A part surface quality inspection device based on artificial vision

A surface quality and detection device technology, which is applied in the direction of measuring devices, optical testing flaws/defects, instruments, etc., can solve problems such as inability to perform all-round detection and affect the accuracy of product detection, and achieve elimination of vibration, improvement of stability, and stability The effect of conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

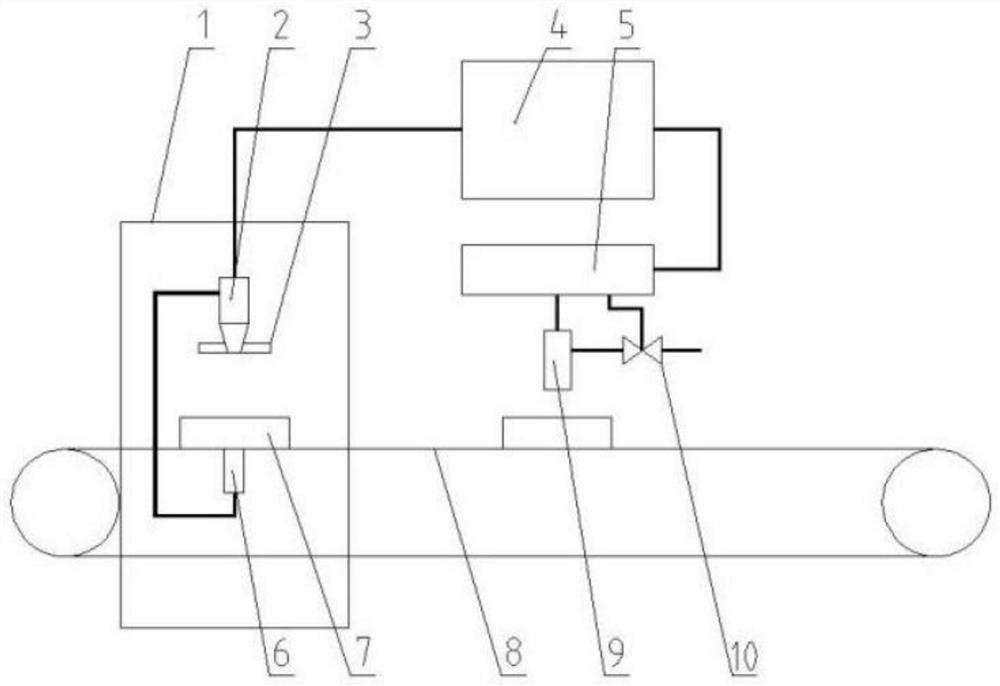

[0030] A machine vision-based target surface defect detection system and detection method include a detection box, a CCD camera, a light source, a controller, a photoelectric switch, a conveyor chain, a vacuum chuck manipulator, and a conveyor chain drive device. The CCD camera is provided with two, A CCD camera is respectively arranged above and below the conveying chain, and the conveying chain driving device is used to eliminate the vibration generated by the conveying chain when conveying the tested product.

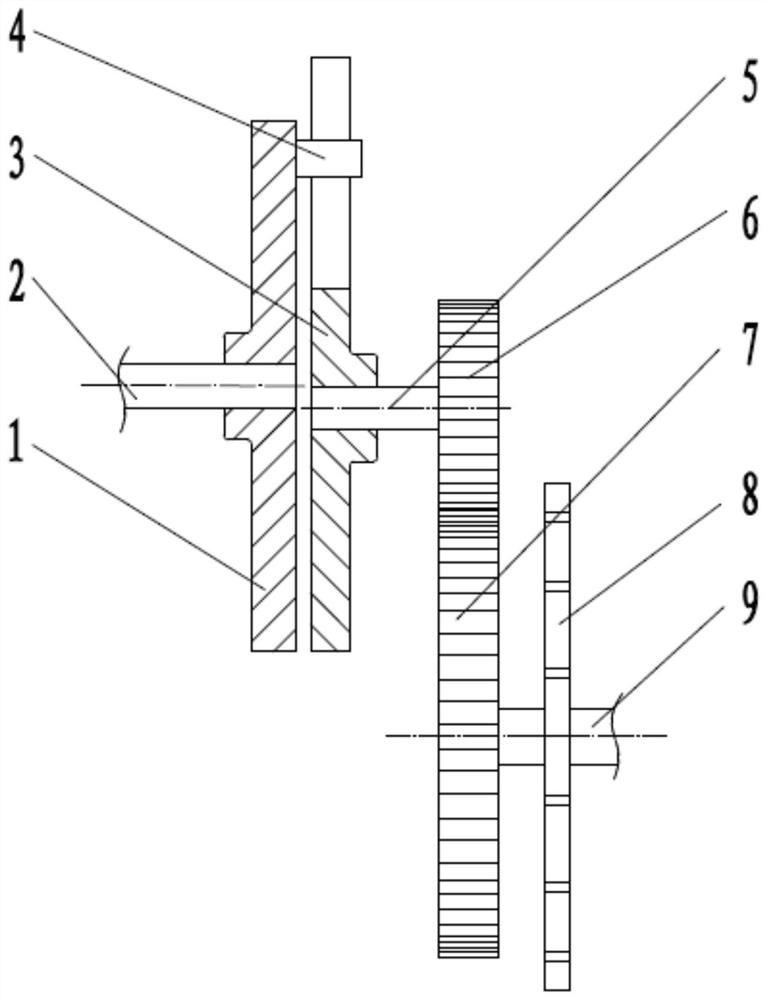

[0031] Such as figure 1 As shown, the conveyor chain driving device includes a first transmission disc 1, a first transmission shaft 2, a second transmission disc 3, a transmission column 4, a second transmission shaft 5, a first gear 6, a second gear 7 and a third Transmission shaft 9, the first transmission shaft 2 is connected to the drive motor, the first transmission disc 1 is fixed on the first transmission shaft 2, and the right side of the first transmission ...

Embodiment 2

[0037] A machine vision-based target surface defect detection system and detection method include a detection box, a CCD camera, a light source, a controller, a photoelectric switch, a conveyor chain, a vacuum chuck manipulator, and a conveyor chain drive device. The CCD camera is provided with two, A CCD camera is respectively arranged above and below the conveying chain, and the conveying chain driving device is used to eliminate the vibration generated by the conveying chain when conveying the tested product.

[0038] Such as figure 1 As shown, the conveyor chain driving device includes a first transmission disc 1, a first transmission shaft 2, a second transmission disc 3, a transmission column 4, a second transmission shaft 5, a first gear 6, a second gear 7 and a third Transmission shaft 9, the first transmission shaft 2 is connected to the drive motor, the first transmission disc 1 is fixed on the first transmission shaft 2, and the right side of the first transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com