Material unwinding and winding device and speed regulating method thereof

A technology of coiling device and coiling speed, which is applied in the direction of coiling strips, sending objects, thin material processing, etc., can solve the problem that the cloth coiling and material conveying speed are not synchronized, disturb the rhythm control of conveying materials, and affect process control. and other problems, to achieve obvious adaptability, control equipment costs, and reduce labor load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

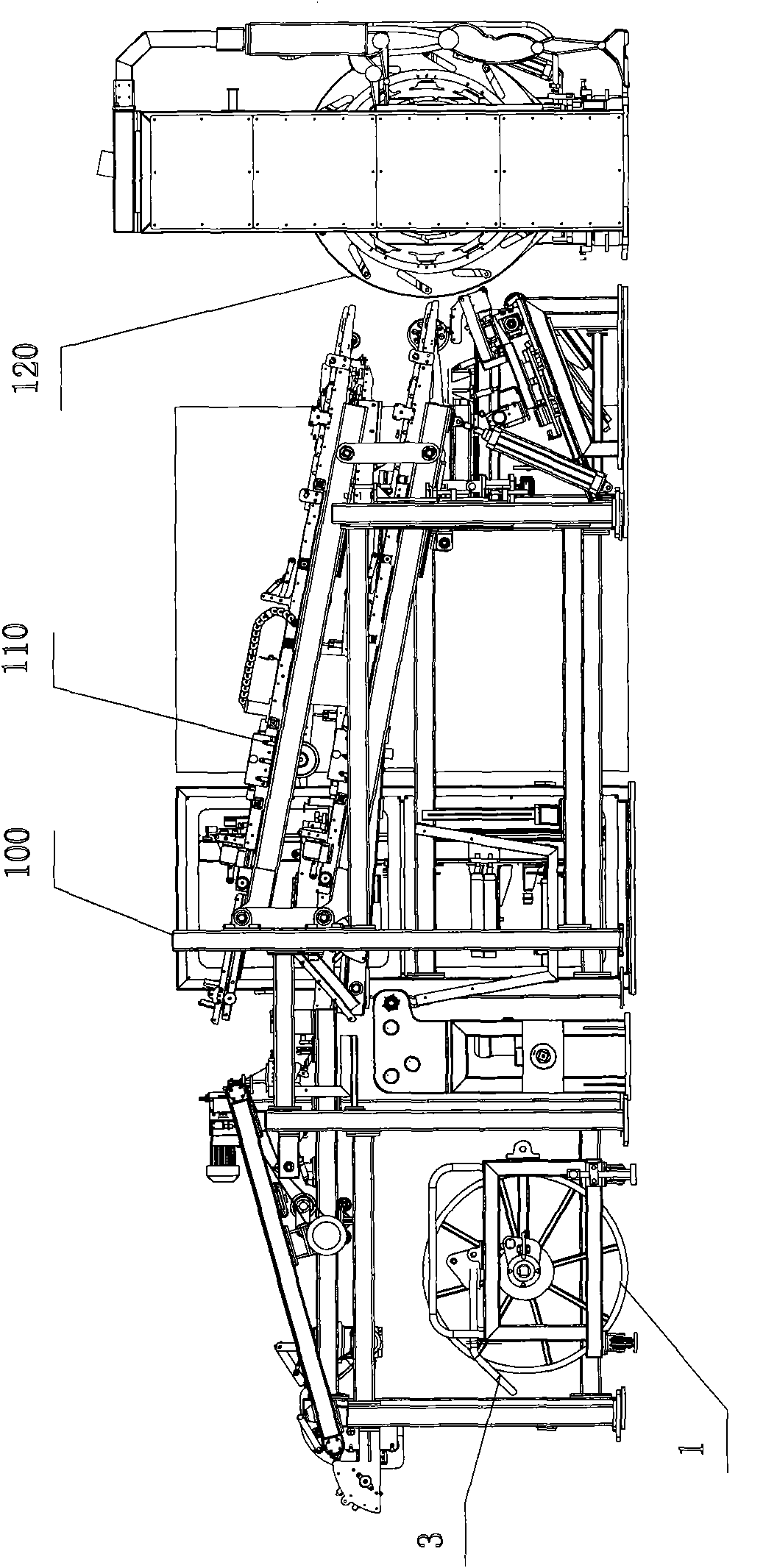

[0040] Example 1, in figure 1 In the application of the feeding device of the present invention, the material 300 that has been guided and separated from the pad 200 is transported forward from the roll device 1 to the conveying template 110 of the feeding frame 100, and then the winding is completed on the forming drum 120 , Laminating process.

