefore the conveying motor can drive the conveying rollers to rotate.

Owner:WUXI MINGZHU STEEL BALL

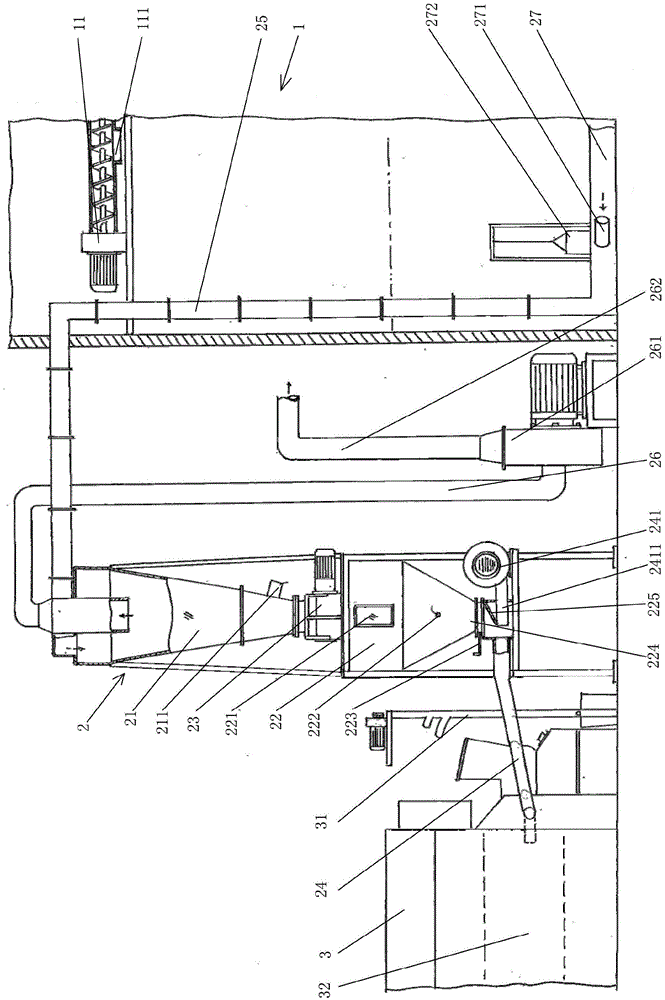

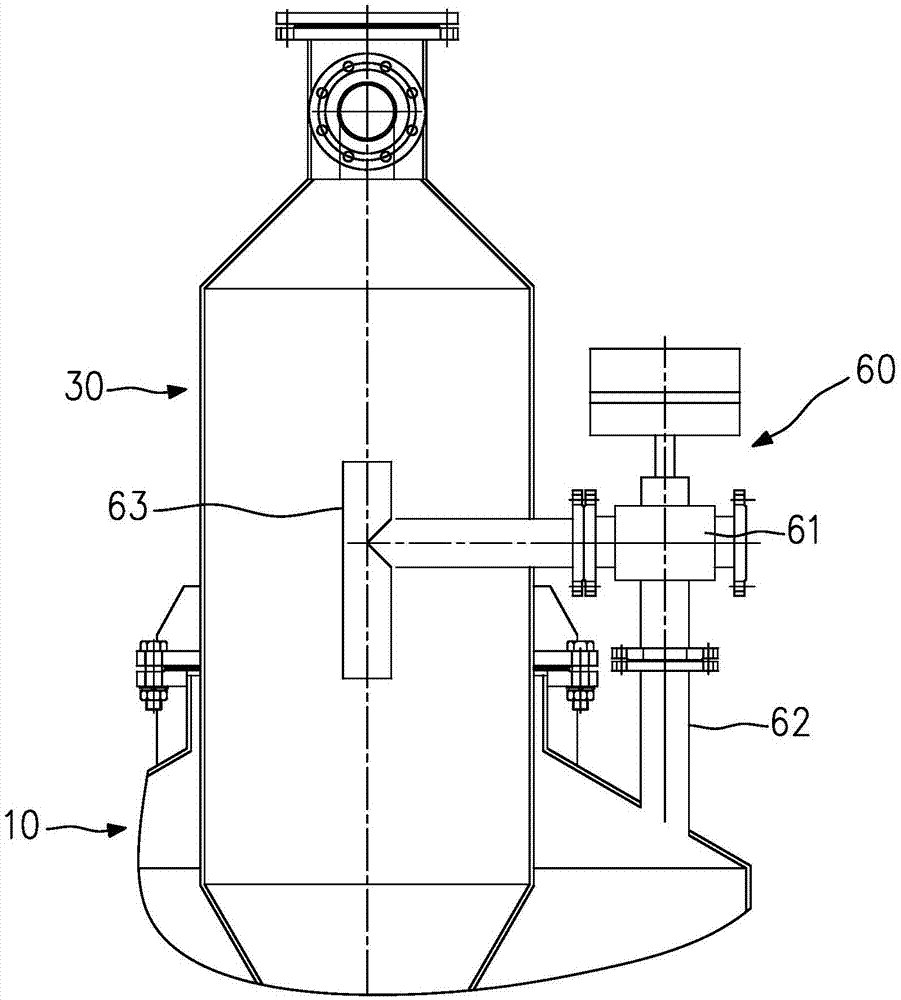

Rice husk conveying device for coal-fired boiler

InactiveCN105650664AThe conveying speed is continuously stableStable conveying speedFuel feeding arrangementsLump/pulverulent fuel feeder/distributionAssistive device/technologyHusk

The invention discloses a rice husk conveying device for a coal-fired boiler and belongs to the technical field of auxiliary equipment for boiler feeding. The rice husk conveying device comprises a conveying tower connected with a rice husk room and the coal-fired boiler through pipelines. The conveying tower comprises a negative-pressure suction hopper and a bin. The negative-pressure suction hopper communicates with the bin through an air lock. A feeding guide pipe is arranged on the side, close to the lower portion of a discharging opening, at the bottom of the bin, and a fan is mounted on the other side of the bin. An air outlet of the fan carries out intermittent air supply towards the feeding guide pipe. The upper portion of the negative-pressure suction hopper communicates with one end of a conveying pipe and one end of an air suction pipe. The other end of the conveying pipe stretches into the rice husk room and communicates with a suction main pipe. The other end of the air suction pipe communicates with an induced draft fan. An exhaust pipe is arranged on the induced draft fan. The conveying speed of rice husks is continuous and stable, and conveying cost is reduced. Feeding speed can be controlled, the stable fuel quantity can be provided for the coal-fired boiler, and the feeding guide pipe can be prevented from being blocked. Coal resources are saved, the use cost is reduced, and environment friendliness is achieved.

Owner:CHANGSHU YUSHENG AGRI PROD SPECIALIZED COOP

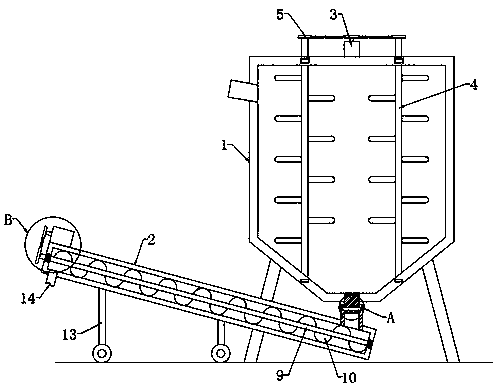

Raw material conveying device for production of modified bituminous waterproof sheet

InactiveCN109132604AImprove liquidityThe conveying speed remains stableRotary stirring mixersLarge containersBituminous waterproofingOperational requirements

The invention discloses a raw material conveying device for the production of a modified bituminous waterproof sheet. The raw material conveying device comprises a burdening box and a conveying cylinder; a feeding pipe is mounted on the bottom wall of the burdening box; a sleeve sleeves one end, close to the conveying cylinder, of the feeding pipe; the other end of the sleeve is mounted on the topwall, close to the burdening box, of the conveying cylinder; a limiting plate is mounted on the side wall, close to the bottom end, of the feeding pipe; a limiting groove matched with the limiting plate is formed in the inner wall of the sleeve; a first motor is mounted on the top wall of the burdening box; a charging pipe is mounted on one side of the burdening box; and two stirrers are rotationally connected into the burdening box. Bituminous raw materials are sufficiently mixed through the arrangement of all structures, the fluidity of the raw materials is improved, the condition that theraw materials are accumulated to block a pipeline is avoided, moreover, the stable conveying quantity and the stable conveying speed of the raw materials are kept, conveying points and conveying angles of the device can be adjusted, the actual operational requirement is met, and the flexibility of the device is improved.

