Cutting platform transmission device of half-feeding combine for rice and wheat

A technology for combine harvesters and transmission devices, which is applied to harvesting platforms, harvesters, cutters, etc., and can solve problems such as high cost, increased load on continuously variable transmissions and travel gearboxes, and travel speed restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

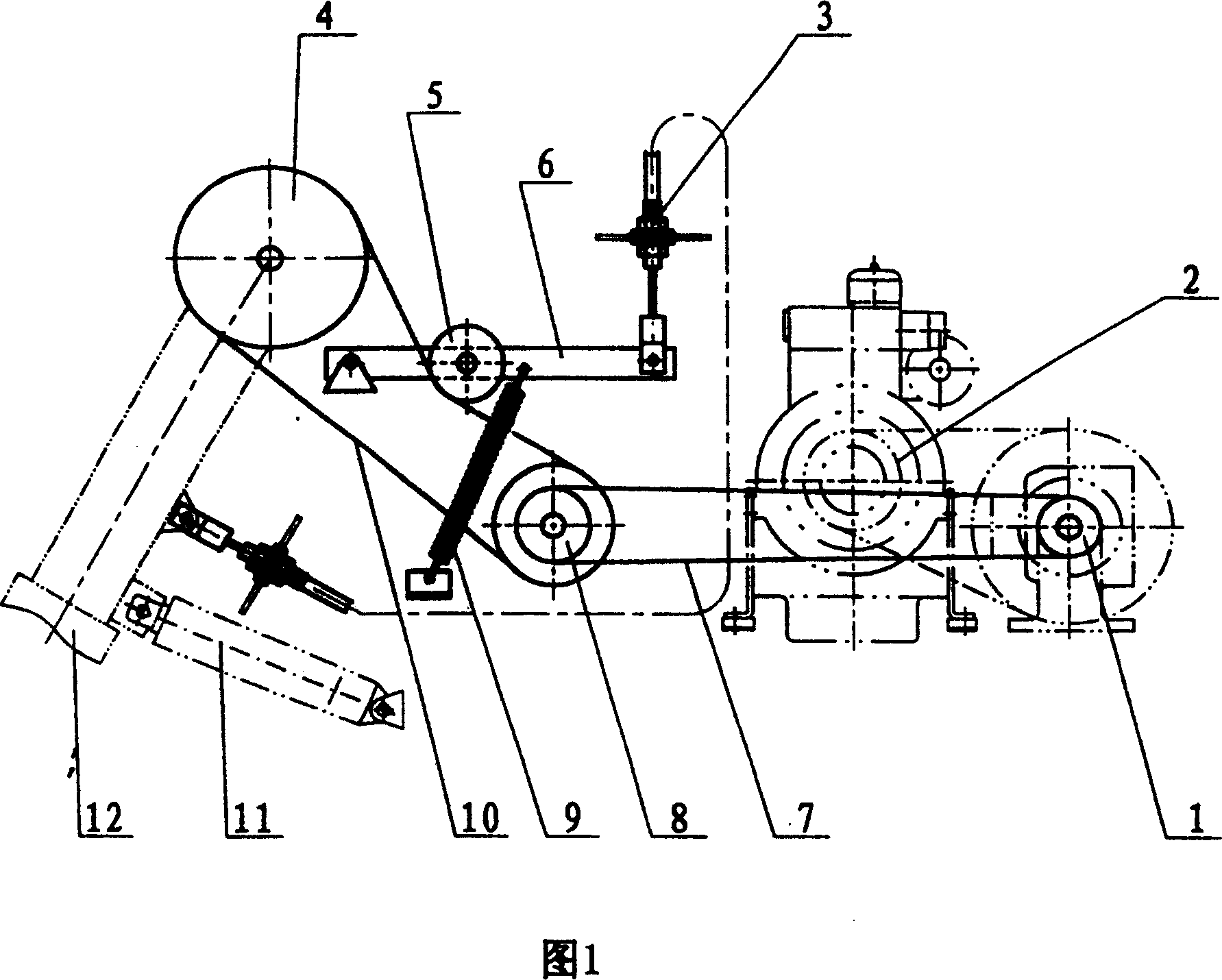

[0009] In Fig. 1, the first stage is a chain transmission, the driving sprocket is mounted on the output shaft of the intermediate transmission box 1, the passive sprocket is mounted on the transition transmission shaft 8, and the driving sprocket and the passive sprocket are driven through the chain 7; The second stage is a belt transmission, and its driving pulley is contained on the transition transmission shaft 8, and the passive pulley is the header power input wheel 4, which is installed on the header input drive shaft, and two belt pulleys pass through belt 10 transmissions. One side of the belt 10 is provided with an automatic tension separation mechanism, which is mainly composed of tension pulley 5, tension support 6, tension spring 9 and separation flexible shaft 3. One end of the separation flexible shaft 3 is connected to the header transmission box 12, and the other end is connected to the rear end of the tension bracket 6. One end of the tension spring 9 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com