Camshaft grinding chuck automatic loading and unloading mechanism

An automatic loading and unloading, camshaft technology, applied in metal processing, metal processing equipment, manufacturing tools and other directions, can solve the problems of inability to meet automation, mass production, increase production costs of enterprises, low degree of automation, etc., to achieve easy and accurate guidance, The effect of improving production efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

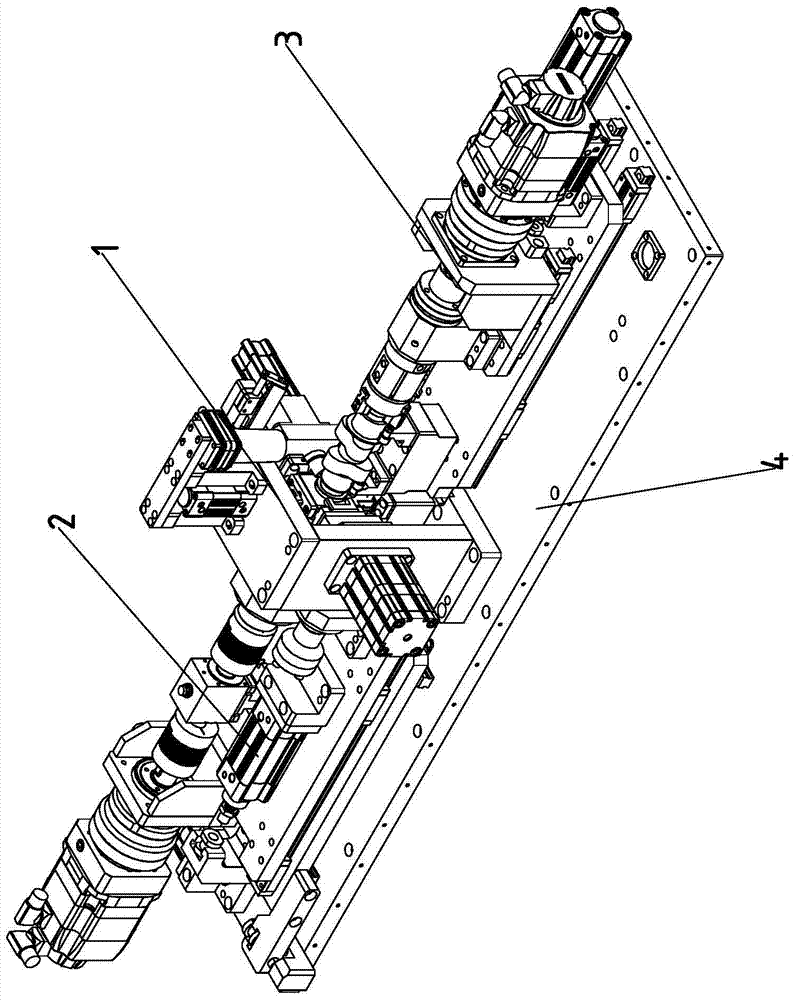

[0022] Such as figure 1 As shown, the present invention mainly includes chuck fixing device 1, nut tightening device 2 and camshaft fixing device 3, and nut tightening device 2, chuck fixing device 1 and camshaft fixing device 3 are sequentially fixed on fixed base plate 4 from left to right superior.

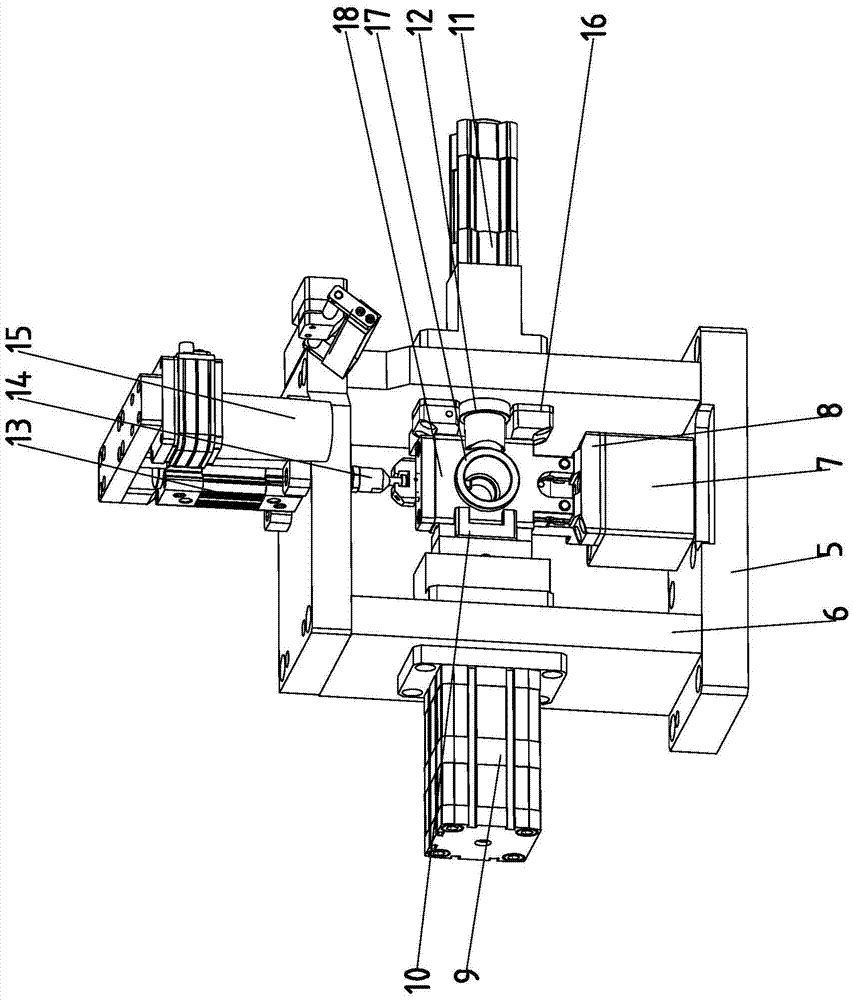

[0023] Such as figure 2 As shown, the collet fixing device 1 includes a collet 17, the collet 17 is installed in the collet fixing seat 18, the upper end of the collet fixing seat 18 is connected to the bolt 14, the upper end of the bolt 14 is connected to the piston rod of the upper mounting cylinder 13, and the upper end of the collet fixing seat 18 is connected to the piston rod of the cylinder 13, Install cylinder 13 and be fixed on cylinder support 6 upper ends. The lower end of the chuck holder 18 is connected to the positioning plate base 7, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com