Owner:江苏贝施特防水科技有限公司

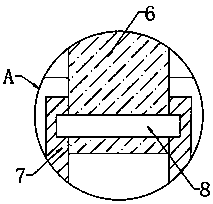

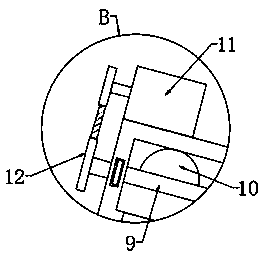

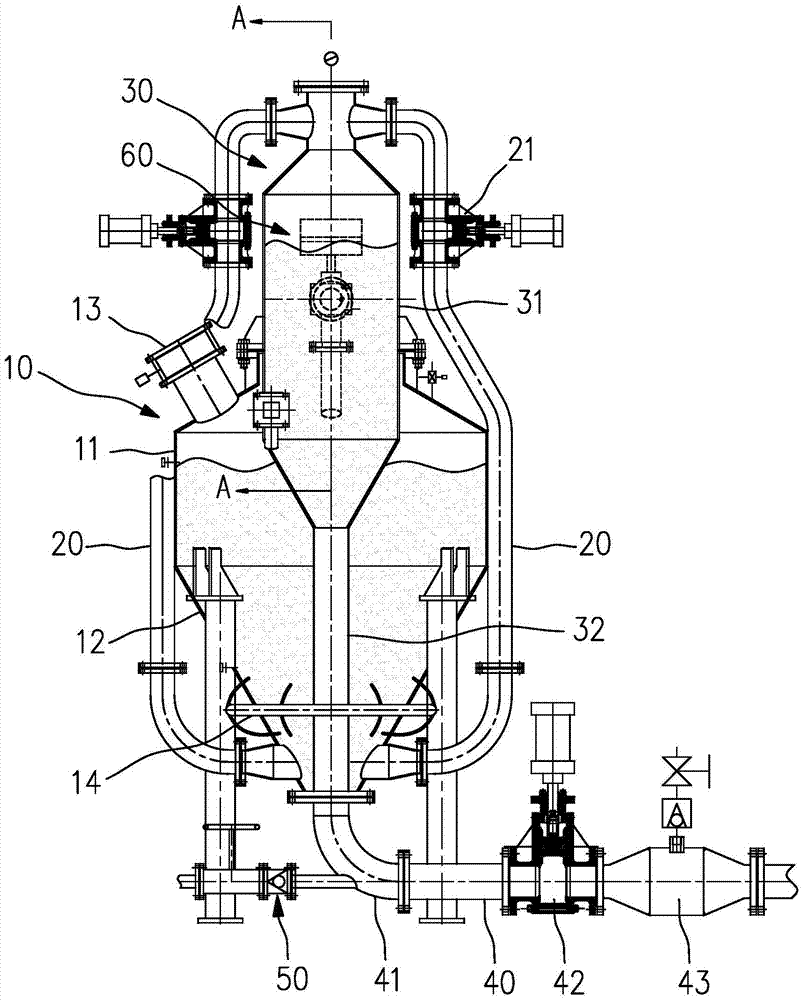

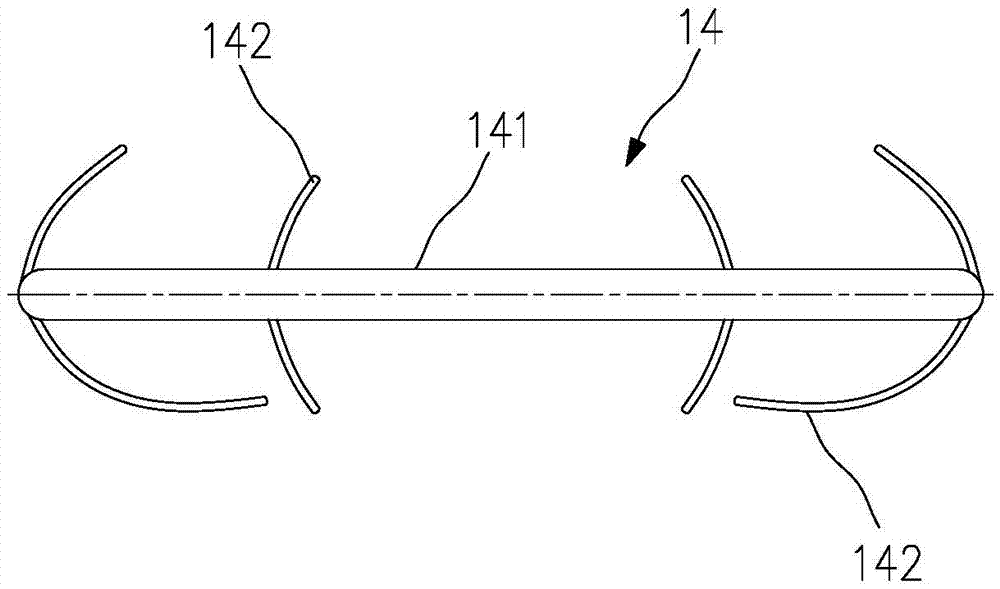

Continuous bin type pneumatic conveying pump

ActiveCN105438838AImprove delivery efficiencyPermanent and stable jobBulk conveyorsEngineeringStorage material

The invention belongs to the technical field of material conveying, and particularly relates to a continuous bin type pneumatic conveying pump capable of continuously achieving material conveying. The conveying pump comprises an intermittent-working storage material conveying bin and a continuous-working conveying bin. A feeding opening is formed in the upper side of the storage material conveying bin, the volume of the storage material conveying bin is larger than that of the conveying bin, and the conveying bin is inserted in the storage material conveying bin from top to bottom. A plurality of conveying pipes connecting the storage material conveying bin with the conveying bin and conveying powder are arranged between the storage material conveying bin and the conveying bin. The continuous bin type pneumatic conveying pump further comprises a pneumatic pressure feed device supplying air to the storage material conveying bin and the conveying bin, and a discharging device is arranged at a bottom outlet of the conveying bin. According to the continuous bin type pneumatic conveying pump, continuous material conveying can be achieved, accordingly, the conveying efficiency is improved, the conveying pipeline abrasion is reduced, the production efficiency is improved, and time cost is reduced. Meanwhile, the equipment manufacturing cost can be saved, the equipment occupied area is reduced, the functions of saving energy and reducing consumption are achieved, and the defects that the equipment manufacturing cost is high, and assembling is difficult are overcome.

