Aromatic meat gourmet powder and manufacturing process thereof

A manufacturing process and meat flavoring technology, which is applied in the field of food seasonings and condiments, can solve technical difficulties and problems that need to be further deepened, and achieve the effects of improving deep processing utilization, heating evenly, and shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

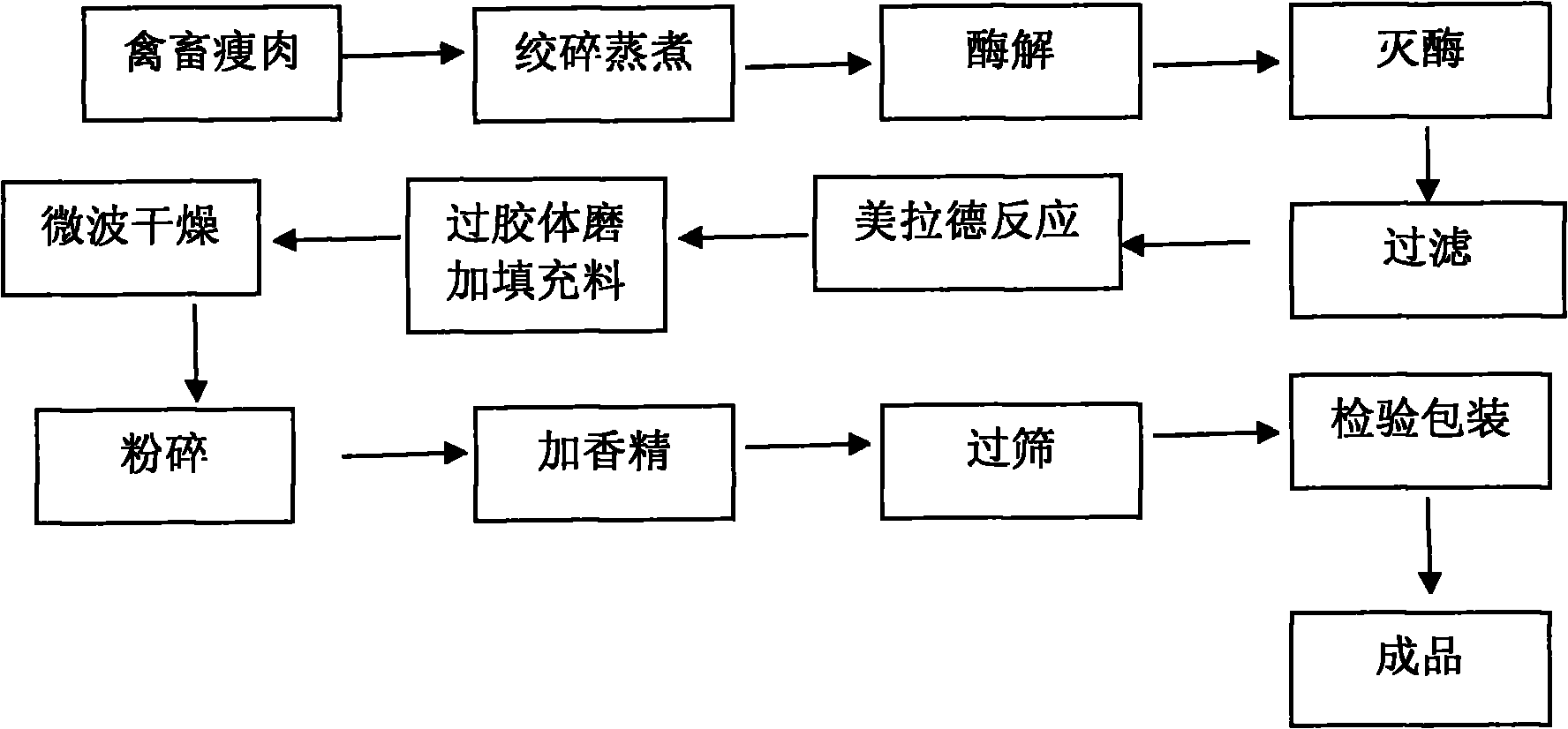

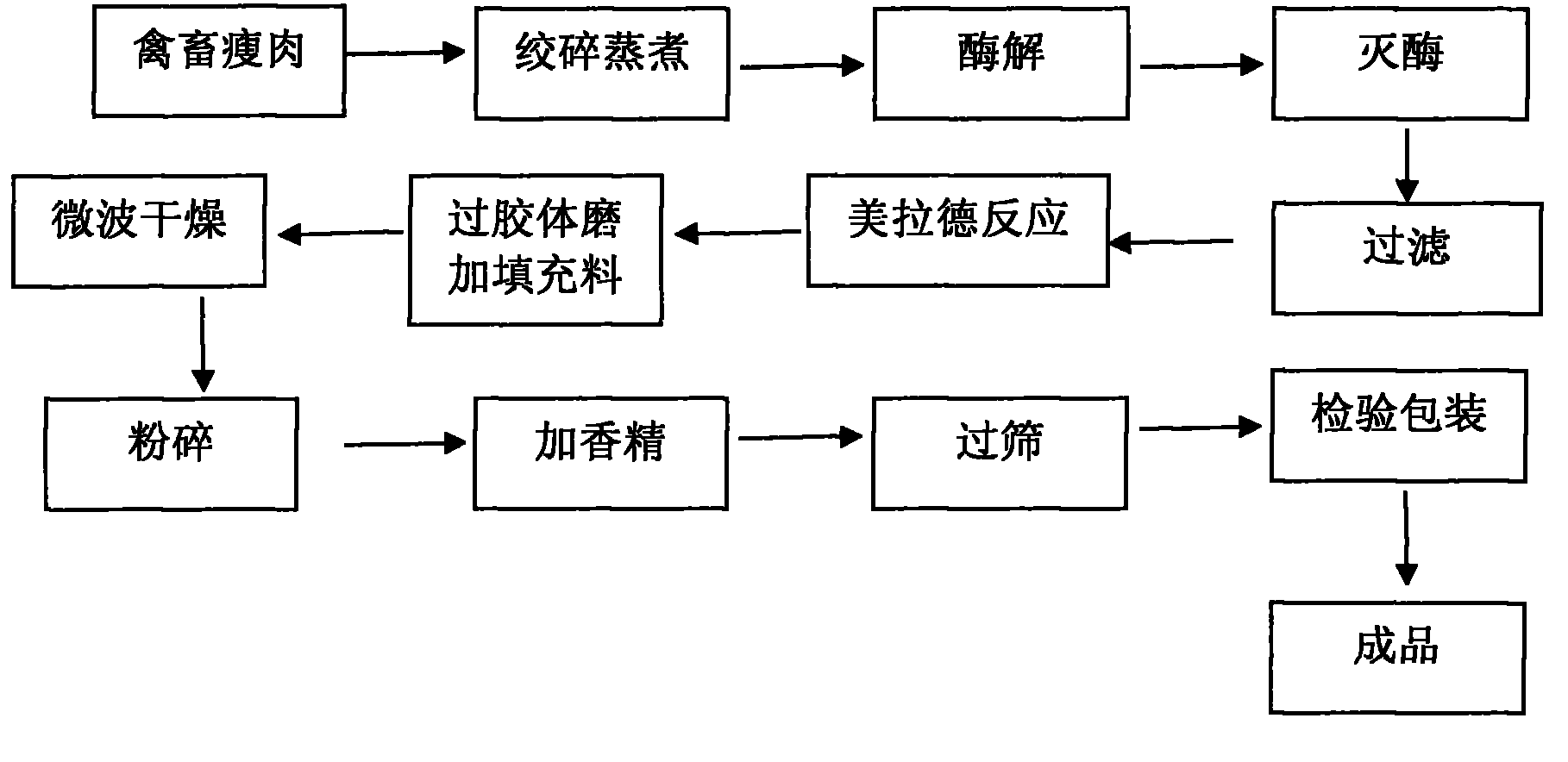

Image

Examples

Embodiment 1

[0026] Embodiment 1: Get 100kg of fresh pork, twist it into meat paste with a meat grinder, put it into a cooking pot, add 100kg of water, heat up to 100-110°C and boil for 1-2 hours, then cool down to 50-55°C ℃, add 0.1kg of compound protease and 0.3kg of flavor protease to the cooking pot, control the temperature at 55℃, start enzymolysis, the enzymolysis time is 3.5 hours, then rapidly raise the temperature to 80℃-100℃ and keep it warm for 10 minutes to inactivate the enzyme The pork enzymatic hydrolyzate was obtained, taken out and filtered for later use.

[0027] Get 100kg of pork enzymatic solution, 60kg of hydrolyzed vegetable protein, 16kg of yeast extract, 10kg of glucose, 1.5kg of glycine, 0.75kg of alanine, 3.75kg of cysteine hydrochloride, and 2kg of vitamin (B1), and add them to the reaction kettle. Raise the temperature to 100°C-102°C, start the Maillard reaction, keep it warm for 1.5 hours, and the resulting meat flavoring reaction liquid is passed through a c...

Embodiment 2