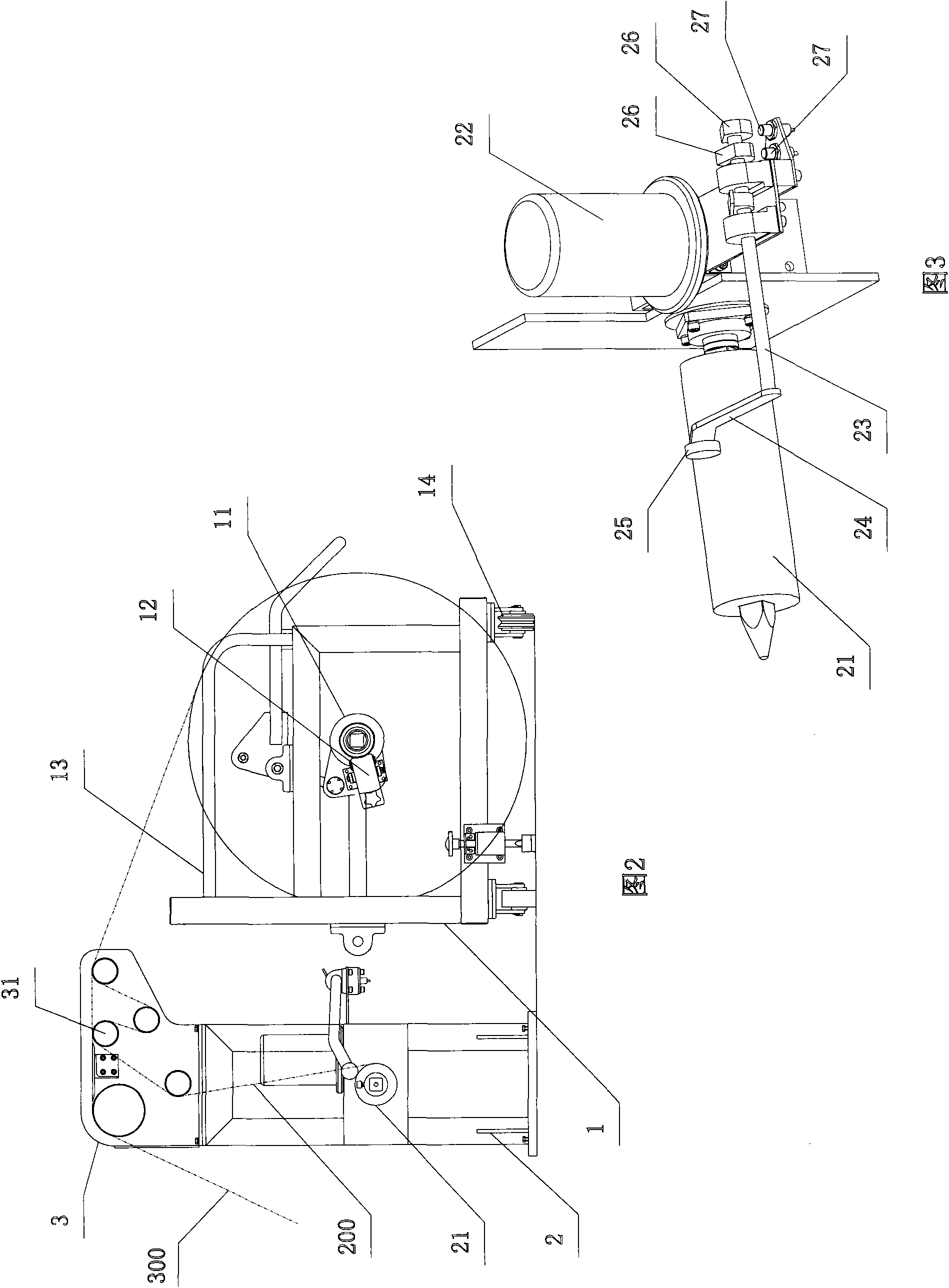

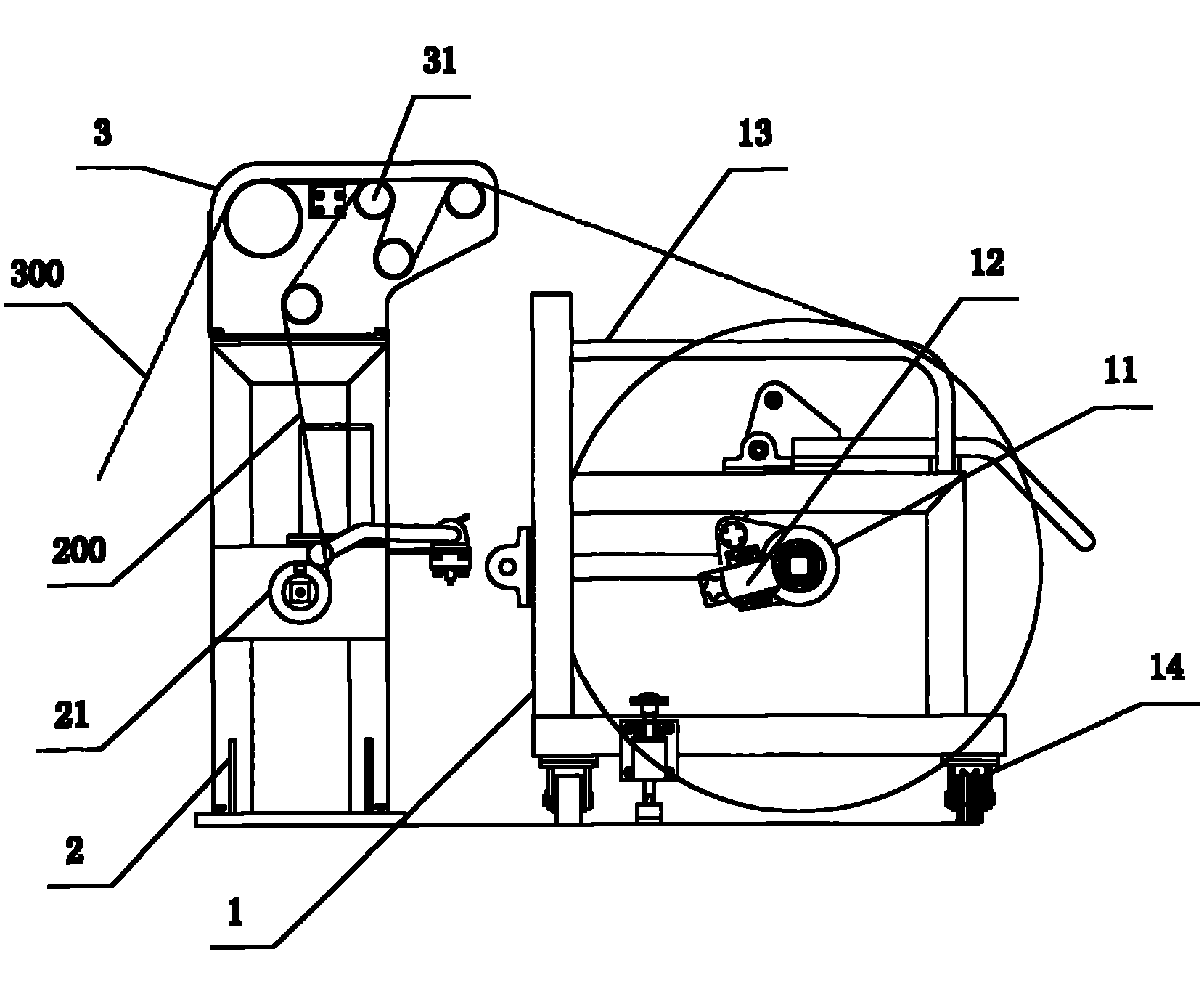

[0041] like figure 2 and image 3 As shown, the material decoiling device mainly includes a material coiling device 1 , a pad coiling device 2 and a decoiling bracket 3 . in,

[0042] On the guide shaft 31 of the guide bracket 3 , the pad 200 is separated from the material 300 . The separated materials 300 continue to be transported forward to the conveying template 110 , and the pad 200 is wound and stored on the reel 21 of the pad winding device 2 .

[0043] The material roll device 1 has a DC frequency conversion motor 12 that drives the reel 11 to rotate and can adjust the speed of the reel 11. Several pulleys 14 are instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com