Owner:ANHUI NAILIDE PNEUMATIC CONVEYING CO LTD

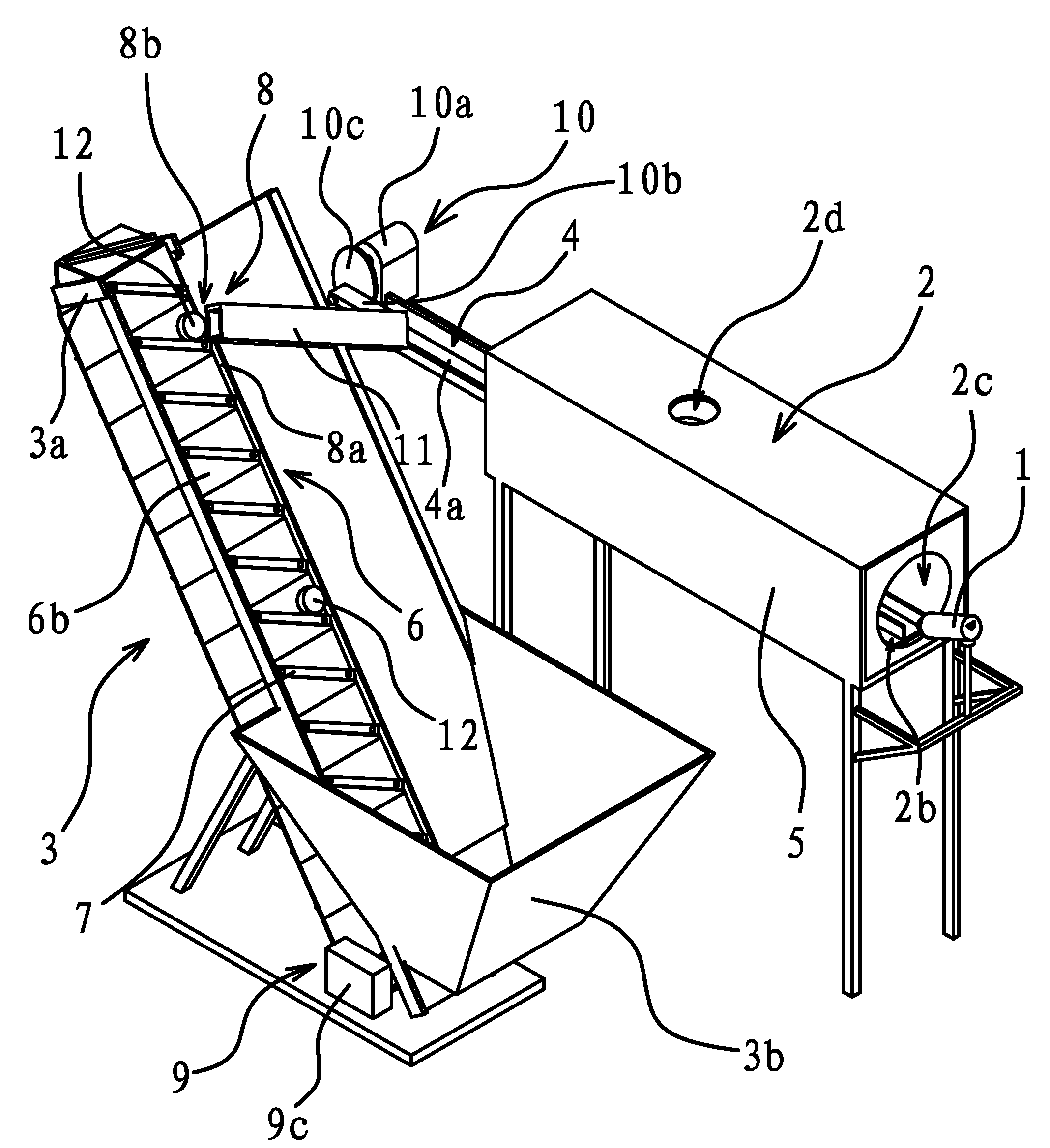

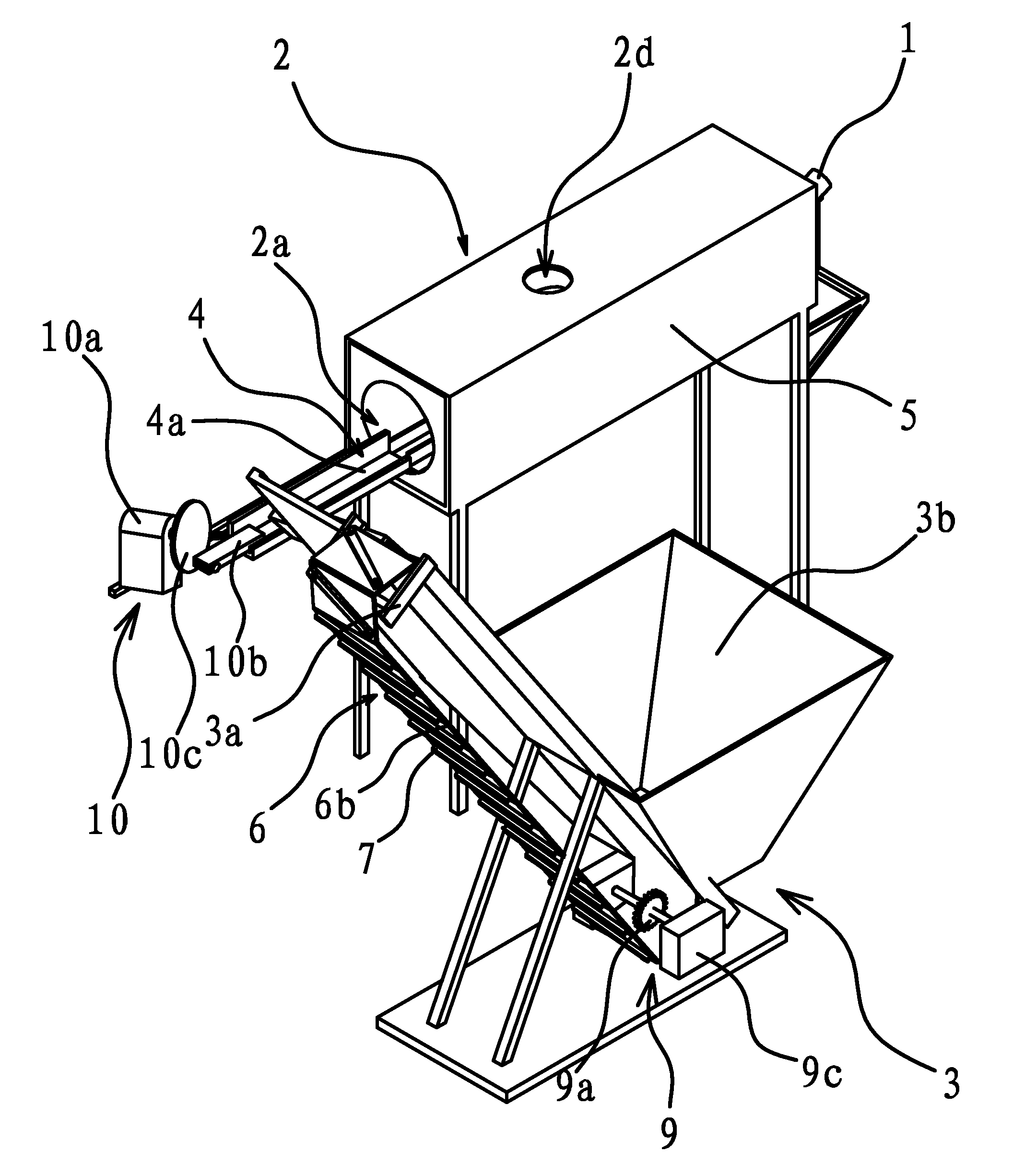

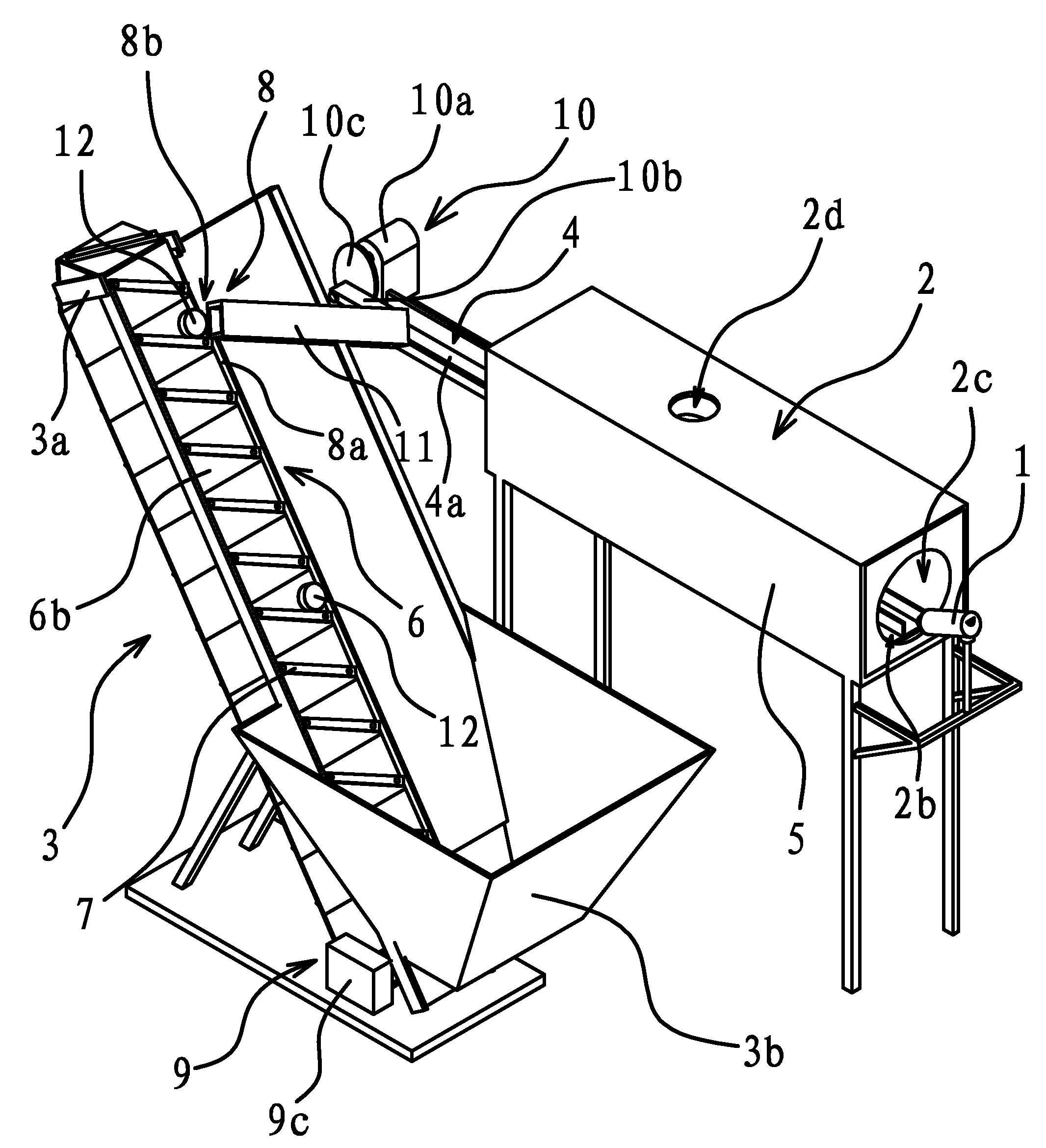

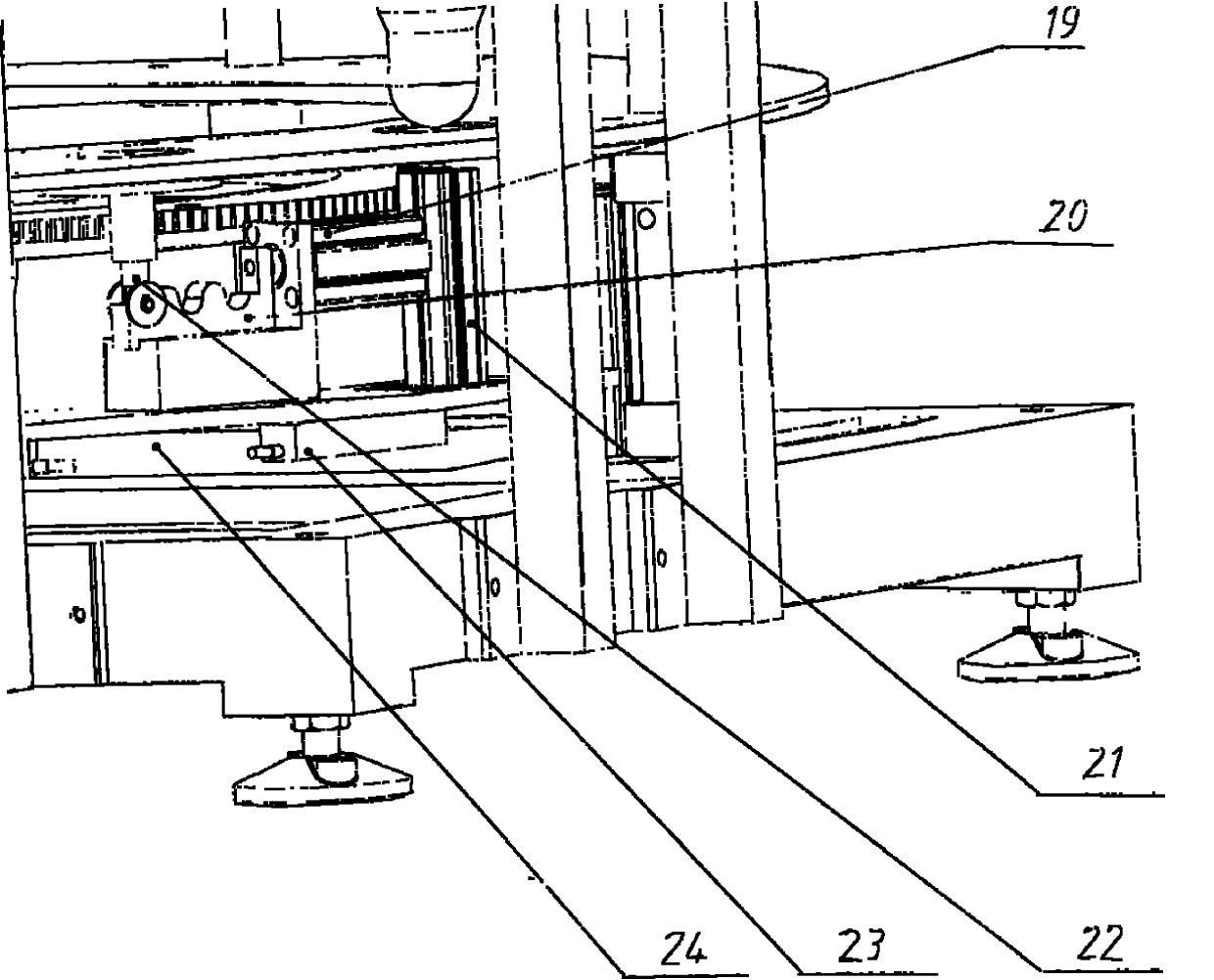

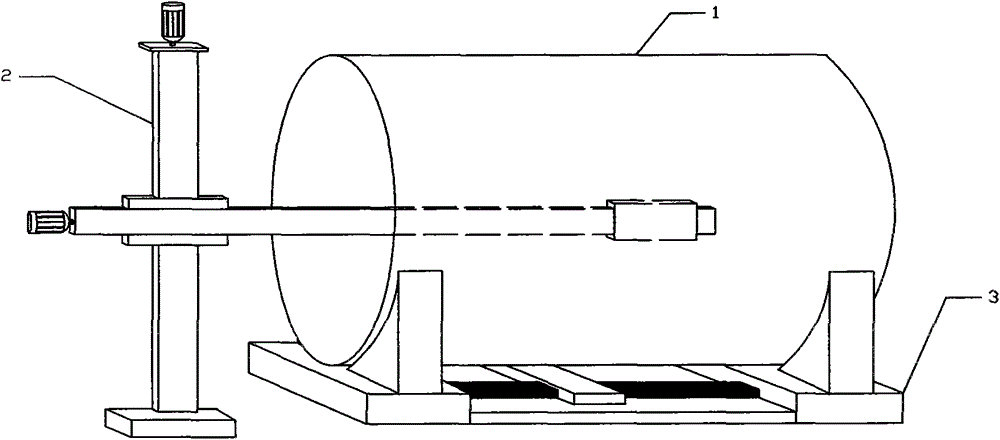

Heating furnace before forging

The invention provides a heating furnace before forging, which belongs to the technical field of machinery and solves the problems of severe production environment, low work efficiency and large energy waste when traditional heating equipment before forging works. The heating furnace before forging comprises a heating device and a furnace body, wherein the furnace body is provided with a feed opening and a discharge opening, an automatic feeding mechanism is arranged at the feed opening of the furnace body, a conveying device capable of conveying a blank from the feed opening to the dischargeopening is arranged in the furnace body, the heating device is arranged on the furnace body and used for heating the blank conveyed in the furnace body, and a heat insulating device is also arranged on the side wall of the furnace body. When in working, the heating furnace before forging has the advantages of good working environment, simple operation, high work efficiency, less energy waste and high quality of processed products.

