Rice husk conveying device for coal-fired boiler

A coal-fired boiler and conveying device technology, applied in the direction of combustion method, supply configuration, combustion equipment, etc., can solve problems such as fuel shortage, waste of organic energy, environmental pollution, etc., achieve continuous and stable conveying speed, save coal resources, and reduce usage cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The applicant will describe in detail in the form of the following examples, but the description of the examples is not a limitation to the technical solution of the present invention, and any equivalent transformation made according to the concept of the present invention is only a formal rather than a substantive equivalent transformation All should be regarded as the scope of the technical solution of the present invention.

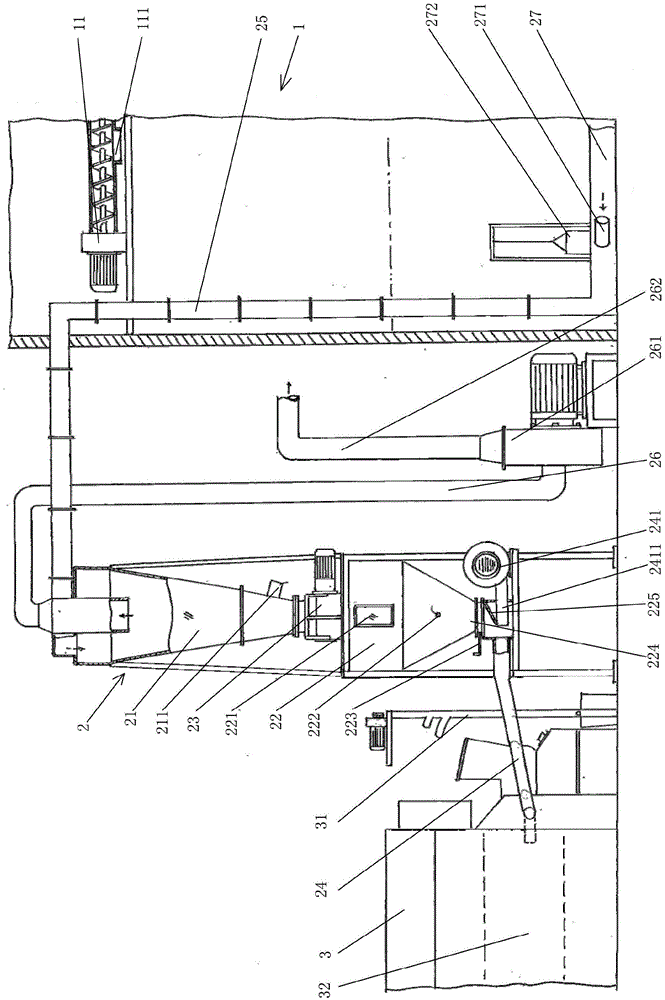

[0016] see figure 1 , the present invention relates to a rice husk conveying device for a coal-fired boiler, comprising a conveying tower 2 for respectively connecting a rice husk house 1 and a coal-fired boiler 3 through pipelines, and the conveying tower 2 includes a negative pressure suction hopper 21 and the silo 22 located below the height direction of the negative pressure suction hopper 21, the negative pressure suction hopper 21 communicates with the silo 22 through the air lock 23, and the silo 22 is at the bottom and close to the disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com