[0030] Embodiment 2: Get 100kg of fresh chicken, twist it into meat paste with a meat grinder, put it into a cooking pot, add 100kg of water, heat up to 100-110°C and boil for 1-2 hours, then cool down to 50-55°C ℃, add 0.1kg of compound protease and 0.3kg of flavor protease to the cooking pot, control the temperature at 55℃, start enzymolysis, the enzymolysis time is 3.5 hours, then rapidly raise the temperature to 80℃-100℃ and keep it warm for 10 minutes to inactivate the enzyme Obtain the chicken enzymatic hydrolyzate, take it out and filter it for later use.

[0031] Get 100kg of chicken enzymatic solution, 60kg of hydrolyzed vegetable protein, 16kg of yeast extract, 10kg of glucose, 1.5kg of glycine, 0.75kg of alanine, 3.75kg of cysteine hydrochloride, and 2kg of vitamin (B1), and add them to the reaction kettle. Raise the temperature to 100°C-102°C, start the Maillard reaction, keep it warm for 1.5 hours, and the resulting meat flavoring reaction liquid is passed through...

Embodiment 3

[0034] Embodiment 3: Get 100kg of fresh beef, twist it into meat paste with a meat grinder, put it into a cooking pot, add 100kg of water, heat up to 100-110°C and boil for 1-2 hours, then cool down to 50-55°C ℃, add 0.1kg of compound protease and 0.3kg of flavor protease to the cooking pot, control the temperature at 55℃, start enzymolysis, the enzymolysis time is 3.5 hours, then rapidly raise the temperature to 80℃-100℃ and keep it warm for 10 minutes to inactivate the enzyme Obtain the beef enzymatic hydrolyzate, take it out and filter for later use.

[0035] Get 100kg of beef enzymatic solution, 60kg of hydrolyzed vegetable protein, 16kg of yeast extract, 10kg of glucose, 1.5kg of glycine, 0.75kg of alanine, 3.75kg of cysteine hydrochloride, and 2kg of vitamin (B1), and add them to the reaction kettle. Raise the temperature to 100°C-102°C, start the Maillard reaction, keep it warm for 1.5 hours, and the resulting meat flavoring reaction liquid is passed through a colloid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com