Owner:杨少华

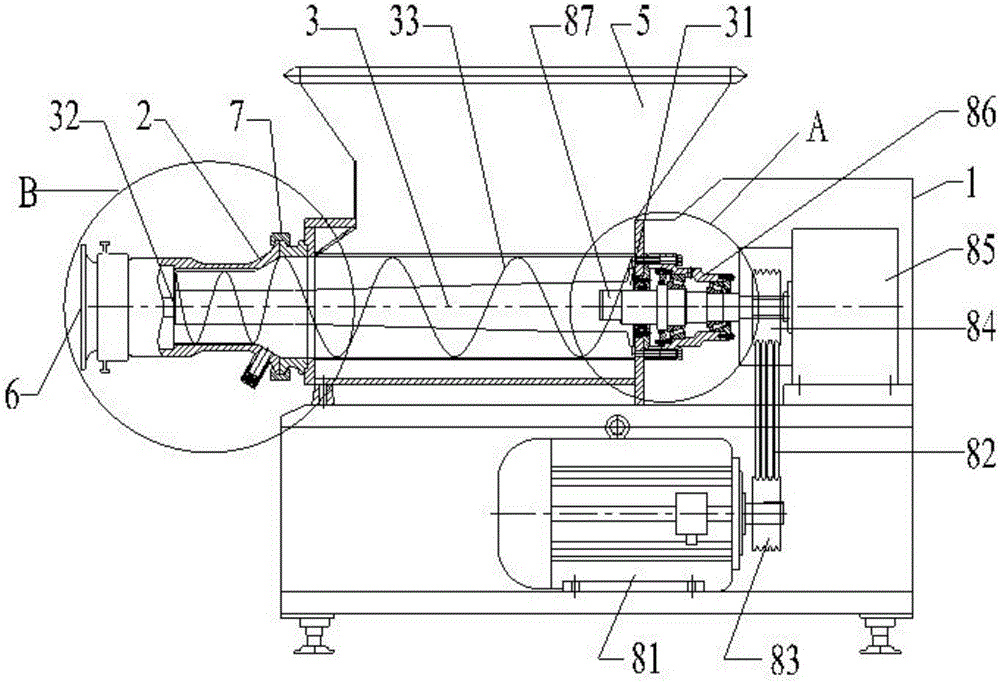

Meat grinder

The invention discloses a meat grinder, and belongs to the technical field of meat grinding devices. The meat grinder comprises a shell, a driving mechanism, a meat grinding cavity, a spiral shaft, a meat grinding part, a feed port and a discharge port; the feed port is formed in the upper part of the shell; the discharge port is formed in one side of the shell; the meat grinding cavity is formed between the feed port and the discharge port in the shell; the spiral shaft is arranged in the meat grinding cavity, and includes a first end and a second end; an output end of the driving mechanism is connected with the first end of the spiral shaft; the meat grinding part is arranged in the discharge port; the second end of the spiral shaft is connected with the meat grinding part; and the diameter of the first end of the spiral shaft is larger than the diameter of the second end of the spiral shaft. The first end of the spiral shaft is high in swallowing capacity during feeding; and the meat grinding capacity of the second end is lower than the feeding capacity of the first end, so that the meat grinder can always work with materials without generating idle or shortening the idle time, the conveying speed is stable, the work is stable, and the machining efficiency is high.

Owner:SUNBY MACHINERY CO LTD

A continuous chamber pneumatic conveying pump

ActiveCN104670909BReduce wearReduce automatic deliveryBulk conveyorsEngineeringMechanical engineering

The invention relates to a continuous chamber-type pneumatic conveying pump comprising a continuous pump unit and a discharging device connected to the bottom of the continuous pump unit. The continuous pump unit comprises a tubular conveying chamber and a conveying chamber on the outer side of the tubular conveying chamber; the upper end of the tubular conveying chamber is connected to a material chamber; the bottom of the discharging device is provided with an inner tube and an outer tube, the inner tube is connected to the opening of the bottom of the tubular conveying chamber, the outer tube is connected to the opening of the bottom of the conveying chamber, an outer circulating pipe is connected to the inner tube and the upper portion of the conveying chamber to communicate the tubular conveying chamber and the conveying chamber, and the outer tube is connected to an air supplement pipe and a discharge pipe provided with a fluidization controller. The pump is capable of conveying material continuously, the conveying and mixing ratio is increased, the conveying efficiency is improved, the wearing of the conveying pipe is reduced, the producing efficiency is improved, and the producing cost is saved.

Owner:ANHUI NAILIDE PNEUMATIC CONVEYING CO LTD

Automatic die punching machine for lithium battery shell

InactiveCN113263092ASolve the problem of difficult transportation and positioningGuaranteed smoothShaping toolsMetal-working feeding devicesPunchingElectric machinery

The invention discloses an automatic die punching machine for a lithium battery shell. The machine comprises a feeding mechanism, a die punching mechanism and a slitting and discharging mechanism, wherein the die punching mechanism is located between the feeding mechanism and the slitting and discharging mechanism; the feeding mechanism is provided with a feeding motor assembly, a tension assembly, a pressing air cylinder assembly and a feeding rack; the feeding motor assembly, the tension assembly and the pressing air cylinder assembly are installed on the feeding rack; the die punching mechanism is provided with a die punching machine, a guide plate assembly and a die punching machine frame; the die punching machine and the guide plate assembly are installed on the die punching machine frame; the slitting and discharging mechanism is provided with a longitudinal slitting assembly, a transverse slitting assembly, a material pulling assembly and a discharging rack; and the discharging rack is provided with a guide rail and a discharging groove, the longitudinal slitting assembly, the transverse slitting assembly and the material pulling assembly are installed on the guide rail. The automatic die punching machine can achieve automatic punching and cutting operation, is easy to operate and high in operation efficiency, and has good market application value.

