Meat grinder

A meat grinder and meat grinder technology, applied in the field of meat grinder, can solve problems such as untimely supply of raw materials, affecting product processing quality, and low processing efficiency, and achieve the effects of shortened idle time, stable work, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

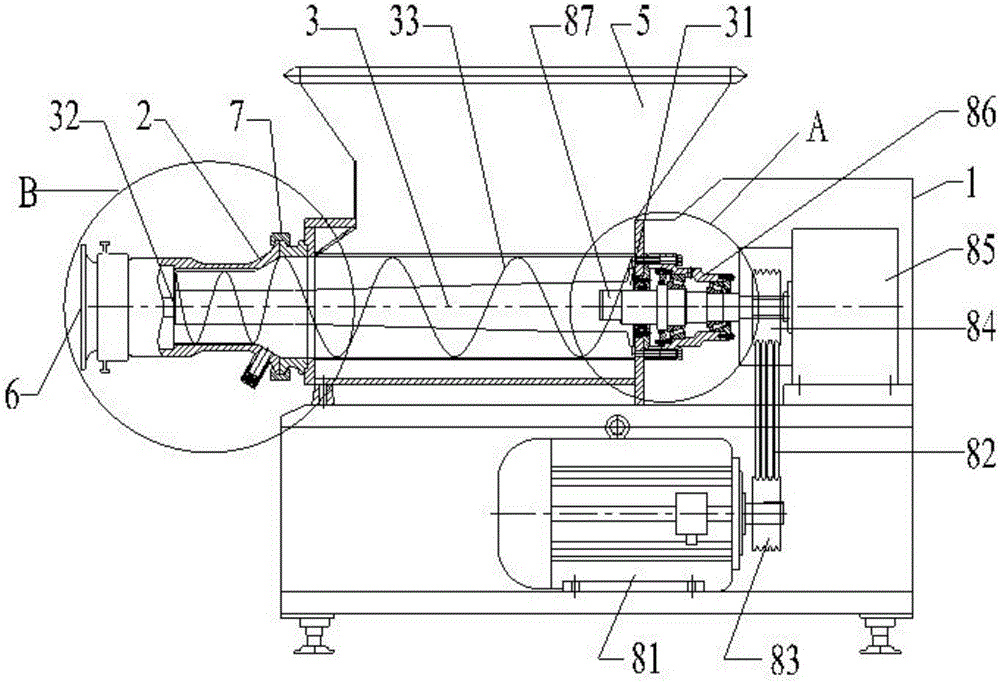

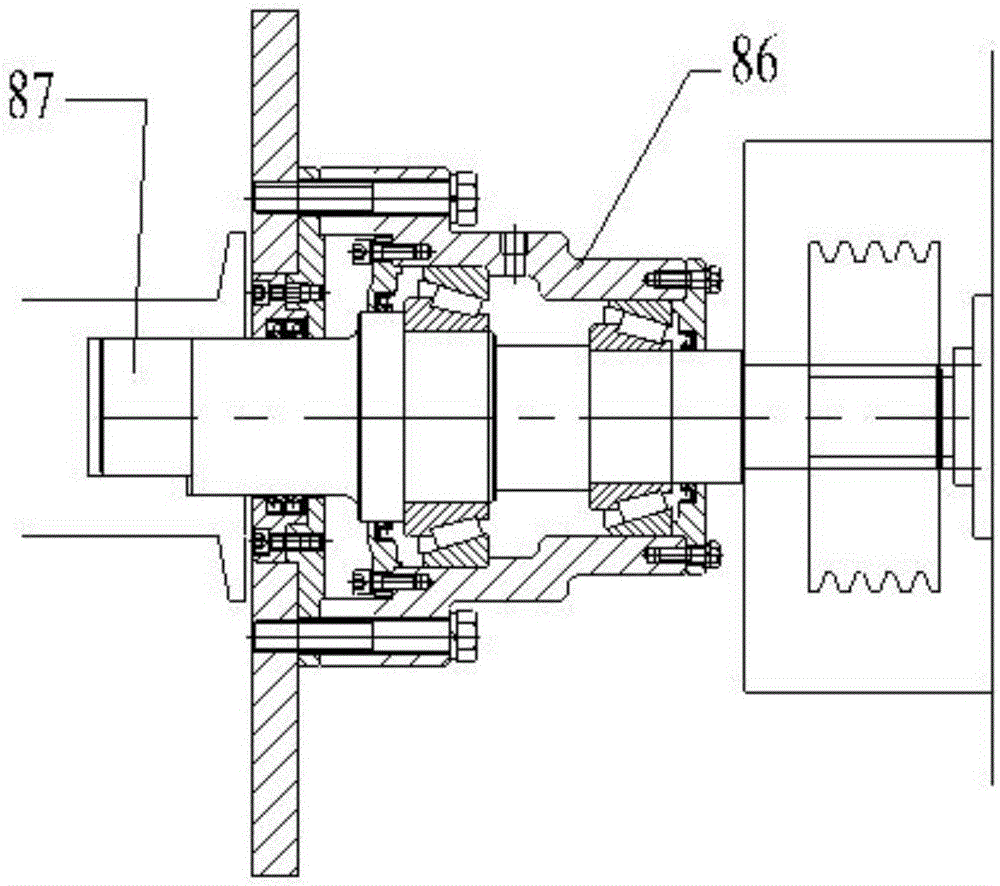

[0036] This embodiment provides a kind of meat grinder, such as figure 1 , 4 As shown, it includes a housing 1, a driving mechanism, a meat grinding cavity 2, a screw shaft 3, a meat grinding part 4, a feed port 5 and a discharge port 6. The upper part of the housing 1 is provided with a feed port 5, and the housing 1 One side is provided with a discharge port 6, and the inside of the housing 1 is located between the feed port 5 and the discharge port 6, and a meat grinding cavity 2 is provided. The meat grinding cavity 2 is provided with a screw shaft 3, and the screw shaft 3 includes a second One end 31 and the second end 32, the output end of the driving mechanism is connected with the first end 31 of the screw shaft 3; Connection, the diameter of the first end 31 of the screw shaft 3 is greater than the diameter of the second end 32 of the screw shaft 3 .

[0037] The first end 31 has a strong ability to swallow material when feeding, and the ability of the second end 32...

Embodiment 2

[0039] This embodiment is an embodiment further improved on Embodiment 1, which includes all the content of Embodiment 1, that is, the meat grinder provided in this embodiment includes all the structural features of Embodiment 1 meat grinder, and the improvements are:

[0040] Such as Figure 1-12 As shown, on the basis of the first embodiment, the diameter of the first end 31 of the screw shaft 3 in this embodiment is twice the diameter of the second end 32 of the screw shaft 3 .

[0041] The shell is 3 meters long, 1.4 meters wide and 2.1 meters high. Feeding port 5 is an inverted square prism type, the large end of feeding port 5 is located at the upper side, the length of the large end of feeding port 5 is 1546mm, the width of the large end of feeding port 5 is 1000mm, and the small The length of the end is 1000mm, the width of the small end of the feed port 5 is 420mm, and the height of the feed port 5 is 550mm.

[0042] The feed port 5 in this embodiment is much larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com