Owner:深圳联钜自控科技有限公司

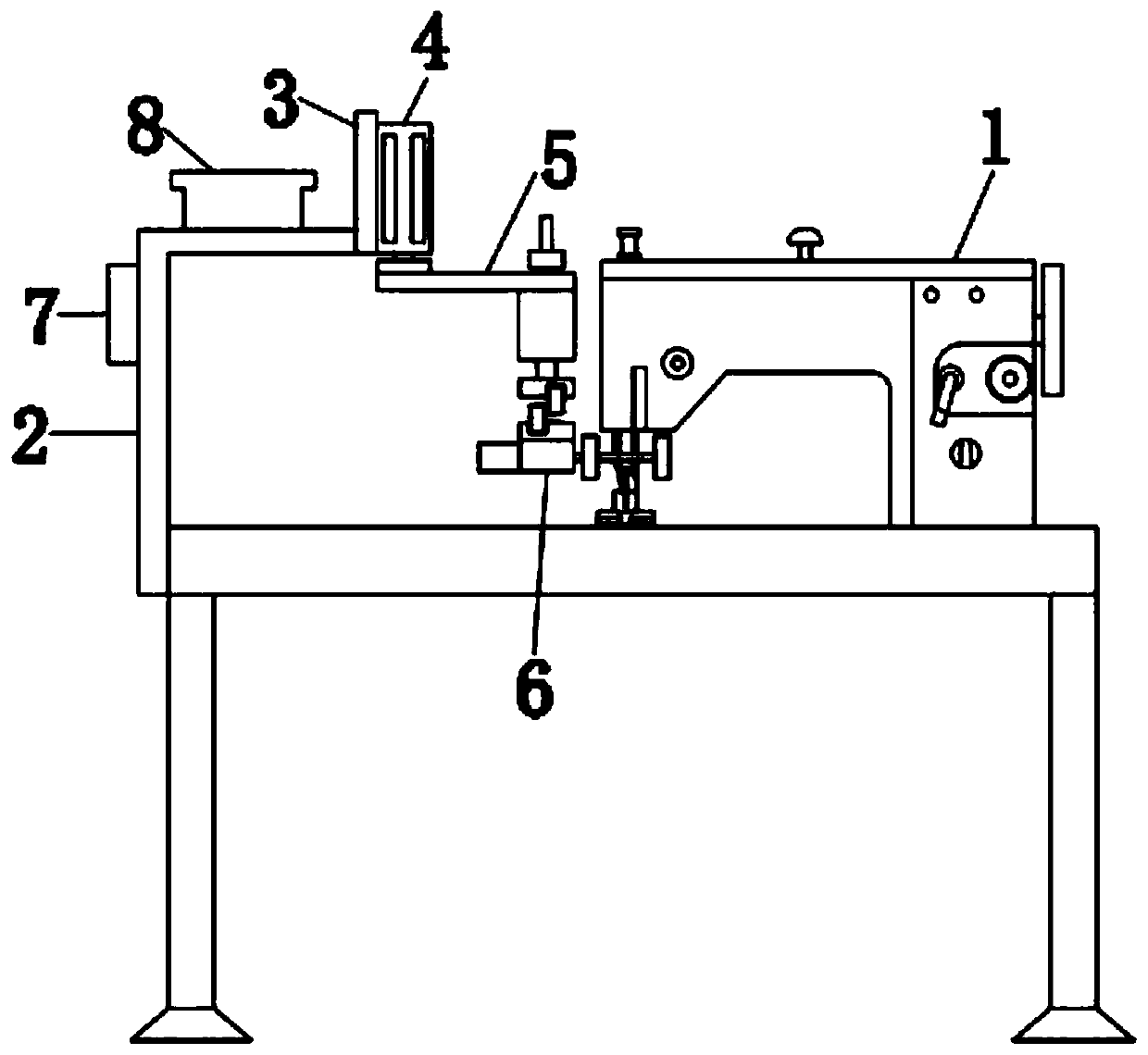

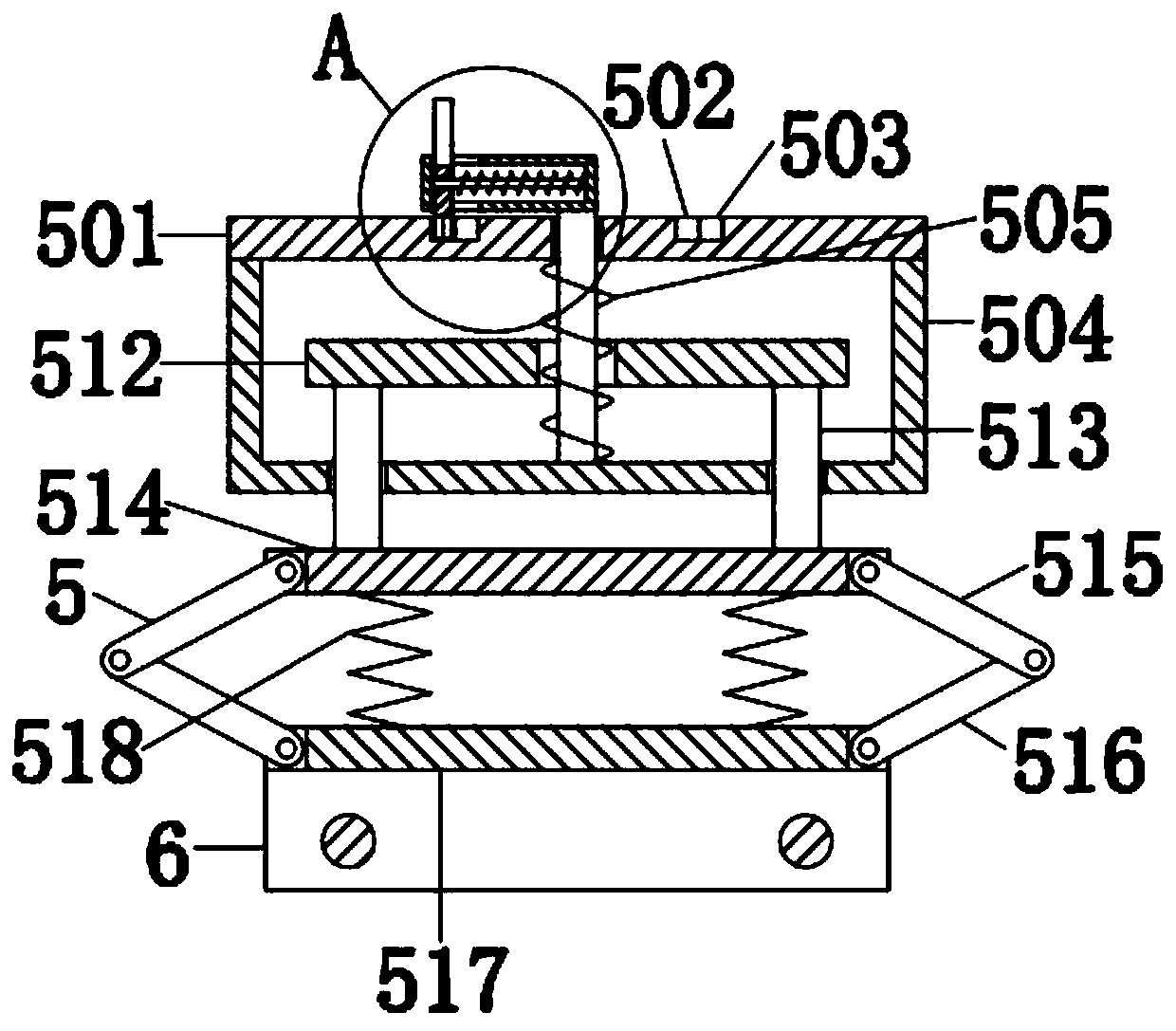

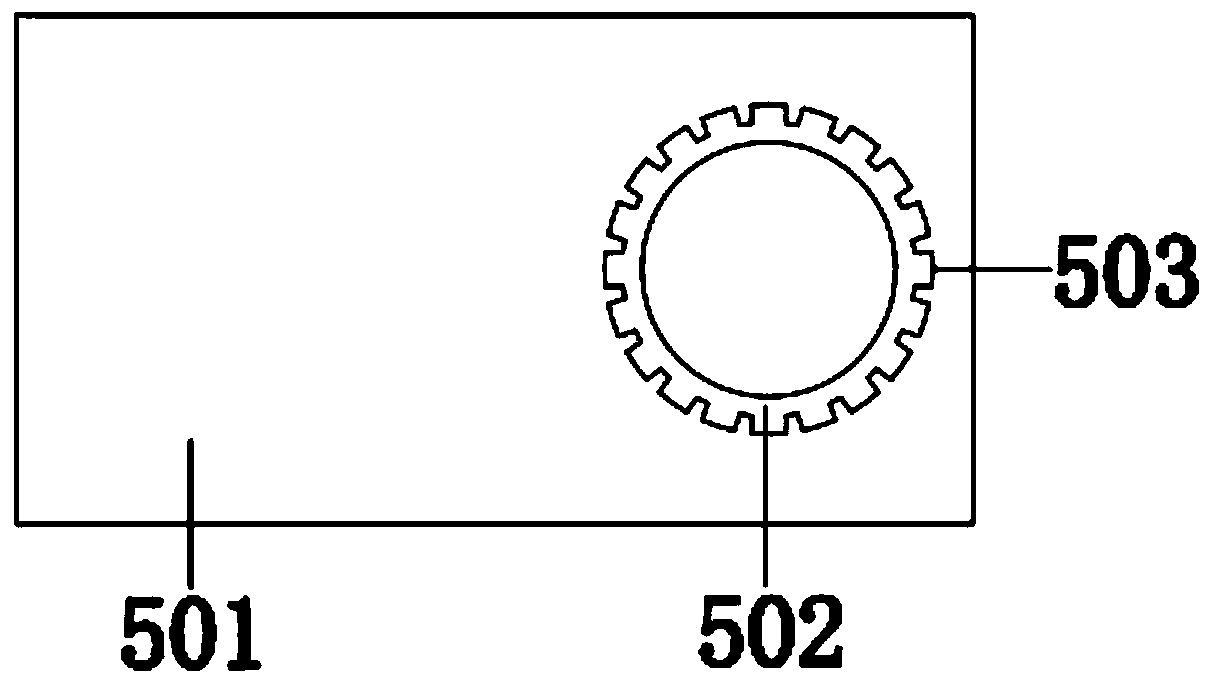

Planar sewing device

PendingCN110685078AStable conveying speedImprove product qualityWork-feeding meansProgrammable logic controllerSewing machine

The invention discloses a planar sewing device, which comprises a sewing machine body; a vertical plate is mounted at the center of the top end of the left side of the sewing machine body; The top endof the left side of the vertical plate is connected with a switch box through screws, and the top end of the vertical plate is connected with a PLC (programmable logic controller) through screws; thePLC is electrically connected with the switch box and a control system of the sewing machine body; a base plate vertically arranged is mounted on the right side of the vertical plate, and a cylinderis connected with the right side of the base plate through screws; the cylinder is electrically connected with the PLC, and the bottom end of the cylinder is provided with a pressing mechanism. The planar sewing device can provide automatic sewing of cloth, the conveying speed of the cloth is stable during sewing, no deviation of sewing lines occurs, and the product quality is improved; the planarsewing device can convey different kinds of cloth, so that the practicability is high, more time can be taken for other work by workers, the processing efficiency is improved, and the requirements ofgarment production are greatly met.

Owner:宁波太平鸟时尚服饰创意研究院有限公司

Camshaft grinding chuck automatic loading and unloading mechanism

ActiveCN105397449BPrecisely control the delivery positionReduce loadMetal working apparatusProduction lineEngineering

The invention relates to an automatic assembling and disassembling mechanism for a camshaft grinding chuck and particularly relates to a mechanism for automatic assembling and disassembling between the camshaft grinding chuck and a camshaft, and belongs to the technical field of mechanical part processing and manufacturing in an automatic production line. The automatic assembling and disassembling mechanism comprises a chuck fixing device, a nut tightening device and a camshaft fixing device, wherein the chuck fixing device, the nut tightening device and the camshaft fixing device are fixed on a fixing base plate from the left to the right in sequence. The automatic assembling and disassembling mechanism provided by the invention can achieve automatic assembling and disassembling between the grinding chuck and the camshaft in an automatic grinding production line of the camshaft, the work efficiency is improved, and the labor intensity is lowered.

Owner:WUXI BEST PRECISION MACHINERY

Bar material conveying device

ActiveCN105645096BEasy to transportAvoid failures that stop productionConveyorsConveyor partsEngineeringMechanical engineering

The invention provides a rodlike material conveying device which comprises two sets of material input channels, a material temporary storage cavity and one set of material output channel. A channel opening and closing switching turnover plate is arranged between outlets of the two sets of material input channels. The material temporary storage cavity is provided with a material inlet and a material outlet. The outlets of the two sets of material input channels communicate with the material inlet through the channel opening and closing switching turnover plate. An inlet of the material output channel communicates with the material outlet. The rodlike material conveying device has the beneficial effects of being scientific in design, high in practicality, capable of achieving automatic switching, convenient to use and stable in conveying speed.

Owner:XUCHANG TOBACCO MACHINERY

Continuous warehouse pneumatic conveying pump

ActiveCN105438838BStable conveying speedUniform conveying speedBulk conveyorsEngineeringStorage material

The invention belongs to the technical field of material conveying, and particularly relates to a continuous bin type pneumatic conveying pump capable of continuously achieving material conveying. The conveying pump comprises an intermittent-working storage material conveying bin and a continuous-working conveying bin. A feeding opening is formed in the upper side of the storage material conveying bin, the volume of the storage material conveying bin is larger than that of the conveying bin, and the conveying bin is inserted in the storage material conveying bin from top to bottom. A plurality of conveying pipes connecting the storage material conveying bin with the conveying bin and conveying powder are arranged between the storage material conveying bin and the conveying bin. The continuous bin type pneumatic conveying pump further comprises a pneumatic pressure feed device supplying air to the storage material conveying bin and the conveying bin, and a discharging device is arranged at a bottom outlet of the conveying bin. According to the continuous bin type pneumatic conveying pump, continuous material conveying can be achieved, accordingly, the conveying efficiency is improved, the conveying pipeline abrasion is reduced, the production efficiency is improved, and time cost is reduced. Meanwhile, the equipment manufacturing cost can be saved, the equipment occupied area is reduced, the functions of saving energy and reducing consumption are achieved, and the defects that the equipment manufacturing cost is high, and assembling is difficult are overcome.

Owner:ANHUI NAILIDE PNEUMATIC CONVEYING CO LTD

Automatic feeding device

ActiveCN103708177BPrecise position controlStable conveying speedConveyorsStructural engineeringMechanical engineering

The invention relates to an automatic feeding device. The automatic feeding device comprises a bottom support part, an upper transmission part and a conveying suspender. The bottom support part comprises a left support and a right support, a left rack is installed on the left support, and a right rack is installed on the right support. Left guide strips are installed at the front end of the left support and the rear end of the left support and right guide strips are installed at the front end of the right support and the rear end of the right support. The upper transmission part comprises a left transmission assembly and a right transmission assembly. Left sliding blocks on the left transmission assembly are matched with the left guide strips, right sliding blocks on the right transmission assembly are matched with the right guide strips, left conveying boat bodies on the left transmission assembly and right conveying boat bodies on the right transmission assembly are equal in number and corresponding in position in a left-and-right mode, and the left end of the conveying suspender and the right end of the conveying suspender are supported by the left conveying boat bodies and the right conveying boat bodies respectively. The automatic feeding device is ingenious in structure, reasonable in design and capable of realizing automatic feeding between a phosphorization line and a powder spraying line, improves the production efficiency and lowers the labor intensity.

Owner:WUXI BEST PRECISION MACHINERY

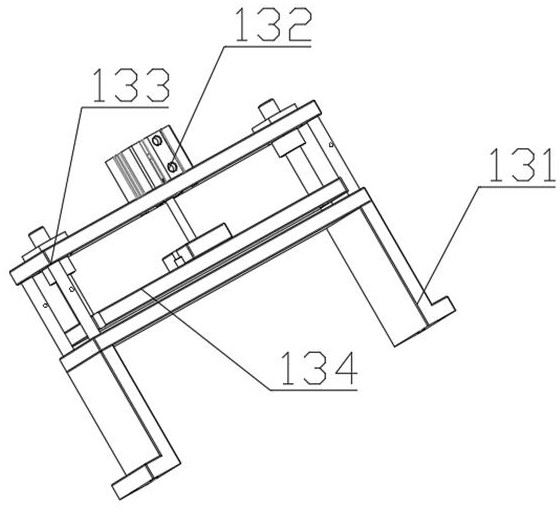

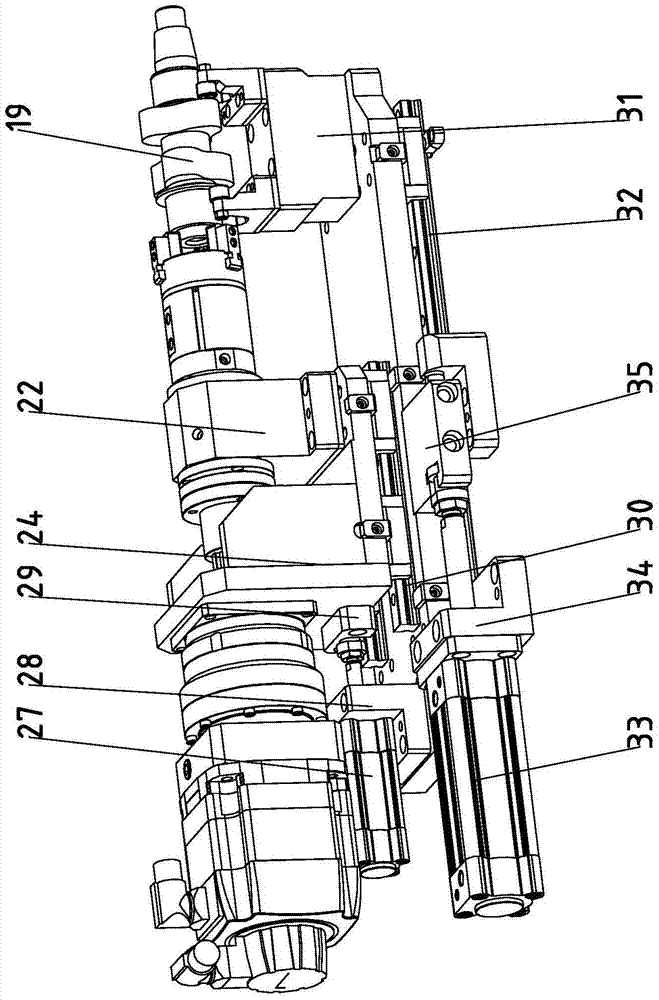

Orientation device and method for yarn core-embedded tapered outer tube

Owner:浙江三友塑业股份有限公司

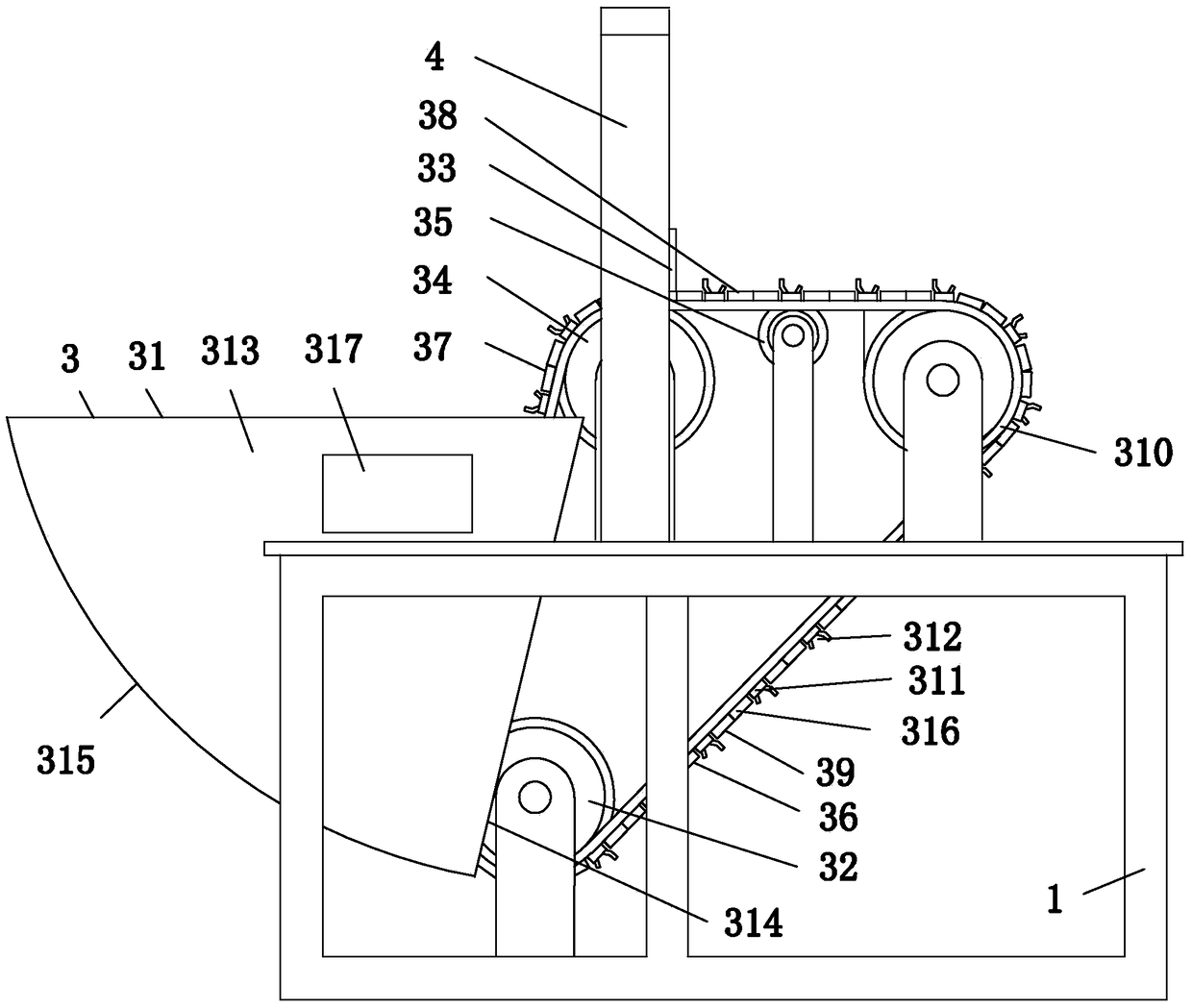

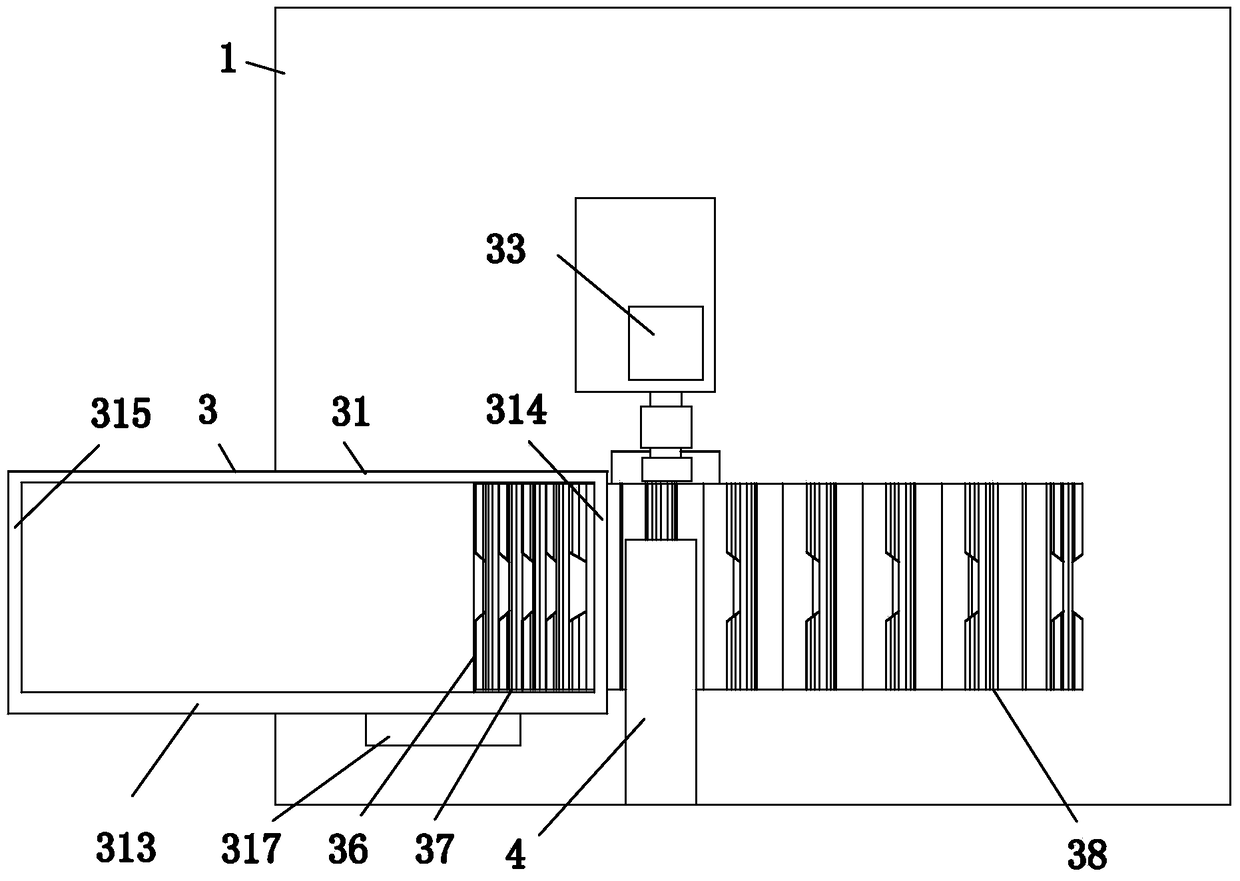

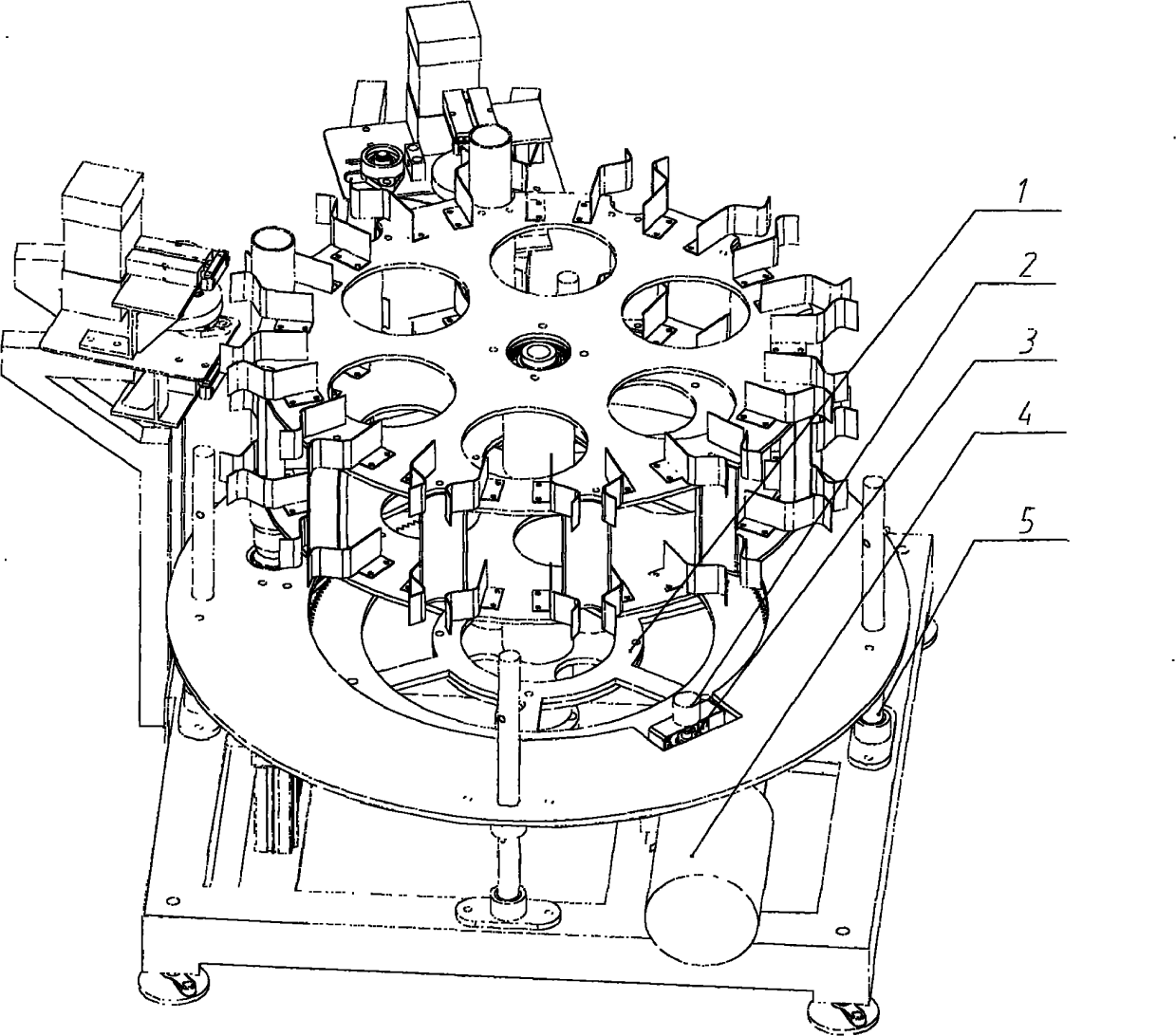

Conveyor Orientation Device and Conveyor Orientation Method for Conical Outer Tube Inserted with Yarn Tube

The invention discloses a conveying and orienting device of a spool inlaid core conical outer pipe, comprising a frame. The conveying and orienting device of the spool inlaid core conical outer pipe further comprises a conical outer pipe conveying device and a conical outer pipe orienting manipulator. When the conveying and orienting device of the spool inlaid core conical outer pipe is used, the conical outer pipe conveying device conveys the conical outer pipe in place; the conical outer pipe orienting manipulator adjusts the conical outer pipe with opposite large-end and small-end directions to a direction accordant with the inlaying requirement. The conveying and orienting device of the spool inlaid core conical outer pipe is higher in conveying of the conical core pipe and direction adjusting efficiency of the conical core pipe. The conveying and orienting method of the conveying and orienting device of the spool inlaid core conical outer pipe can satisfy the conveying and orienting requirements of the conical outer pipe, and is higher in conveying of the conical core pipe and direction adjusting efficiency of the conical core pipe.

Owner:浙江三友塑业股份有限公司

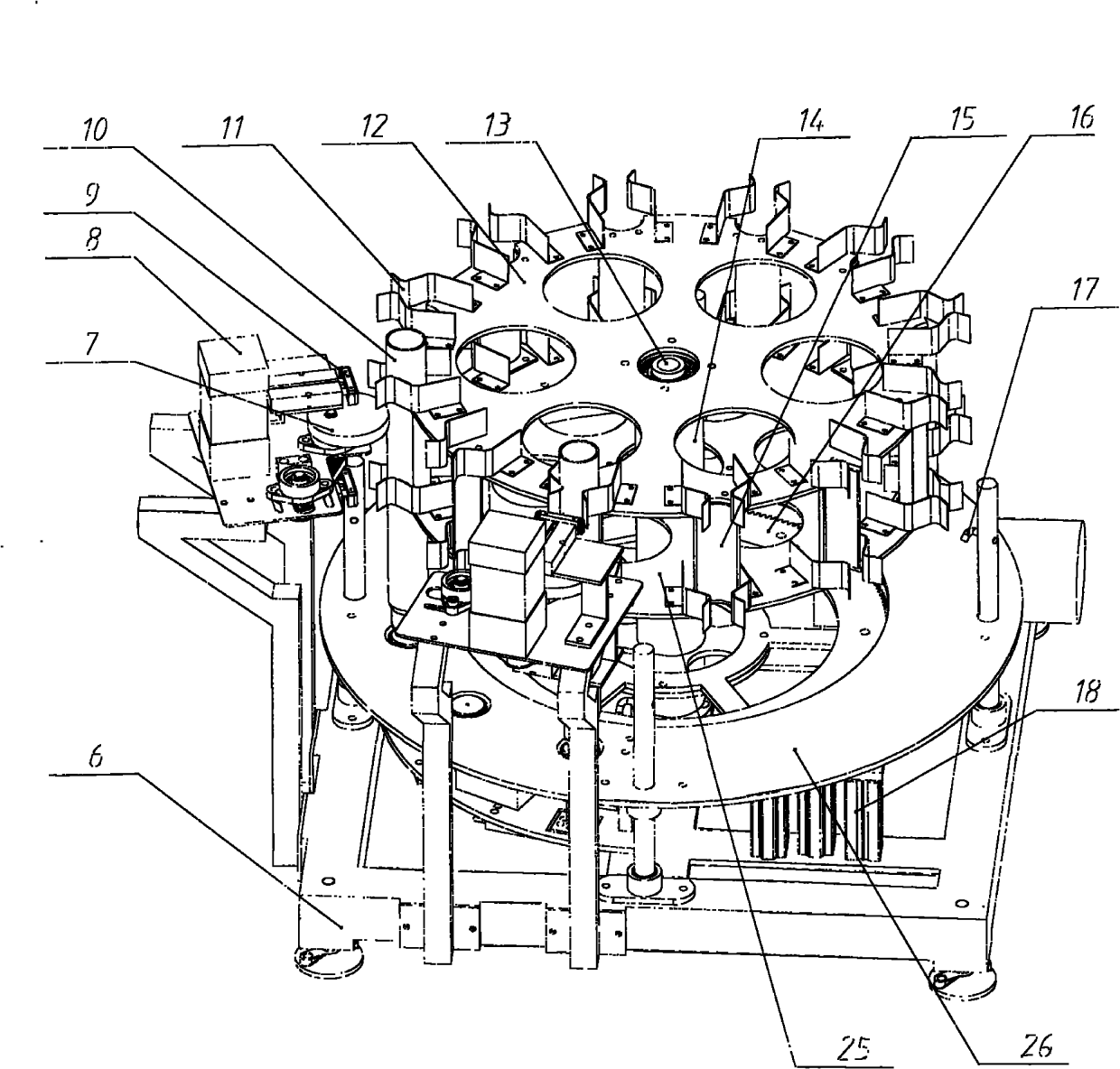

Automatically-rotating explosive machine

The invention relates to an automatically-rotating explosive machine. The machine comprises a frame, a small gear, a big gear, a prop, an axis, a spindle, a baseplate, a motor, an upper turntable, a lower turntable, n clips, a vibrating mechanism and a holding and clamping mechanism, wherein n is an even number; the spindle, the motor, the vibrating mechanism and the holding and clamping mechanism are respectively arranged on the frame; the baseplate is connected to four stationary shafts on the frame by a sliding bearing; the big gear is fixed on the spindle by a fixed plate; the small gear is fixed on the shaft of the motor; the small gear and the big gear are mutually meshed; the upper turntable and the lower turntable are respectively arranged on the spindle, and arranged on the frameby the axis; the n clips are uniformly and correspondingly arranged on the upper turntable and the lower turntable respectively; and the prop is fixed between a pair of corresponding upper and lower clips. The automatically-rotating explosive machine has the advantages of simple structure, small volume, convenient installation and quick transmission speed, no need of human intervention in the process of explosive loading, and capability of ensuring the personal safety of the explosive loading workers to the maximum extent.

Owner:WUHAN RENTIAN PACKAGING TECH

Novel efficient mold repairing device

InactiveCN111570972AChange up and down positionChange front and rear positionsWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryEngineering

The invention relates to the technical field of mold repairing, and discloses a novel efficient mold repairing device. The novel efficient mold repairing device comprises a base, wherein a position adjusting mechanism is slidably arranged at the top of the base through a sliding groove and a sliding block, a carbon dioxide gas tank is fixedly connected to the top of the base, two vertical plates are symmetrically and fixedly connected to the top of the base, a top plate is fixedly connected between the tops of the two vertical plates, two first motors are symmetrically and fixedly connected tothe left side face of the vertical plate located on the left side through supporting plates, lead screws are fixedly connected to the output ends of the first motors, and the right ends of the lead screws penetrate through the left vertical plate and are rotationally connected with the left side face of the right vertical plate. The problems that when most existing mold repairing devices repair molds, due to the fact that welding wires need to be moved frequently, the stability of the welding wire conveying speed is difficult to guarantee, the mold repairing quality is reduced, and the mold repairing efficiency is seriously reduced are solved.

Owner:CHUZHOU MODERN MOLD MFG

A part surface quality inspection device based on artificial vision

ActiveCN109374643BEliminate vibrationEasy to hangOptically investigating flaws/contaminationPhotoswitchRobot hand

The invention discloses a part surface quality detection device based on artificial vision, which includes a detection box, a camera, a light source, a controller, a photoelectric switch, a conveying chain, a vacuum suction cup manipulator and a conveying chain driving device, and the CCD camera is provided with two , a camera is arranged above and below the conveyor chain, and the conveyor chain driving device is used to eliminate the vibration generated by the conveyor chain when transporting the product to be tested. Due to the setting of the conveyor chain, it is convenient to hang the tested product to realize the simultaneous detection of the upper and lower cameras. Due to the setting of the regular hexagonal sprocket, it can carry a larger moment and transport heavier items; the second transmission The speed fluctuation of the disc offsets the fluctuation of the conveyor chain speed driven by the regular hexagonal sprocket, thus obtaining a relatively stable conveying speed, eliminating the vibration generated by the conveyor chain during the conveying process, and improving the stability of the product under test.

Owner:张家港利云智能科技有限公司

Core inserting machine and core inserting method

ActiveCN105583605BMounting position error is smallReduce mistakesMetal working apparatusBobbinNuclear engineering

Owner:浙江三友塑业股份有限公司

Continuous conveying system for powder

The invention discloses a continuous conveying system for powder. The continuous conveying system for powder comprises a main hopper, a main feeding machine and a spiral conveying device, wherein the main feeding machine is located under the main hopper, and the spiral conveying device is connected with the main feeding machine. The spiral conveying device comprises a shell, a first conveying device body and a second conveying device body, wherein the first conveying device body and the second conveying device body are fixed in the shell in parallel with one above the other, partition plates are arranged in the first conveying device body and the second conveying device body correspondingly, and a cavity is formed by the partition plates and the shell. The continuous conveying system is suitable for production of inorganic nano-particles and polymer composite materials or production of inorganic nano-master batches, and a steady conveying speed can be kept for inorganic nano-powder.

Owner:李荣亮

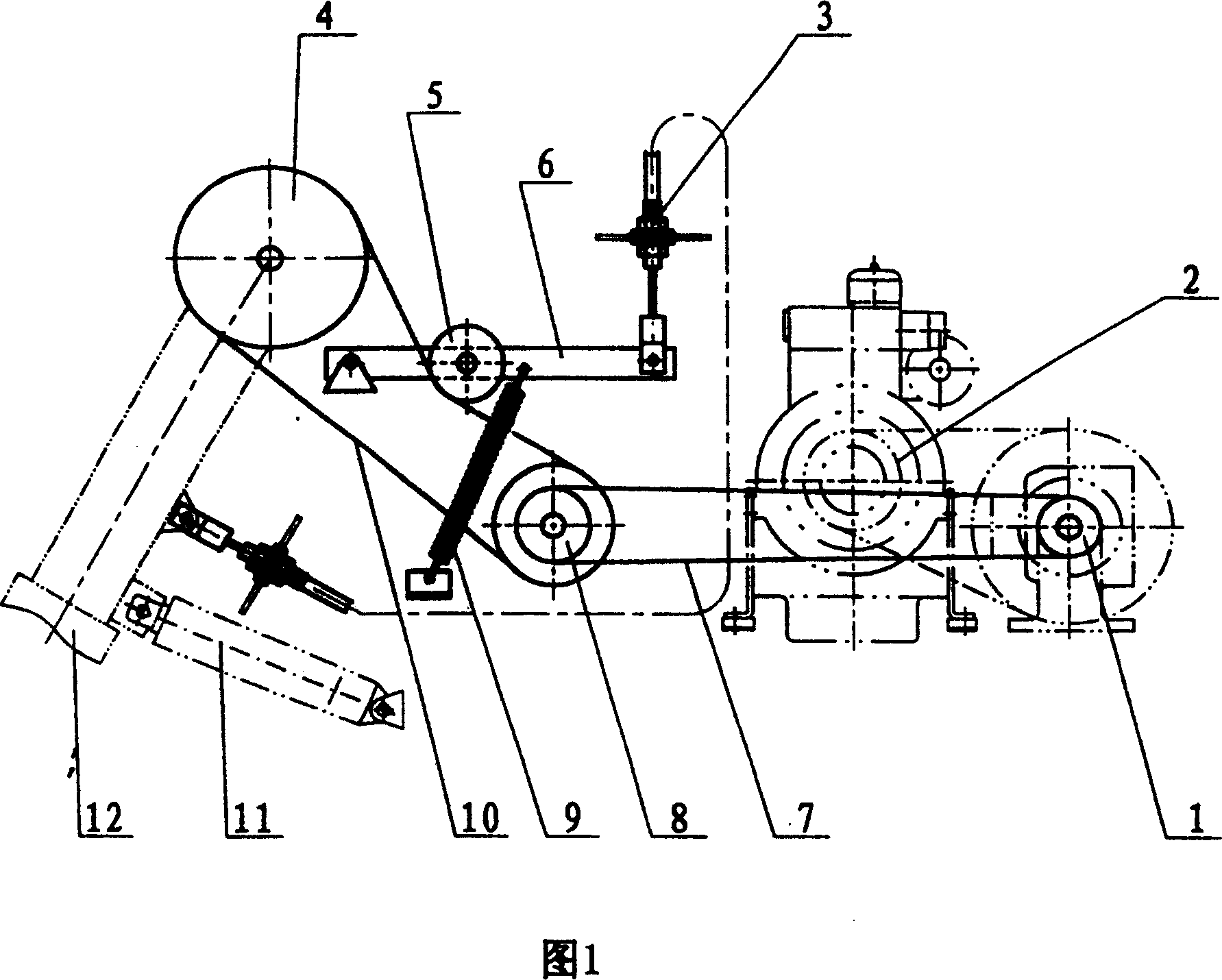

Fully automatic lead filling machine

ActiveCN103451590BSuitable for useStable conveying speedMolten spray coatingGas flame welding apparatusCouplingSlide plate

The invention discloses a fully-automatic lead enameling manipulator. The lead enameling manipulator comprises a lead enameling main machine and an auxiliary mechanism, wherein the lead enameling main machine comprises an upright post on which a screw rod is mounted; a bracket is in transmission with the upright post through a screw rod nut so as to regulate the height up and down; a cross arm is fixed by the bracket up and down; a top plate is arranged at the top end of the upright post; a stepping motor is fixedly placed on the top plate; the stepping motor is connected with the screw rod of the upright post through a coupler to control the position regulation of the bracket; guide rails are arranged at one end of the cross arm; a flux spray head is mounted at one end of a sliding plate; racks are mounted between the guide rails; a sliding block moves on the guide rails; an electromagnetic heating module is mounted on the sliding block. A flux is sprayed automatically and can be uniformly sprayed on a preheated position which is pre-enameled with lead, so that good lamination between the lead and a working piece is ensured. The whole lead enameling process does not need direct manual operation, so as to ensure the health of the worker.

Owner:NANJING TECH UNIV

Cutting platform transmission device of half-feeding combine for rice and wheat

The invention discloses a transmission arrangement for half-feed-in type rice and wheat combine-harvester cutting platform which includes two-stages of speed reducing, the first stage being a chain drive, which is driven by intermediate gearing box and transitional drive shaft arranged on the housing through chains, the second stage being a belt drive which is driven by the transitional drive shaft and cutting platform power feed-in wheel through a belt. The invention can be applied to guarantee the stabilization cutting and transporting velocity for the harvesters.

Owner:TAIZHOU CHANGFA AGRI EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com